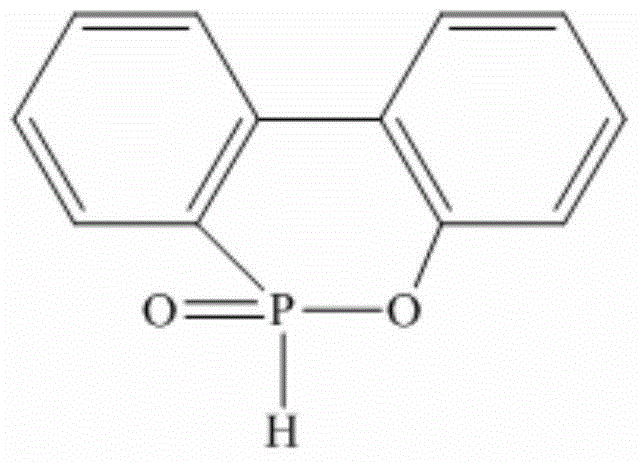

Phosphorus-containing flame retardant system polyester after-treatment and preparation and application thereof

A post-finishing and systematic technology, applied in fiber treatment, textiles and papermaking, fiber types, etc., can solve the problems of poor flame retardancy and washability, and achieve good flame retardancy, good flame retardancy, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

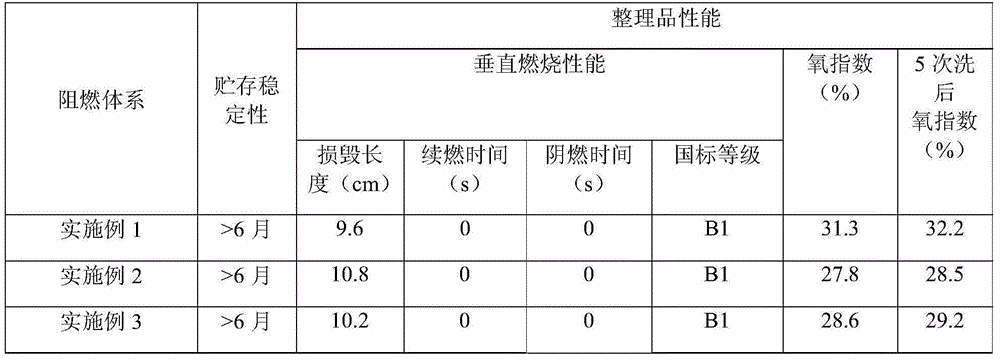

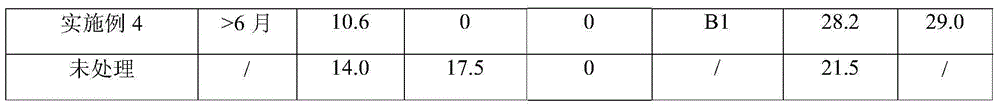

[0031] Example 1

[0032] 400g DOPO, 50g sodium lignosulfonate and 350g water were added to the colloid mill and ground for 8 hours, 200g of 5% carboxymethyl cellulose was added, and the grinding was continued for 20 minutes to obtain a yellow-brown flame-retardant dispersion system with a particle size of 1.3 μm.

Example Embodiment

[0033] Example 2

[0034] 200g DOPO, 60g dispersant MF and 540g water were added to the colloid mill and ground for 4 hours, 200g 5% hydroxyethyl cellulose was added, and the grinding was continued for 10 minutes to obtain a yellow-brown flame-retardant dispersion system with a particle diameter of 1.6 μm.

Example Embodiment

[0035] Example 3

[0036] 200g of DOPO, 60g of dispersant NNO and 540g of water were added to the colloid mill to grind for 12 hours, 200g of 5% methylcellulose was added, and the grinding was continued for 30 minutes to obtain a white flame-retardant dispersion system with a particle size of 1.1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com