Friction generator

A technology for triboelectric generators and electrodes, which is applied in the directions of triboelectric generators, layered products, chemical instruments and methods, etc., can solve the problems of low power generation efficiency of the device, inability to collect and convert irregular kinetic energy, etc., and achieve huge commercial use. and practical potential, easy processing, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below, the specific implementation manners of the present invention will be further described in conjunction with the accompanying drawings.

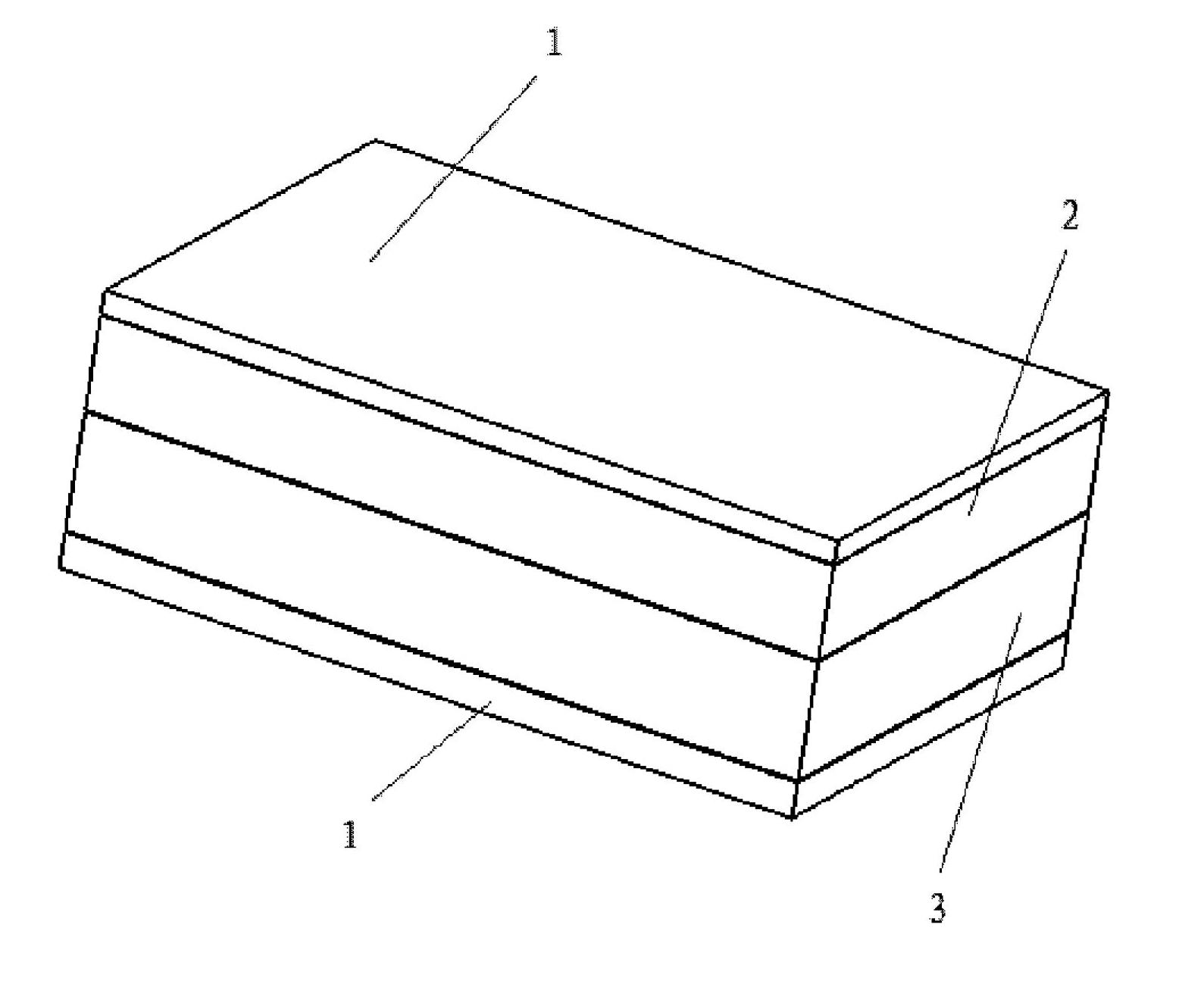

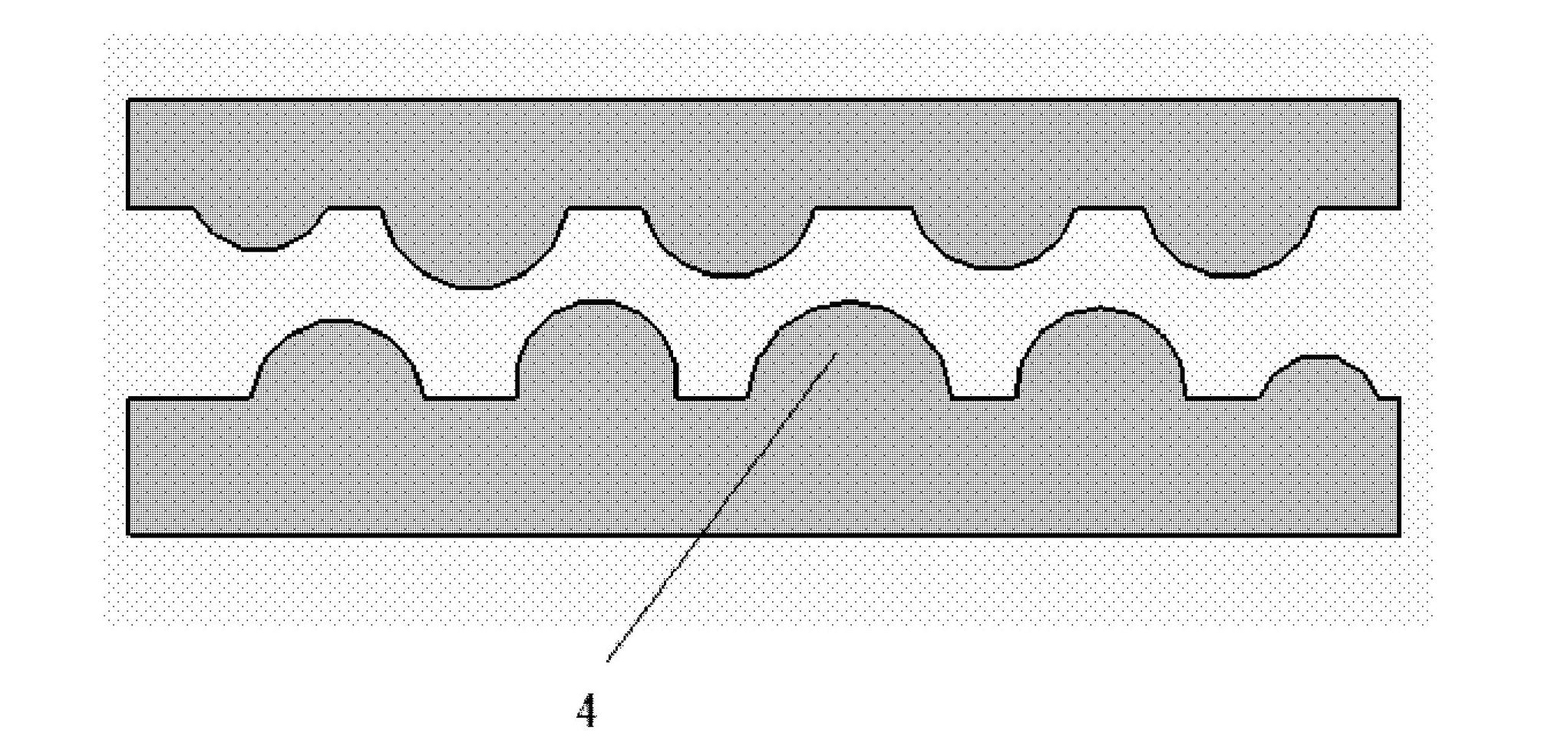

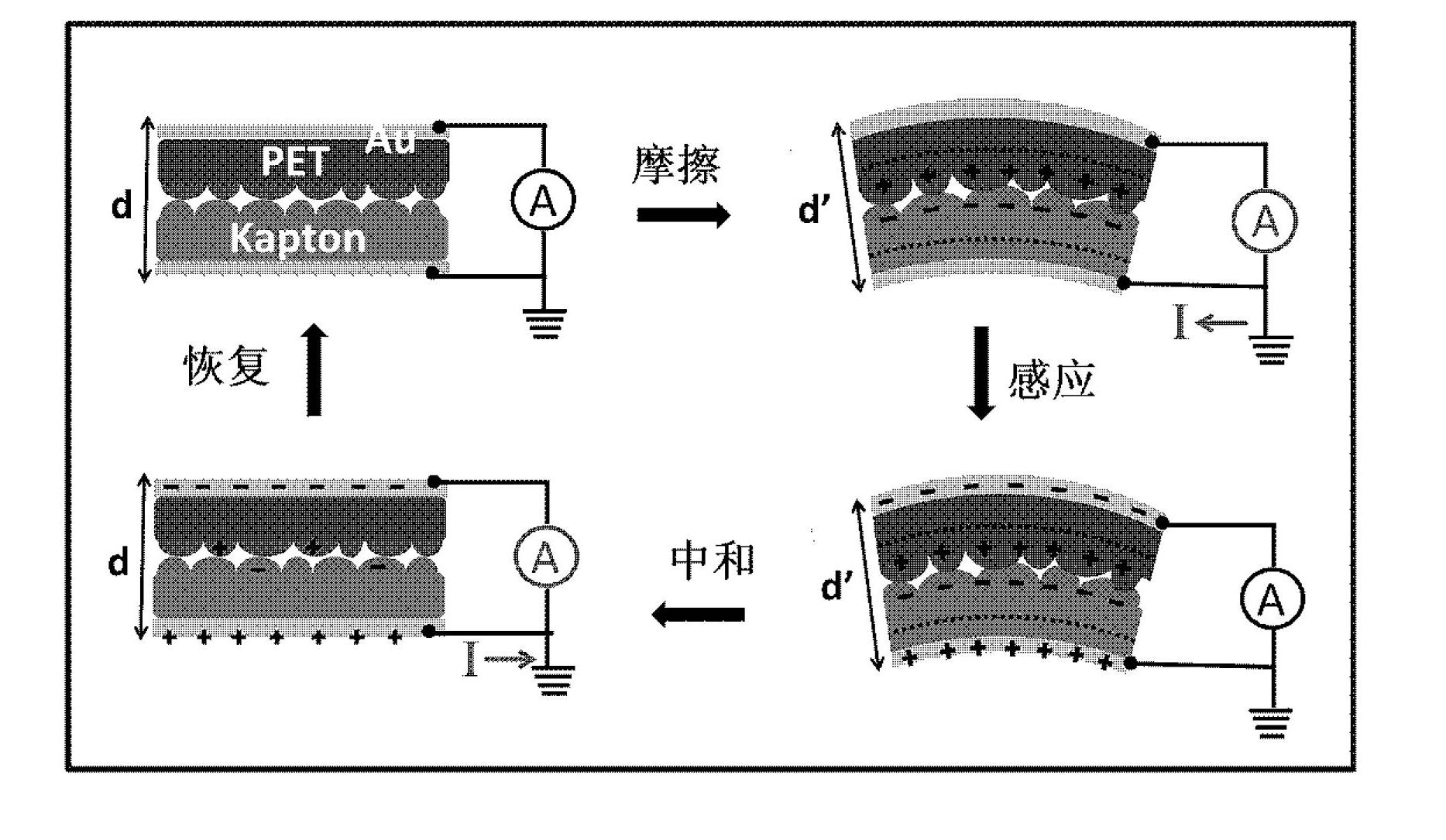

[0017] attached figure 1 Represents a typical structure of a polymer-based triboelectric generator. The triboelectric generator is like a sandwich structure consisting of two different polymer sheets stacked on top of each other without any adhesive between the layers. Such as figure 1 As shown, a rectangular (4.5cm×1.2cm) polyimide film (thickness 125μm, DuPont 500HN, attached image 3 Kapton) as the first electrode polymer insulating layer 4, placed on the second polymer insulating layer 2 flexible polyester film substrate (thickness 220 μm, attached image 3 in PET). The two short edges of the device were sealed with common tape to ensure proper contact between the two polymer insulating layers. The two surfaces of the top and bottom of the structure are coated with an alloy metal film 1 (thickness 100nm, attached image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com