High-performance self-clean type building structural membrane material and preparation method thereof

A building structure, self-cleaning technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problem of the high price of imported architectural membrane materials, the inability to localize architectural membrane materials, and the impact on architectural membrane structure. To promote the use and other issues, to achieve excellent waterproof, anti-seepage and anti-fouling effect, improve the effect of light and weather resistance, and low surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

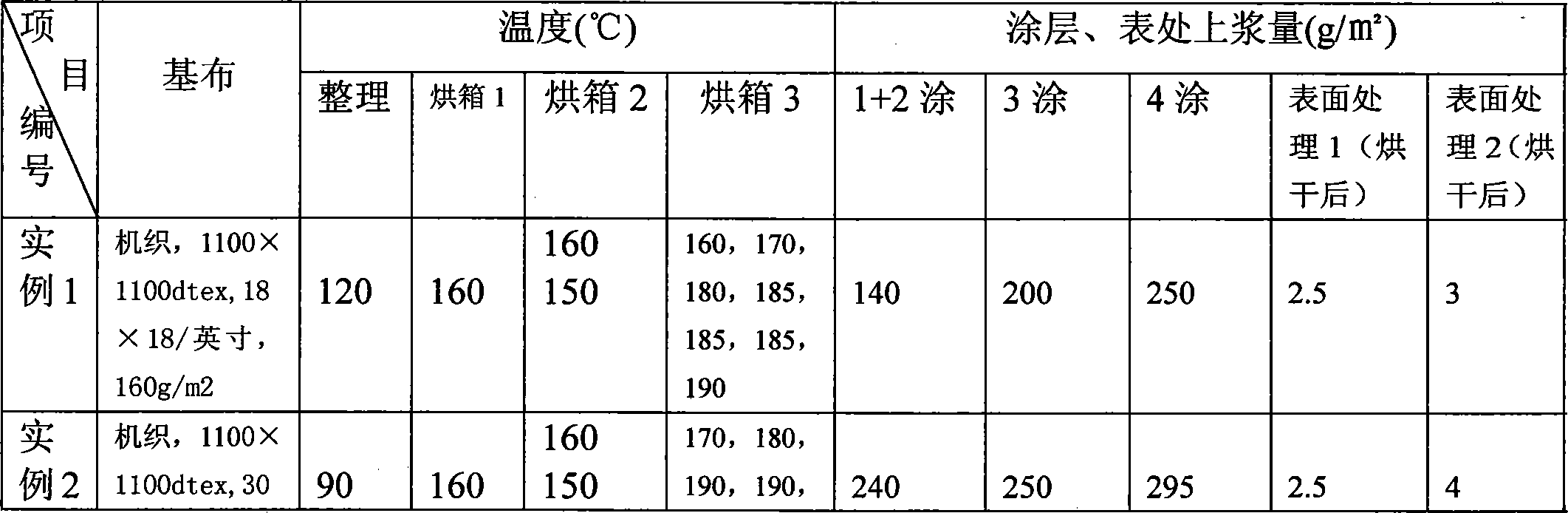

[0045] Example 1: a white tent with a weight of 750g / m2, fire-resistant and flame-retardant French standard (NFP92503) M2; TYPE I architectural membrane;

example 2

[0046] Example 2: a white tent with a weight of 1050g / m2, fire-resistant and flame-retardant French standard (NFP92503) M2; TYPE II architectural membrane;

[0047] The preparation method of the high-performance self-cleaning type building structure membrane material of embodiment 1 and 2 comprises the following technical steps:

[0048] Step 1 Prepare PVC slurry

[0049] Add DINP, Ba / Zn liquid stabilizer to the bucket according to the formula requirements in the form, and then add resin, CaCO3, flame retardant, etc. in turn under stirring, and stir for 10 minutes to complete the premixing; then grind with a three-roll mill , stored in another clean bucket after filtering. Then according to the required color of the product, add the color paste soaked and ground with plasticizer, and stir to make the system evenly dispersed. Finally vacuum stirring and defoaming for 20 minutes, the batching is finished.

