Preparation methods of anisotropic conductive silk screen, block and diaphragm, and product

An anisotropic, conductive wire mesh technology, applied in the microwave field, can solve the problems of low test efficiency, failure to provide, long time consumption, etc., and achieve the effect of reducing the difficulty of production and test installation, improving test efficiency and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

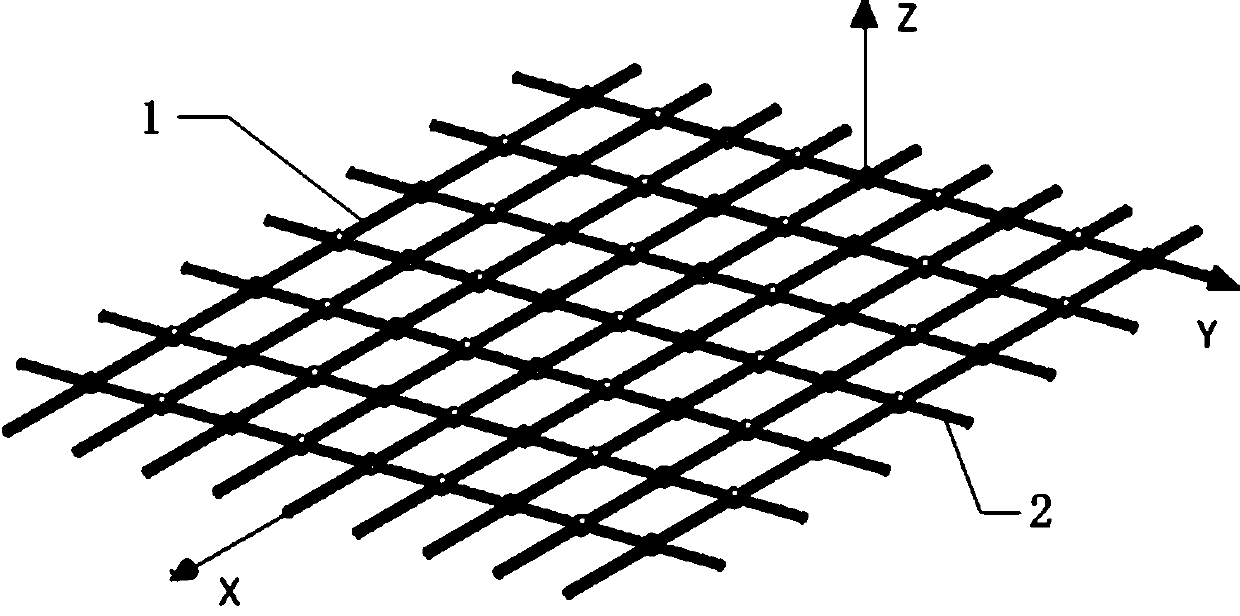

[0049] This embodiment discloses a wire mesh weaving method for preparing an anisotropic conductive wire mesh, the weaving method includes:

[0050] Conductive wires coated on the surface are woven with insulating fiber wires in a mesh shape. During the weaving process, the direction of the conductive wires is guaranteed to be consistent to obtain a two-dimensional unidirectional conductive wire mesh.

[0051] In one embodiment, the weaving method is as follows:

[0052] Coating the surface of the conductive wire used for weaving to obtain a conductive wire with coating protection;

[0053] The coated conductive wire and insulating fiber wire are mixed and woven to form a mesh structure; during the weaving process, the direction of the conductive wire is guaranteed to be consistent. In this way, a two-dimensional unidirectional conductive mesh is obtained.

[0054] The so-called plating treatment refers to coating a protective layer on the surface of an object to prevent the...

Embodiment 2

[0057] This embodiment discloses a wire mesh weaving method for preparing an anisotropic conductive wire mesh, the weaving method includes:

[0058] One or more of stainless steel wires, beryllium copper wires, tungsten wires, molybdenum copper wires, aluminum wires, etc. are coated with one or more coatings of gold, nickel gold, nickel cadmium, etc. The coating material in this embodiment has good electrical conductivity, thermal conductivity and wear resistance.

[0059] The two-dimensional unidirectional conductive wire mesh is obtained by weaving the coated conductive thread with one or more of polyester fiber, acrylic fiber, vinylon fiber, spandex fiber, nylon fiber, etc. in warp and weft directions.

[0060] In a specific embodiment, the diameter of the conductive filament can be selected from 5-300 microns according to the difficulty of preparation and the application scenario, and the diameter of the fiber filament can be selected from 5-500 microns. For example, in t...

