Patents

Literature

44results about How to "Prevent a short circuit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

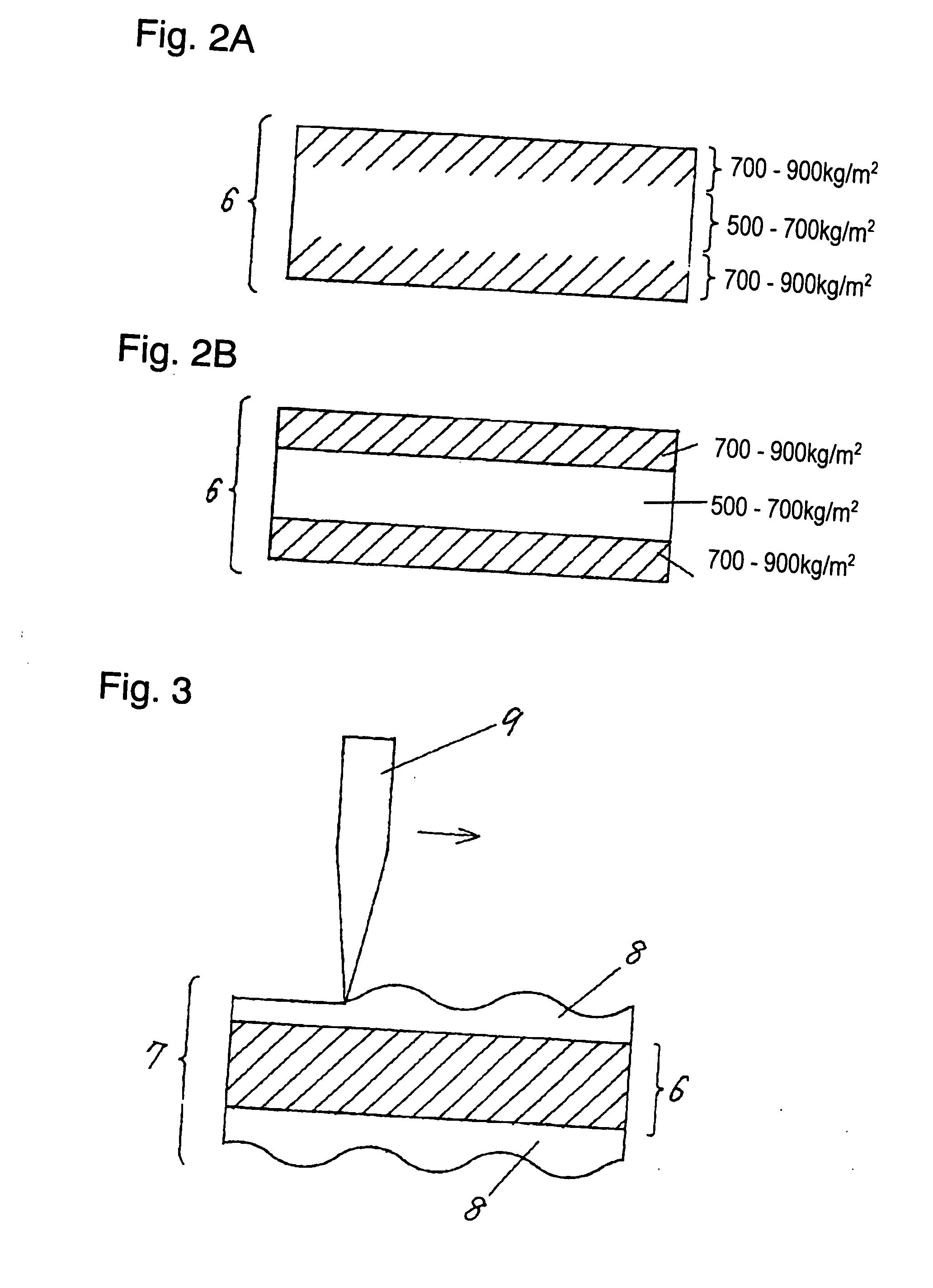

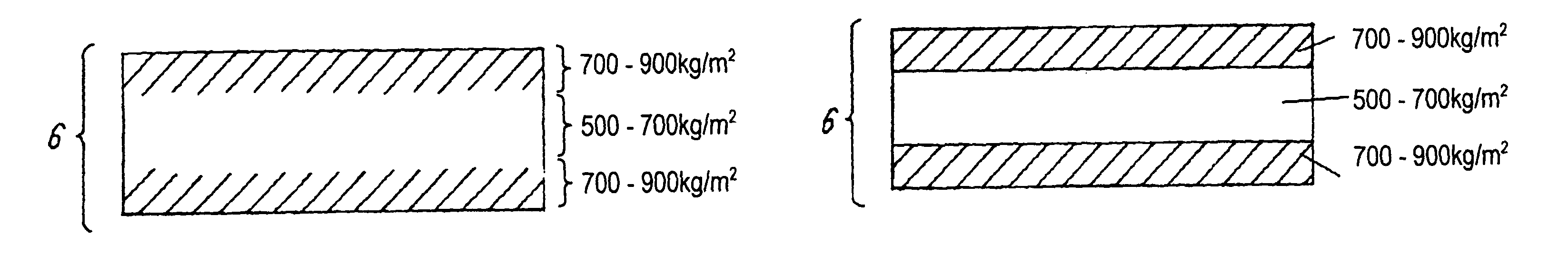

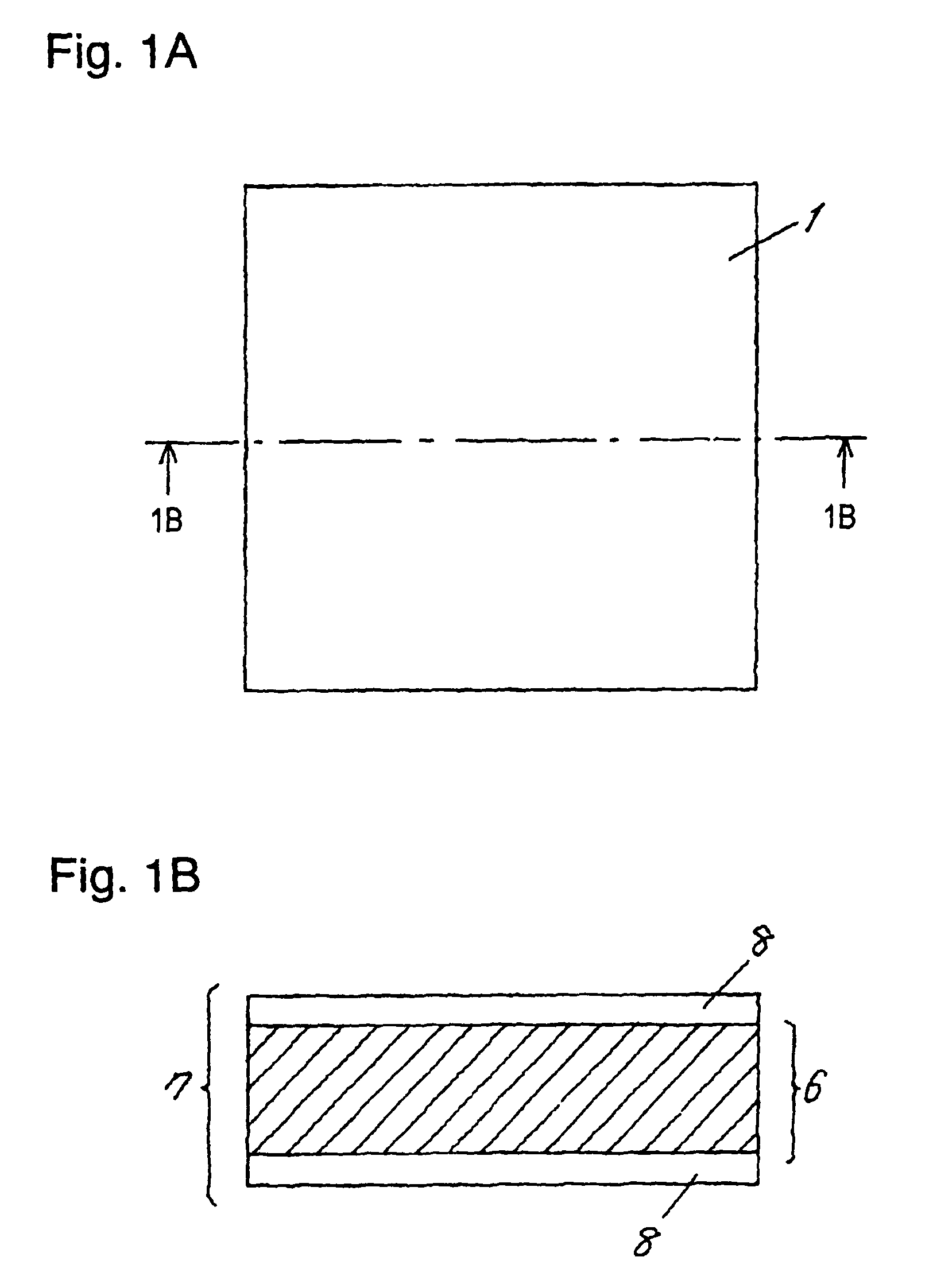

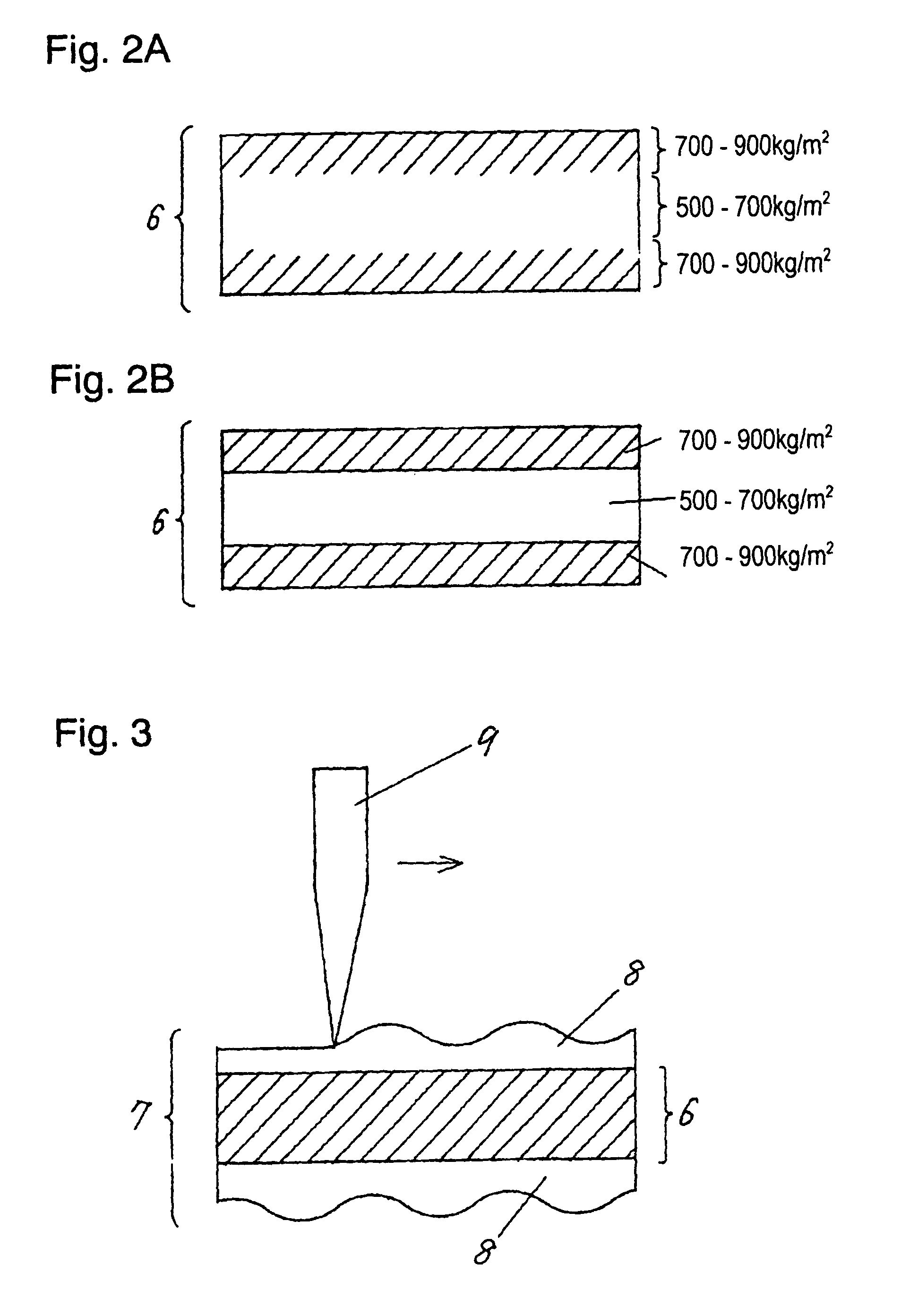

Production method for sintered metal-ceramic layered compact and production method for thermal stress relief pad

InactiveUS20050002818A1Reduce in quantityEfficient executionThermoelectric device manufacture/treatmentTransportation and packagingMicrowaveStress relief

The present invention provides a production method for a sintered metal-ceramic layered compact, comprising steps of: filling and layering a metal powder and a ceramic powder, or filling and layering a metal powder, a mixed powder of a metal powder and a ceramic powder, and a ceramic powder; forming a green compact of the layered powders by compacting the layered powders; and sintering a layer including the metal of the green compact at a temperature of lower than a melting point of the metal by heating by irradiation of microwaves in a non-oxidizing atmosphere.

Owner:HITACHI POWDERED METALS COMPANY

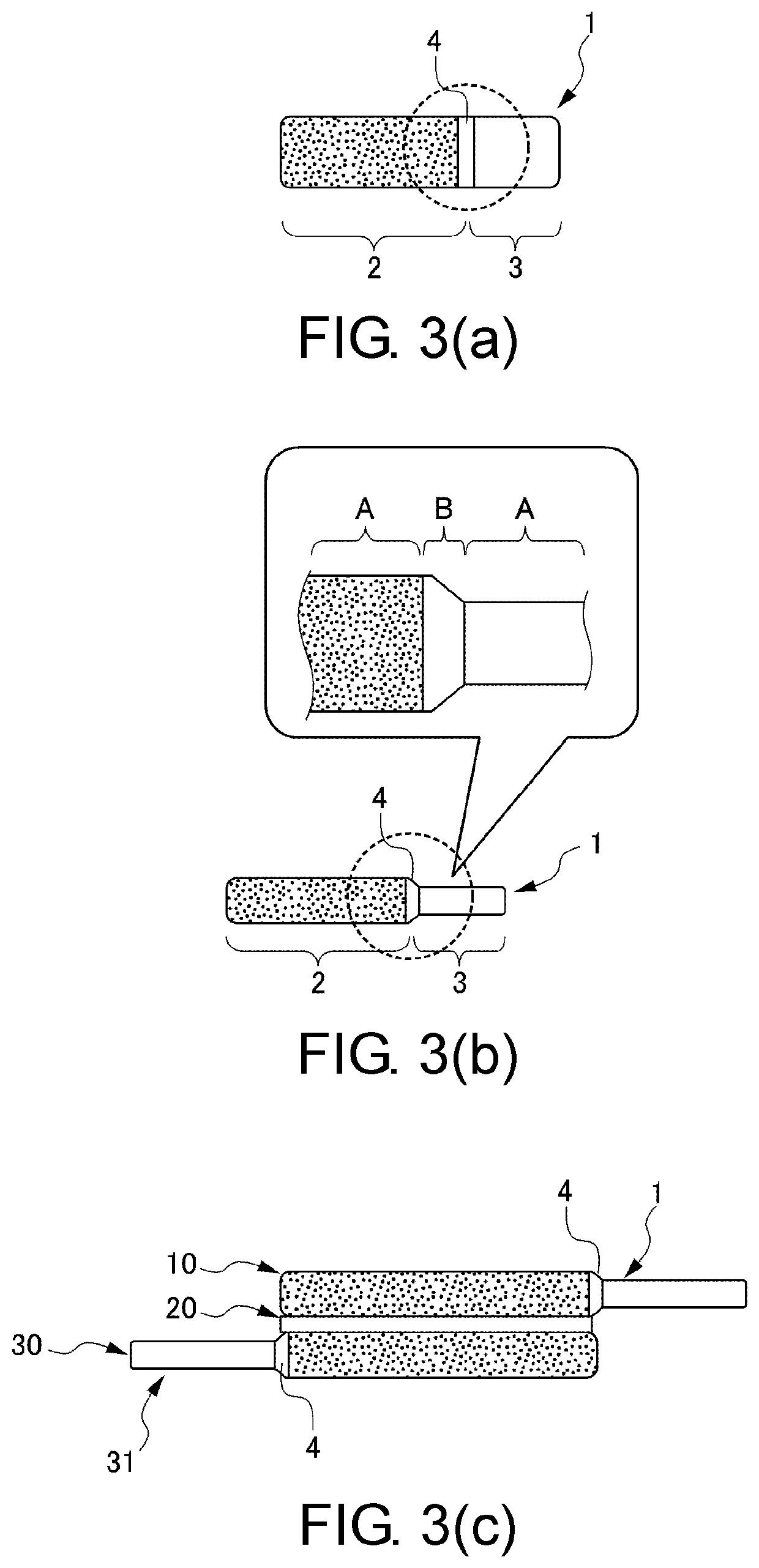

Battery

ActiveUS20100227217A1Improve securityLarge capacitySmall-sized cells cases/jacketsCell sealing materialsEngineeringElectrolyte

The present invention provides a battery including: a battery case having a bottom, a side wall, and an upper opening; an electrode assembly; an electrolyte; and a sealing plate covering the upper opening of the battery case accommodating the electrode assembly and the electrolyte, the electrode assembly including a positive electrode, a negative electrode, and a separator interposed between the positive electrode and the negative electrode, wherein a gasket is interposed between an opening-edge portion of the battery case and the sealing plate, and a first highly-resistive layer is disposed between the opening-edge portion of the battery case and the gasket, or a second highly-resistive layer is disposed between the sealing plate and the gasket. This configuration makes it possible to prevent a short circuit between the battery case and the sealing plate from occurring even when the gasket is broken.

Owner:PANASONIC CORP

Separator for lithium ion secondary battery, method for manufacture thereof, and lithium ion secondary battery

ActiveUS20110171535A1Less fluctuationUniform densityMaterial nanotechnologyPretreated surfacesLithiumInorganic particle

Disclosed are a separator for lithium ion secondary batteries, having an inorganic layer formed from inorganic particles, characterized in that the inorganic particles have a particle diameter distribution in which the 50% cumulative particle diameter D50 is in the range of 100 nm to 500 nm, the 10% cumulative particle diameter D10 is 0.5D50 or more, and the 90% cumulative particle diameter D90 is 2D50 or less; a method for manufacturing the separator; and a lithium ion secondary battery using the separator. When the separator is used, there can be produced a lithium ion secondary battery in which a short circuit caused by contraction or melting can be definitely prevented, as well as the current density applied to the electrodes during charging and discharging is uniform so that charging and discharging can be efficiently achieved.

