Material-increasing manufacturing method for easy-to-segregate high-elasticity Cu-Ni-Sn alloy

A cu-ni-sn, manufacturing method technology, applied in the field of preparation of Cu-Ni-Sn alloy materials with high elasticity and easy segregation, can solve the problem of affecting the uniformity of alloy composition and performance, pressure forming performance, reduction of material utilization, and large obstacles Large-scale application and other issues, to achieve the effect of high material utilization, flexible and convenient processing, and flexible processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

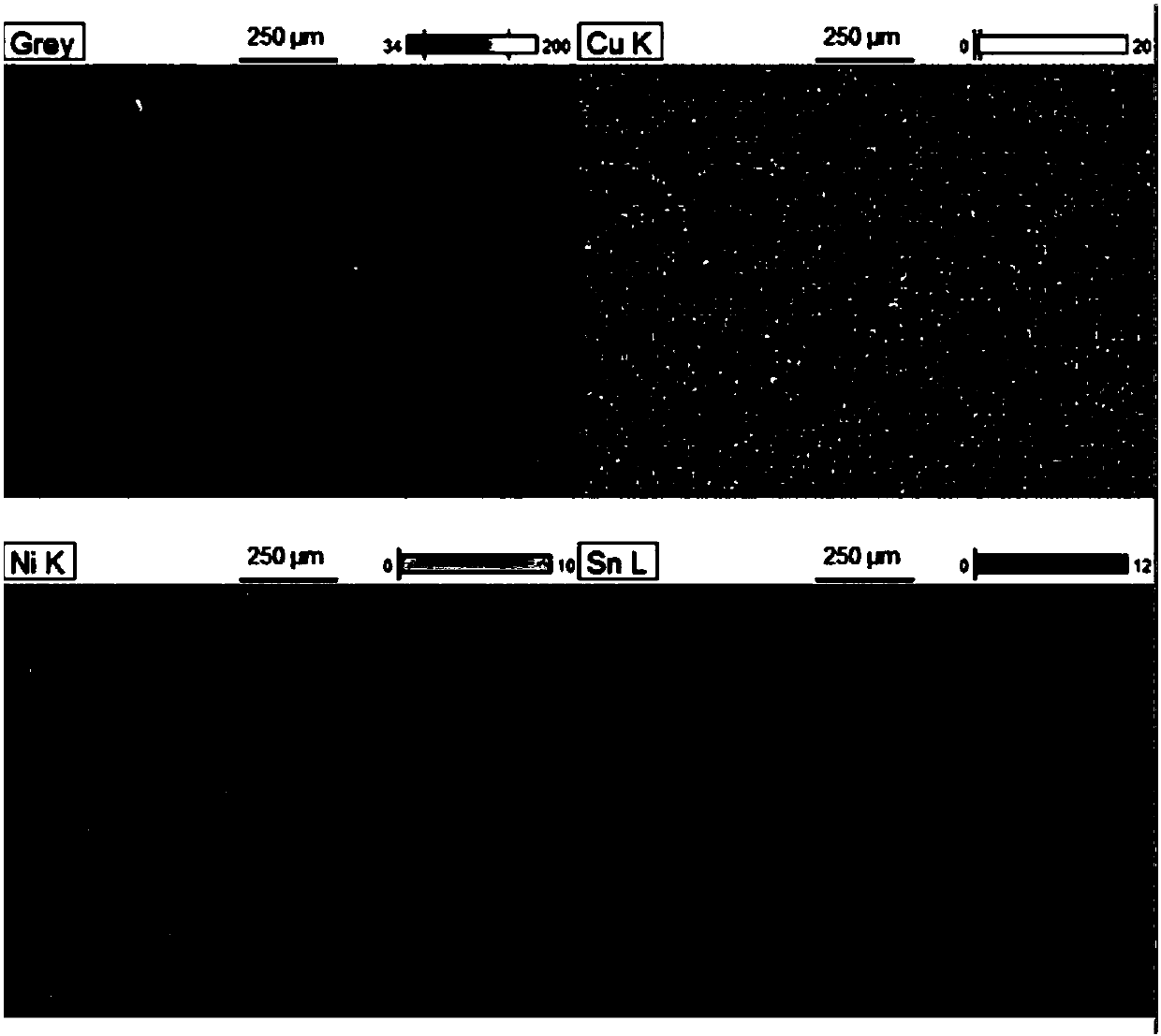

[0030] In this example, Cu-Ni-Sn alloy is produced by selective melting laser additive manufacturing technology. The party uses the gas atomization technology to prepare the alloy powder with a mass ratio of 77Cu-15Ni-8Snwt.%, and the particle size distribution of the powder is 40~100µm. figure 1 As shown, the etchant used is FeCl 3 (5ml)+HCl (15ml)+H 2O (150ml) mixed solution. Before use, the powder was dried in a vacuum oven at a drying temperature of 80°C and a drying time of 6 hours. The substrate material is 45# steel. Before use, use fine sandpaper to remove oil and scale, clean it with alcohol or acetone and dry it. Before additive manufacturing, the substrate is fixed on the platform where the working cylinder moves up and down, and the substrate is leveled to make the powder coating thickness uniform. Input the 3D data model in the forming software of the industrial computer, automatically form the slice layered two-dimensional scanning data, set the process param...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com