Production method for sintered metal-ceramic layered compact and production method for thermal stress relief pad

a technology of sintered metal and compact, which is applied in the manufacture/treatment of thermoelectric devices, metal-working apparatuses, thermoelectric device details, etc., can solve the problems of thermal stress relief pad short circuit, time-consuming, and numerous processes, and achieve efficient performance and reduce the number of processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

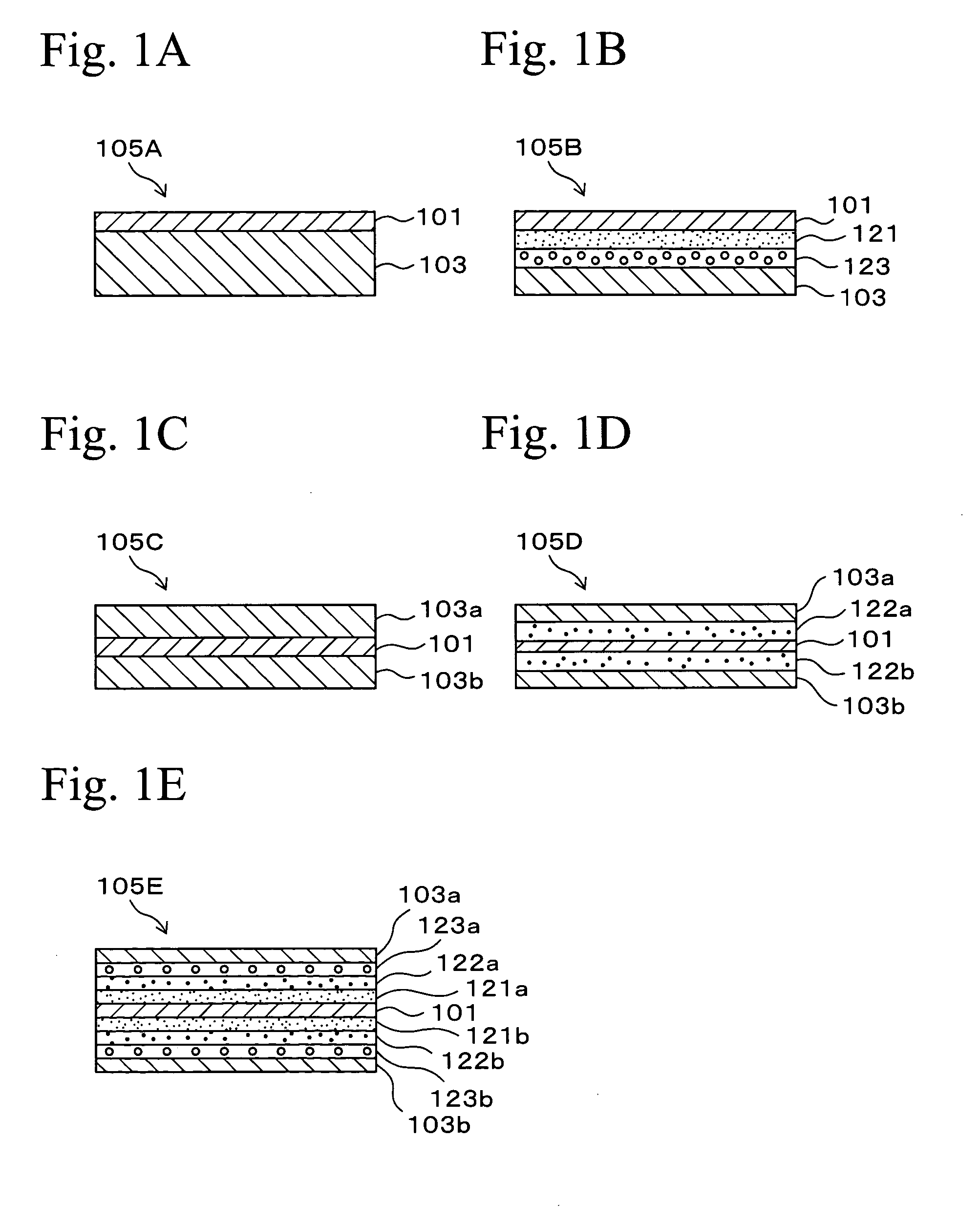

[0041] (A) First Embodiment

[0042] Desirable materials and production method in which the desirable materials are used according to the first embodiment will be described in detail hereinafter.