Owner:NIPPON BAIRIIN

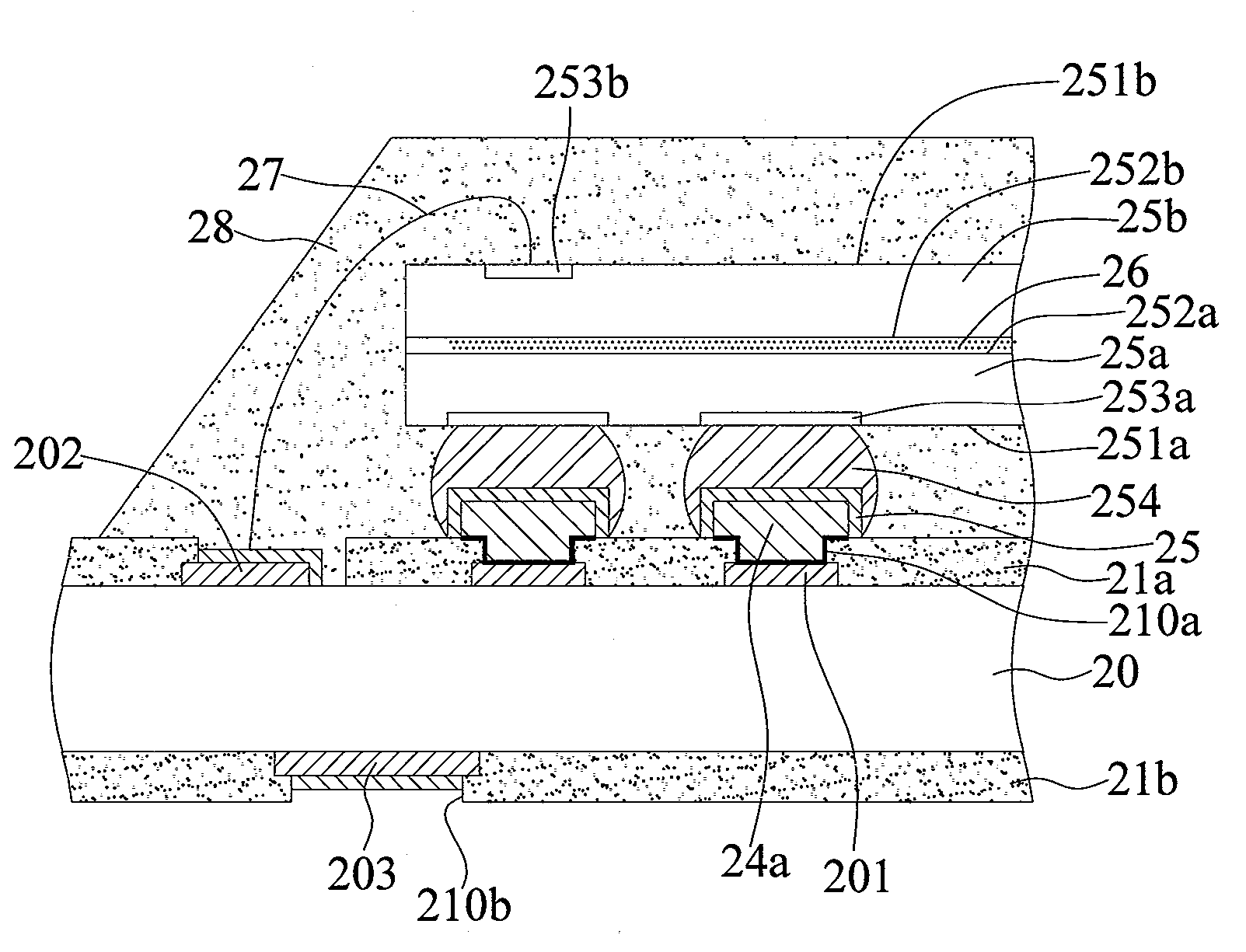

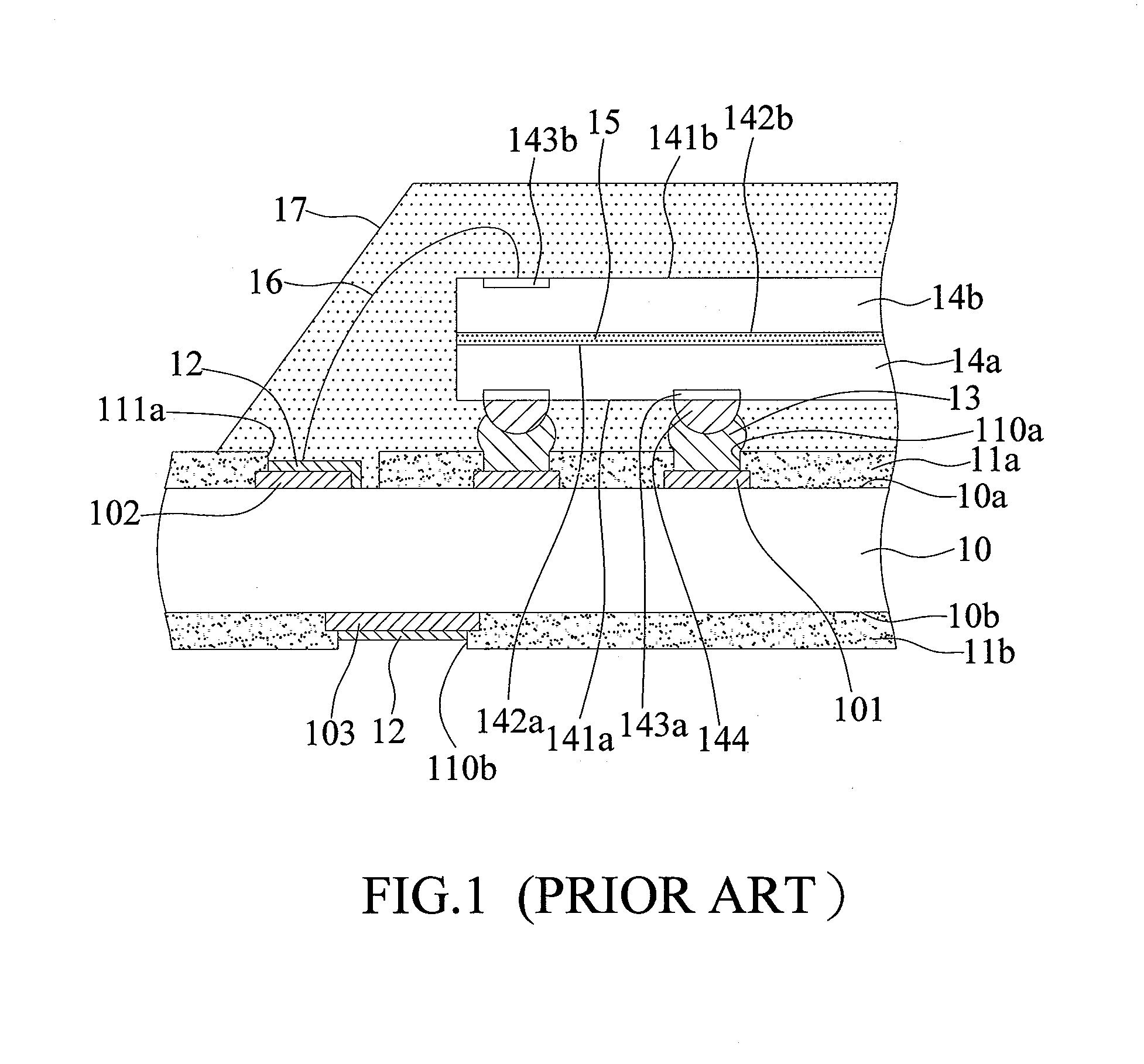

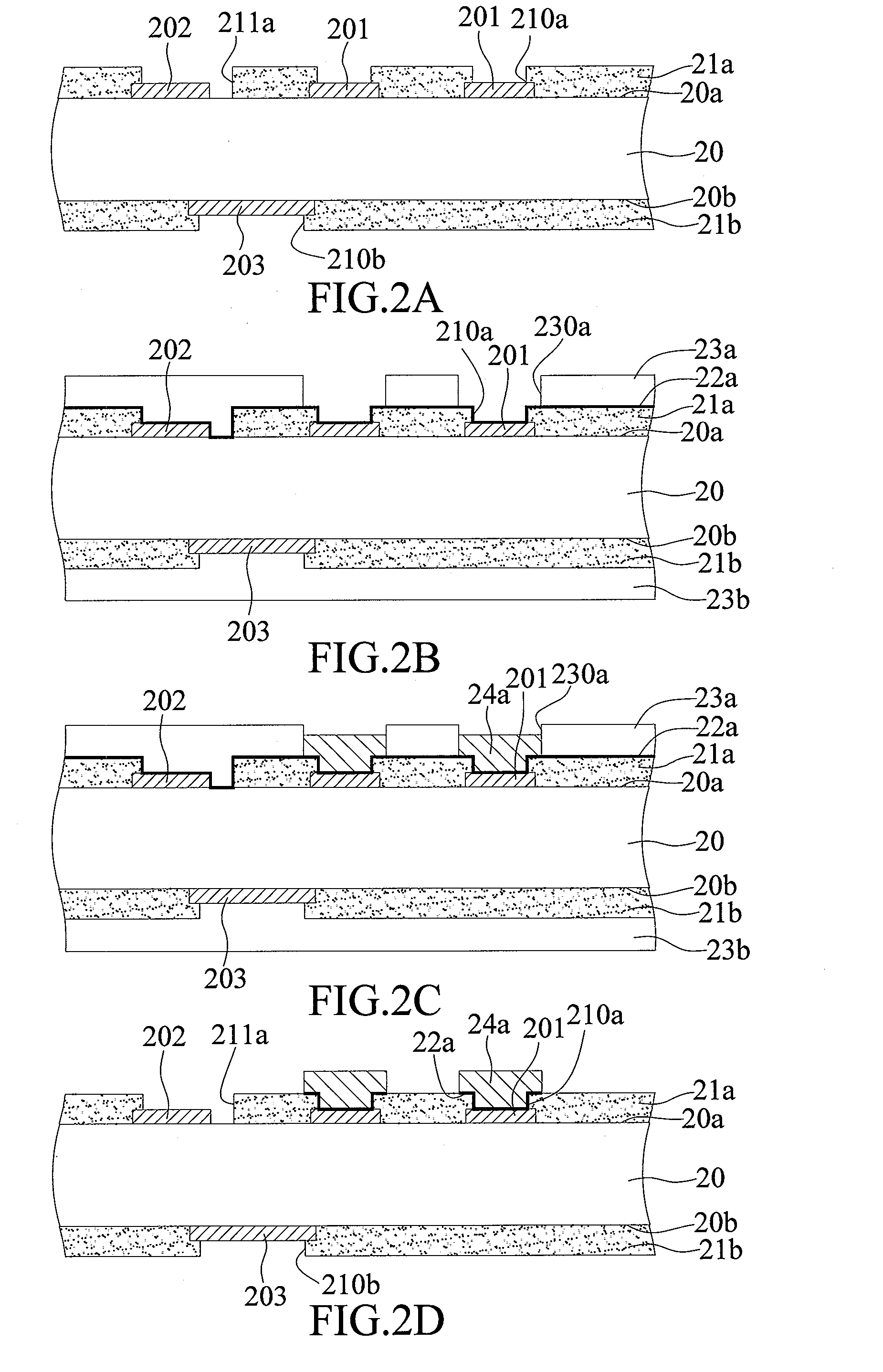

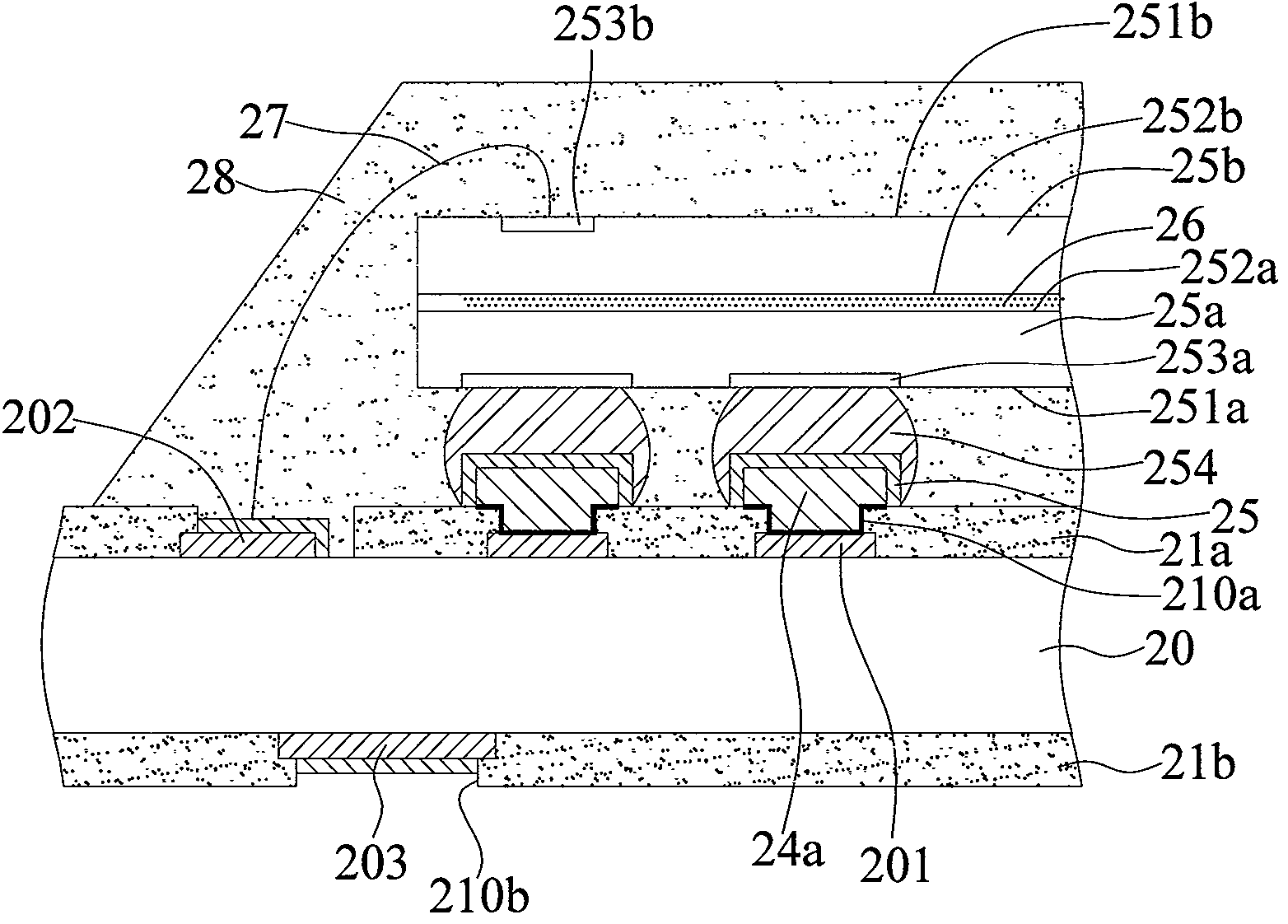

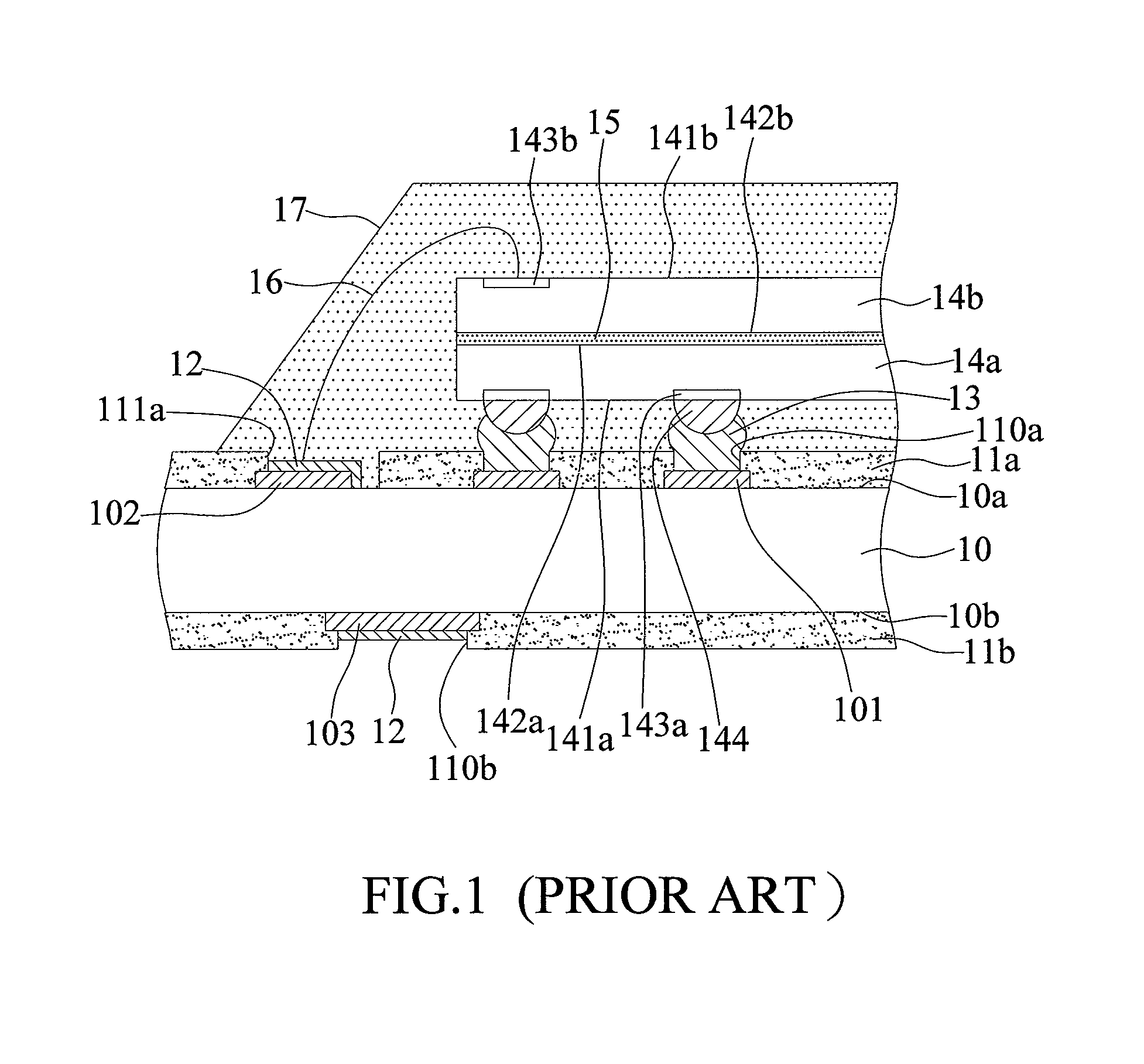

Packaging substrate and method for fabricating the same

ActiveUS20090294962A1Inhibit migrationFacilitate wire bonding processSemiconductor/solid-state device detailsPrinted circuit aspectsSolder maskLead bonding

A packaging substrate and a method for fabricating the same are proposed, including: providing a substrate body having a first surface and an opposing second surface, wherein the first surface has a plurality of flip-chip solder pads and wire bonding pads and the second surface has a plurality of solder ball pads; forming a first and a second solder mask layers on the first and second surfaces respectively and forming openings in the first and second solder mask layers to expose the flip-chip solder pads, the wire bonding pads and the solder ball pads; forming first bumps on the flip-chip solder pads; and forming an electroless Ni / Pd / Au layer on the first bumps and the wire bonding pads by electroless plating, wherein the electroless Ni / Pd / Au layer has a thickness tolerance capable of meeting evenness requirements for fine pitch applications.

