Multi-functional laser processing manufacturing system

A technology of laser processing and manufacturing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

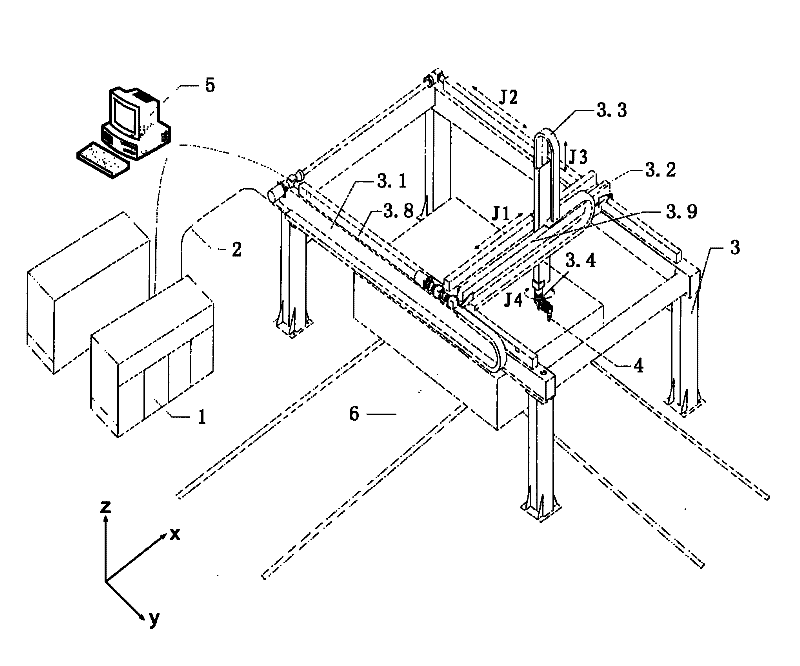

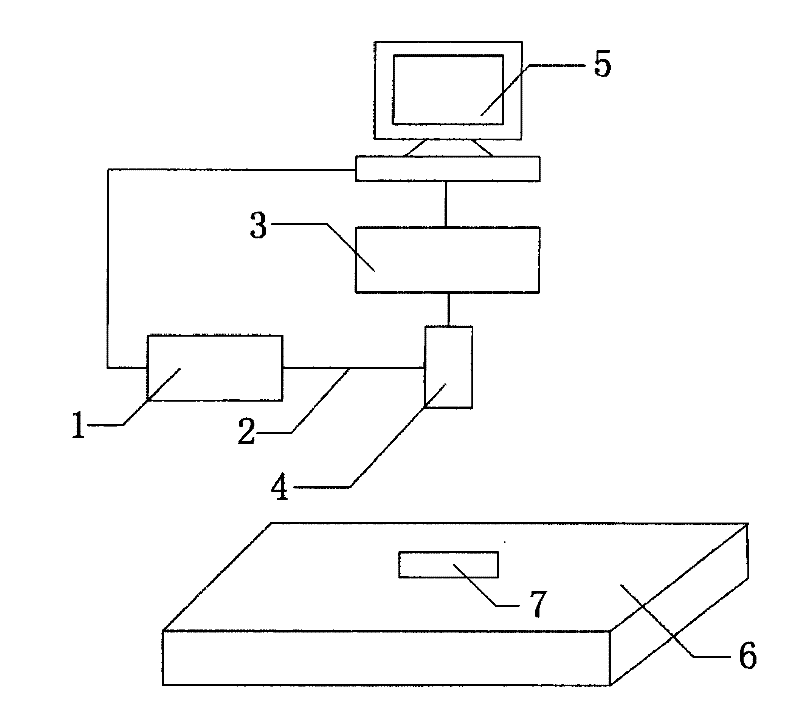

[0017] The multifunctional laser processing and manufacturing system proposed by the present invention is as figure 1 , 2 As shown, the whole system consists of a laser 1, a laser processing head 4, a multi-motion parameter robot 3 with a motor for carrying the laser processing head, a working platform 6 for carrying a workpiece 7 arranged under the robot 3, and a control The laser 1 and the control device of the robot 3 are composed. Wherein, the control device for controlling the laser 1 and the robot 3 includes: a computer 5, a laser control unit, a robot motion control unit and a coordination control unit. The laser output from the laser 1 is transmitted to the laser processing head 4 through the optical fiber 2 for focusing and output. The computer 5 is connected with the laser 1 and the multi-motion parameter robot 3; the laser control unit is connected with the laser 1; the robot motion control unit is connected with the motor on the multi-motion parameter robot 3; th...

Embodiment 2

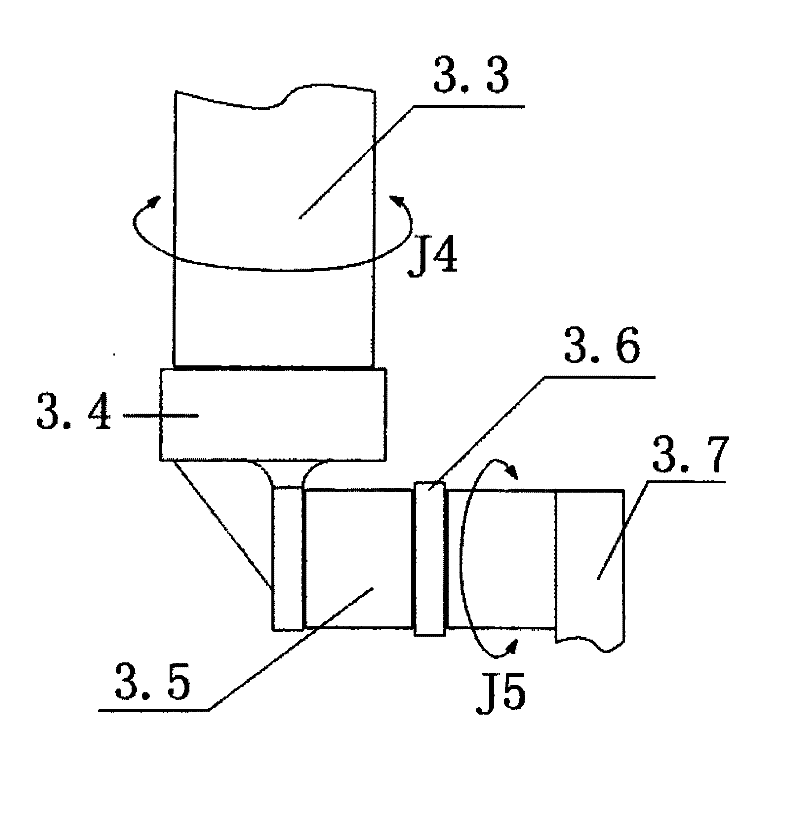

[0021] The structure and workflow of the multifunctional laser processing and manufacturing system in this embodiment are basically the same as those in Embodiment 1, the difference is that, as figure 1 , 3 As shown, the vertical mechanical arm 3.3 of the multi-motion parameter robot also includes a horizontal mechanical arm 3.5 installed on the horizontal rotary joint 3.4, the end of the horizontal mechanical arm 3.5 is connected to the vertical rotary joint 3.6 and connected to the vertical processing arm 3.7 on the vertical rotary joint 3.6 , the rotation direction of the vertical rotary joint 3.6 is shown as J5 in the figure; the laser processing head 4 is fixed at the lower end of the processing arm 3.7. The five motion parameters of the laser processing head 4, including lateral displacement, longitudinal displacement, vertical displacement, horizontal rotary joint rotation, and vertical rotary joint rotation, can be coordinated and moved through the motion control devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com