[0044] A Ceramic powder is composed of alumina or aluminum nitride, which has good electrical insulation and good thermal conductivity. In this case, in particular, alumina has better powder compression compactibility than that of aluminum nitride, and has a lower melting point than that of aluminum nitride, thereby being favorably used. A ceramic powder as a component of a ceramic layer is favorably densified as high as possible by compacting, and has good sinterability, thereby favorably having fine grain size. When a ceramic powder has low flowability due to fine grain size thereof, the ceramic powder is favorably granulated by using a binder such as carboxymethyl cellulose (CMC) so as to have a particle diameter of about 50 to 150 μm, and the flowability thereof i...

second embodiment

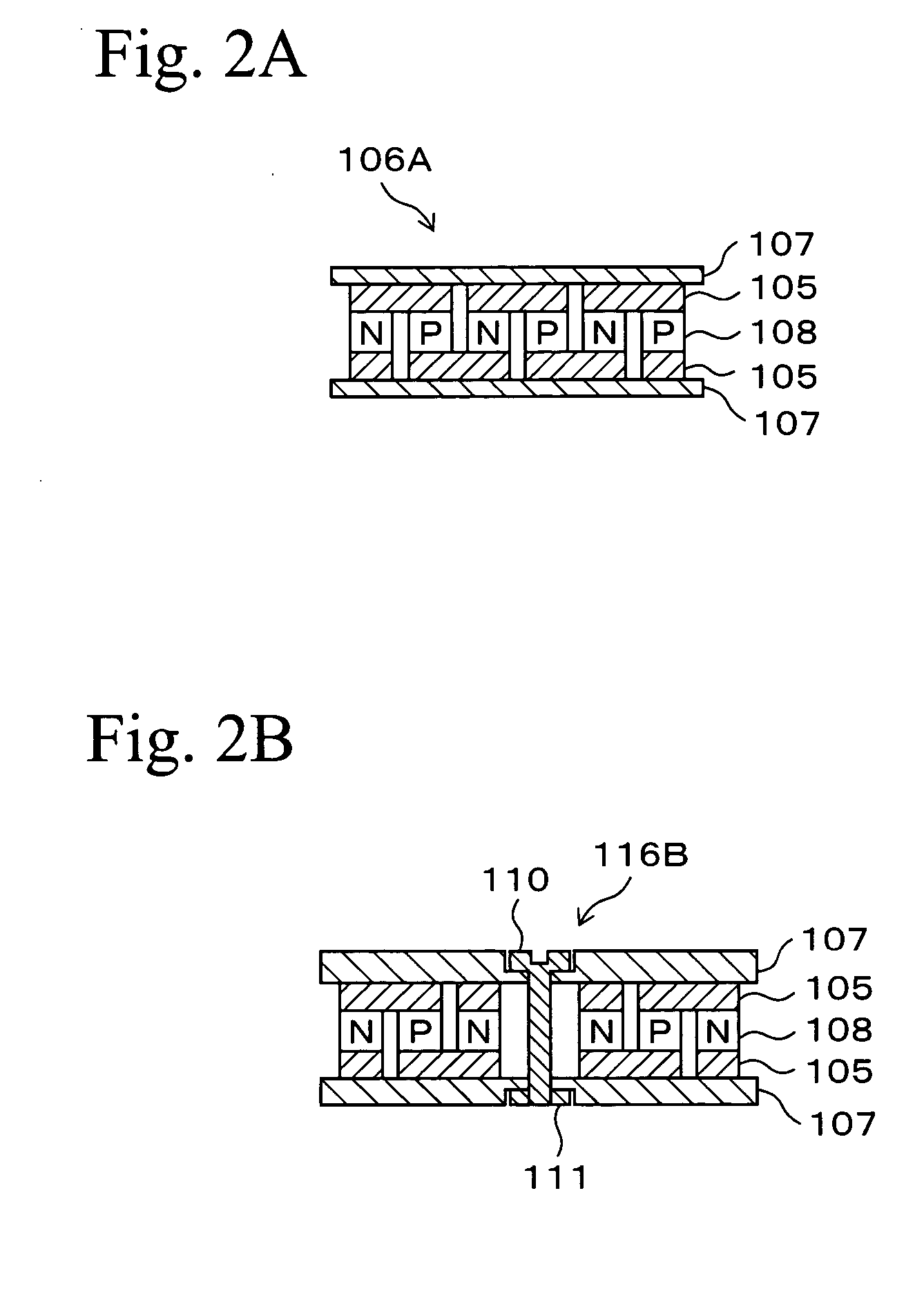

[0089] (B) Second Embodiment

[0090] Desirable materials and production method in which the desirable materials are used according to the second embodiment will be described hereinafter. In the second embodiment, description of the same materials and structures as that of the first embodiment are omitted.