Owner:UNIMICRON TECH CORP

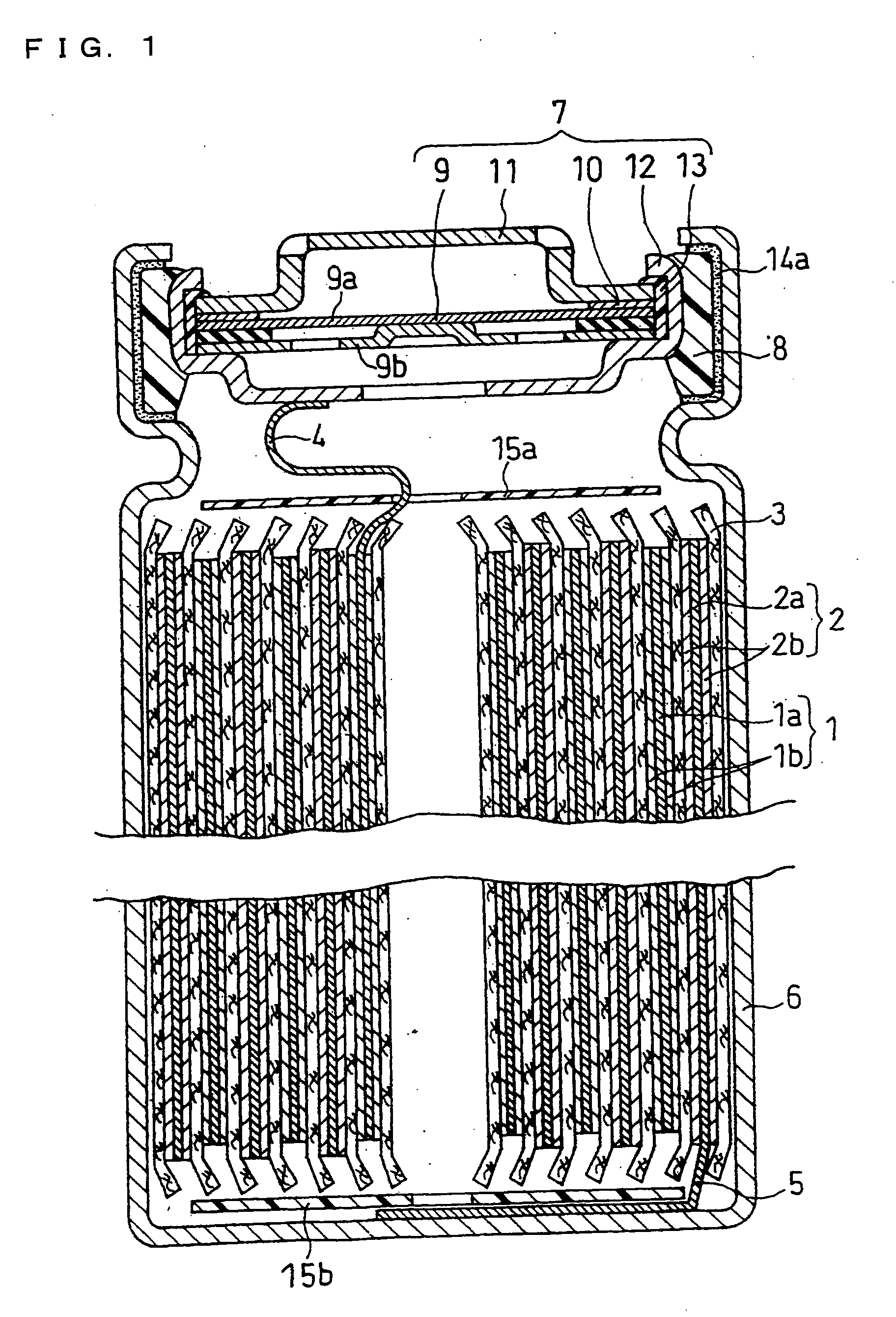

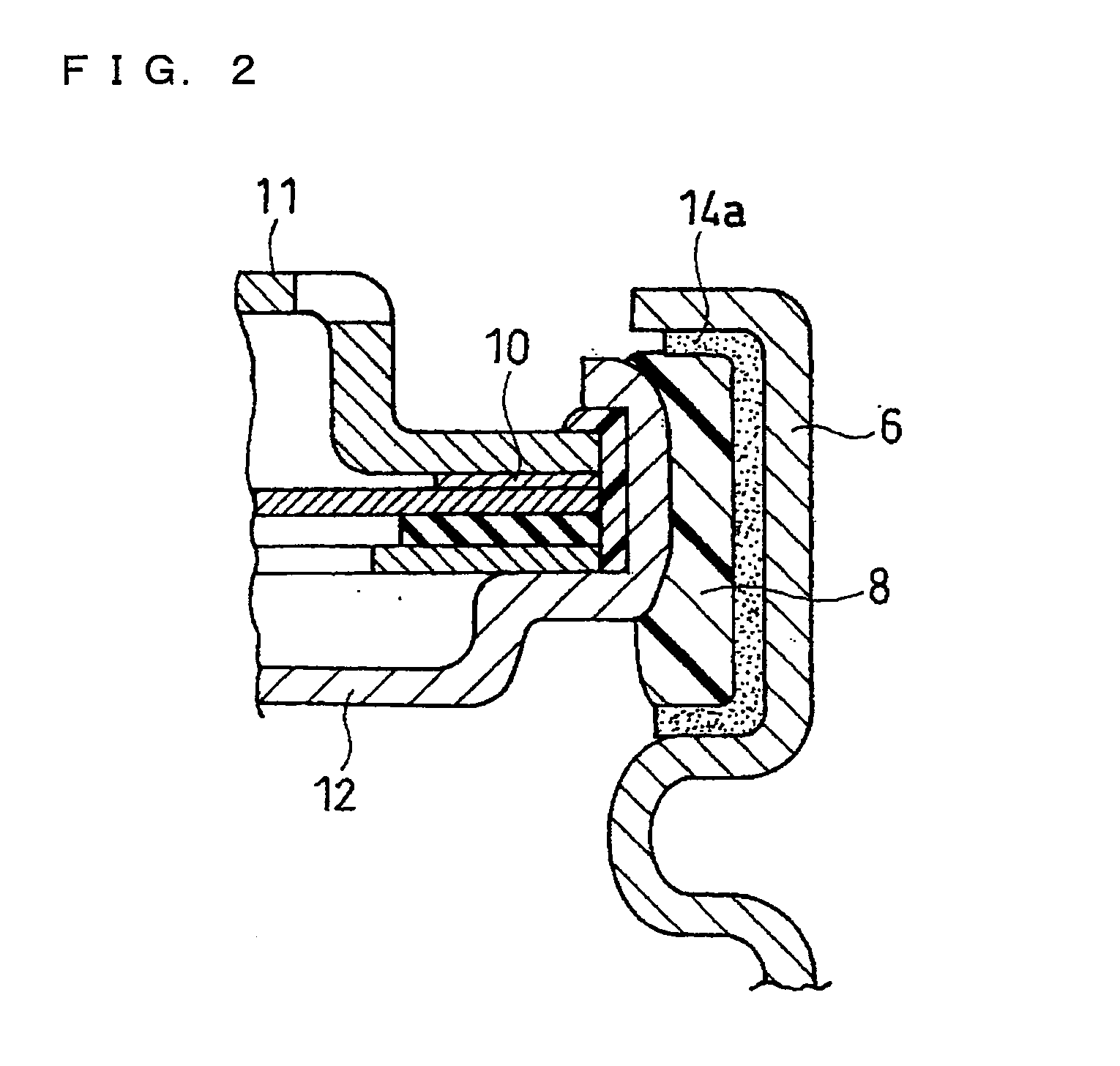

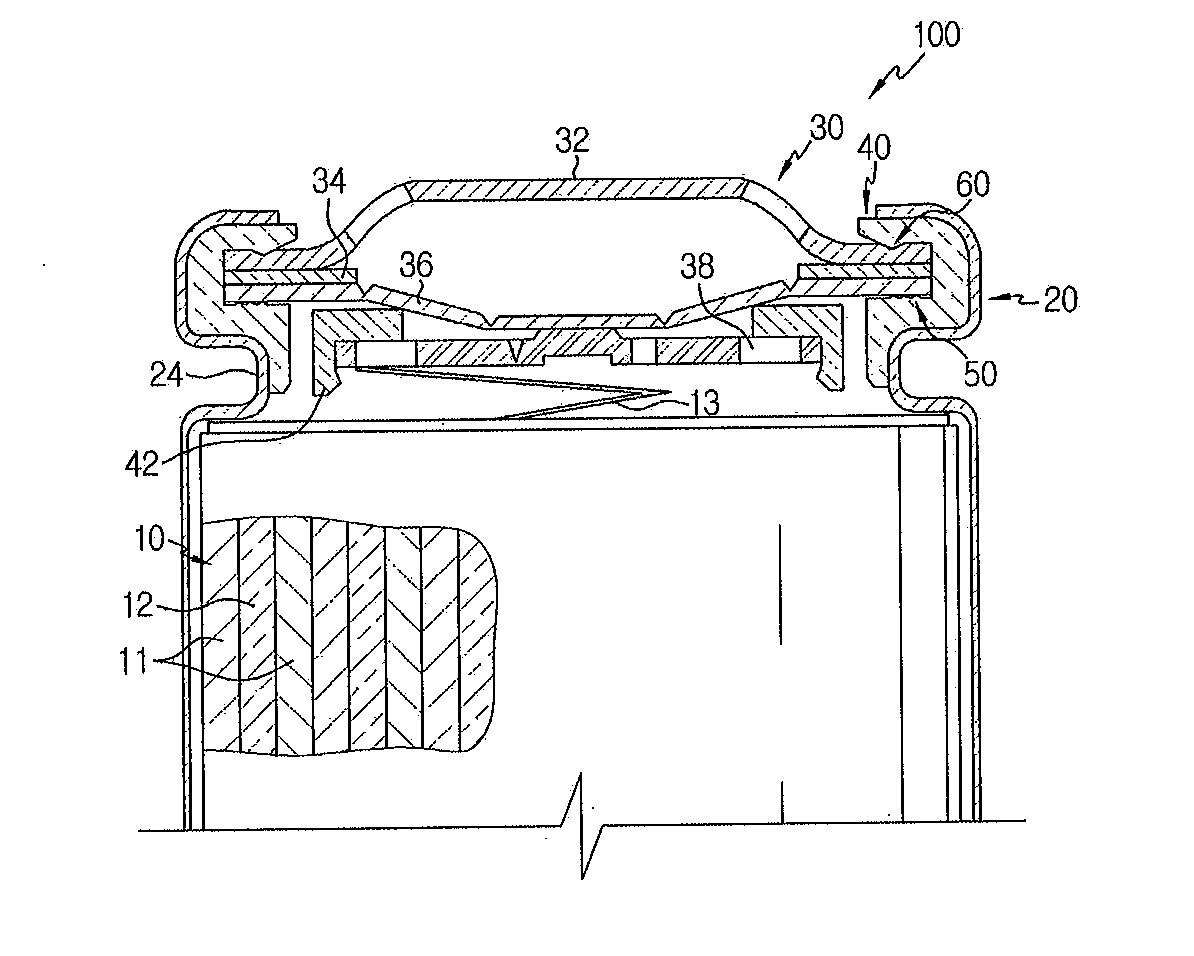

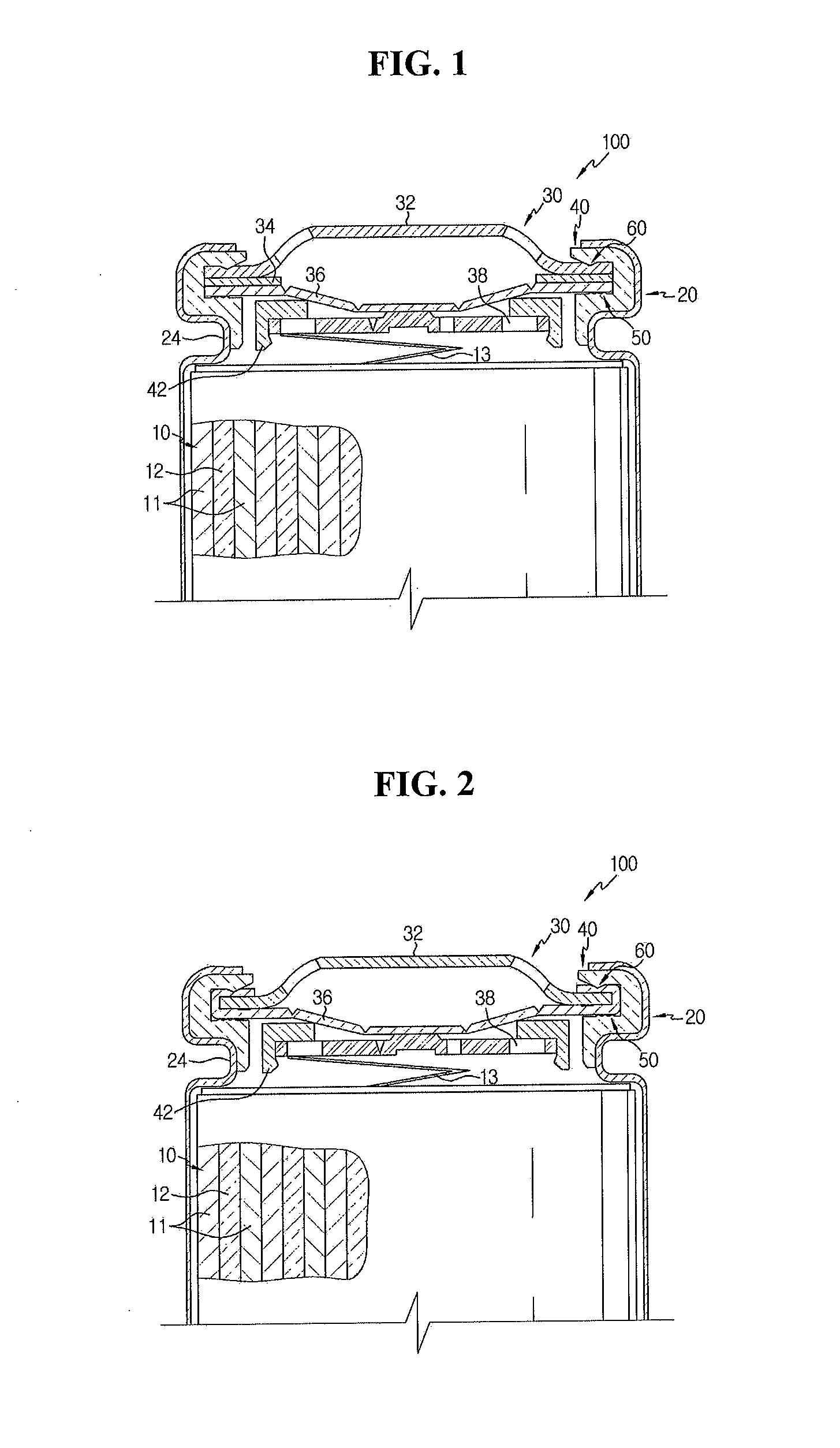

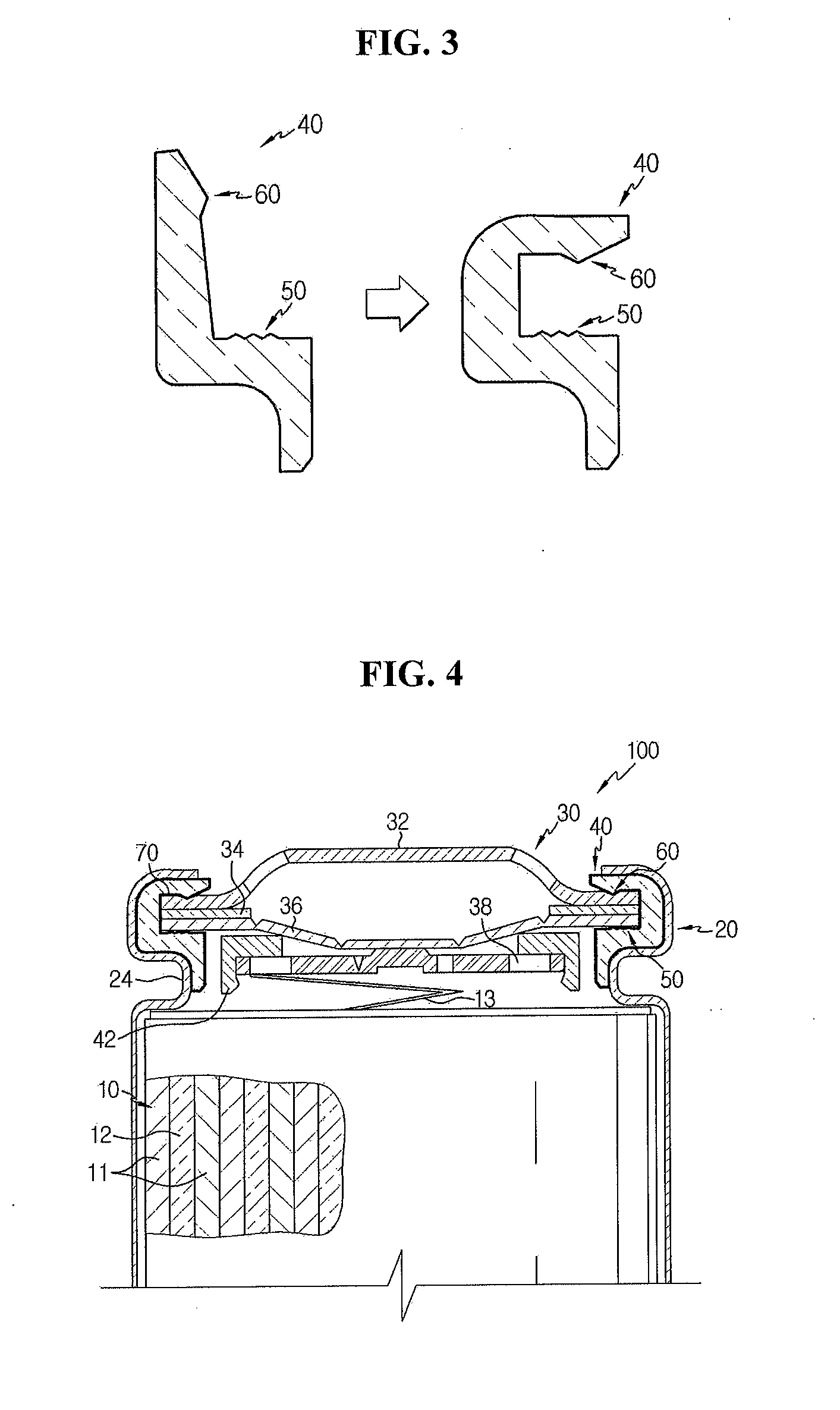

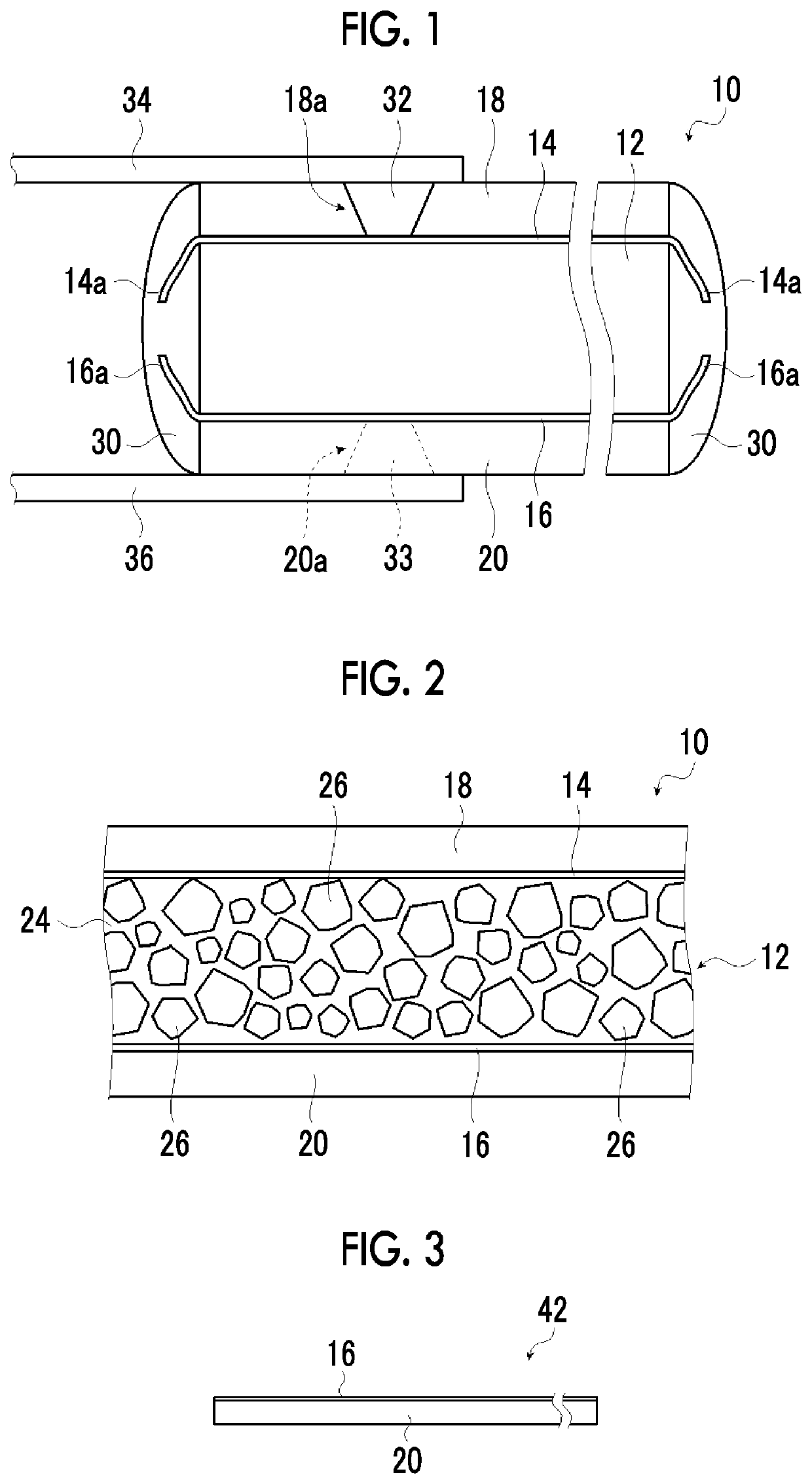

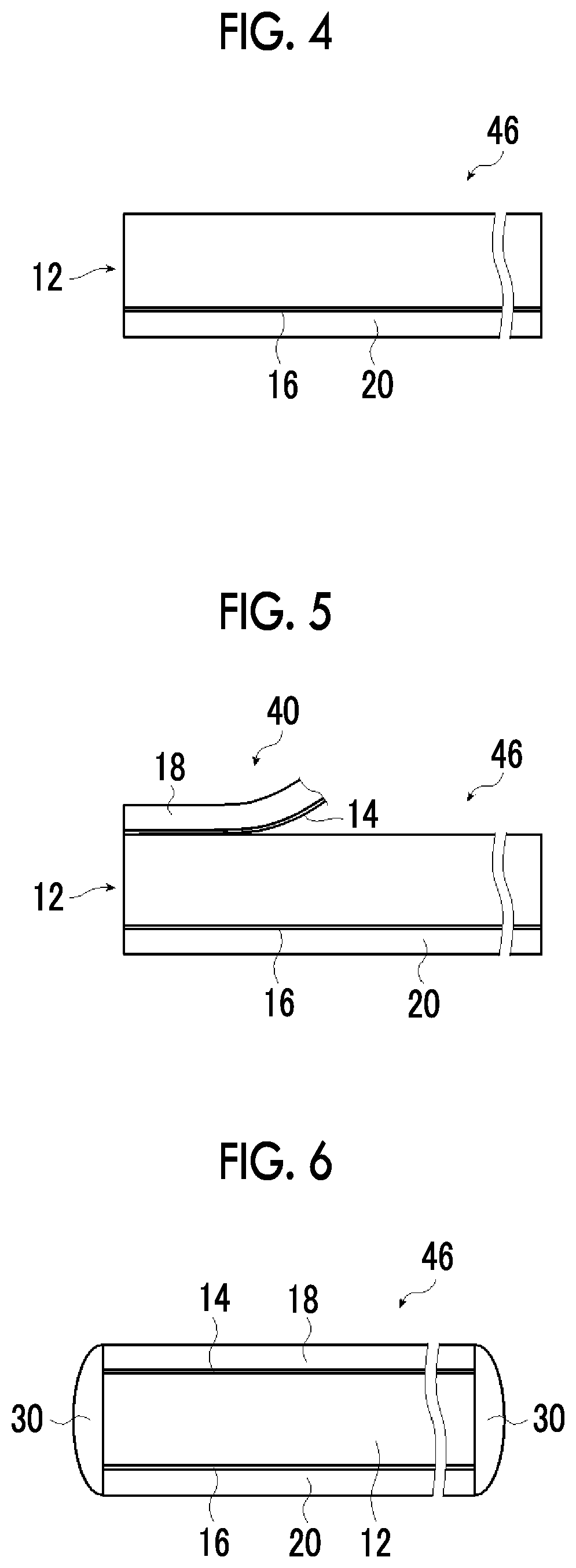

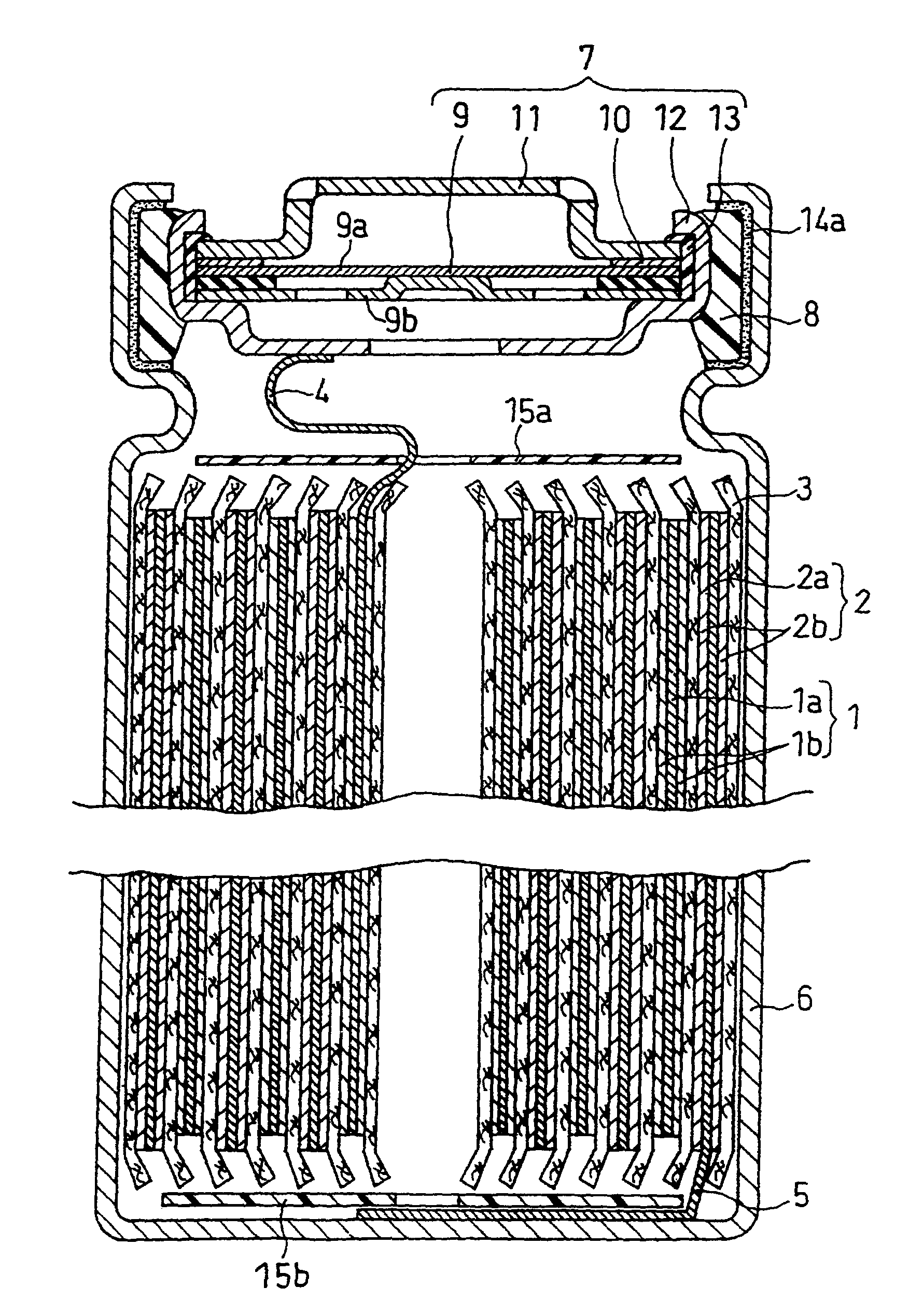

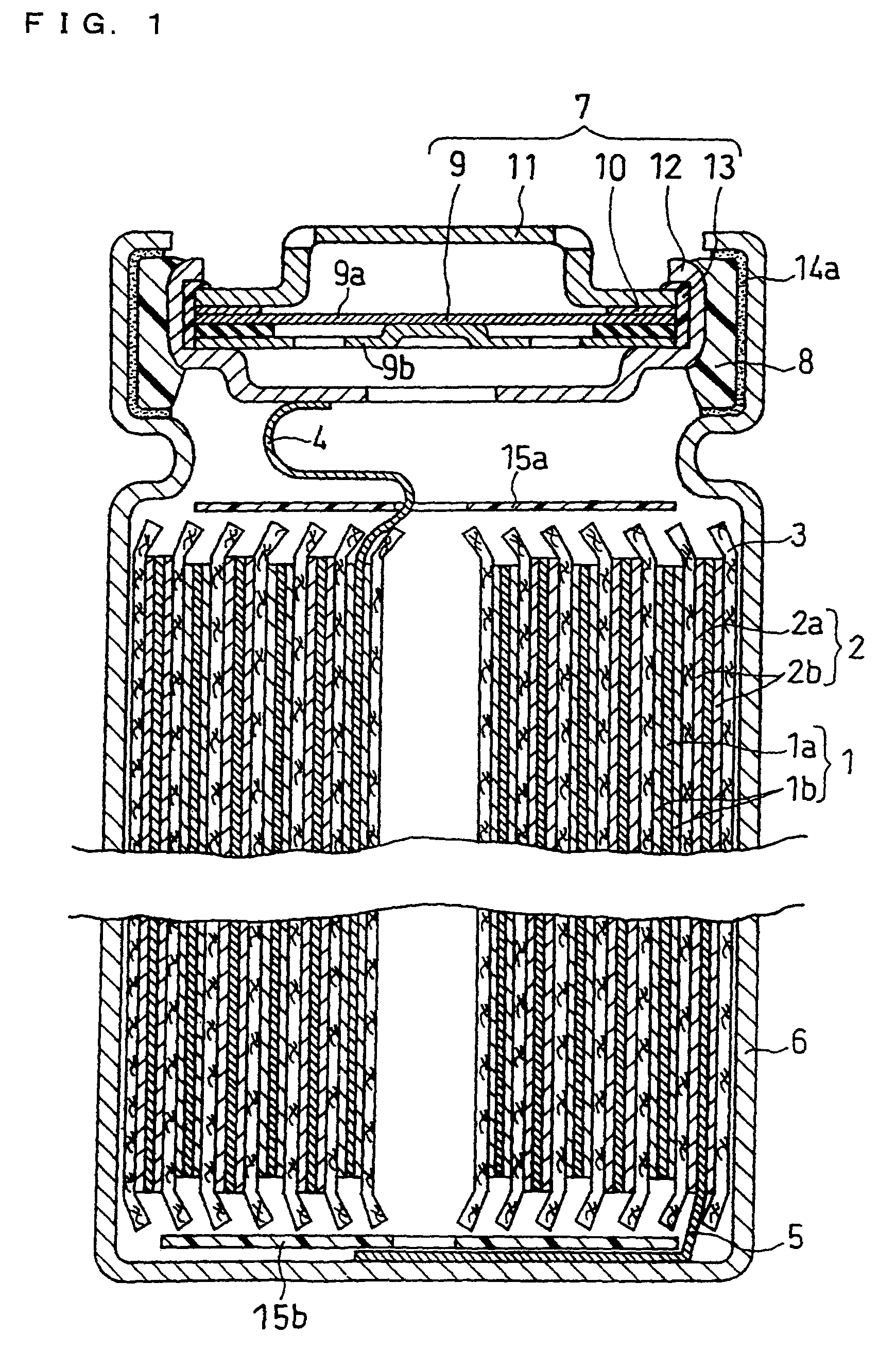

Cylindrical secondary battery

ActiveUS20130273401A1High heat resistanceModerate hardnessSmall-sized cells cases/jacketsCell sealing materialsEngineeringMelting point

Provided is a cylindrical secondary battery, comprising an electrode assembly having a cathode plate, an anode plate, and a separator interposed therebetween; a case for receiving the electrode assembly; a cap assembly for sealing an open-end of the case; and a gasket interposed between the case and the cap assembly, wherein the gasket is made of a polymer resin having a melting point of 200° C. or higher and a hardness of 100D or less.

Owner:LG ENERGY SOLUTION LTD

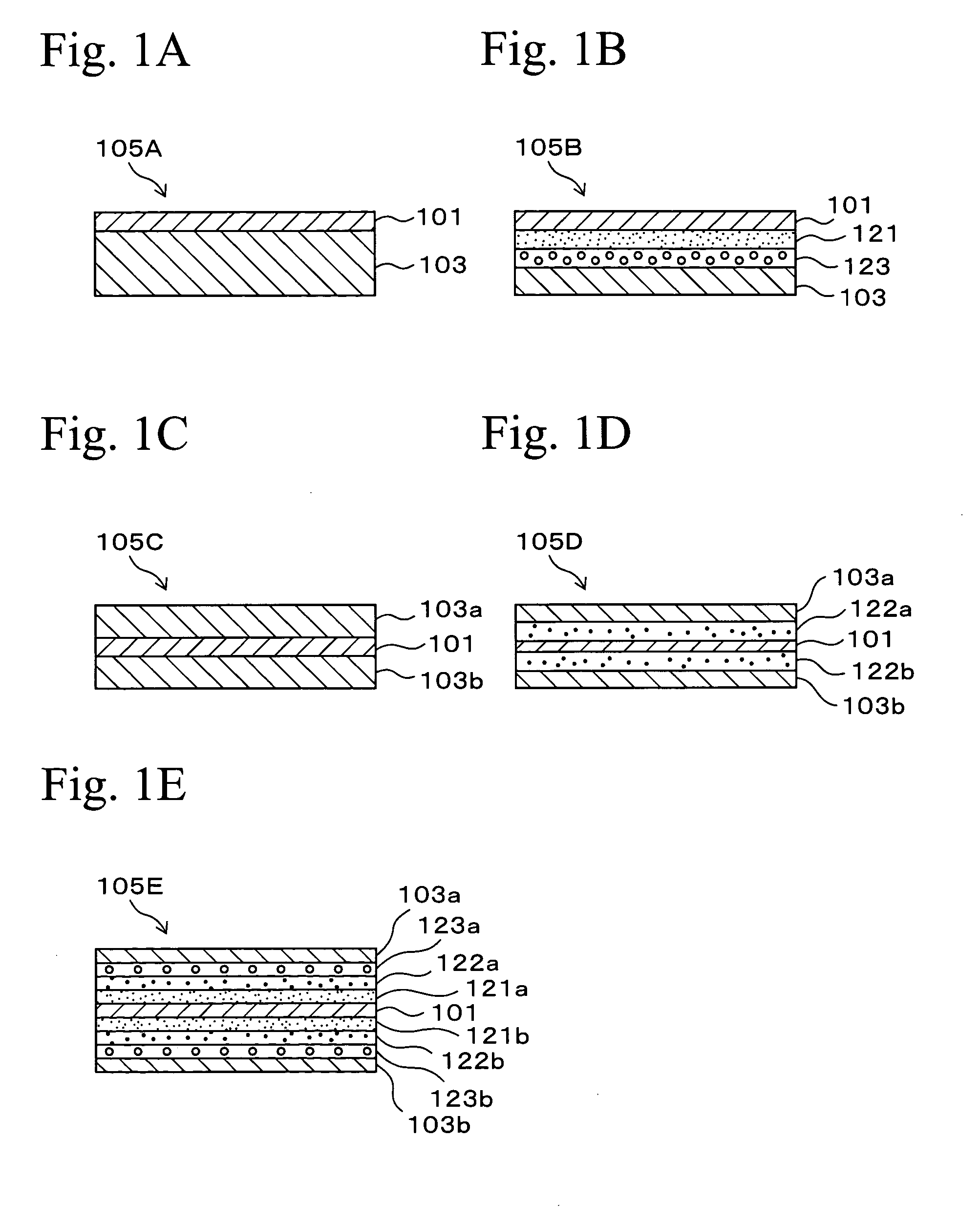

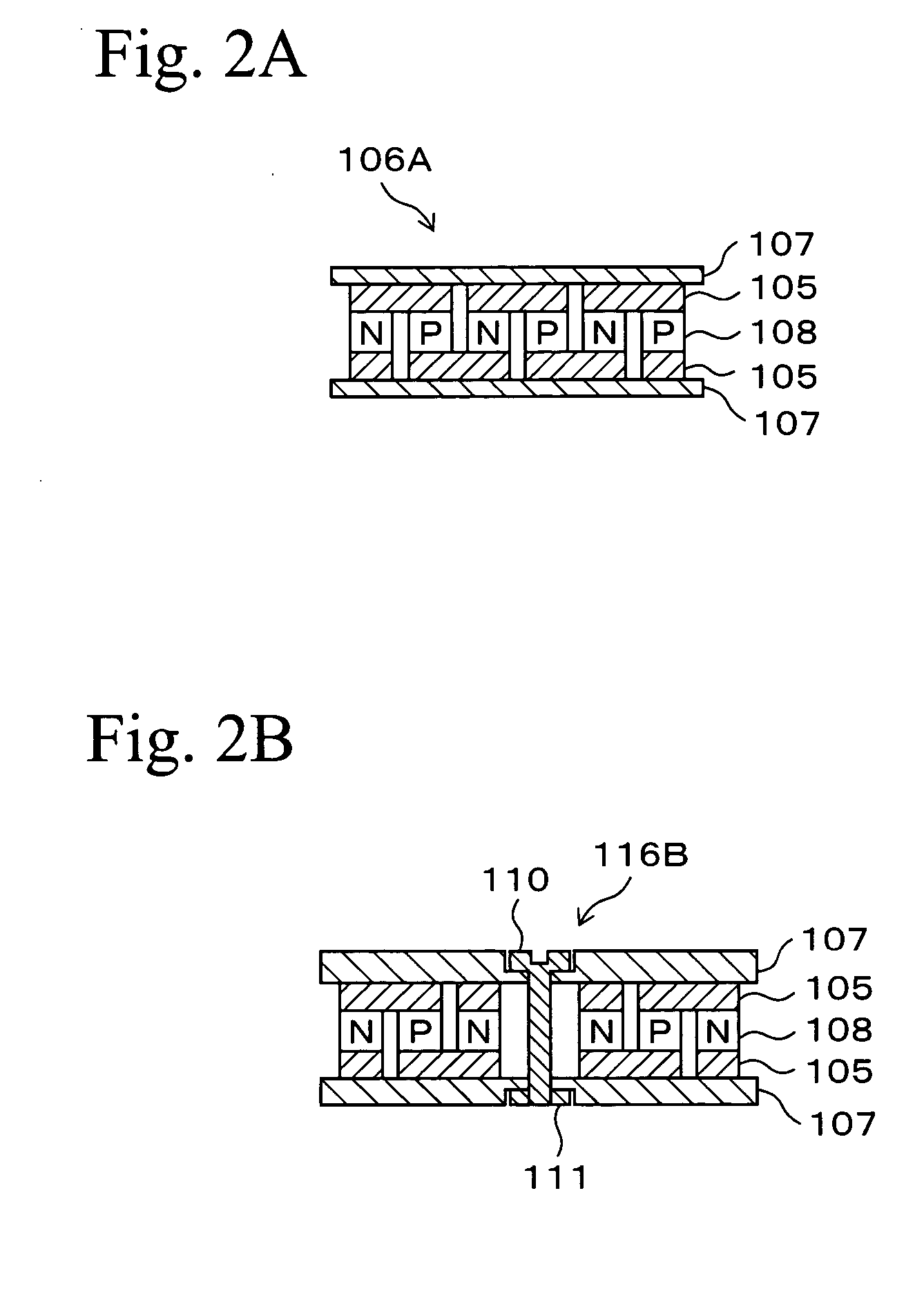

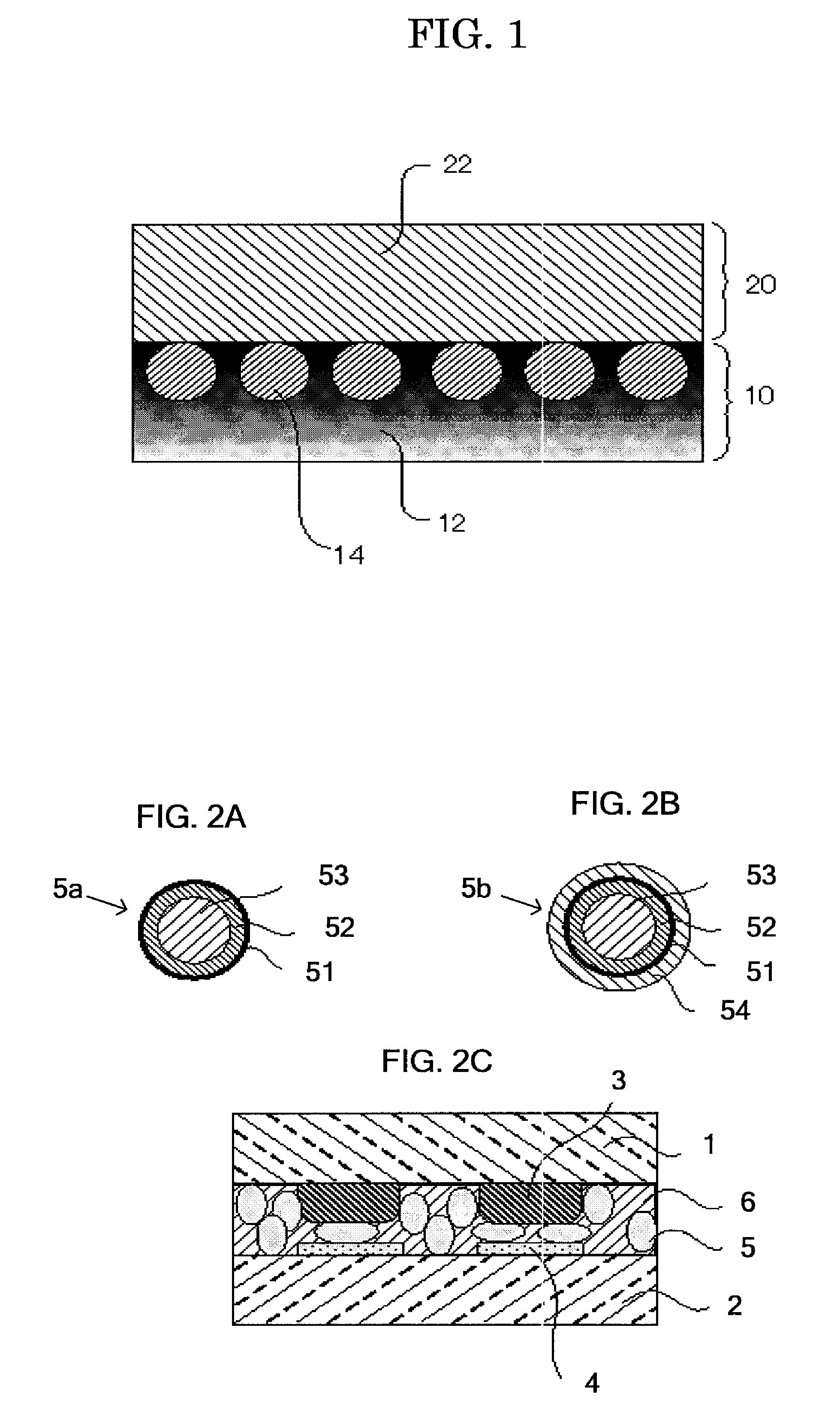

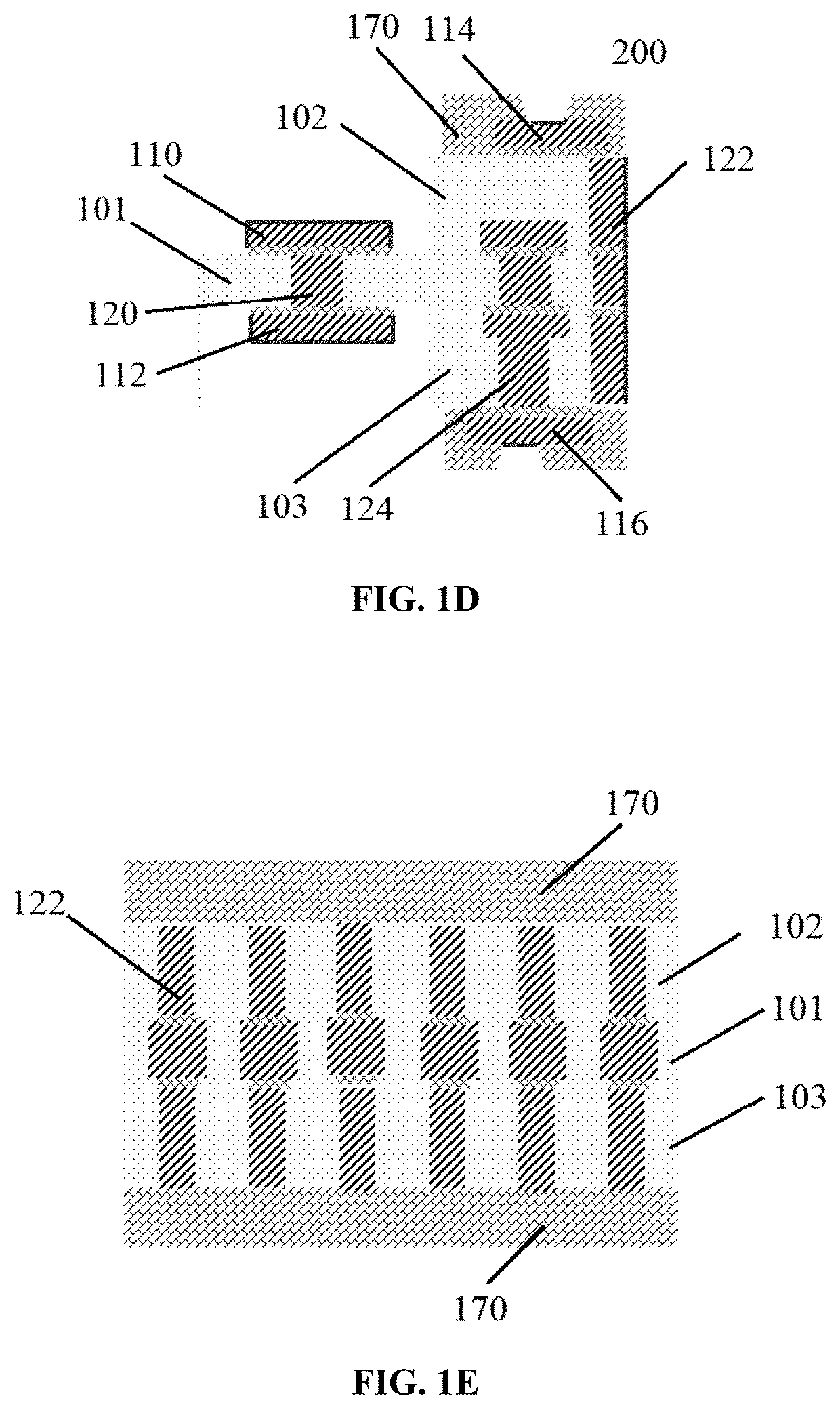

Anisotropic conductive film, method for producing the same, and bonded structure

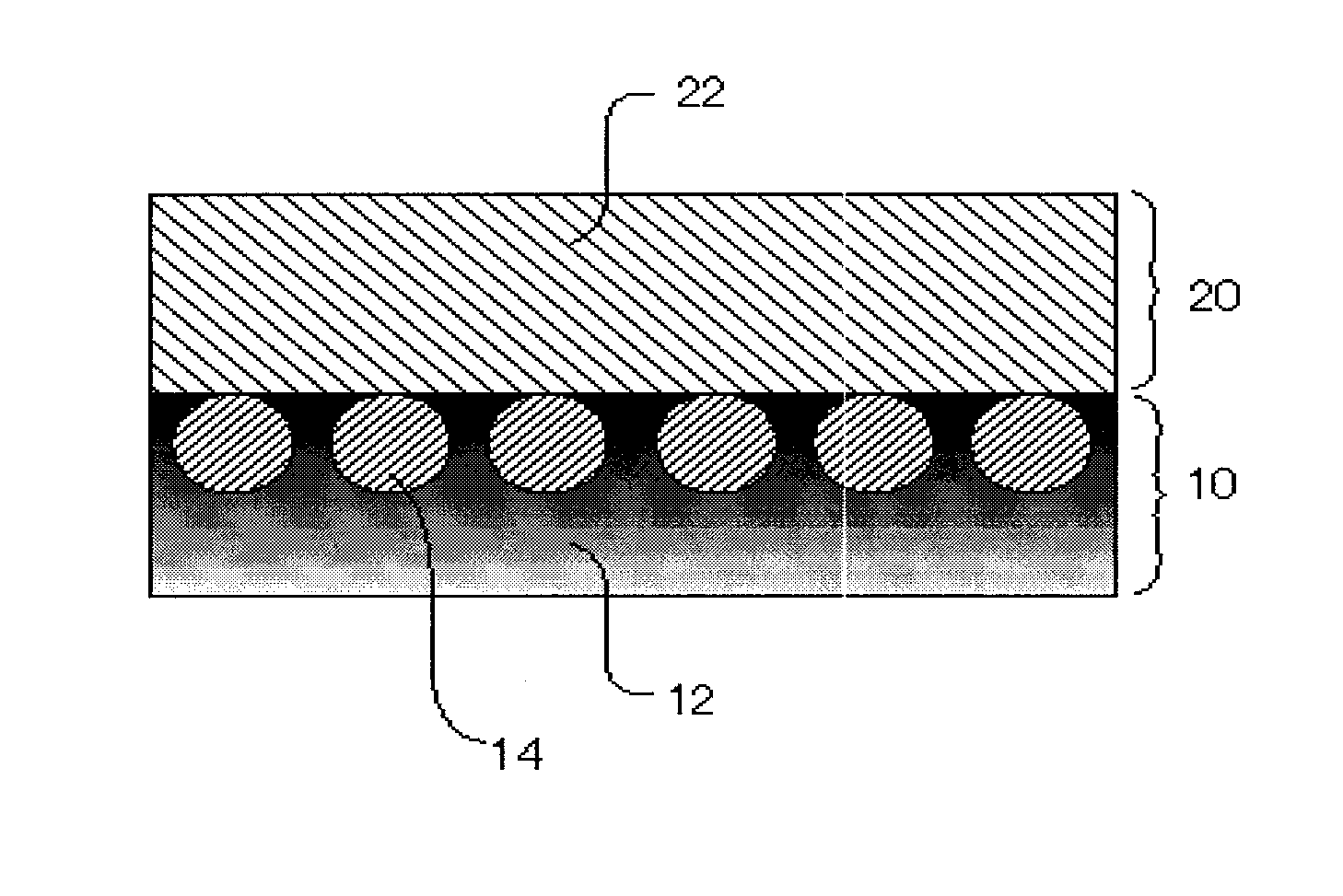

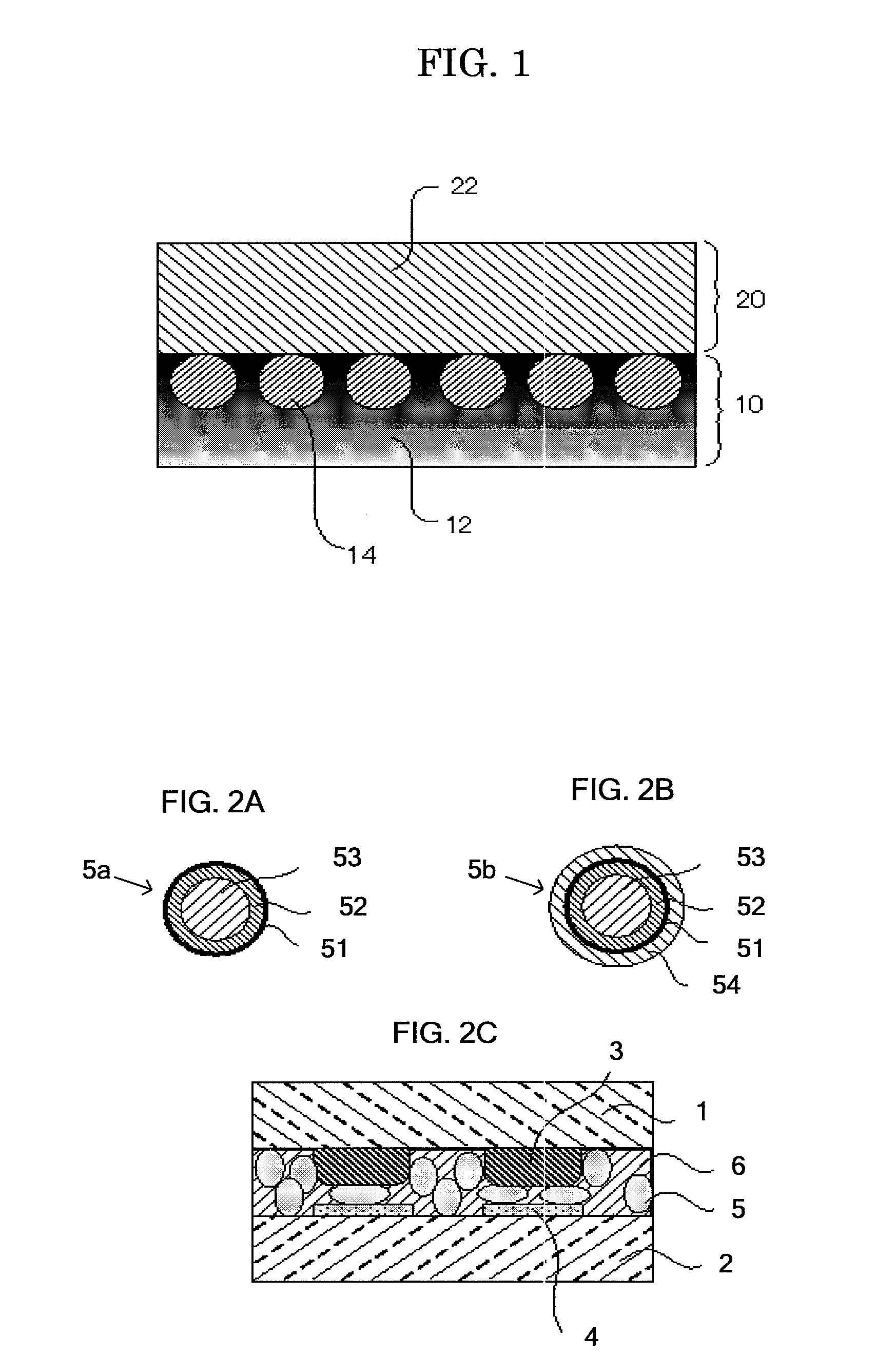

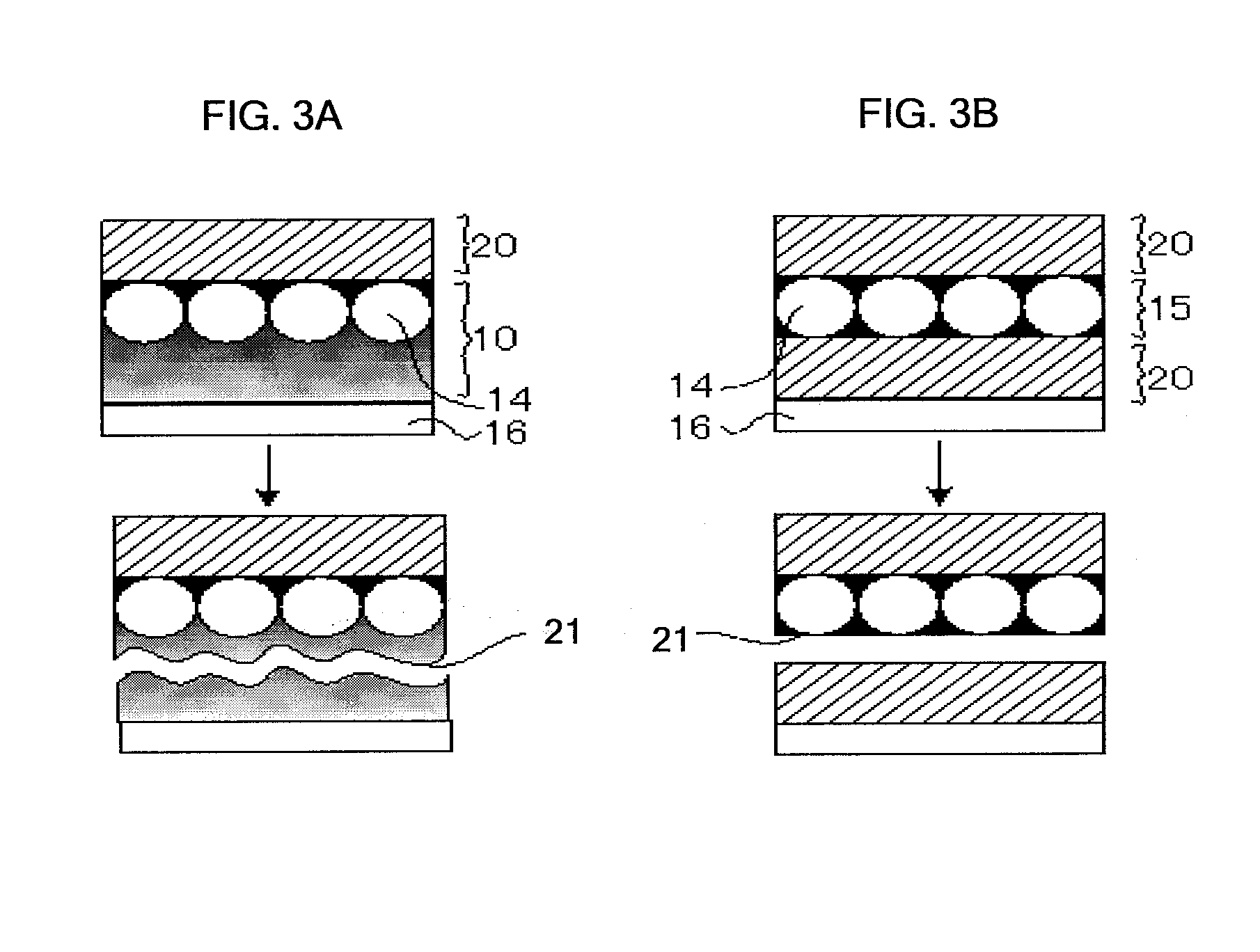

ActiveUS20090239082A1Raise the ratioFacilitate conductionLine/current collector detailsNon-insulated conductorsAnisotropic conductive filmOptoelectronics

Provided is an anisotropic conductive film, containing: an insulating layer formed of an insulating resin composition; and a conductive particle-contained layer containing a photo and thermal curing resin composition and conductive particles, the conductive particles being aligned into a monolayer in a portion adjacent to an interface with the insulating layer, in which the conductive particle-contained layer has a degree of cure which is gradually lowered in a thickness direction of the conductive particle-contained layer, from the side where the conductive particles are present to the side where the conductive particles are not present.

