Special equipment for drilling and reaming large scale equipment dowel hole

A large-scale equipment, positioning pin hole technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of easy loosening and dislocation of accessories, chipping, and difficult to punch and twist holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

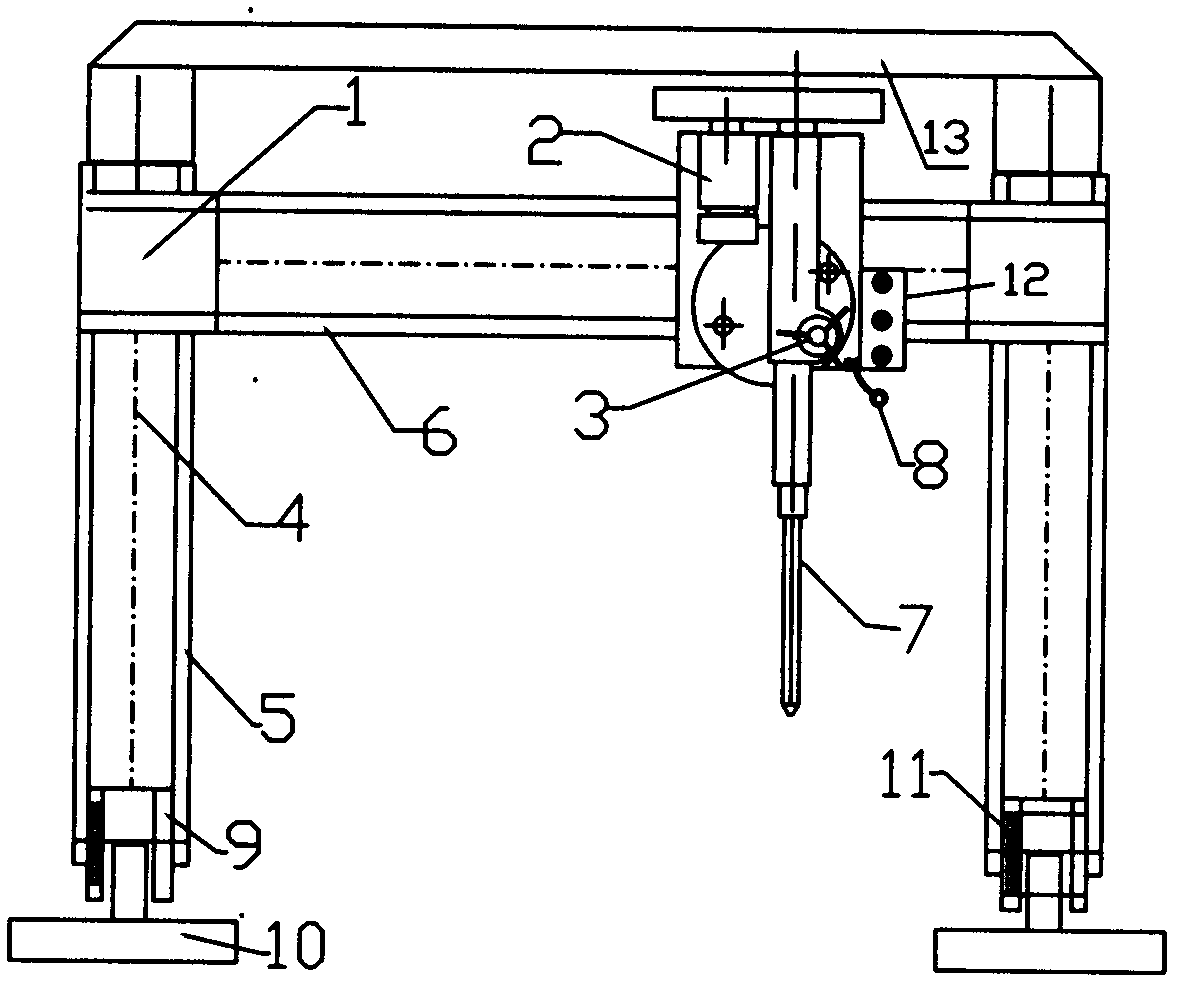

[0006] from figure 1 It can be seen that the special equipment of the present invention is composed of a gantry 1, a headstock 2, a drilling device 3, a lead screw 4, a runner 9, a guide rail 10 and a control device 12. , the middle is the crossbeam 6, a runner 9 is respectively arranged under the two brackets 5, and an expansion brake 11 is housed in the runner, and there are two guide rails 10 below the runner 9, which form the gantry 1 and can move forward and backward and brake. There is a lead screw 4 in the two brackets 5 and the crossbeam 6, and the bracket 5 and the crossbeam 6 are connected by the armature plate of the guide rail. The crossbeam 6 can move up and down on the gantry frame 1 composed of the brackets 5. The armature platen is connected to the crossbeam 6 guide rails, the drilling device 3 is installed on the headstock 2, the headstock 2 and the drilling device 3 can move left and right on the crossbeam 6 guide rails, and the cable tie block 8 is housed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com