Embodiment 3

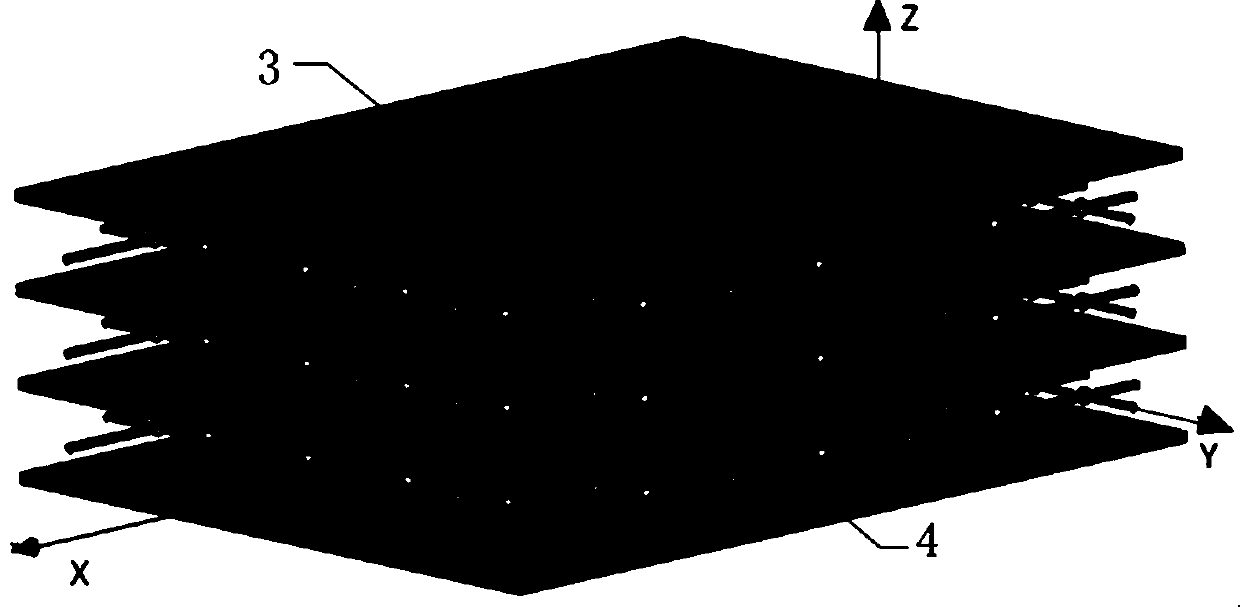

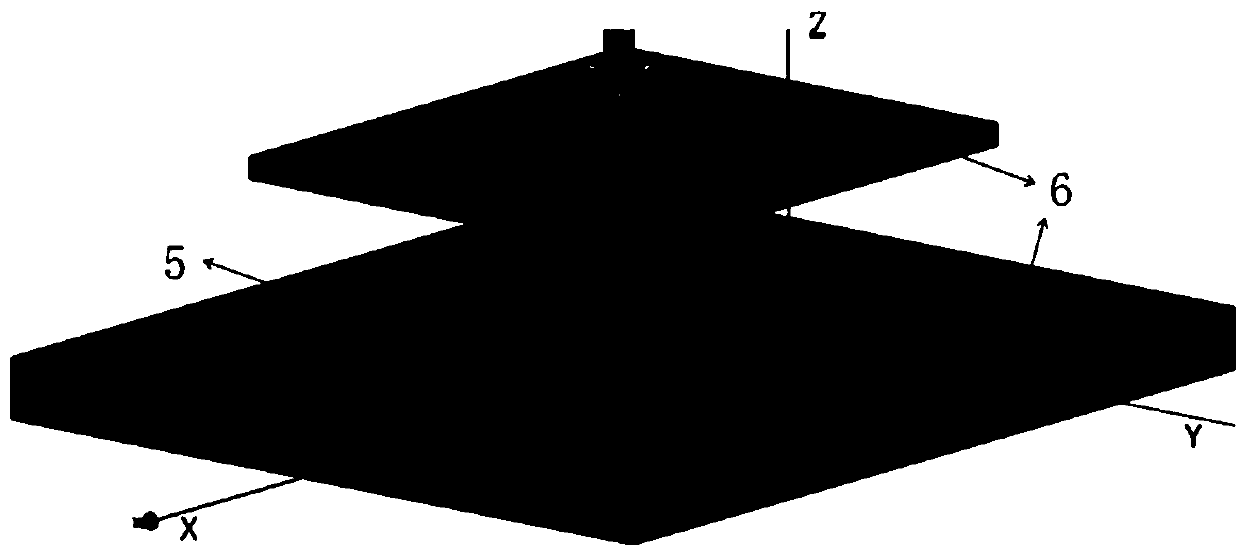

[0062] Based on the above embodiments, this embodiment discloses a method for preparing an anisotropic conductive bulk material, including the following steps:

[0063] Stack the above-mentioned two-dimensional unidirectional conductive wire mesh and the insulating medium in a specified order, for example, stack them alternately to form a laminated structure, and keep the direction of the conductive wires of each layer of the wire mesh consistent during the finishing process;

[0064] Pressurize and heat the laminated structure, so that the wire mesh and the insulating medium are closely bonded to obtain a unidirectional conductive block.

[0065] Through the above embodiments, an anisotropic conductive bulk material can be obtained.

[0066] In a specific embodiment, the above insulating medium is selected from rubber or resin. The rubber is one or a combination of silicone rubber, butadiene rubber, ethylene propylene rubber, polyurethane rubber, etc. The resin is one or mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com