Owner:SONY 50

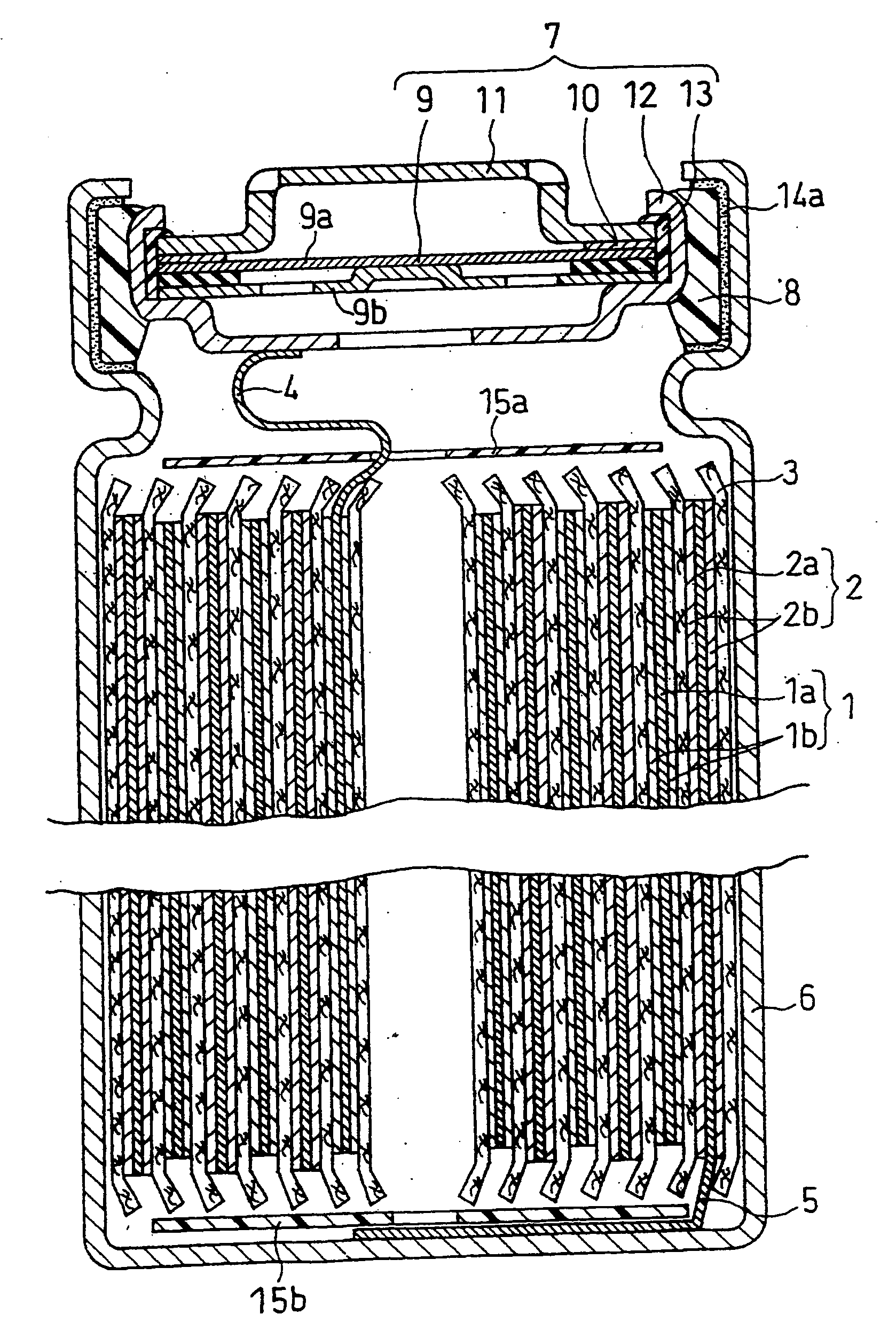

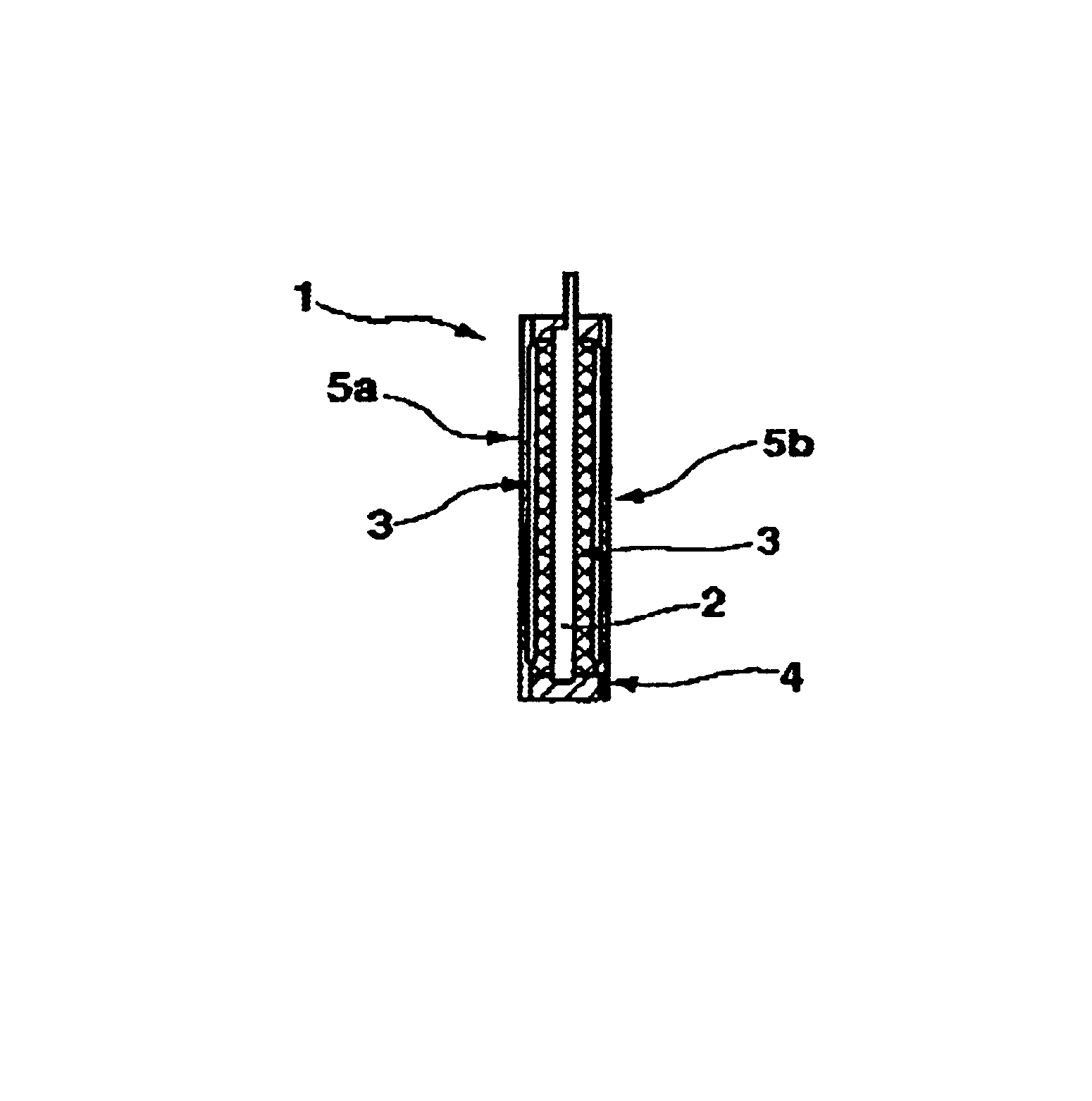

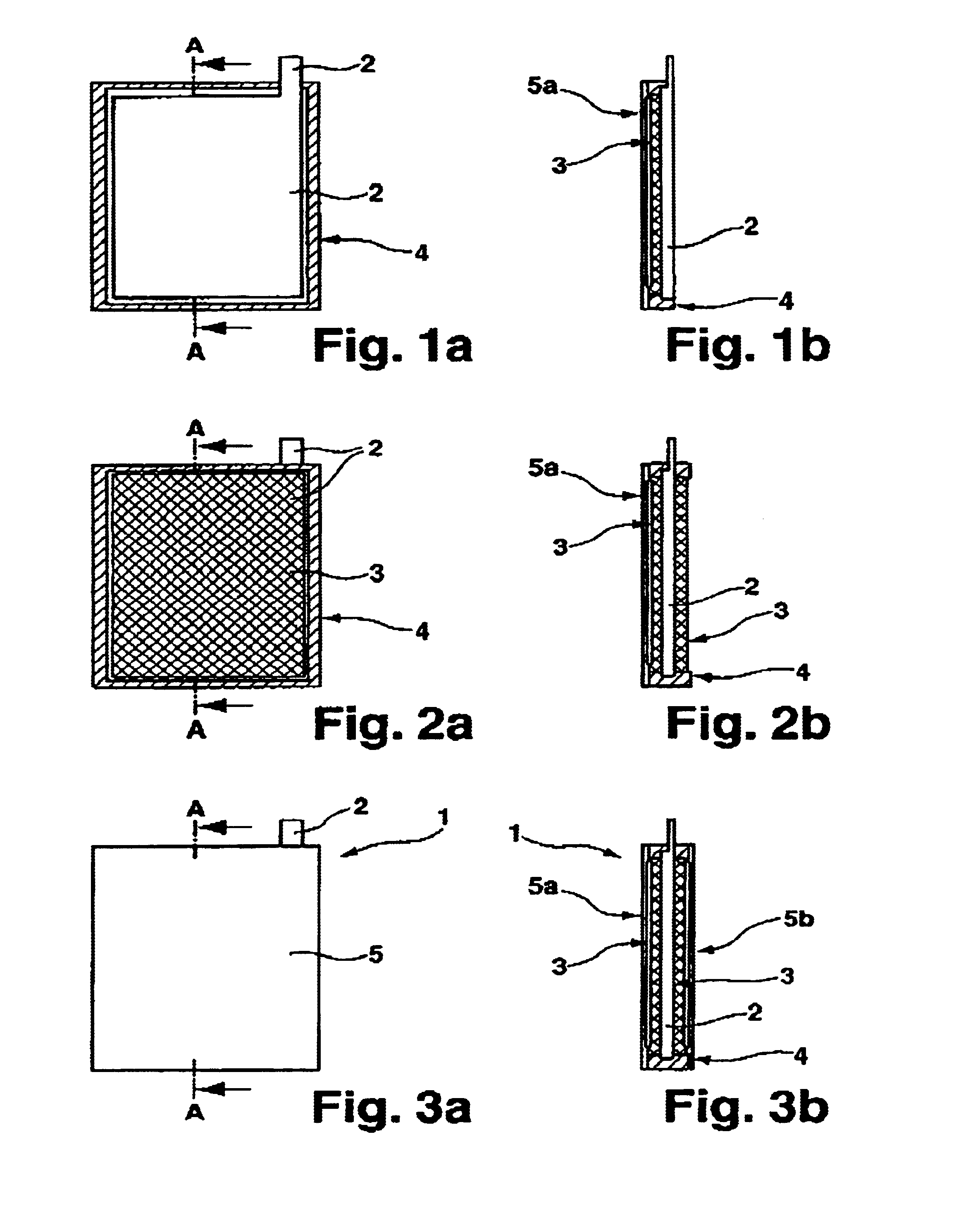

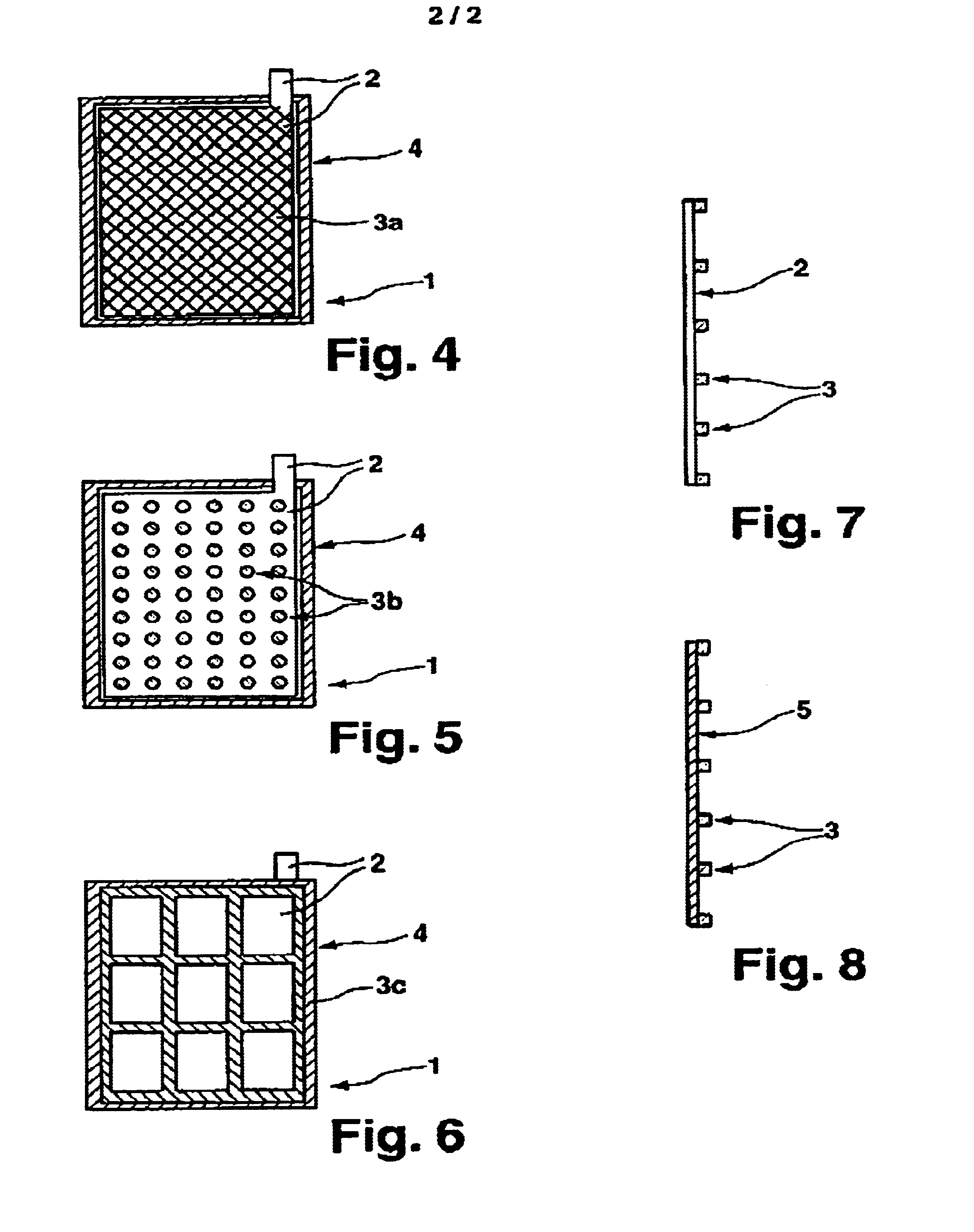

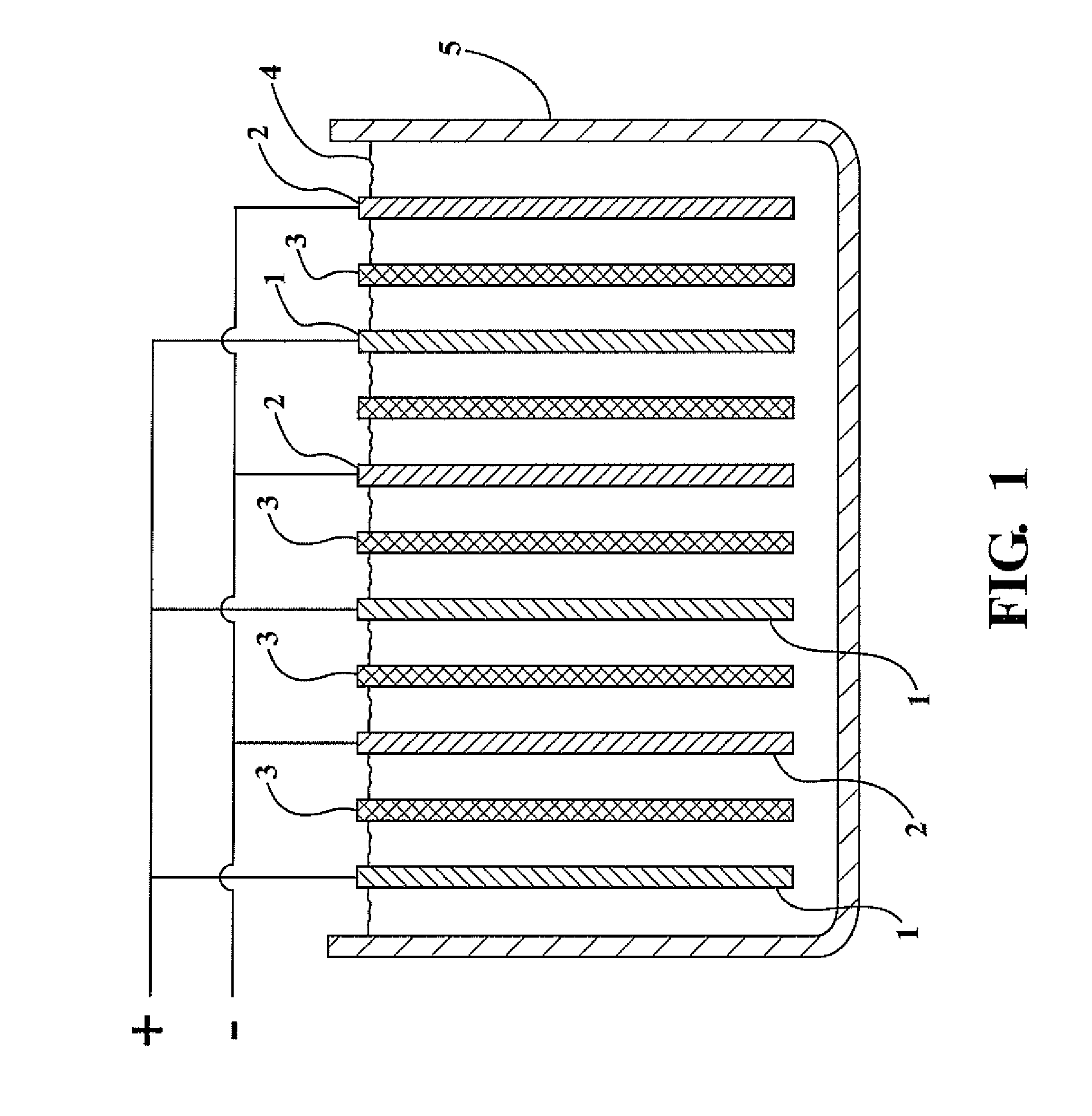

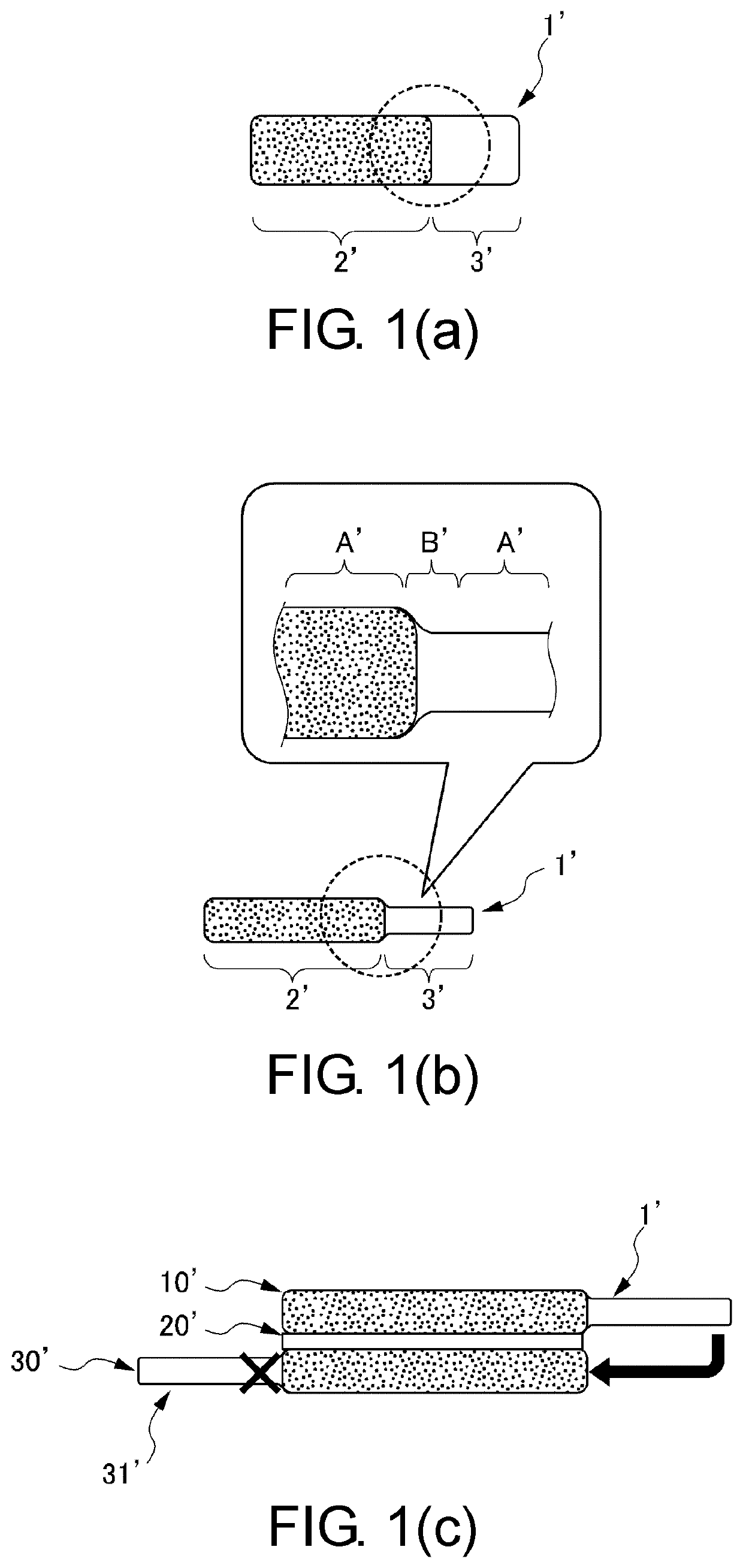

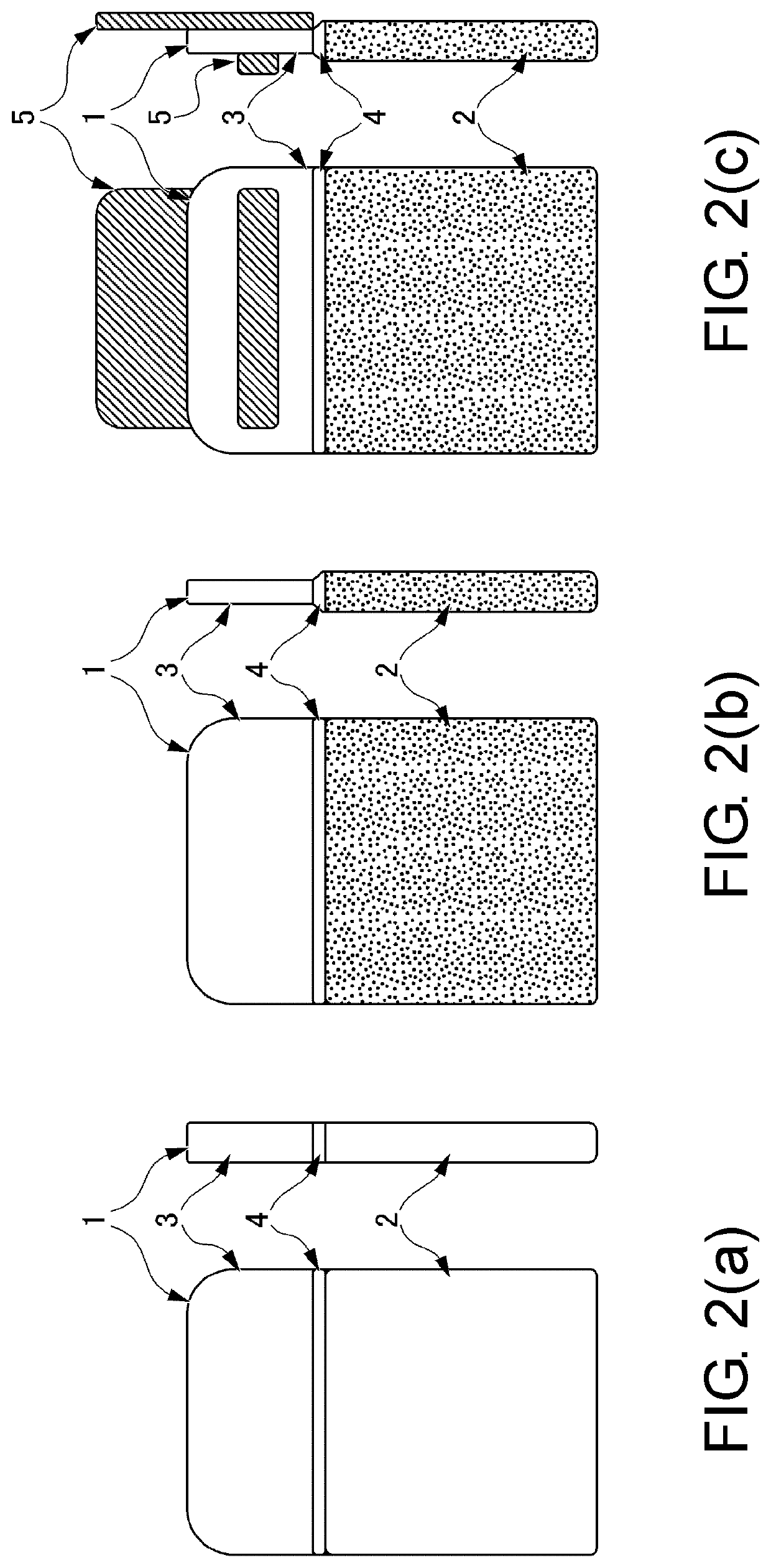

Electrode unit for rechargeable electrochemical cells

InactiveUS6855455B1Avoids mechanical pressure build-upLoad moreLead-acid accumulatorsCell seperators/membranes/diaphragms/spacersElectricityElectrochemical cell

The invention relates to an electrode unit for rechargeable electrochemical cells, e.g. accumulator cells, whose energy storage properties are drawn from the deposition of an element such as metal or an alloy. The electrode unit has an electrode (2) and a porous separator (5a) nearly completely surrounding said electrode, wherein an electrically insulating spacer (3) covering at least one face of the electrode is disposed between the electrode and the separator. The spacer according to the invention makes it possible to provide the necessary space for the metal or alloy deposited on the electrode, particularly during charging of the accumulator cell. The mechanical pressure as a result of changes in the volume of the electrode due to the deposited metal or alloy are intercepted, thereby reliably preventing short circuits.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

