Self-powered pressure sensor

A pressure sensor, self-powered technology, applied in the field of pressure sensors, can solve problems such as weak controllability, short service life, complex production process, etc., achieve good stability, long service life, and improve sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below, the specific implementation manners of the present invention will be further described in conjunction with the accompanying drawings.

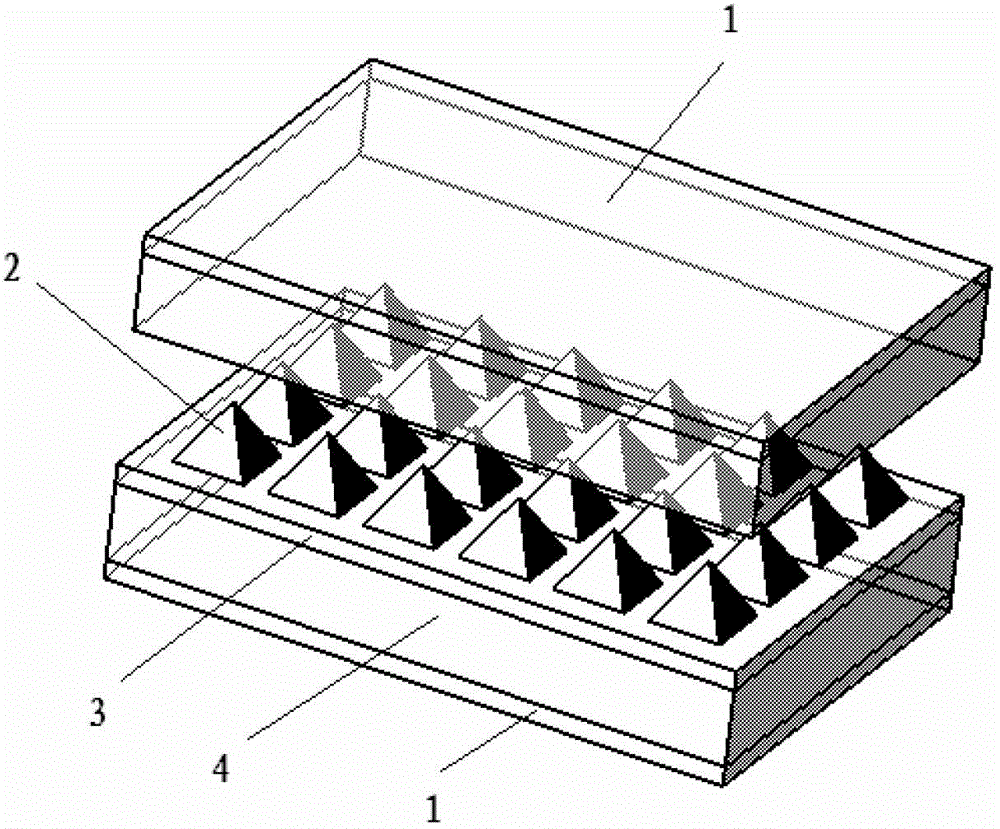

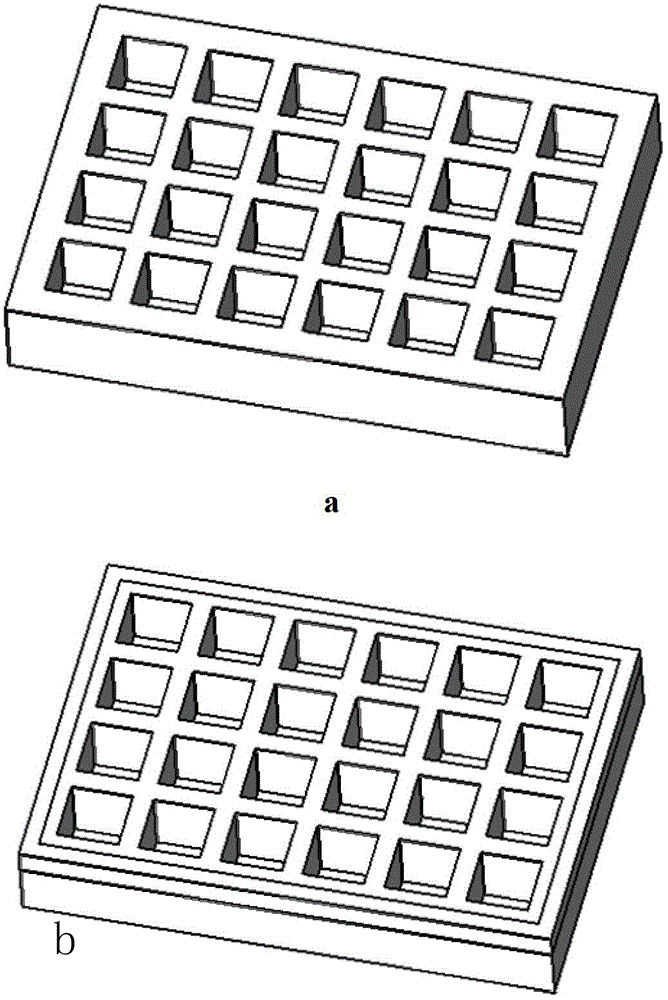

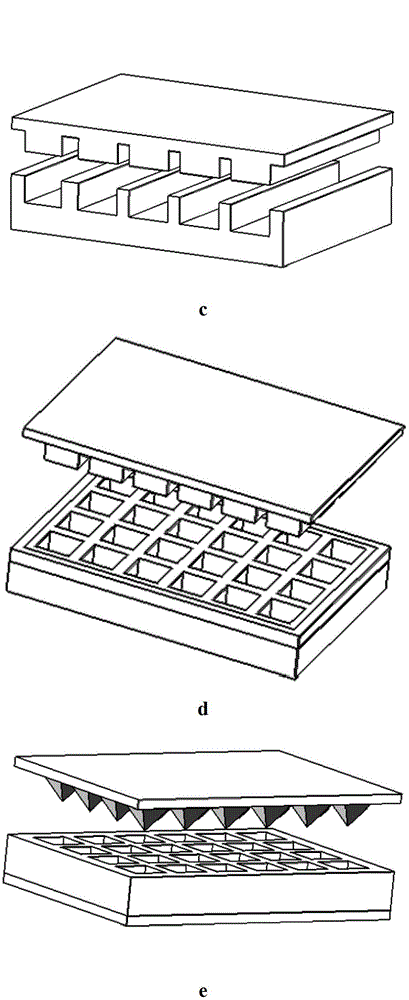

[0021] attached figure 1 Shown is a typical structure of a fully transparent self-powered pressure sensor based on polymers. The self-powered pressure sensor is like a sandwich consisting of two different polymer sheets stacked on top of each other with an intervening membrane3 in between. as attached figure 1 As shown, polyethylene terephthalate (PET) is used as the first polymer insulating layer 2, and one side of the surface is coated with an indium tin oxide (ITO) conductive film 1, and the insulating layer 2 and the conductive film 1 form the first sensing electrode. The other sensing electrode also uses polyethylene terephthalate (PET) as the second polymer insulating layer 4, and is coated with an indium tin oxide (ITO) conductive film 1 on one side of the surface; different An intermediate film 3 is pasted on the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com