[0092] The same ceramic powder as that of the first embodiment is used.

[0093] (2) Low Melting Powder Added to Ceramic Powder

[0094] A ceramic powder composed of only ceramic powder is hardly sintered when heated to a temperature in which the metal layer is sintered. Due to this, the ceramic layer may possibly collapse when a strong impact is imparted thereto although the ceramic layer may be handled. Therefore, the same low melting point powder as that of the first embodiment is used so as to improve the strength of the ceramic layer.

[0095] (3) Binder for Ceramic Powder

[0096] The same binder for the ceramic powder as that of the first embodiment is used. ...

third embodiment

[0114] (C) Third Embodiment

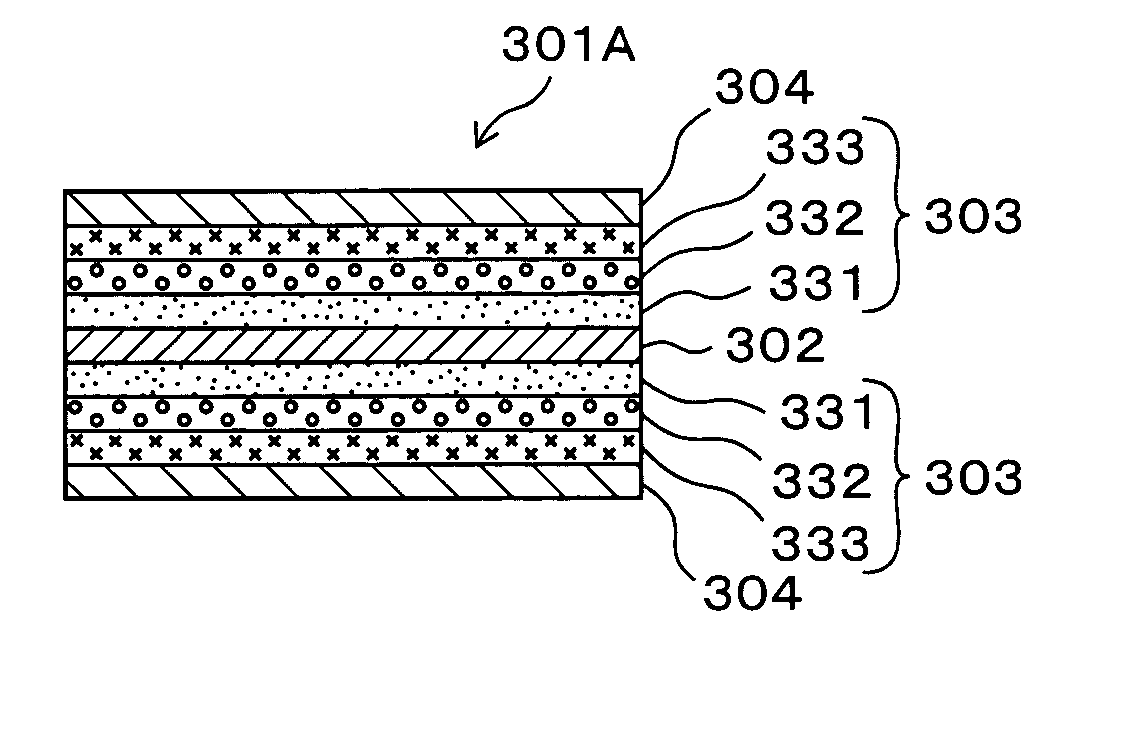

[0115] Desirable materials and production method in which the desirable materials are used according to the third embodiment will be described hereinafter.

[0116] (1) Metal Powder

[0117] A metal layer having electrical conductivity and thermal conductivity is made of a metal powder. The metal powder is composed of one of copper, aluminum, silver, and nickel, or mixture of at least two of copper, aluminum, silver, and nickel. For example, the mixture is composed of copper and aluminum. These powders have good compressibility, and these powders favorably have predetermined grain sizes so as to pass through a 100-mesh sieve, thereby being easily filled into a die. When a fine powder is used, flowability can be improved by granulating. These metal powders used in a mixed powder with an electrical insulation powder are selected so that the mixed powder has low segregation degree and good flowability in consideration of grain size distribution of the electrical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com