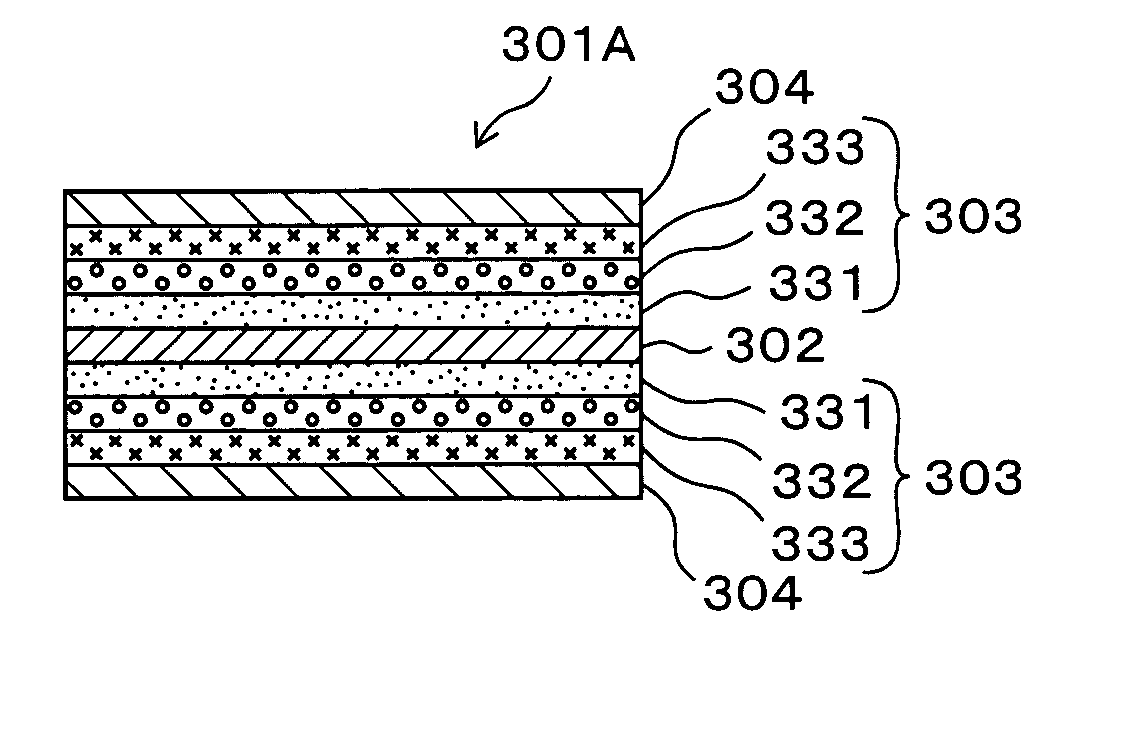

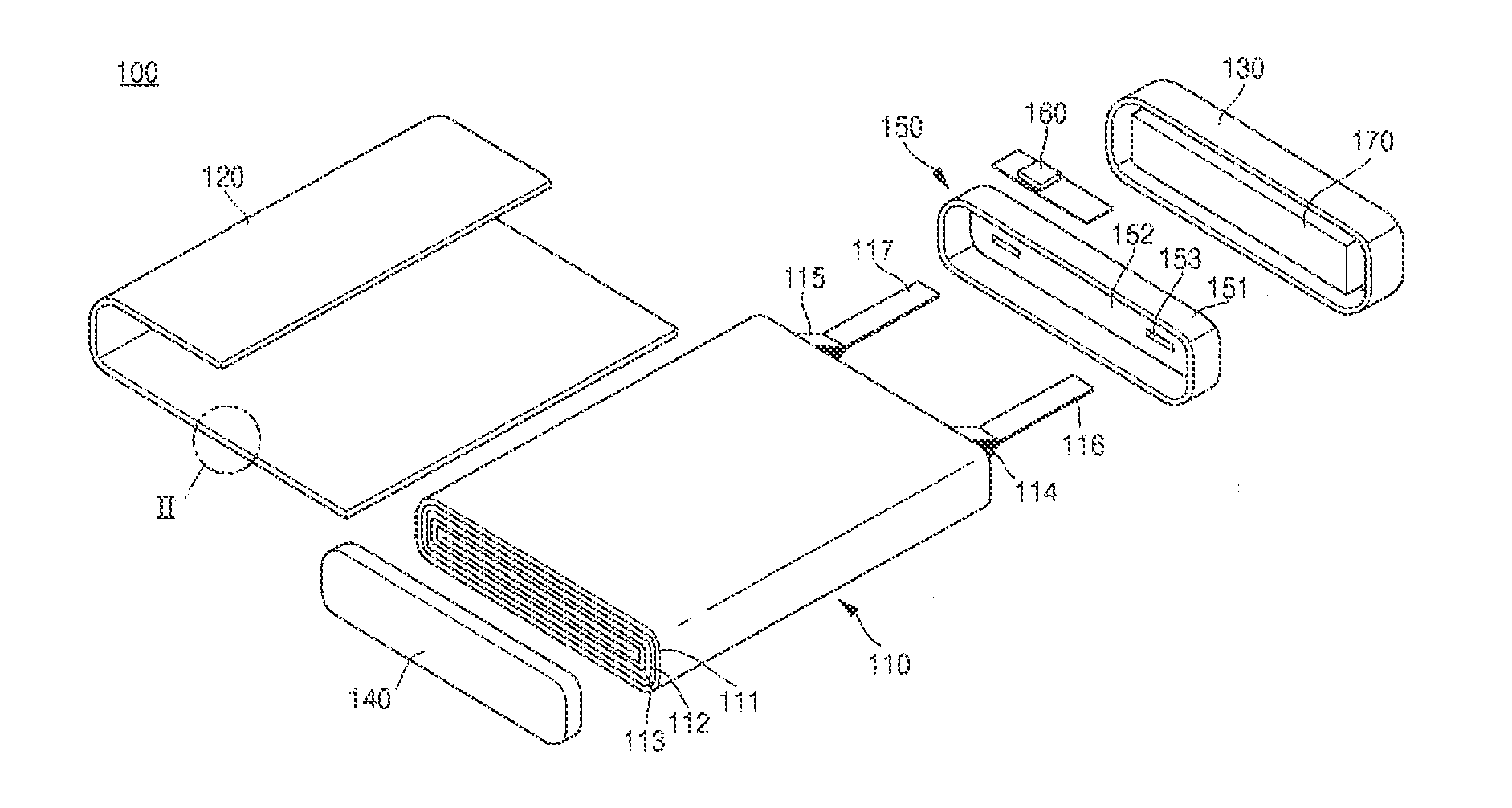

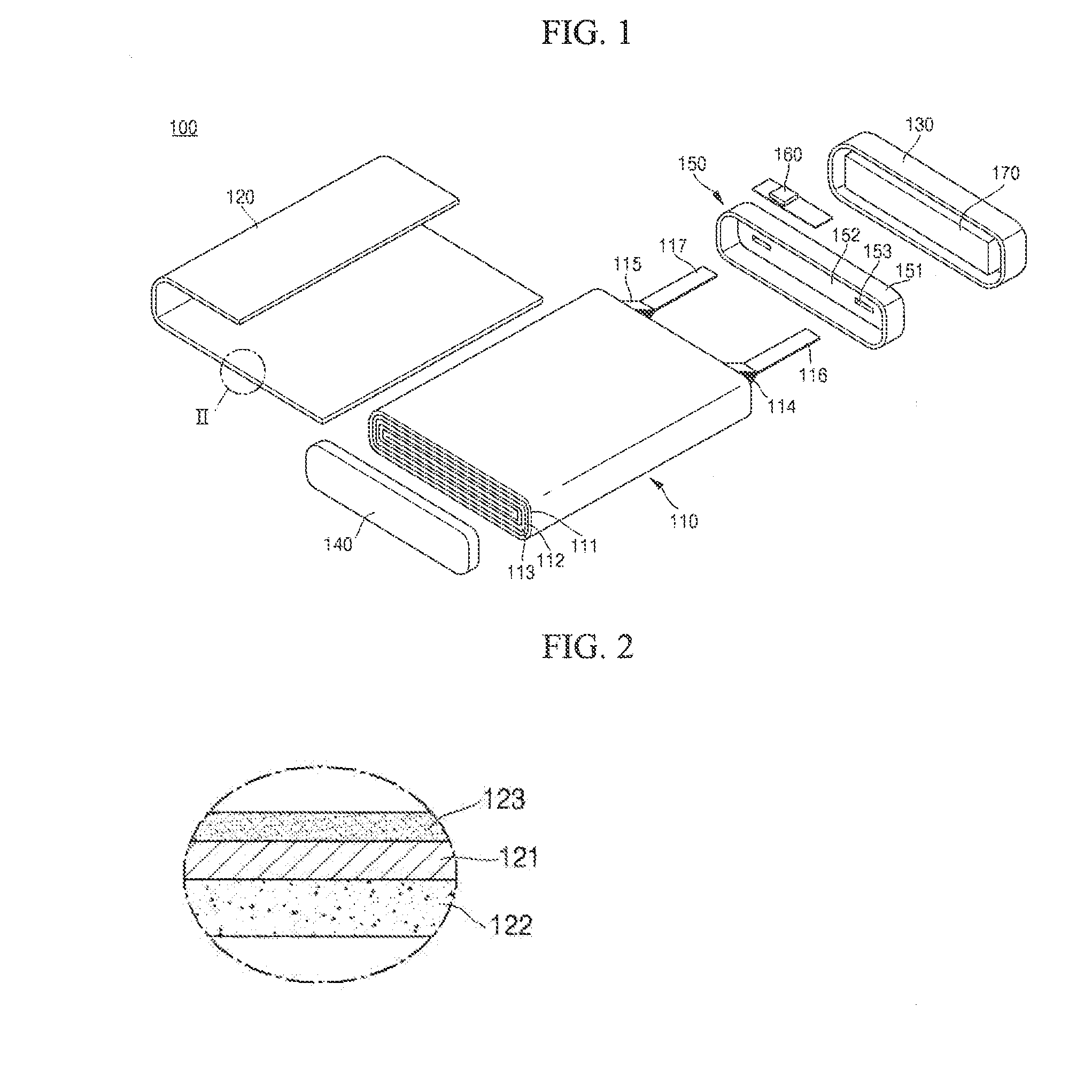

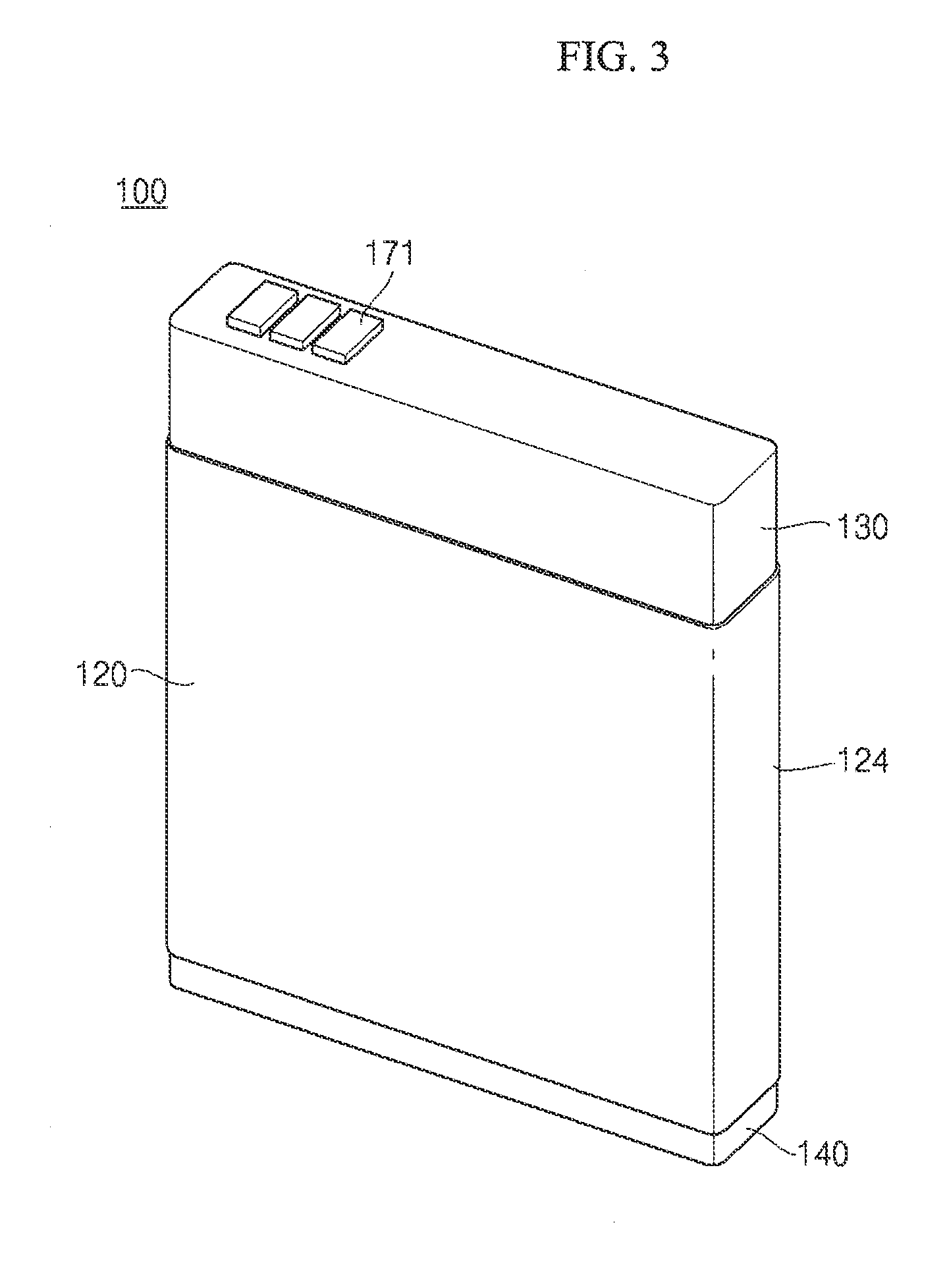

Lithium polymer secondary battery

InactiveUS20110117399A1Large capacityPrevent a short circuitFinal product manufactureSmall-sized cells cases/jacketsElectrical batteryBiomedical engineering

A secondary battery includes an electrode assembly comprising a first electrode, a second electrode, and a separator between the first electrode and the second electrode; an external member wrapped around a side surface of the electrode assembly; a cover coupled to the external member; and a terminal protection member between the electrode assembly and the cover.