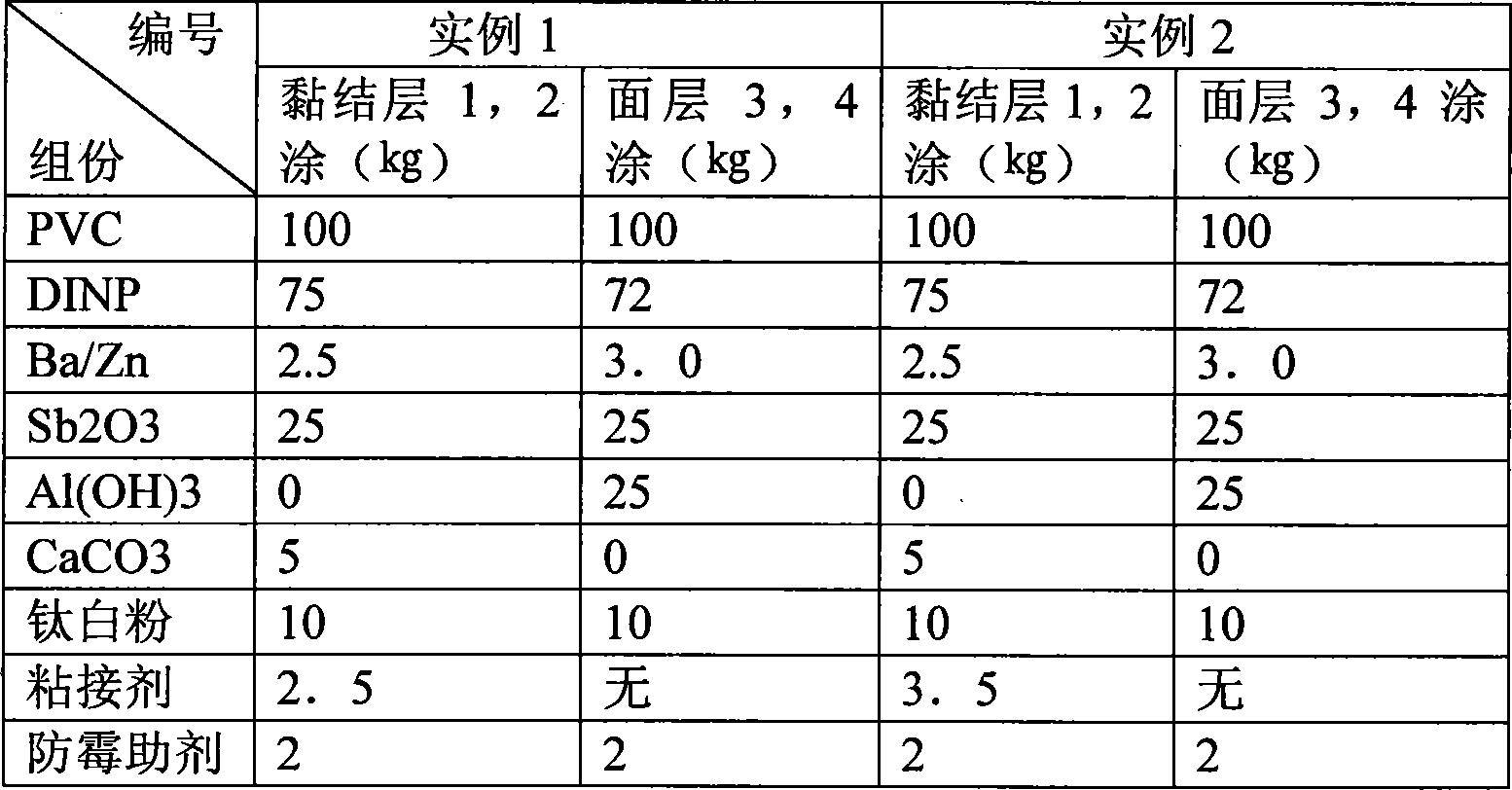

[0050] Table 2: The formula of the PVC slurry of exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com