Multi-purpose core rod machining feeding device

A knife device and mandrel technology, which is applied in the field of mandrel cutting process and multi-use mandrel processing tool, can solve the problems of affecting processing efficiency, increasing production cost, time-consuming and labor-intensive, etc., and achieving time-saving and labor-saving machining accuracy, Satisfy diverse needs, flexible and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

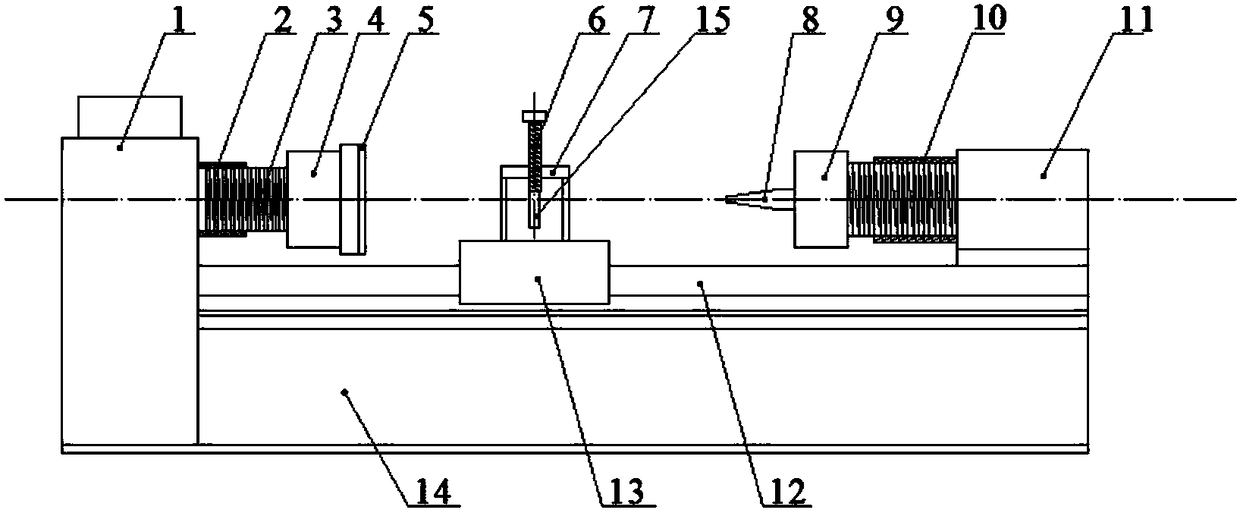

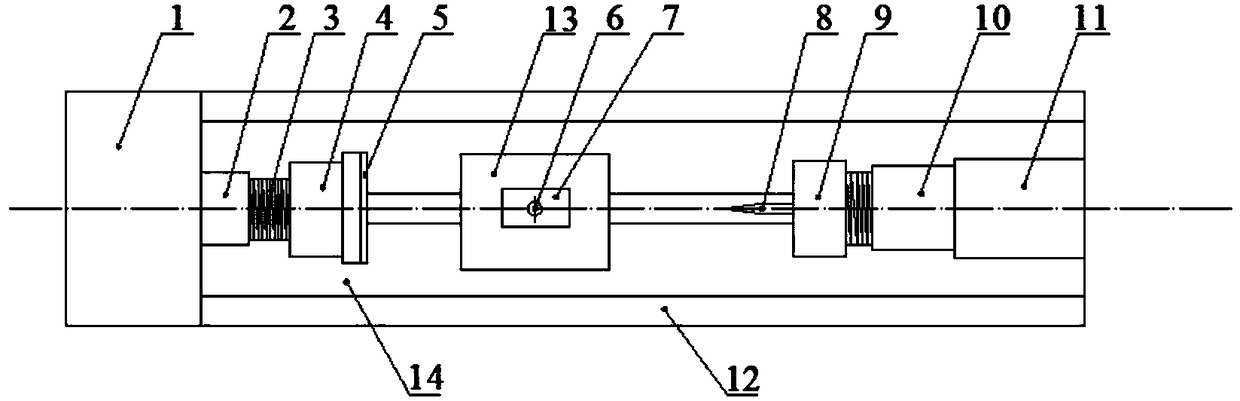

[0018] A multi-purpose mandrel processing knife-feeding device, such as figure 1 , figure 2 As shown, it includes a main chassis 1, a bed 14 and a tailstock 11. The chassis is arranged on one side of the bed, and the other side of the bed is correspondingly provided with the tailstock. On the bed, the A slide rail 12 is arranged between the chassis and the tailstock,

[0019] The innovation of the present invention is:

[0020] 1. A mandrel fixing device is detachably arranged between the main box and the tailstock, and an adjustable knife feeding device is slidably arranged between the slide rails. The mandrel fixing device includes a connecting piece and a detachable The supporting sleeve, the connector includes a first connector 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com