Owner:SAMSUNG SDI CO LTD

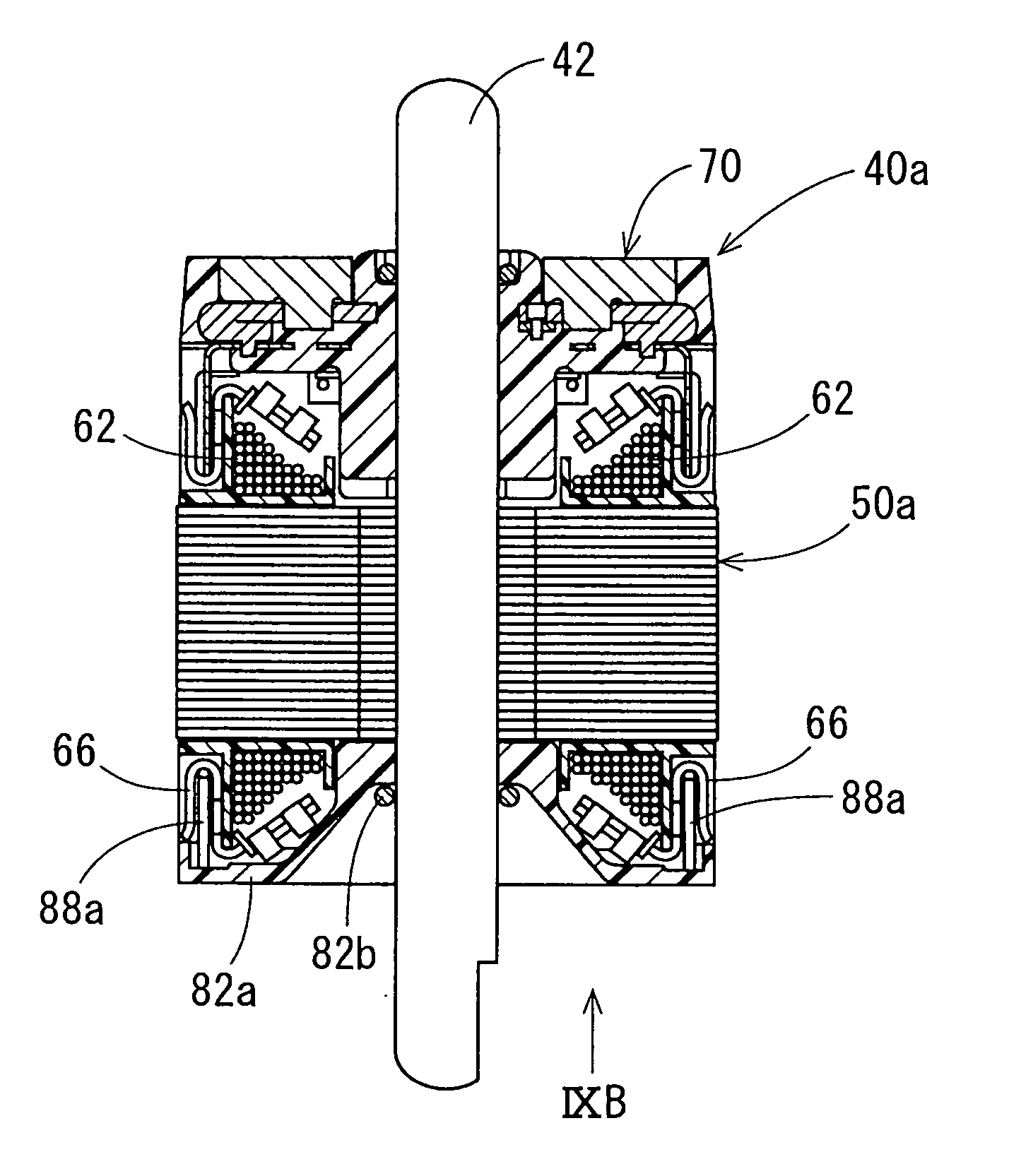

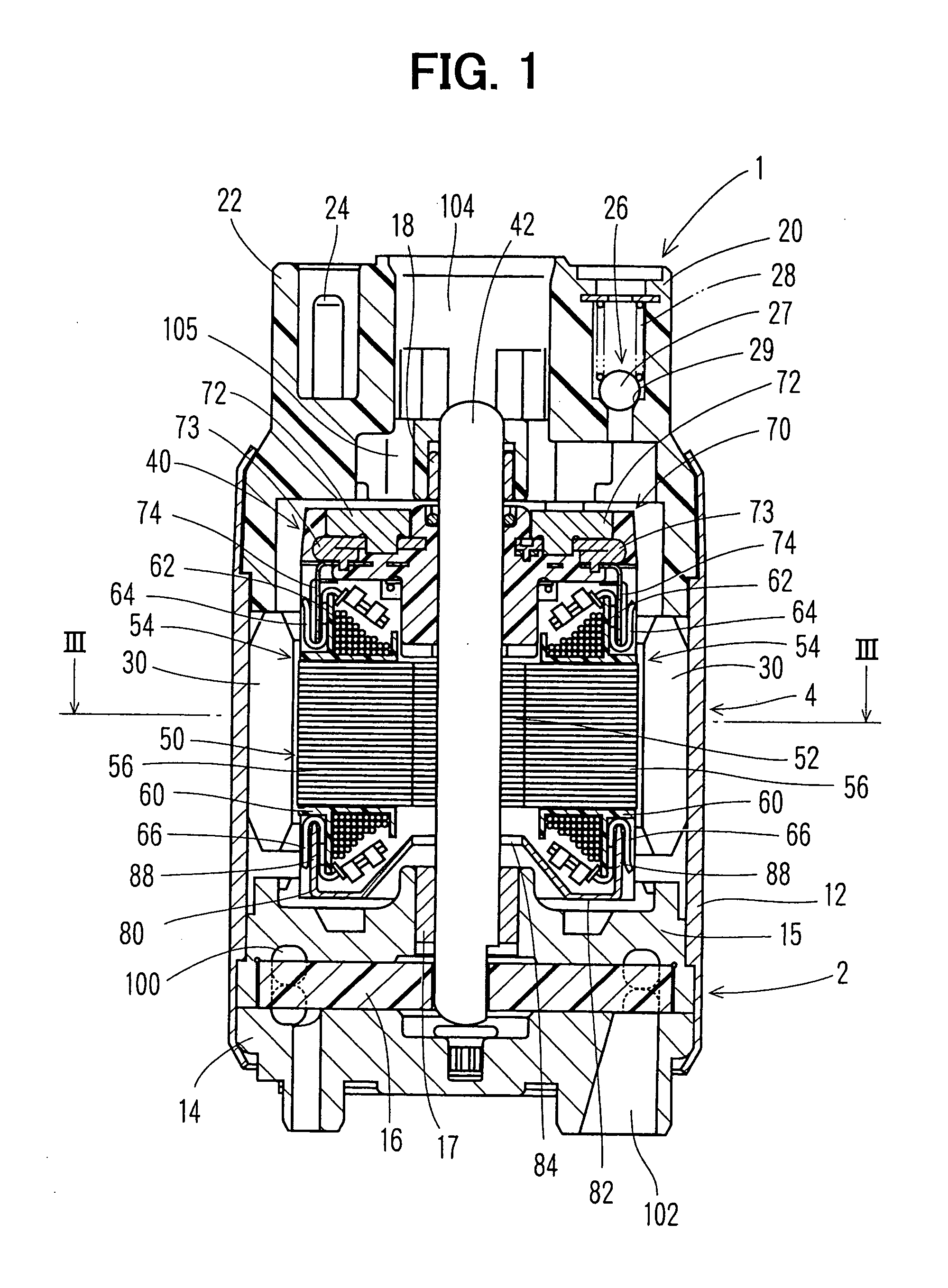

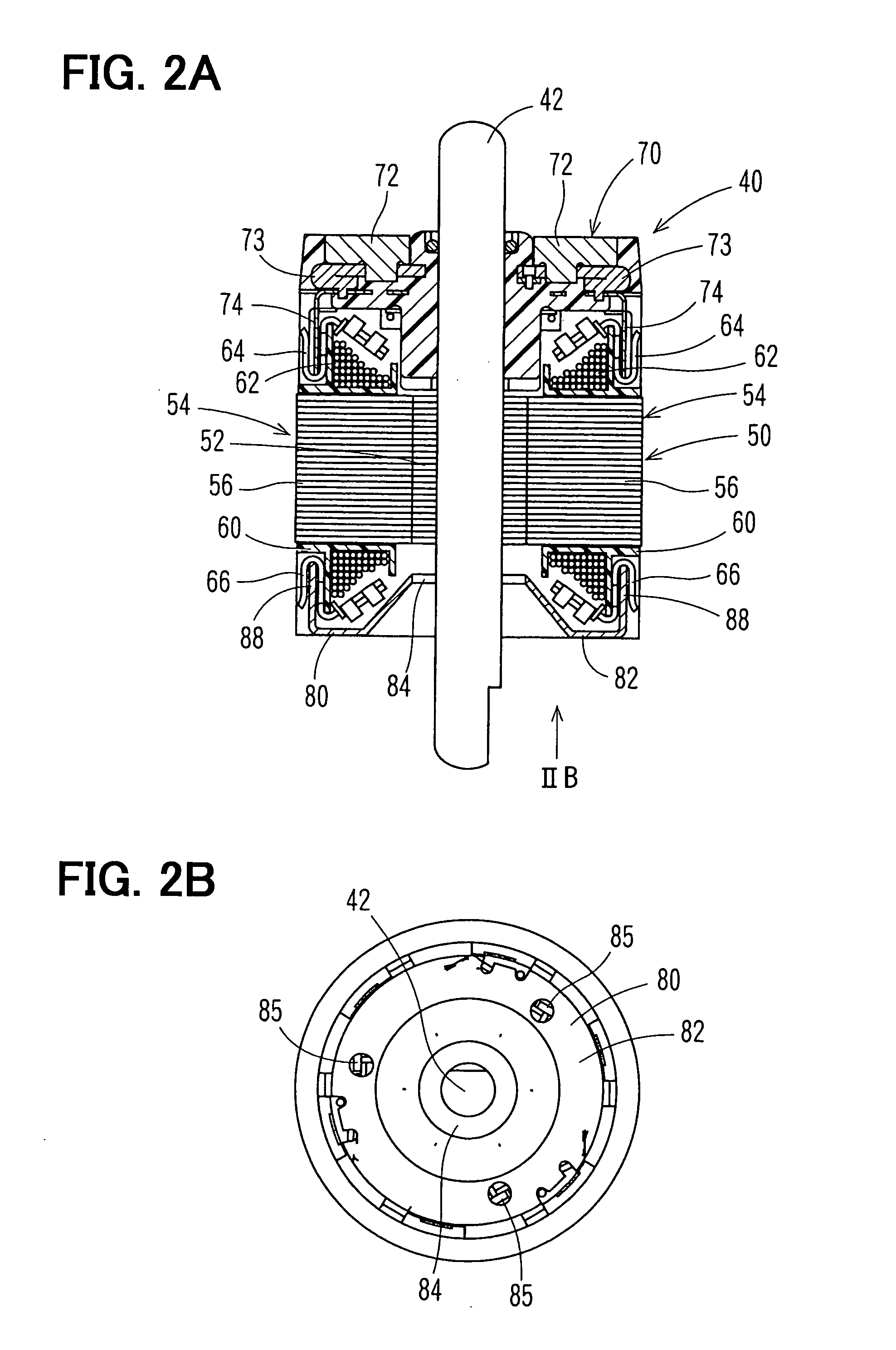

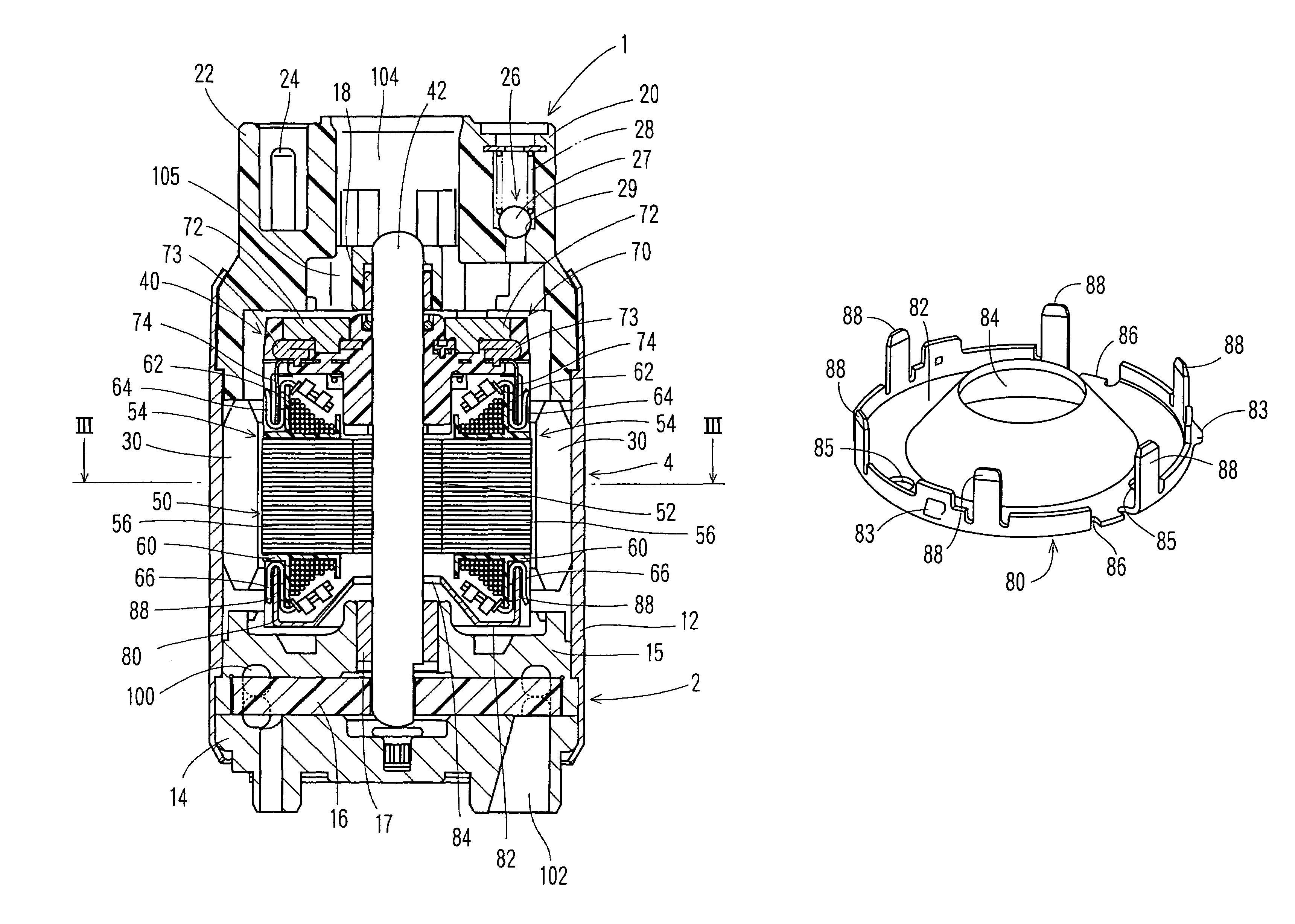

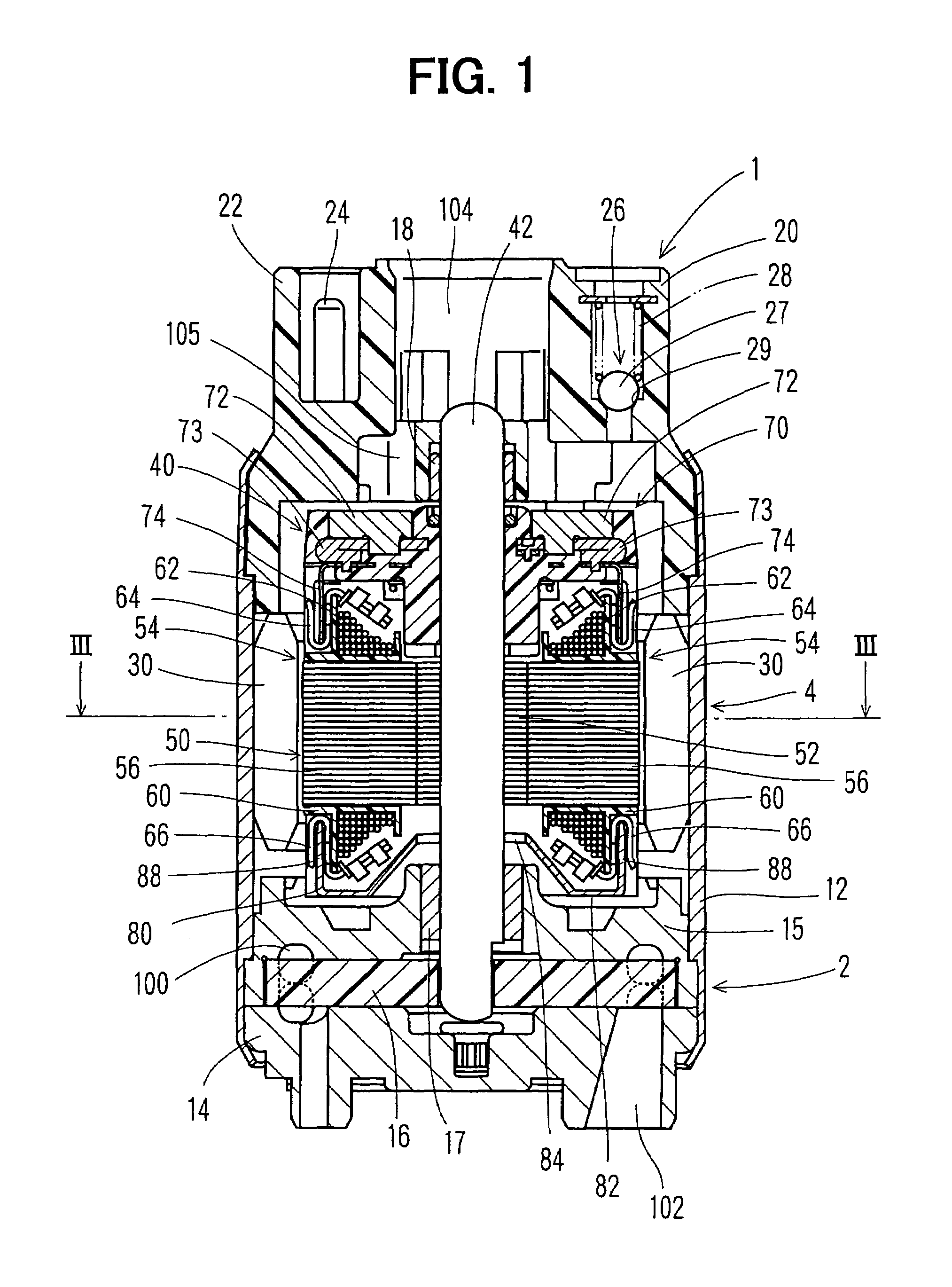

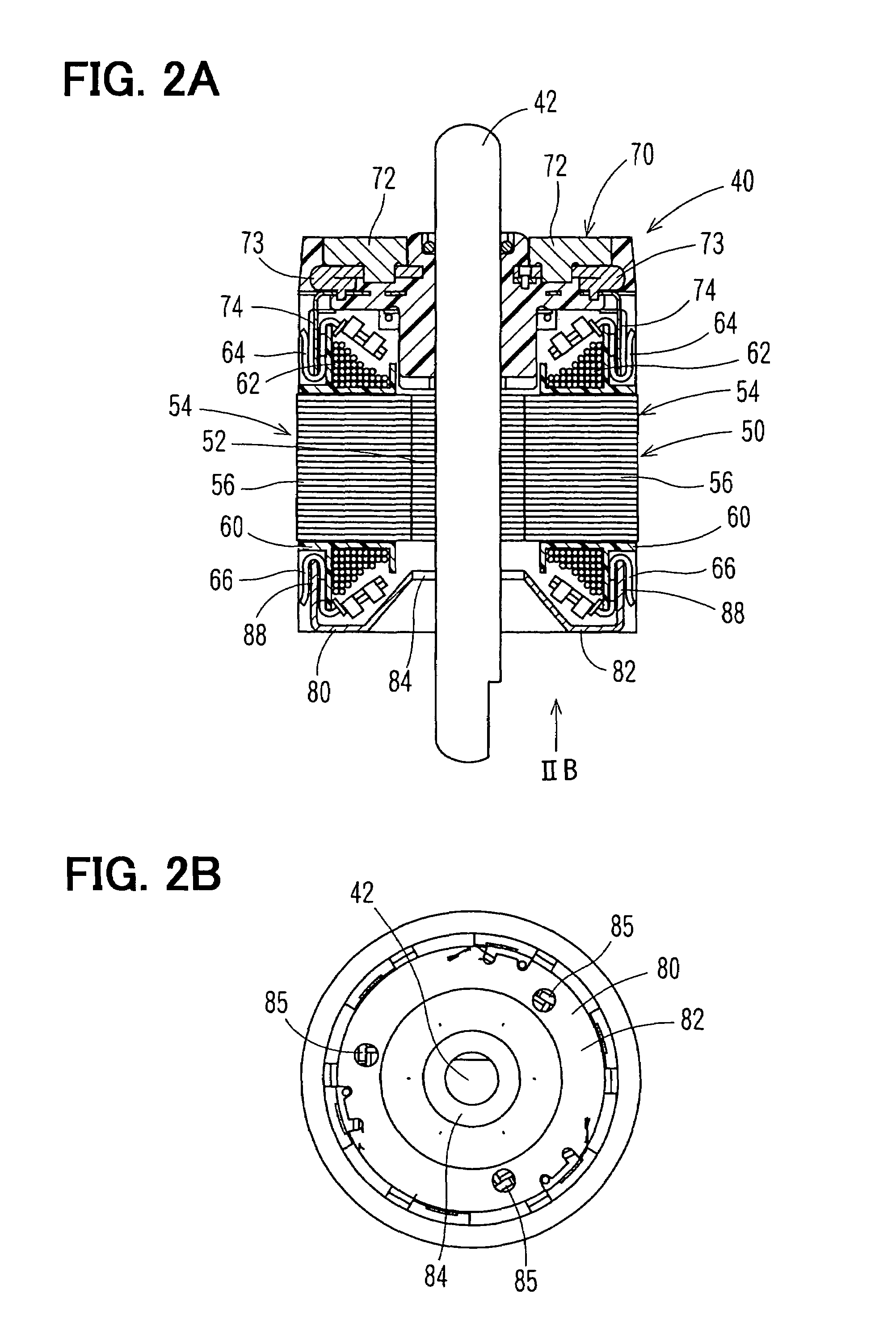

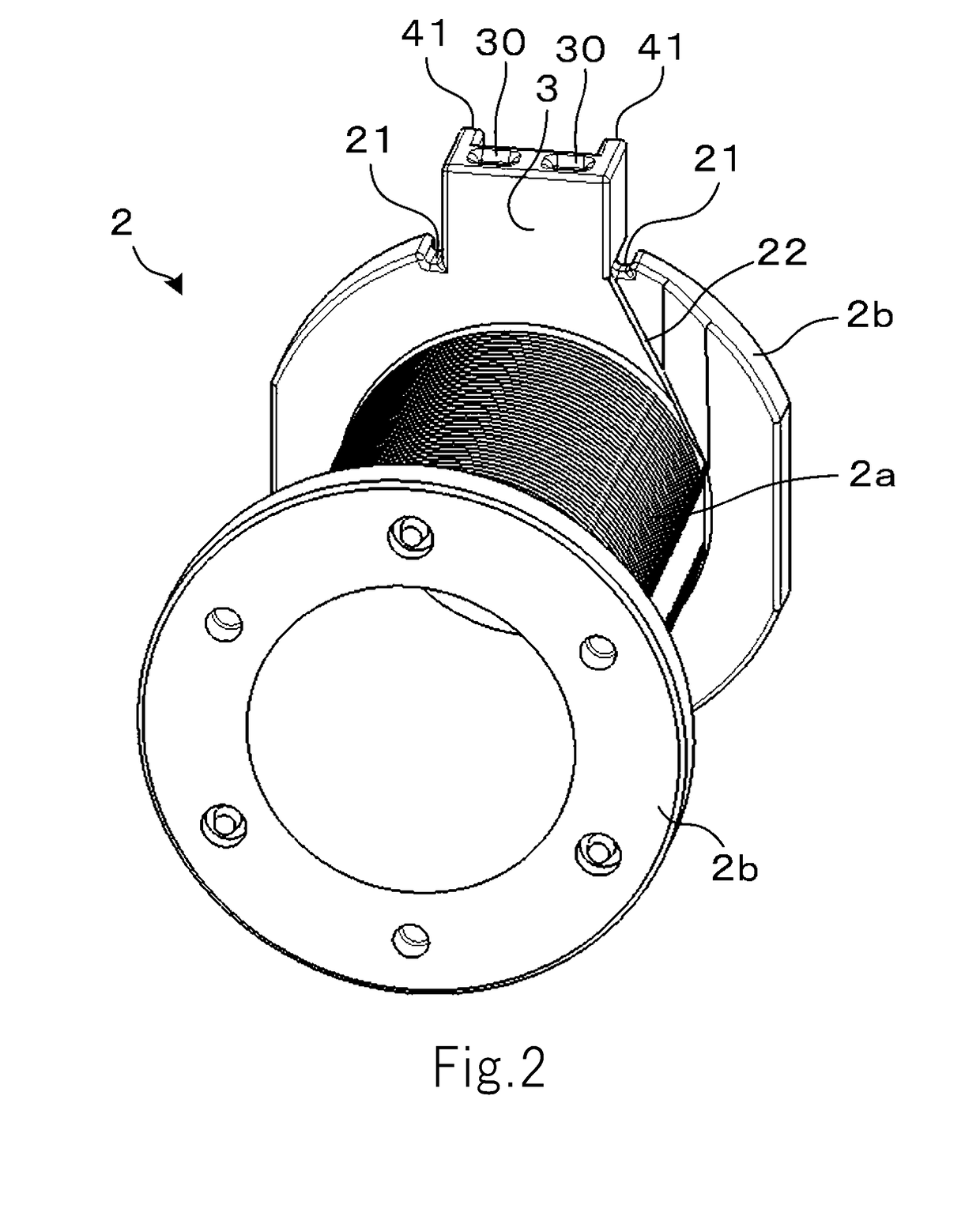

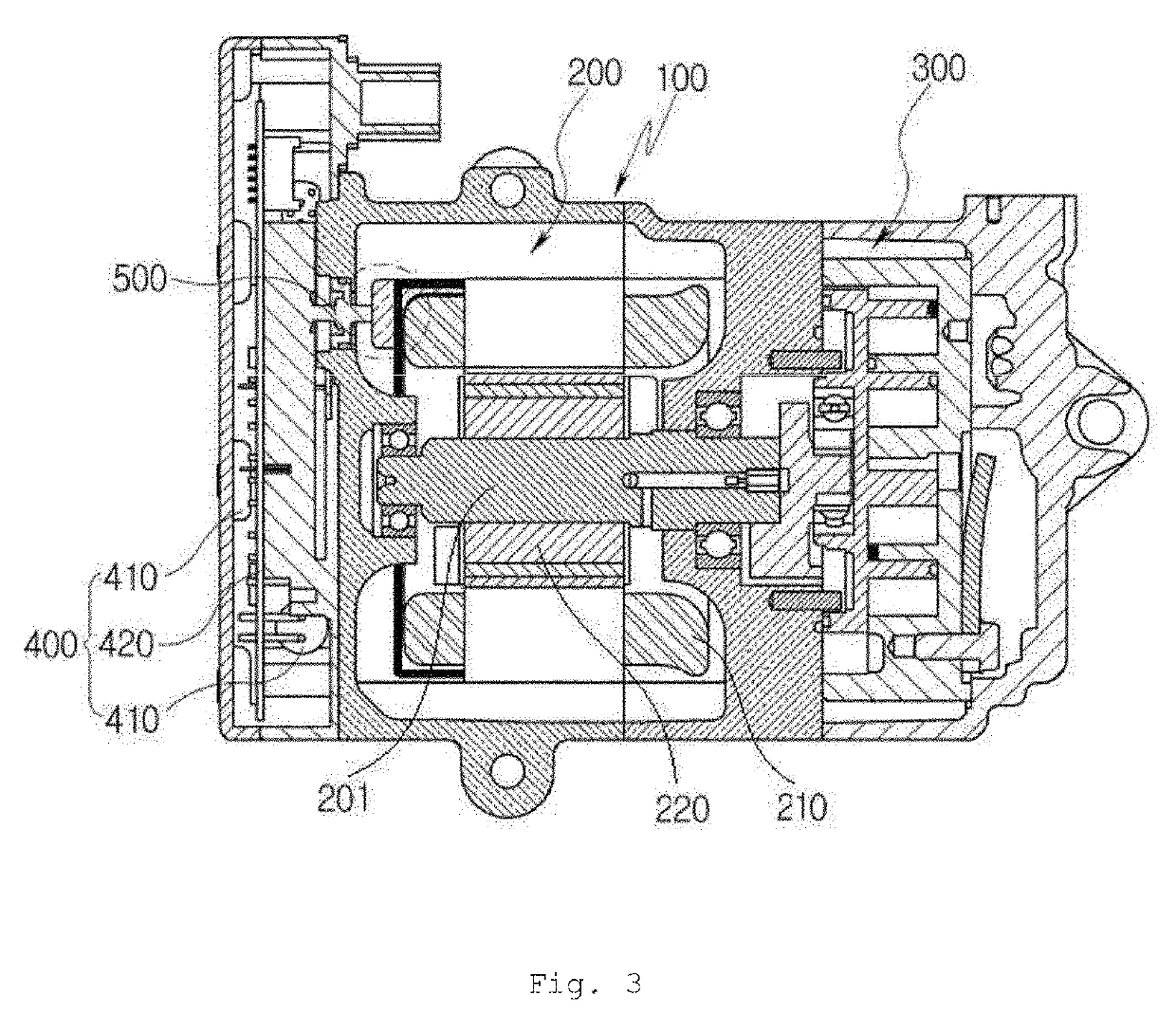

Electrical motor and fluid pump using the same

ActiveUS20050151440A1Reduced assembly stepsReduce in quantityRotary current collectorMagnetic circuit rotating partsEngineeringStructural element

An electrical motor includes a commutator attached to one side of an armature in an axial direction, and a cover structure member attached to the other side of the armature. The cover structure member includes a cover and plural terminals protruding from an outer peripheral portion of the cover toward the armature. In the electrical motor, by attaching the cover structure member to the armature, the other side of the armature in the axial direction is covered by the cover, and the terminals of the cover structure member are fitted to terminals of coils of the armature. Generally, the cover structure member is made of metal. Therefore, the cover structure member is attached to the armature to have a clearance between a through hole portion of the cover and a shaft, so that the cover is electrically insulated from the shaft.

Owner:AISAN IND CO LTD

Electrical motor and fluid pump using the same

ActiveUS7265466B2Reduced assembly stepsReduce in quantityRotary current collectorMagnetic circuit rotating partsStructural elementElectrical force

An electrical motor includes a commutator attached to one side of an armature in an axial direction, and a cover structure member attached to the other side of the armature. The cover structure member includes a cover and plural terminals protruding from an outer peripheral portion of the cover toward the armature. In the electrical motor, by attaching the cover structure member to the armature, the other side of the armature in the axial direction is covered by the cover, and the terminals of the cover structure member are fitted to terminals of coils of the armature. Generally, the cover structure member is made of metal. Therefore, the cover structure member is attached to the armature to have a clearance between a through hole portion of the cover and a shaft, so that the cover is electrically insulated from the shaft.

Owner:AISAN IND CO LTD

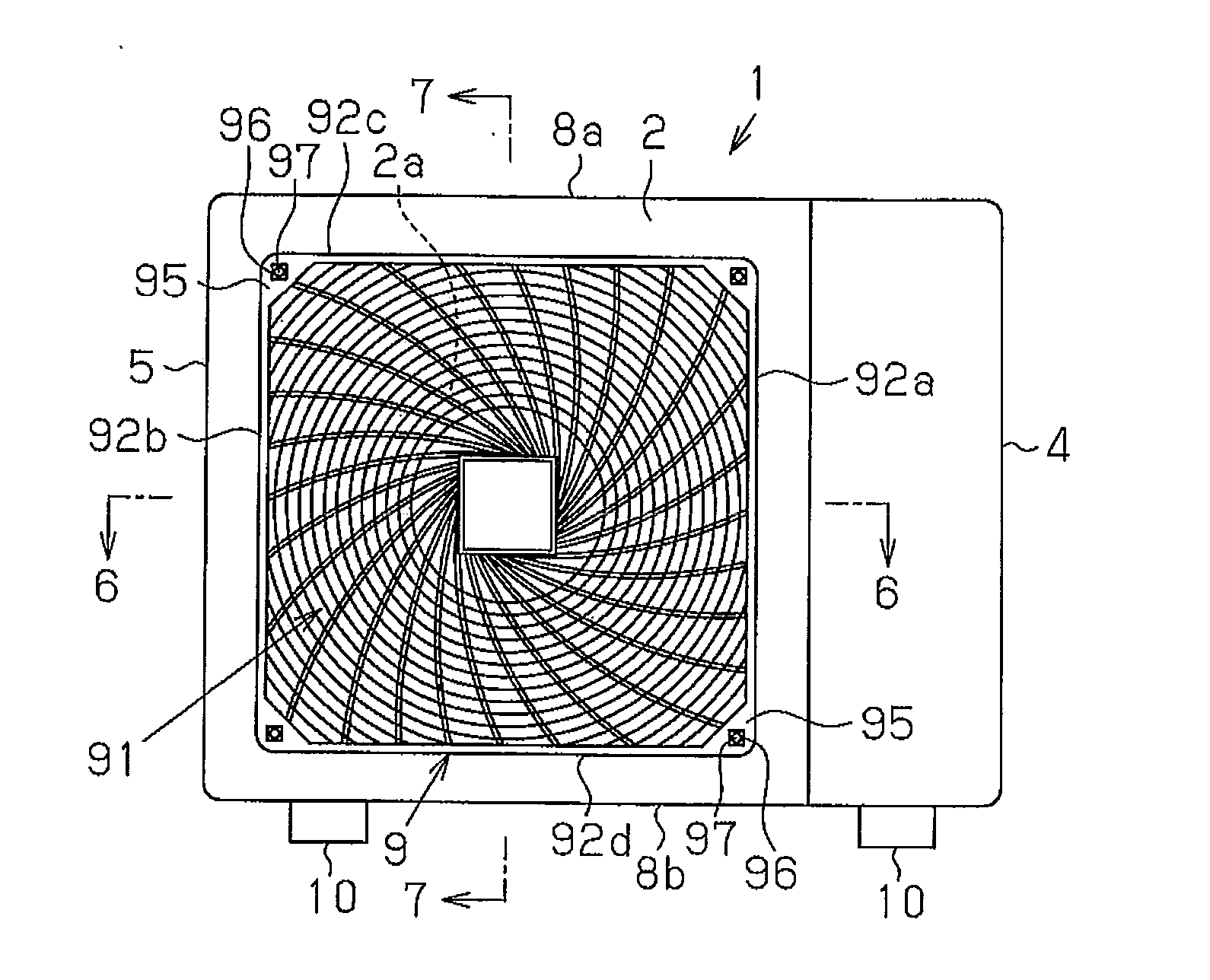

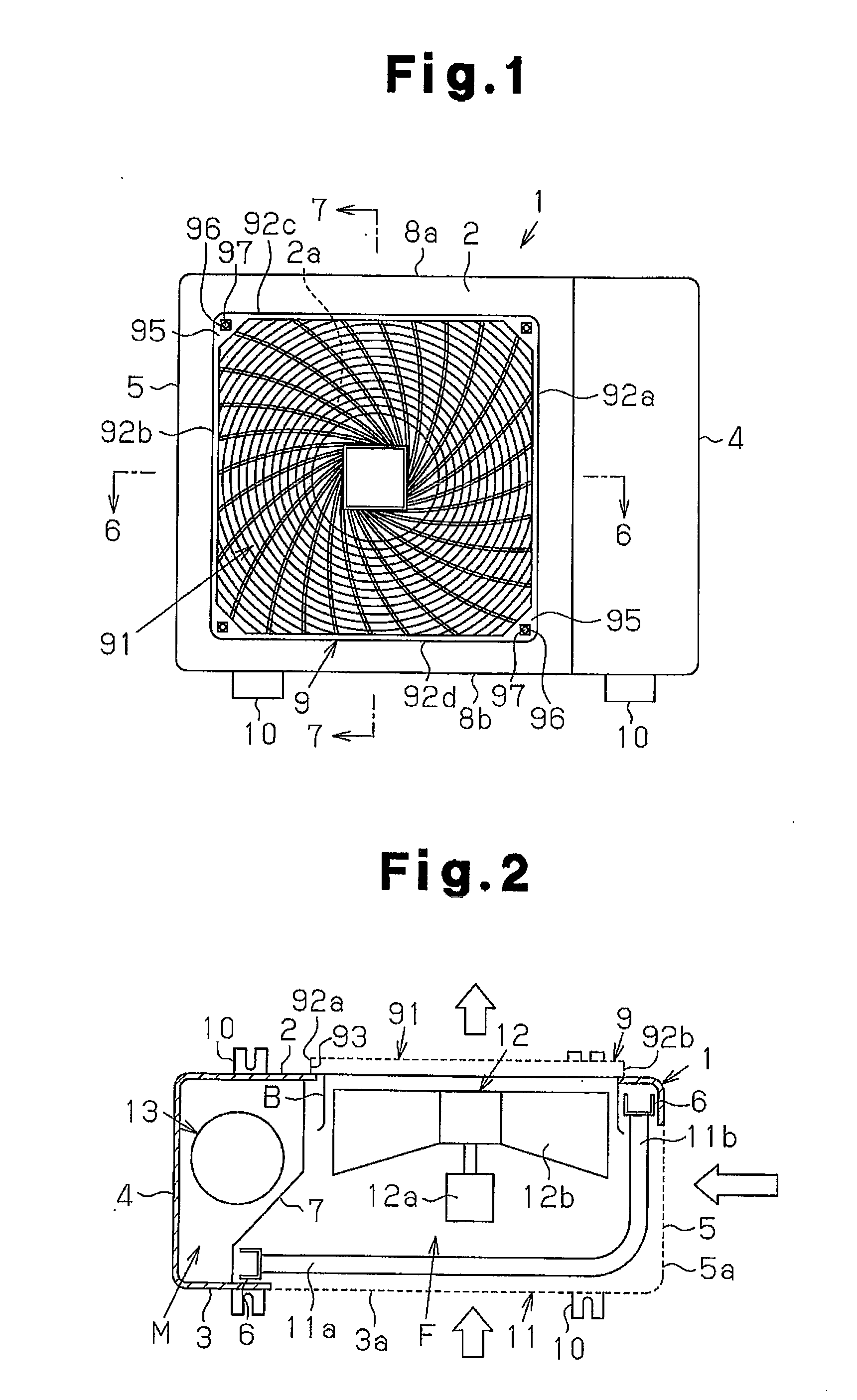

Air delivery unit

InactiveUS20110000653A1Reduce the air speedReduce the amount requiredSemiconductor/solid-state device detailsSolid-state devicesEngineering

An air delivery unit includes a casing, an air delivery device arranged in a fan passage in the casing, and a fan guard that is arranged at an air outlet of the casing and has an air blowing surface having a grill structure and a hollow frame wall portion. An air blowing opening is formed in the frame wall portion of the fan guard. This structure allows the air to be blown also from the opening of the frame wall portion of the fan guard. This reduces the amount and the speed of the air blown from the air blowing surface of the fan guard having the grill structure. As a result, rise of static pressure of the air delivery device is suppressed and noise caused by interference between bars of an air blowing grill and the air is reduced.

Owner:DAIKIN IND LTD

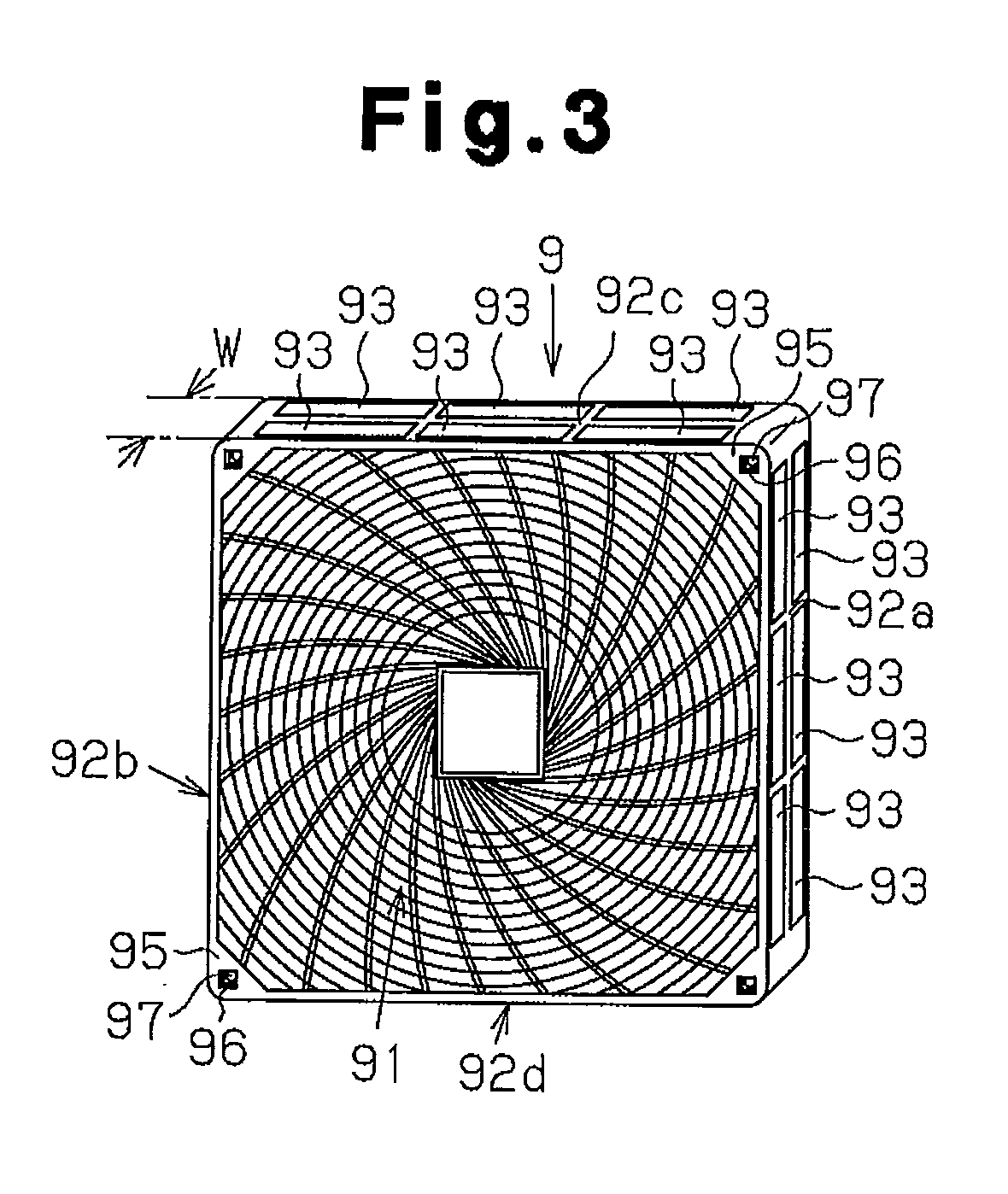

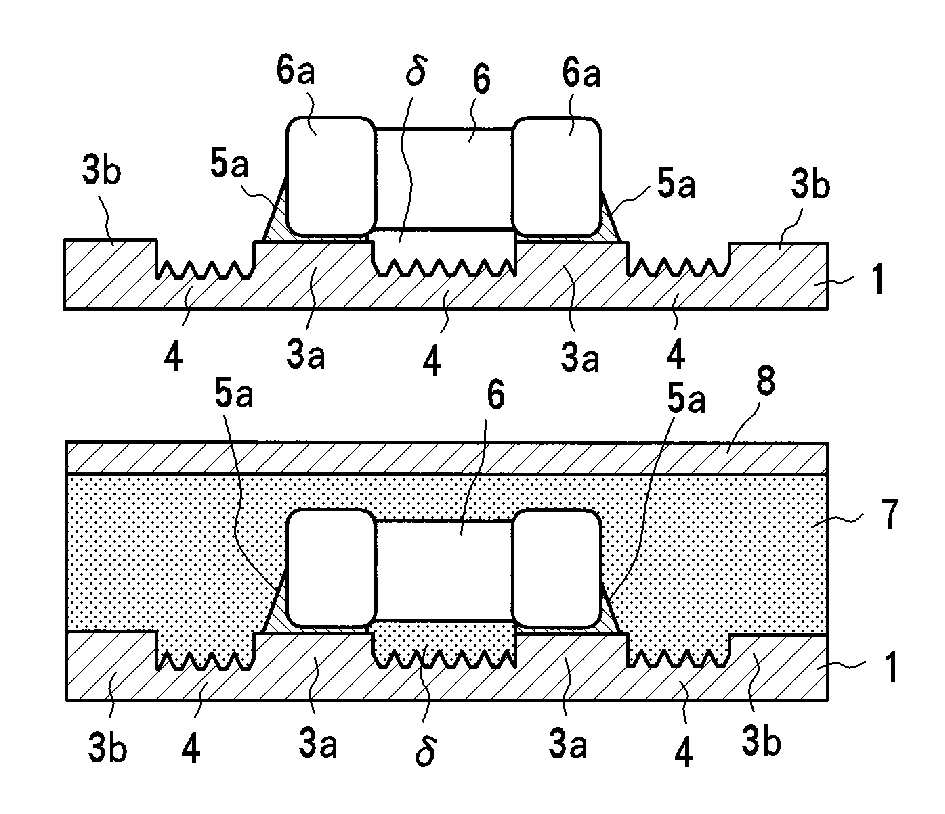

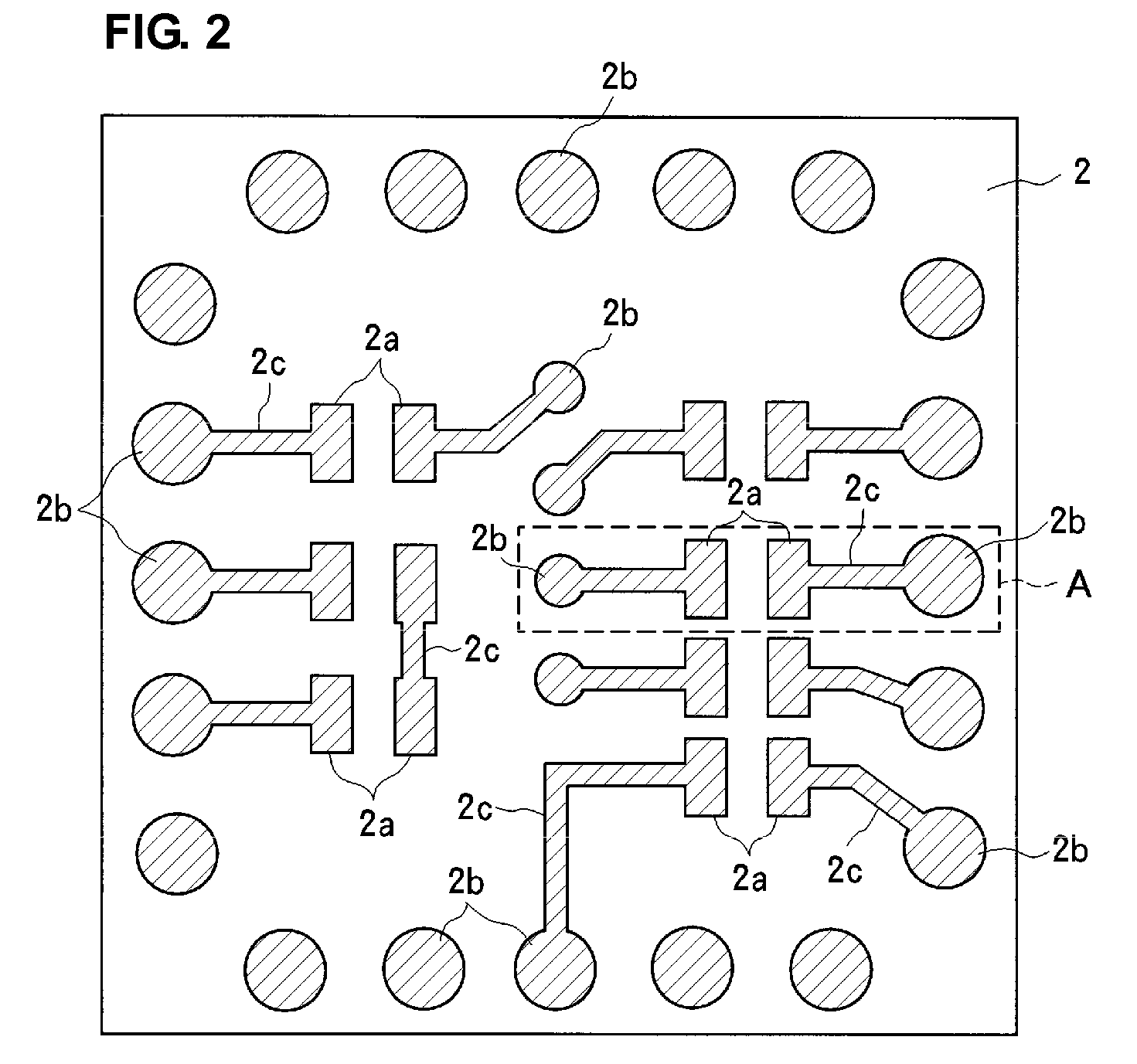

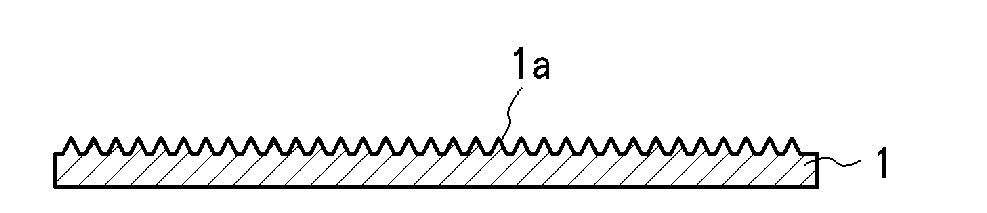

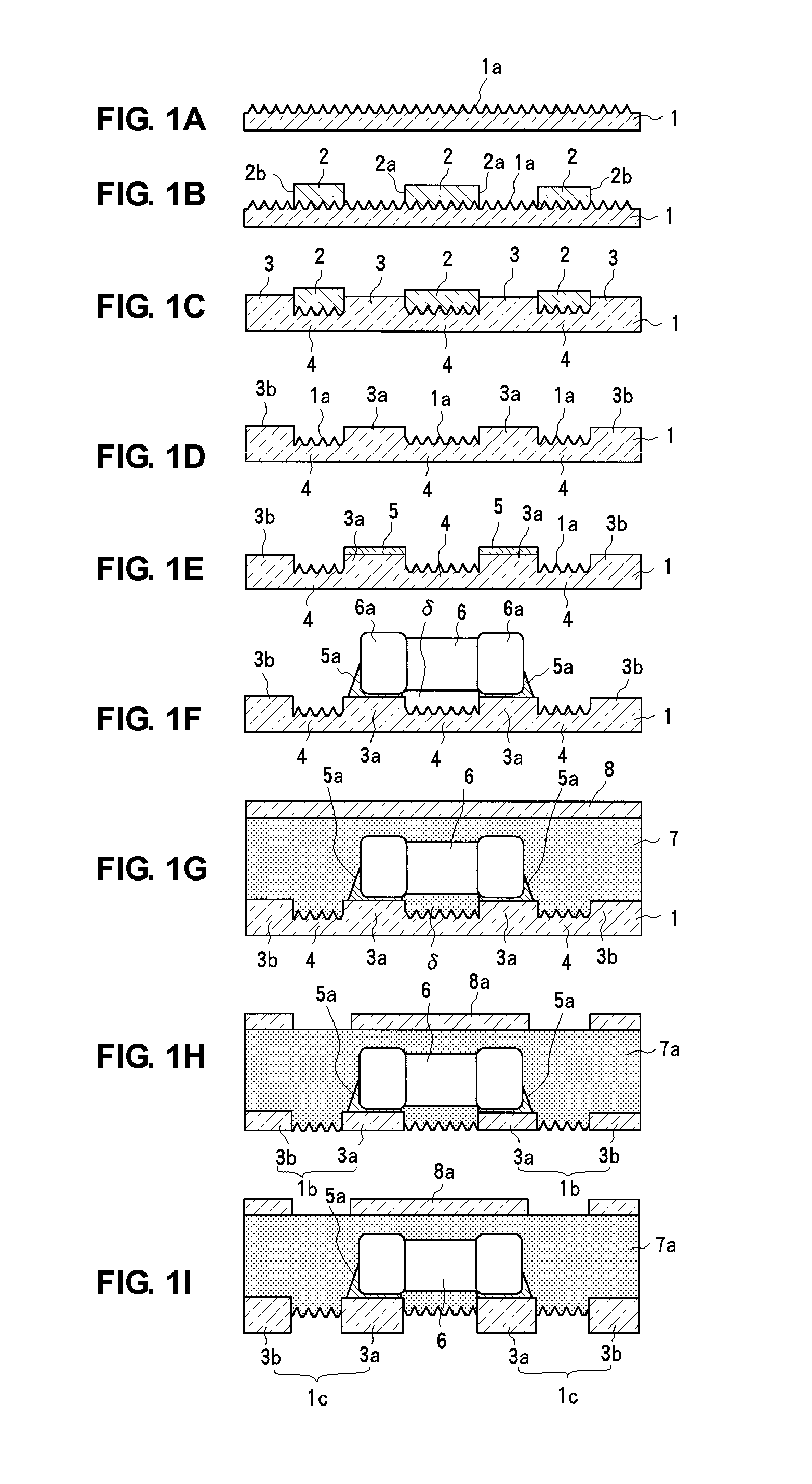

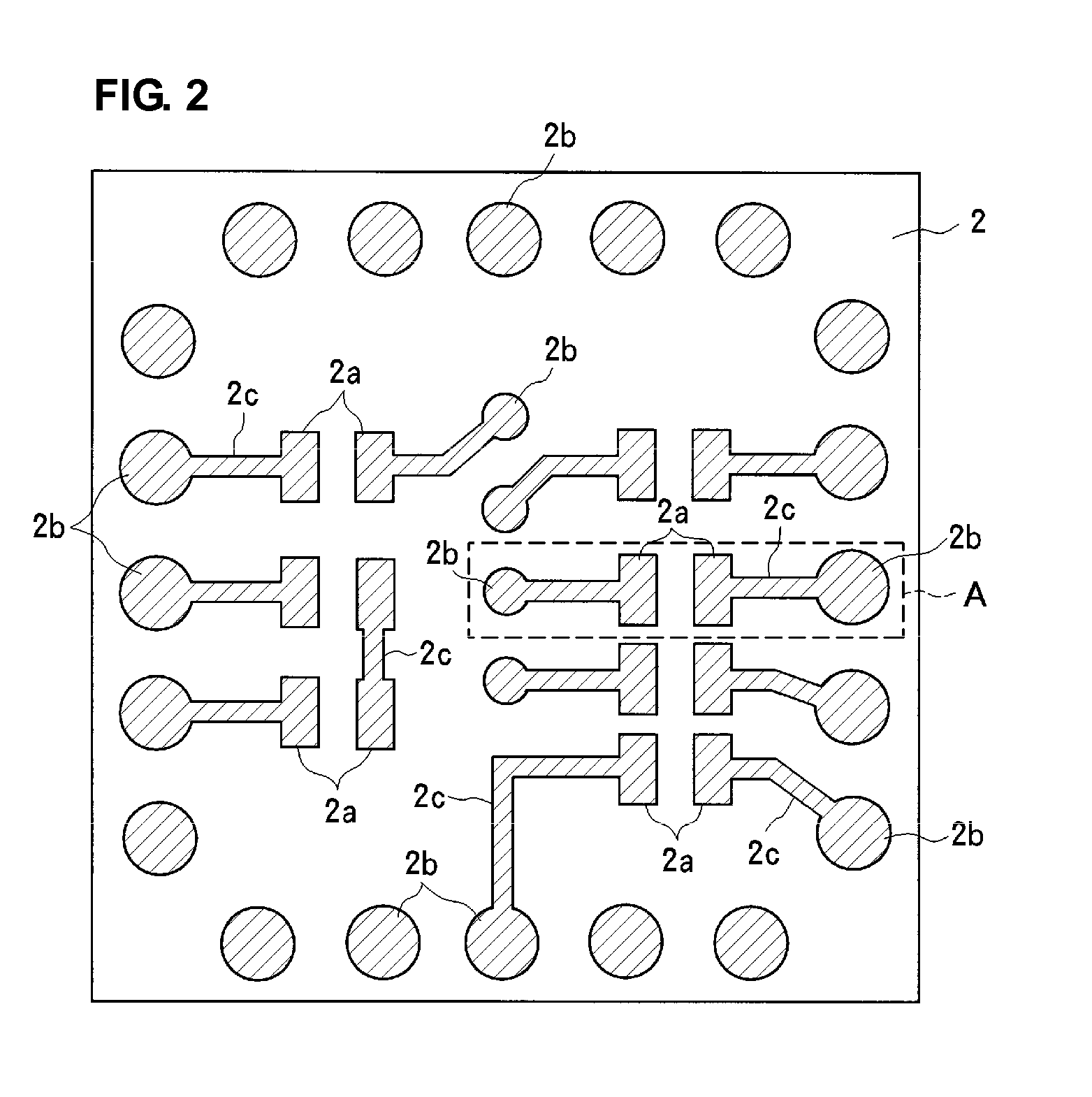

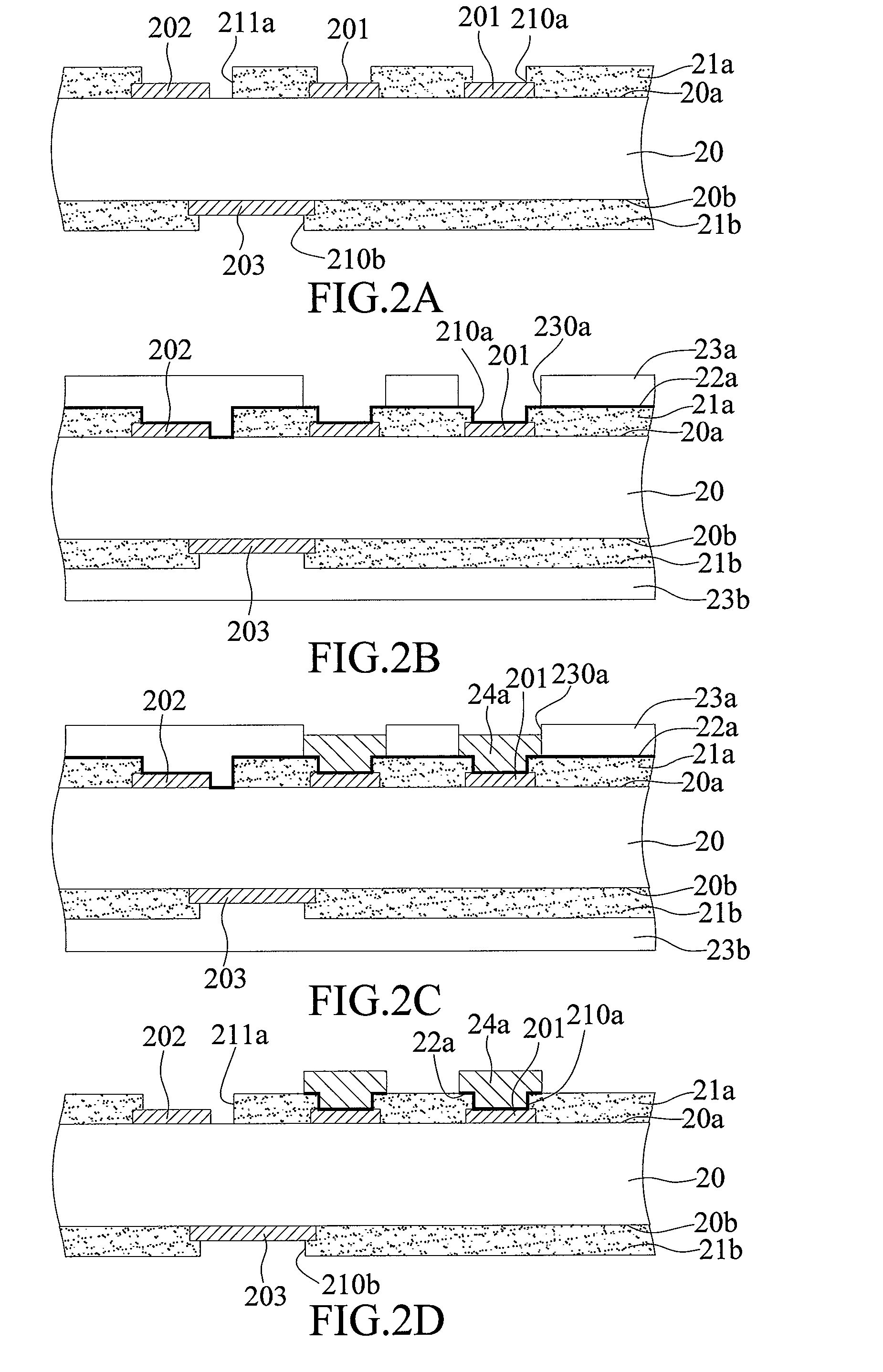

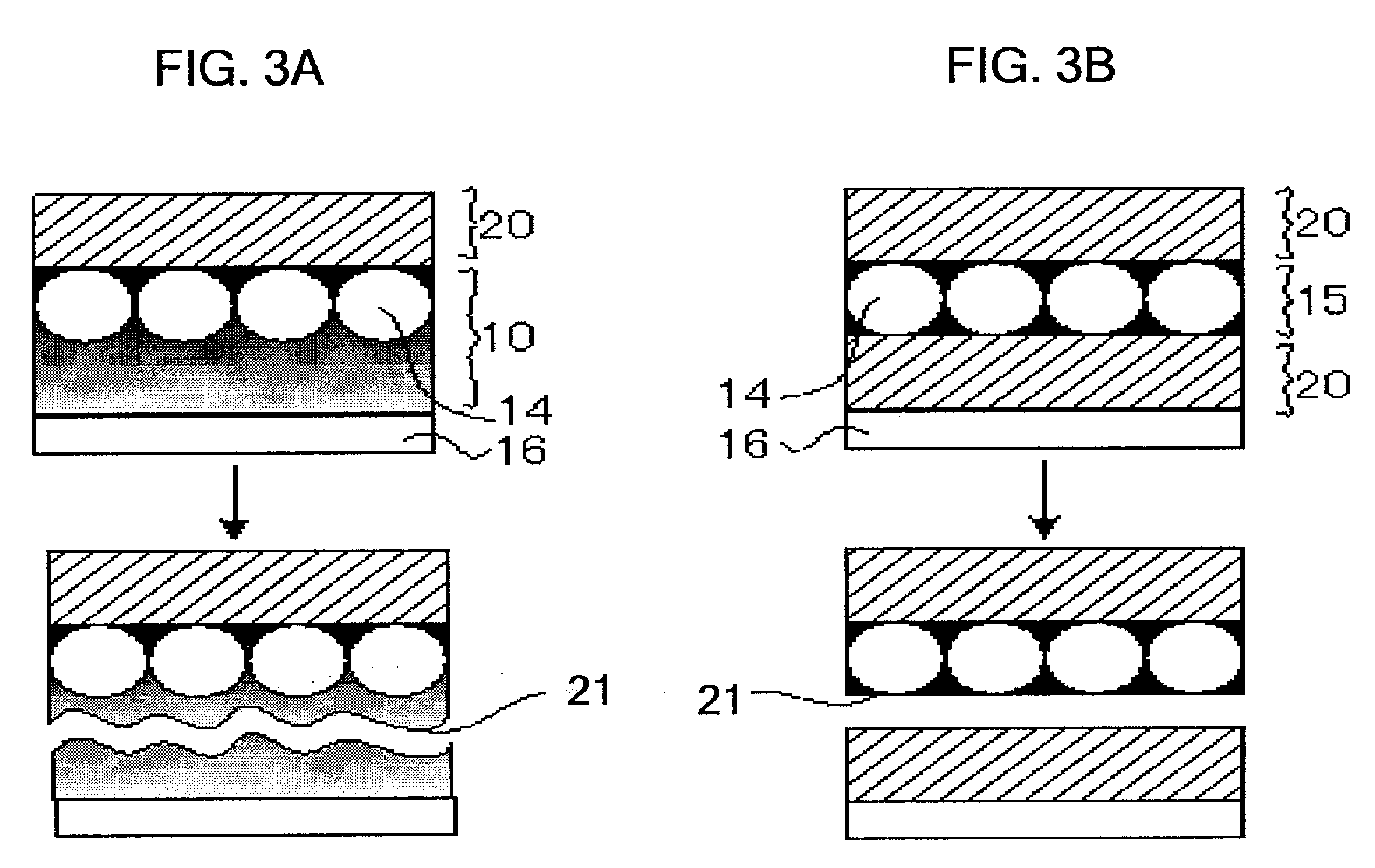

Method for manufacturing substrate having built-in components

ActiveUS8069558B2Prevent a short circuitControl spreadPrinted circuit assemblingLine/current collector detailsAdhesiveMetal foil

A method for manufacturing a substrate having built-in components prevents a short circuit caused by the spread of solder or conductive adhesive. Land regions to connect a circuit component and a wetting prevention region surrounding the land regions are formed on one primary surface of a metal foil. Terminal electrodes of the circuit component are electrically connected to the land regions using solder, and an uncured resin is disposed on and pressure bonded to the metal foil and the circuit component, so that a resin layer in which the circuit component is embedded is formed. Subsequently, a wiring pattern is formed by processing the metal foil. The wetting prevention region is a region obtained by roughening or oxidizing one primary surface of the metal foil so as to reduce solder wettability.

Owner:MURATA MFG CO LTD

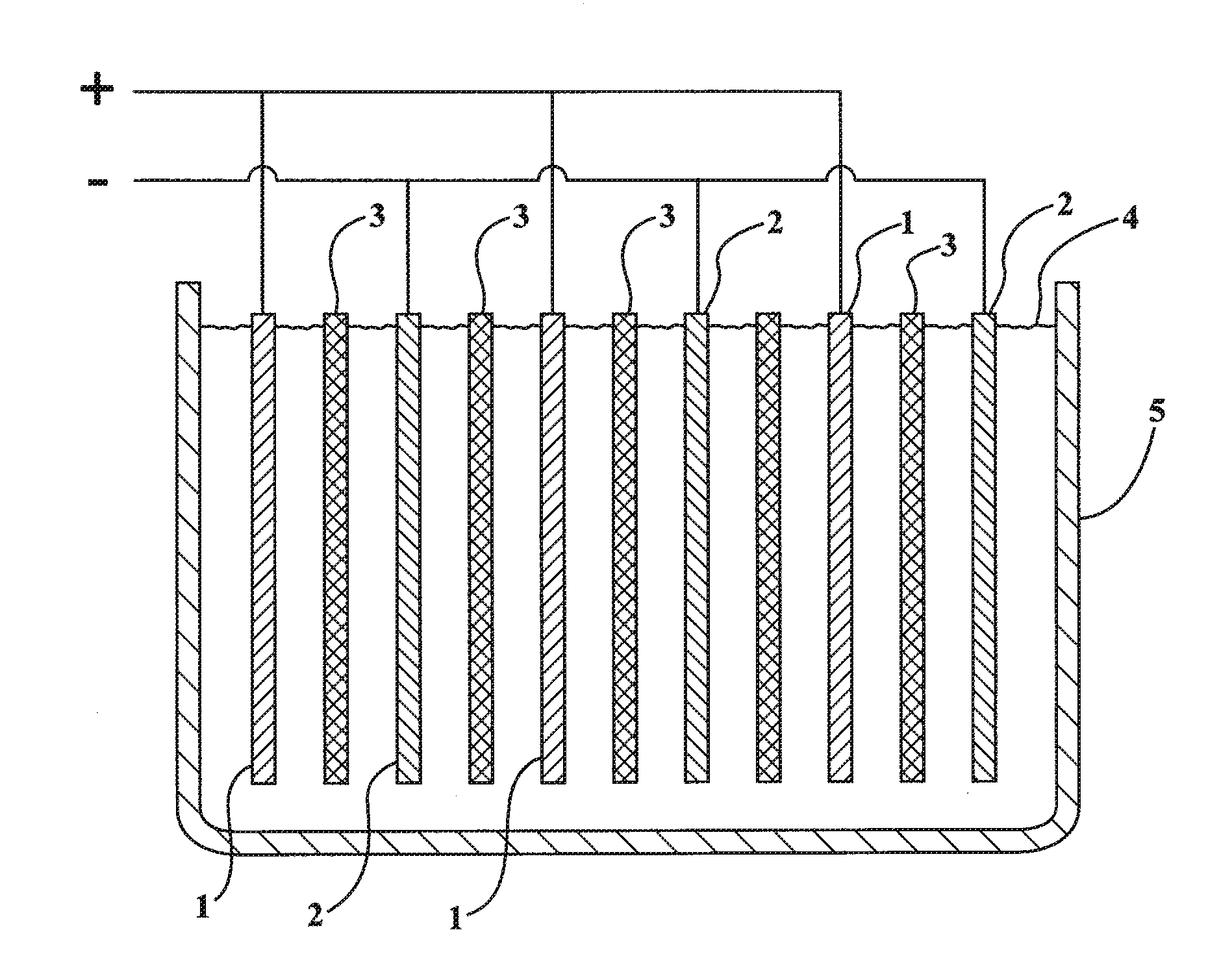

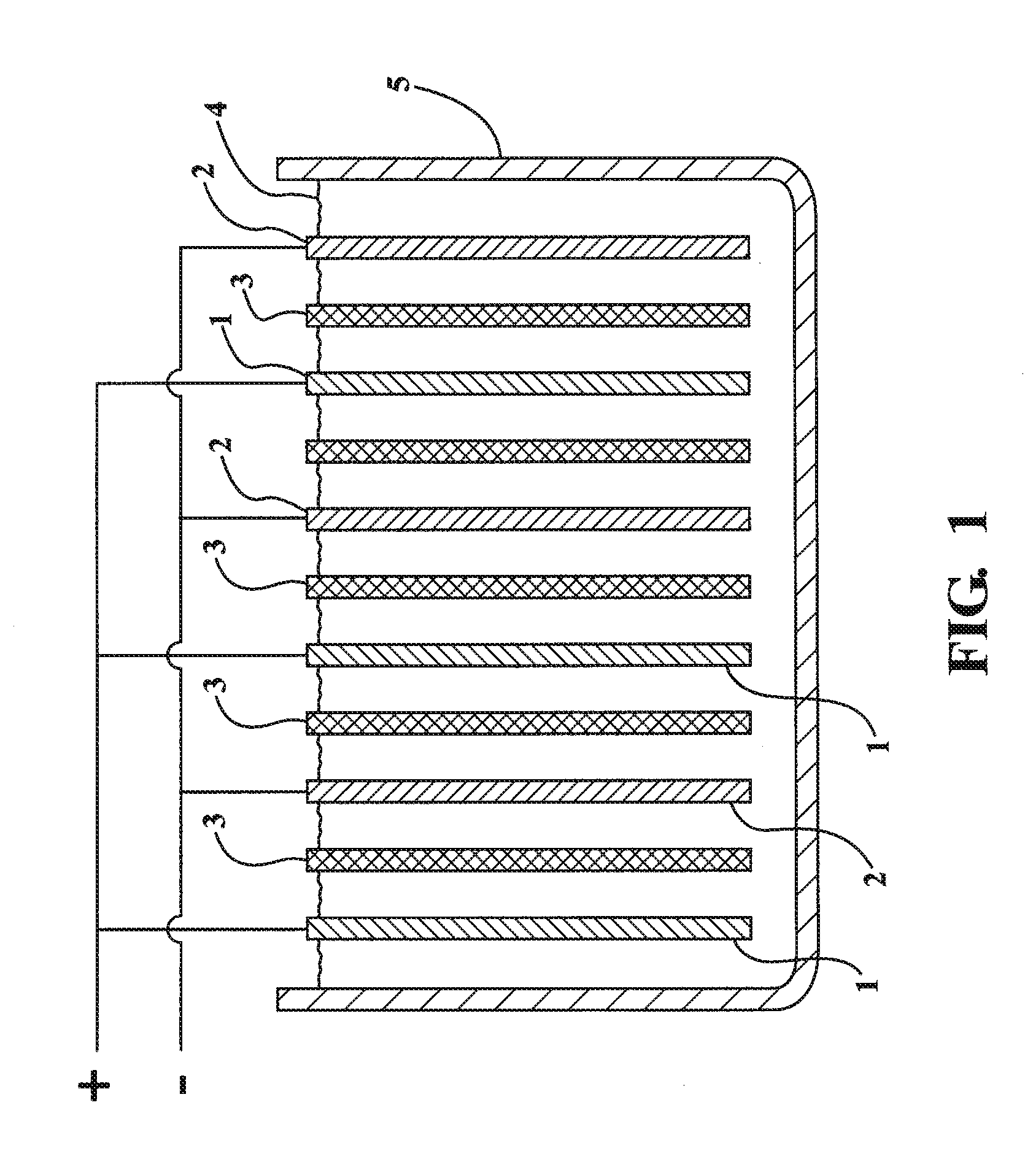

Method for producing silicon

InactiveUS20100059118A1Decrease in silicon concentrationIncreased concentration of siliconCellsSiliconElectrolysisMolten salt

Disclosed is a novel method for producing high-purity silicon at low cost. Particularly disclosed is a novel method for producing high-purity silicon, which can be suitably used as a raw material for solar cells, at low cost. Specifically, a method for producing silicon wherein silica is subjected to molten salt electrolysis in an electrolysis vessel comprises, in the following order, a step (1) wherein the silicon content in an silicon-containing alloy, which is in a liquid phase at the electrolysis temperature, is increased by using the alloy as the cathode and performing electrolysis; a step (2) wherein the silicon-containing alloy serving as the cathode is taken out of the electrolysis vessel before it reaches the concentration at which silicon begins to precipitate at the electrolysis temperature; a step (3) wherein silicon is solidified by cooling the taken-out silicon-containing alloy within the temperature range higher than the eutectic point but lower than the electrolysis temperature; and a step (4) wherein the solidified silicon is collected.

Owner:SUMITOMO CHEM CO LTD +1

Method for manufacturing substrate having built-in components

ActiveUS20100083495A1Improve reliabilityPrevent a short circuitPrinted circuit assemblingLine/current collector detailsAdhesiveMetal foil

A method for manufacturing a substrate having built-in components prevents a short circuit caused by the spread of solder or conductive adhesive. Land regions to connect a circuit component and a wetting prevention region surrounding the land regions are formed on one primary surface of a metal foil. Terminal electrodes of the circuit component are electrically connected to the land regions using solder, and an uncured resin is disposed on and pressure bonded to the metal foil and the circuit component, so that a resin layer in which the circuit component is embedded is formed. Subsequently, a wiring pattern is formed by processing the metal foil. The wetting prevention region is a region obtained by roughening or oxidizing one primary surface of the metal foil so as to reduce solder wettability.

Owner:MURATA MFG CO LTD

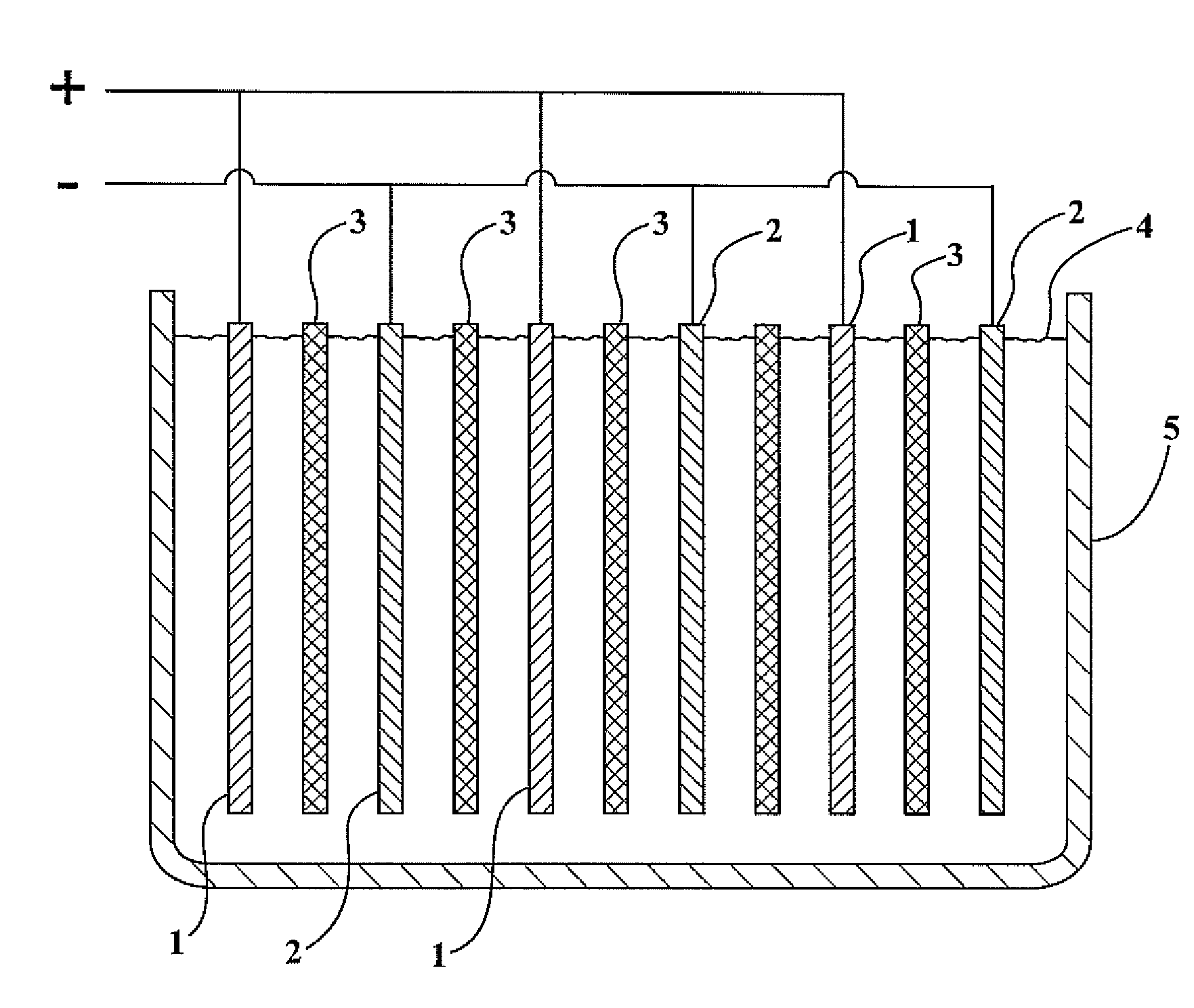

Lead-zinc battery

InactiveUS20130045415A1Maximize electrode surface areaImproved electrical conductivityAlkaline accumulatorsLead-acid accumulatorsAqueous solutionOxide

A rechargeable battery is provided such that the positive electrode comprises lead, the negative electrode zinc, and the electrolyte is an aqueous solution of an alkali metal bisulfate. Upon discharge, lead dioxide is reduced to lead sulfate and zinc is oxidized to zinc oxide. The reactions are reversed when the battery is charged.

Owner:STAUFFER JOHN E

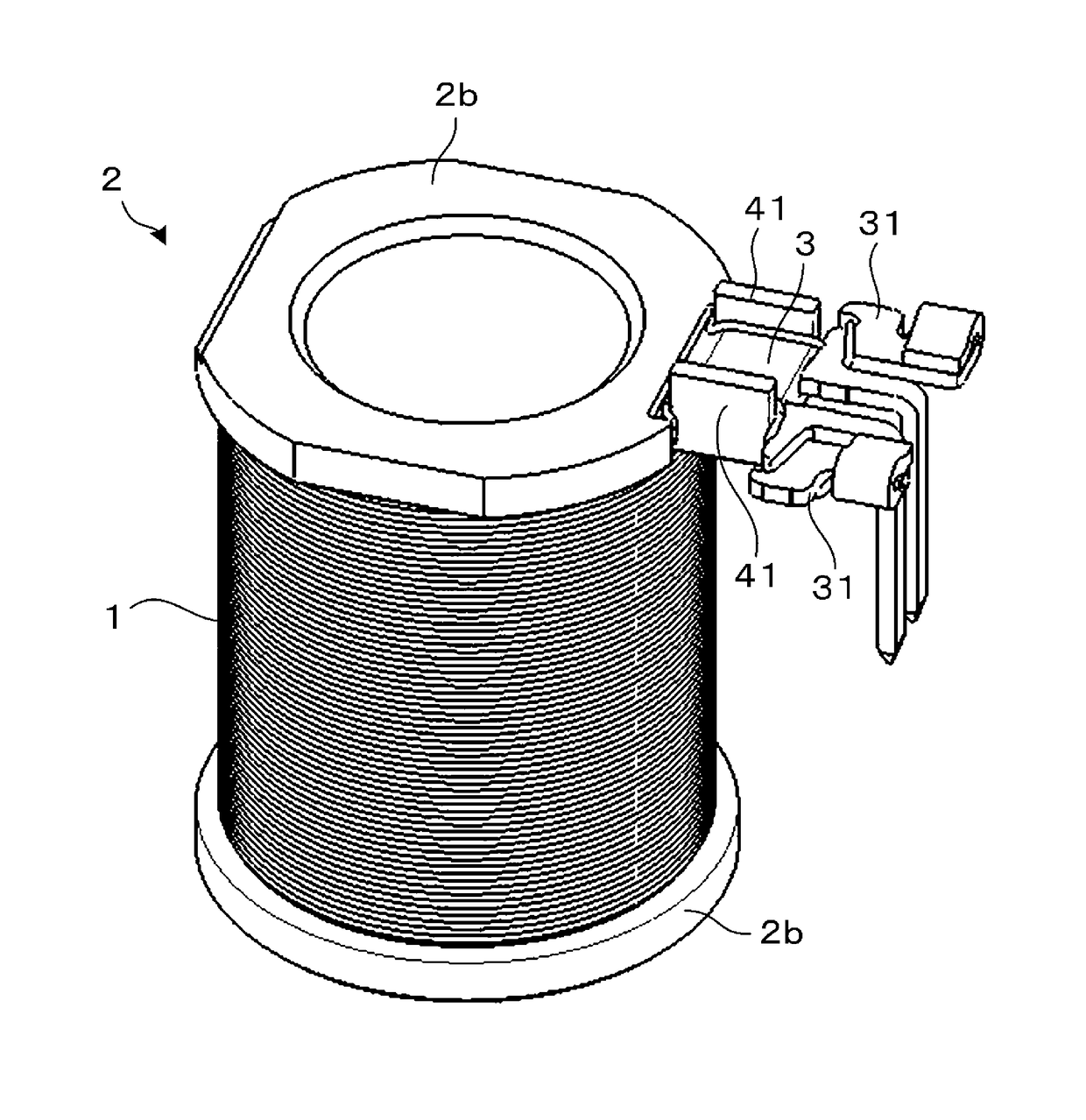

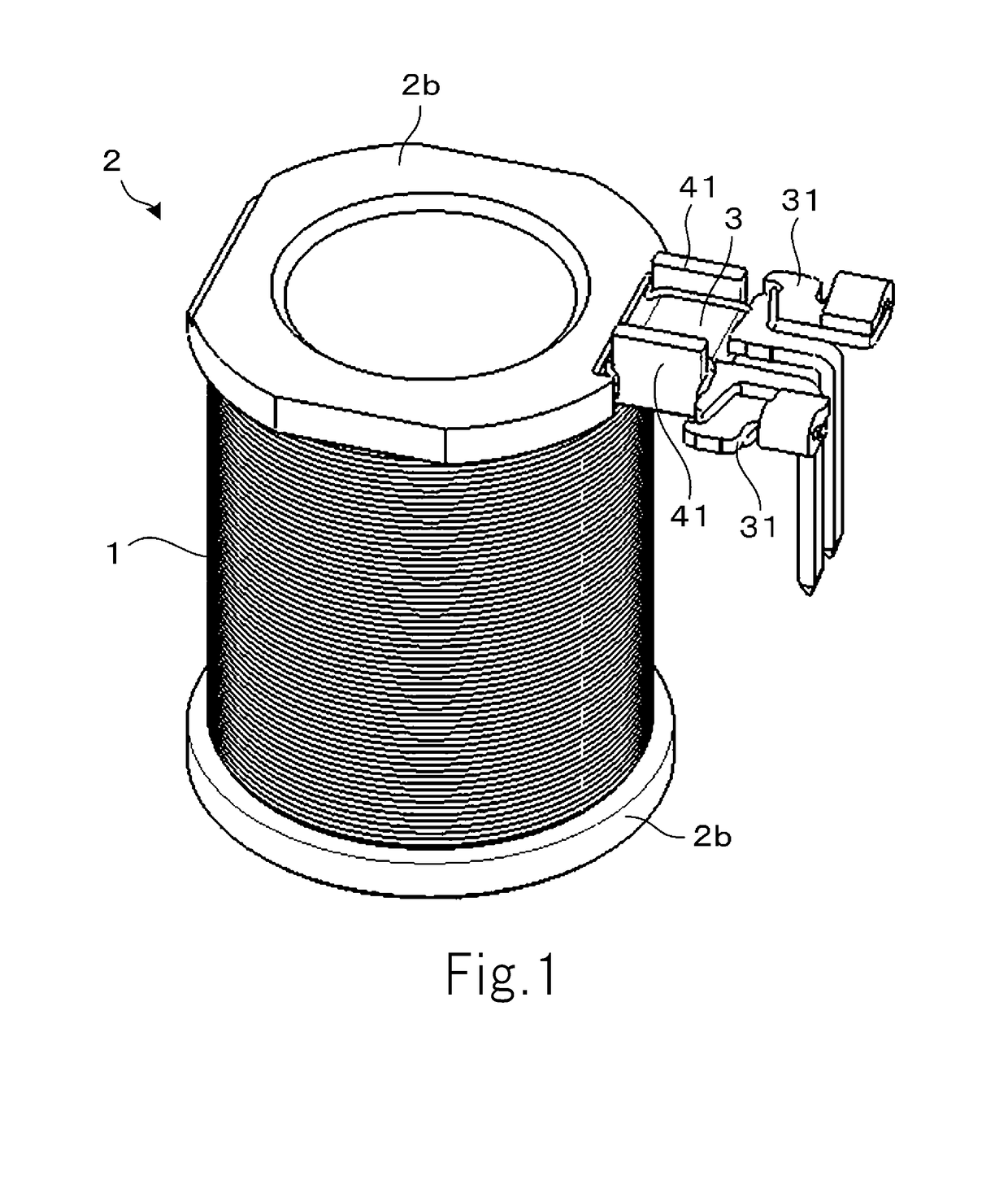

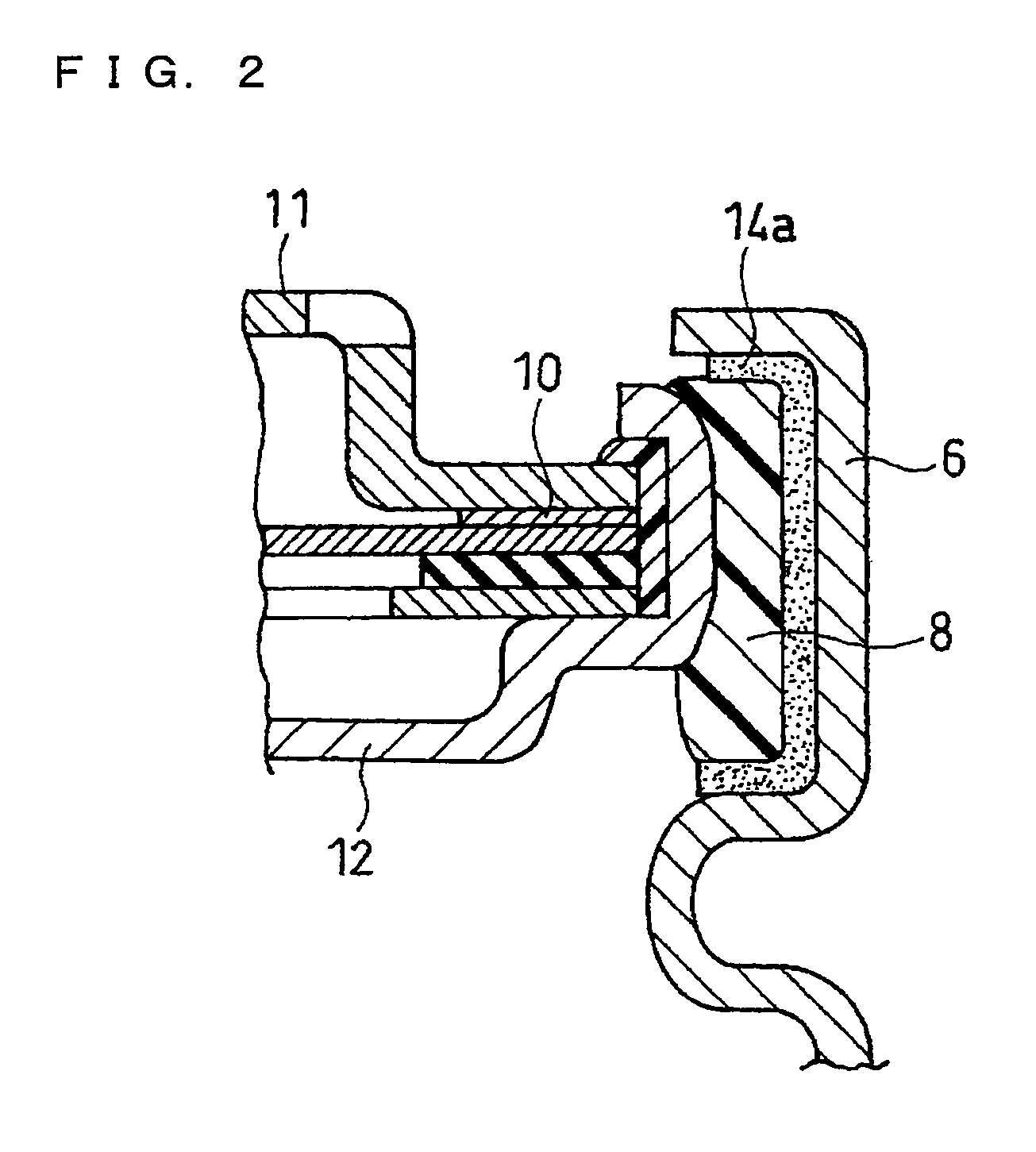

Solenoid of electromagnetic valve

ActiveUS9746097B1Prevent a short circuitElectromagnets without armaturesOperating means/releasing devices for valvesBobbinEngineering

The present disclosure relates to a solenoid of an electromagnetic valve where the number of processes can be reduced and breaking of a conductive wire can be suppressed in a simple structure, and the solenoid of the electromagnetic valve according to the present disclosure comprises a conductive wire; a bobbin having a tubular winding portion where the conductive wire is wound around in a coil shape and a flange portion disposed on both end portions of the winding portion; a terminal portion which is disposed on the flange portion and protrudes in a planar shape in a direction perpendicular to the central axis of the bobbin on a radially outer side than the winding portion relative to the central axis, and in which two terminals are provided on a distal end portion side; and two wall portions which are disposed on both sides of the terminal portion in a width direction, stand upright in a central axis direction and face each other, wherein both end portions of the conductive wire are drawn out from the bobbin to the terminal portion, directed toward a radially outer side from a winding portion side of the two wall portions and electrically connected to the terminals.

Owner:NIDEC TOSOK CORP

Packaging substrate and method for fabricating the same

ActiveUS7812460B2Meet the requirementsReliable electrical connectionSemiconductor/solid-state device detailsPrinted circuit aspectsSolder maskMetallurgy

A packaging substrate and a method for fabricating the same are proposed, including: providing a substrate body having a first surface and an opposing second surface, wherein the first surface has a plurality of flip-chip solder pads and wire bonding pads and the second surface has a plurality of solder ball pads; forming a first and a second solder mask layers on the first and second surfaces respectively and forming openings in the first and second solder mask layers to expose the flip-chip solder pads, the wire bonding pads and the solder ball pads; forming first bumps on the flip-chip solder pads; and forming an electroless Ni / Pd / Au layer on the first bumps and the wire bonding pads by electroless plating, wherein the electroless Ni / Pd / Au layer has a thickness tolerance capable of meeting evenness requirements for fine pitch applications.

Owner:UNIMICRON TECH CORP

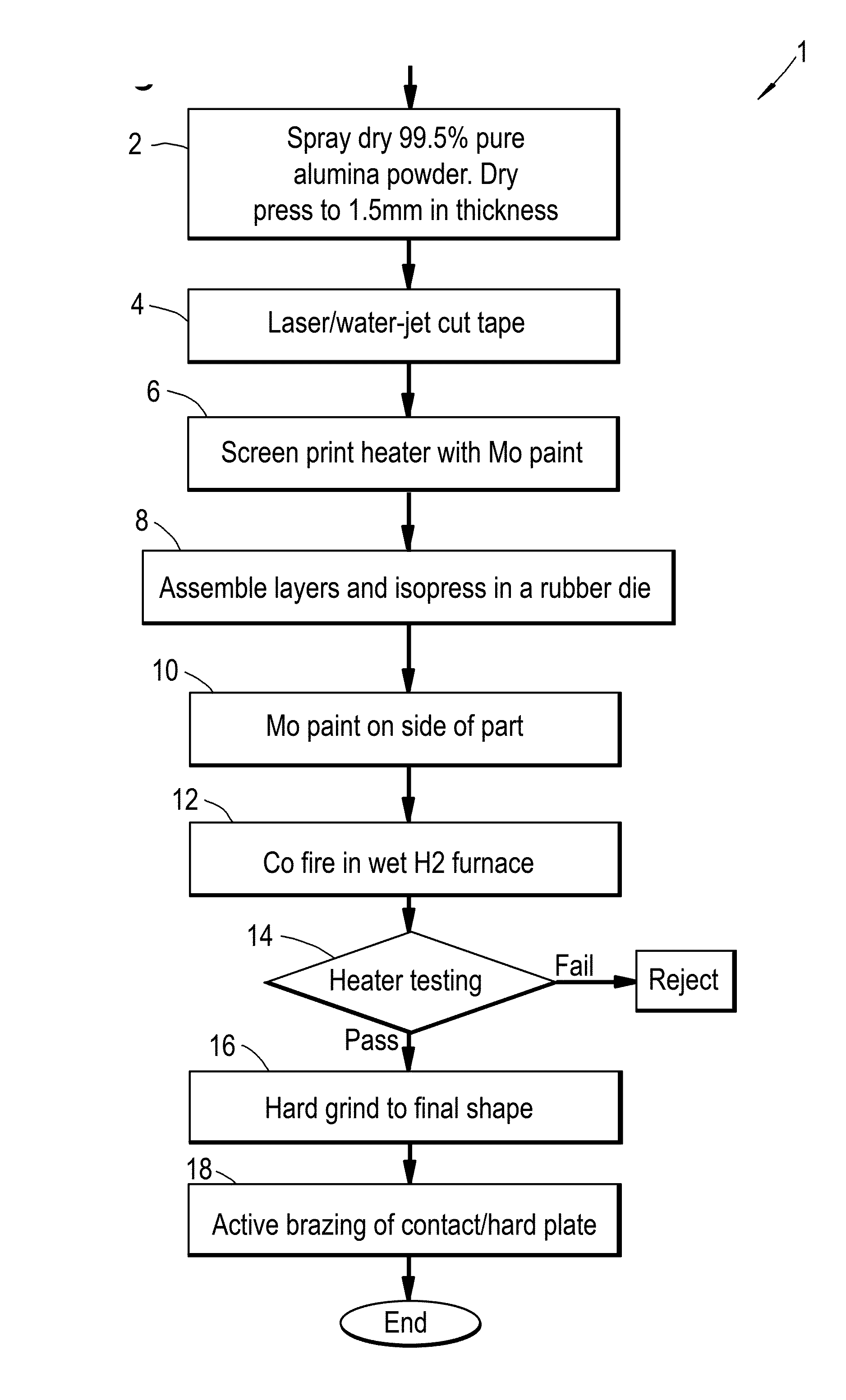

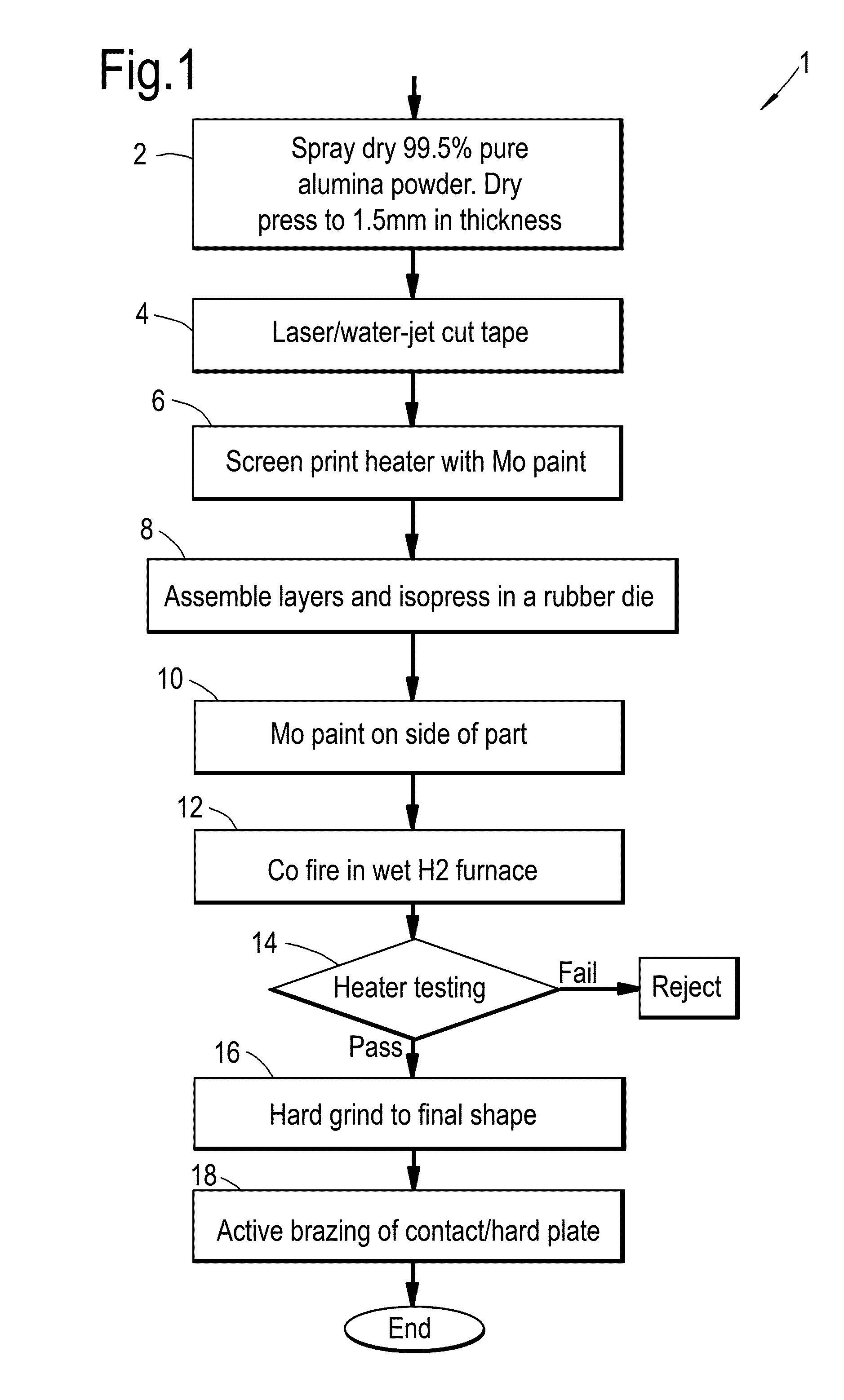

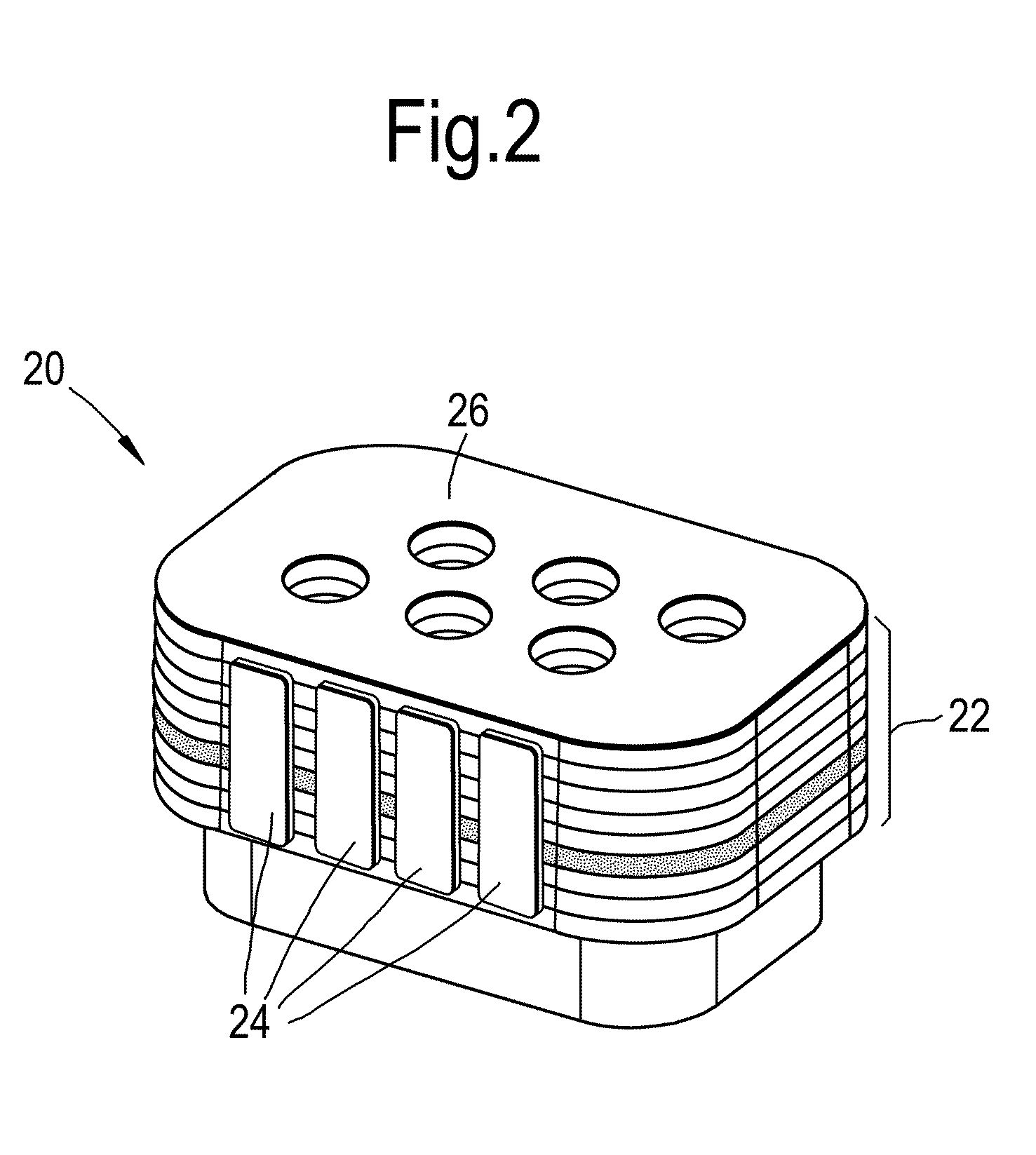

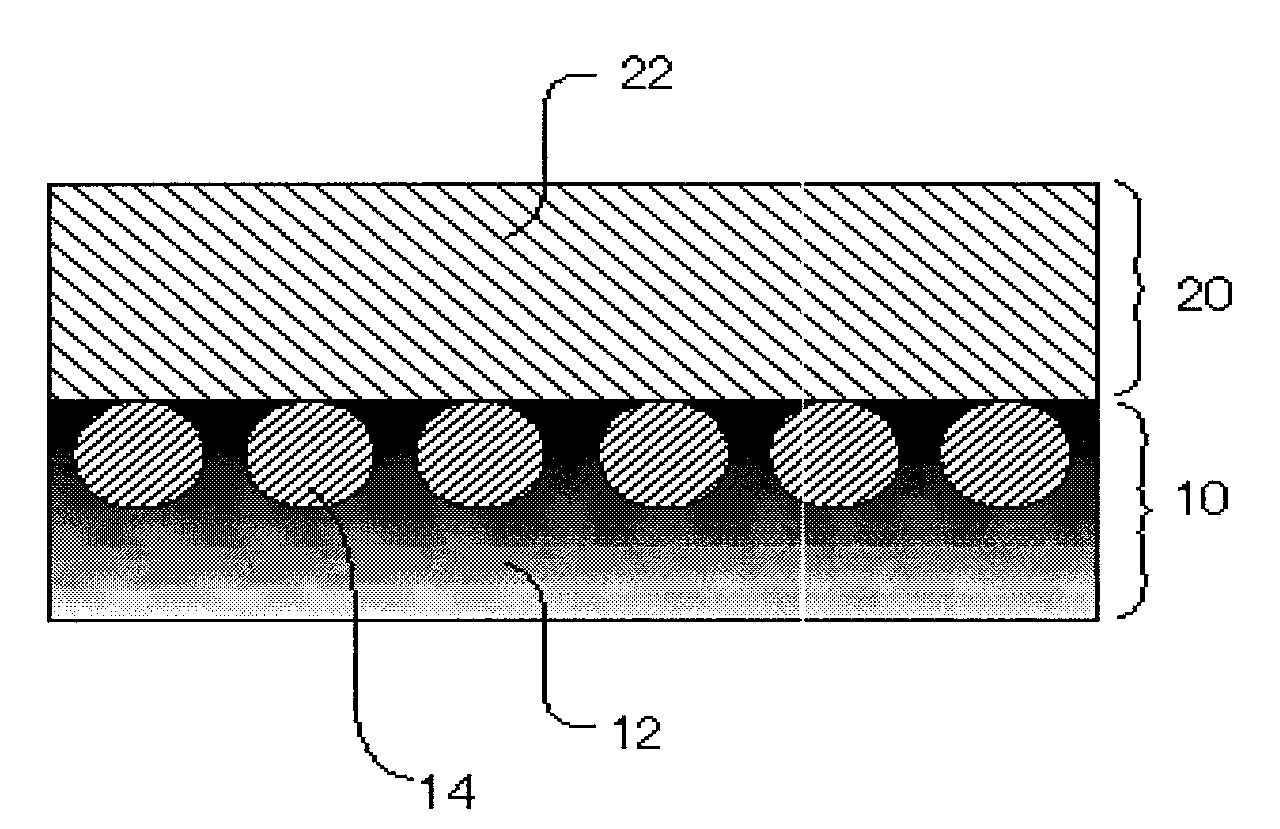

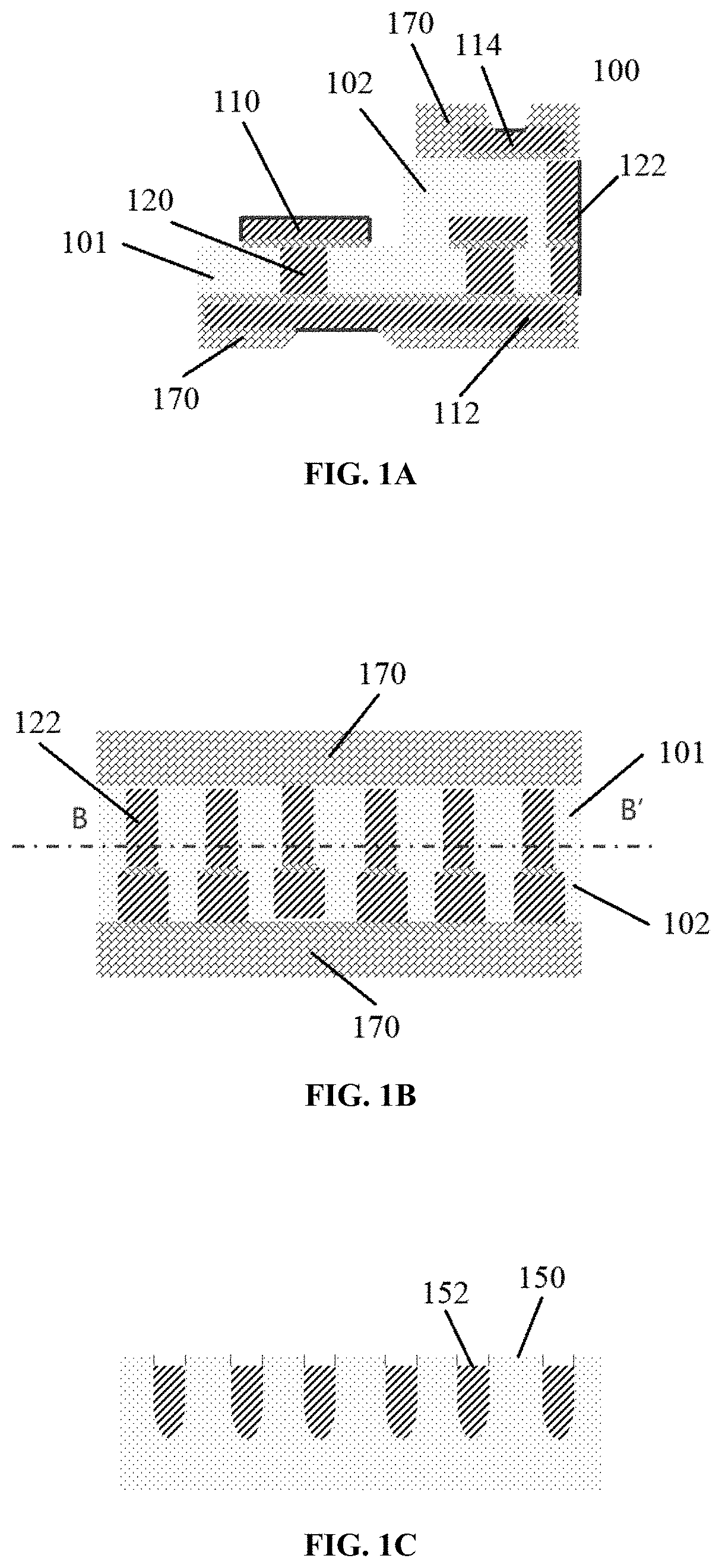

Method for manufacturing large ceramic co-fired articles

InactiveUS20170057880A1High degreeShrink evenlySemiconductor/solid-state device manufacturingCeramic layered productsElectrical conductorMetallurgy

A method of forming one or more high temperature co-fired ceramic articles, comprising the steps of: —a) forming (34) a plurality of green compacts, by a process comprising dry pressing a powder comprising ceramic and organic binder to form a green compact; b) disposing (38) a conductor or conductor precursor to at least one surface of at least one of the plurality of green compacts to form at least one patterned green compact; c) assembling the at least one patterned green compact with one or more of the plurality of green compacts or patterned green compacts or both to form a laminated assembly; d) isostatically (40) pressing the laminated assembly to form a pressed laminated assembly; e) firing (42) the pressed laminated assembly at a temperature sufficient to sinter the ceramic layers together.

Owner:MORGAN ADVANCED CERAMICS

Anisotropic conductive film, method for producing the same, and bonded structure

ActiveUS7931956B2Raise the ratioFacilitate conductionNon-insulated conductorsLine/current collector detailsAnisotropic conductive filmOptoelectronics

Provided is an anisotropic conductive film, containing: an insulating layer formed of an insulating resin composition; and a conductive particle-contained layer containing a photo and thermal curing resin composition and conductive particles, the conductive particles being aligned into a monolayer in a portion adjacent to an interface with the insulating layer, in which the conductive particle-contained layer has a degree of cure which is gradually lowered in a thickness direction of the conductive particle-contained layer, from the side where the conductive particles are present to the side where the conductive particles are not present.

Owner:SONY 50

Lead-zinc battery

InactiveUS20130252083A1Area maximizationImprove conductivityAlkaline accumulatorsLead-acid accumulatorsLead dioxideLead sulfate

A rechargeable battery is provided such that the positive electrode comprises lead, the negative electrode zinc, and the electrolyte is an aqueous solution of an alkali metal bisulfate. Upon discharge, lead dioxide is reduced to lead sulfate, zinc is oxidized to zinc oxide, and the electrolyte is converted to an alkali metal hydroxide. The reactions are reversed when the battery is charged.

Owner:STAUFFER JOHN E

Piezoelectric film and method of producing piezoelectric film

PendingUS20220238787A1Preventing a short circuitPrevent a short circuitPiezoelectric/electrostrictive device material selectionPiezoelectric/electrostrictive devicesThin membranePiezoelectric membrane

An object of the present invention is to provide a piezoelectric film capable of preventing a short circuit caused by electrodes protruding from a piezoelectric layer in the piezoelectric film having electrode layers and protective layers on both surfaces of the piezoelectric layer, and a method of producing the piezoelectric film. The object can be achieved by the piezoelectric film that includes a laminated film including a piezoelectric layer, an electrode layer provided on each of both surfaces of the piezoelectric layer, and a protective layer covering the electrode layer, and an insulating end surface coating layer which covers at least a part of an end surface of the laminated film.

Owner:FUJIFILM CORP

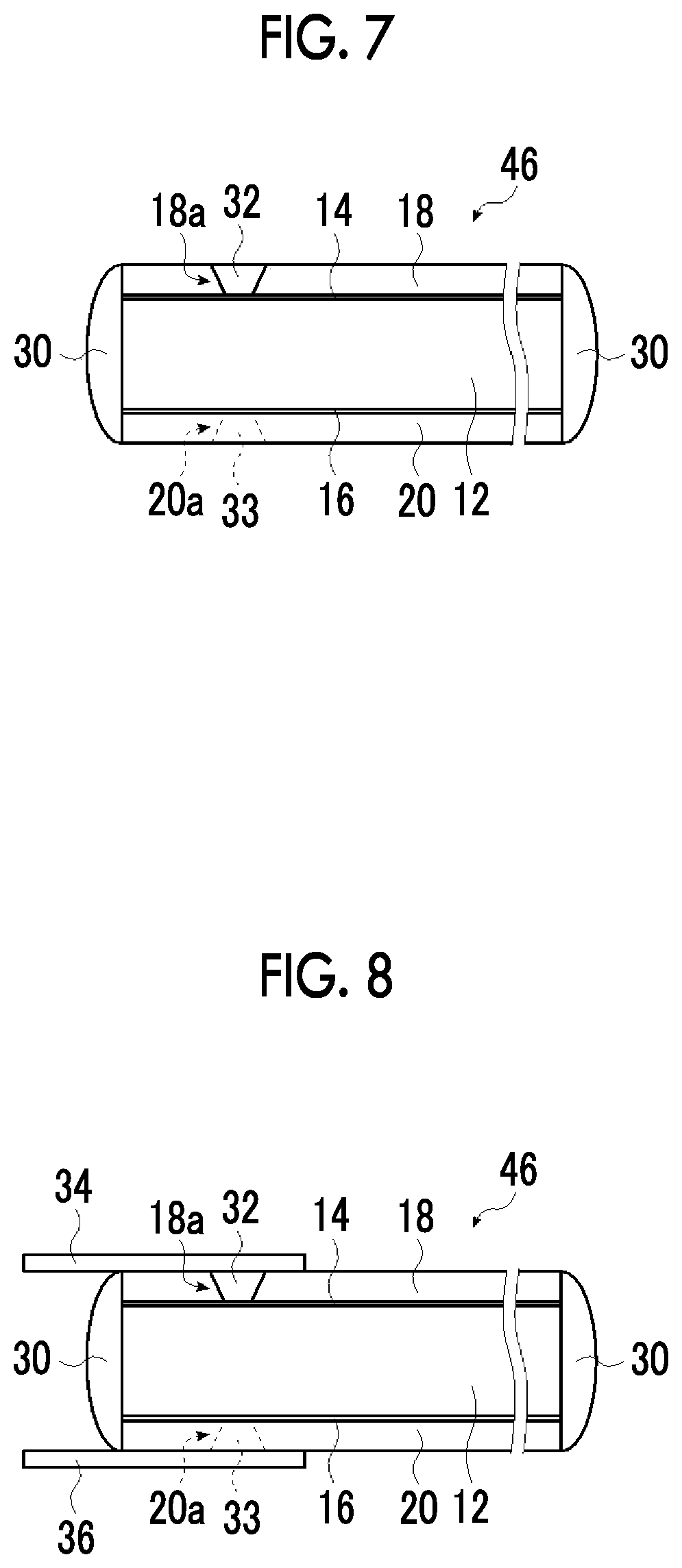

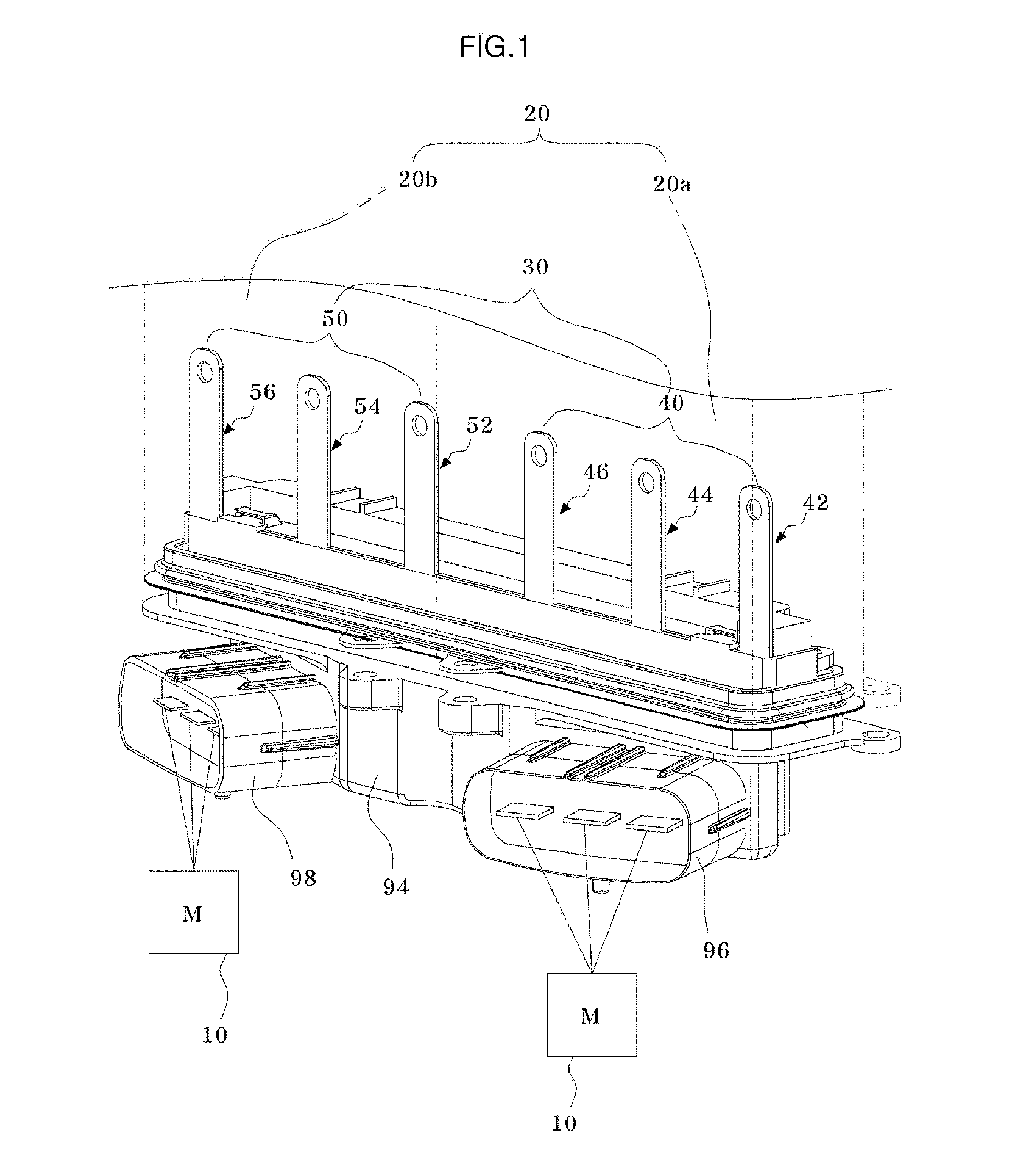

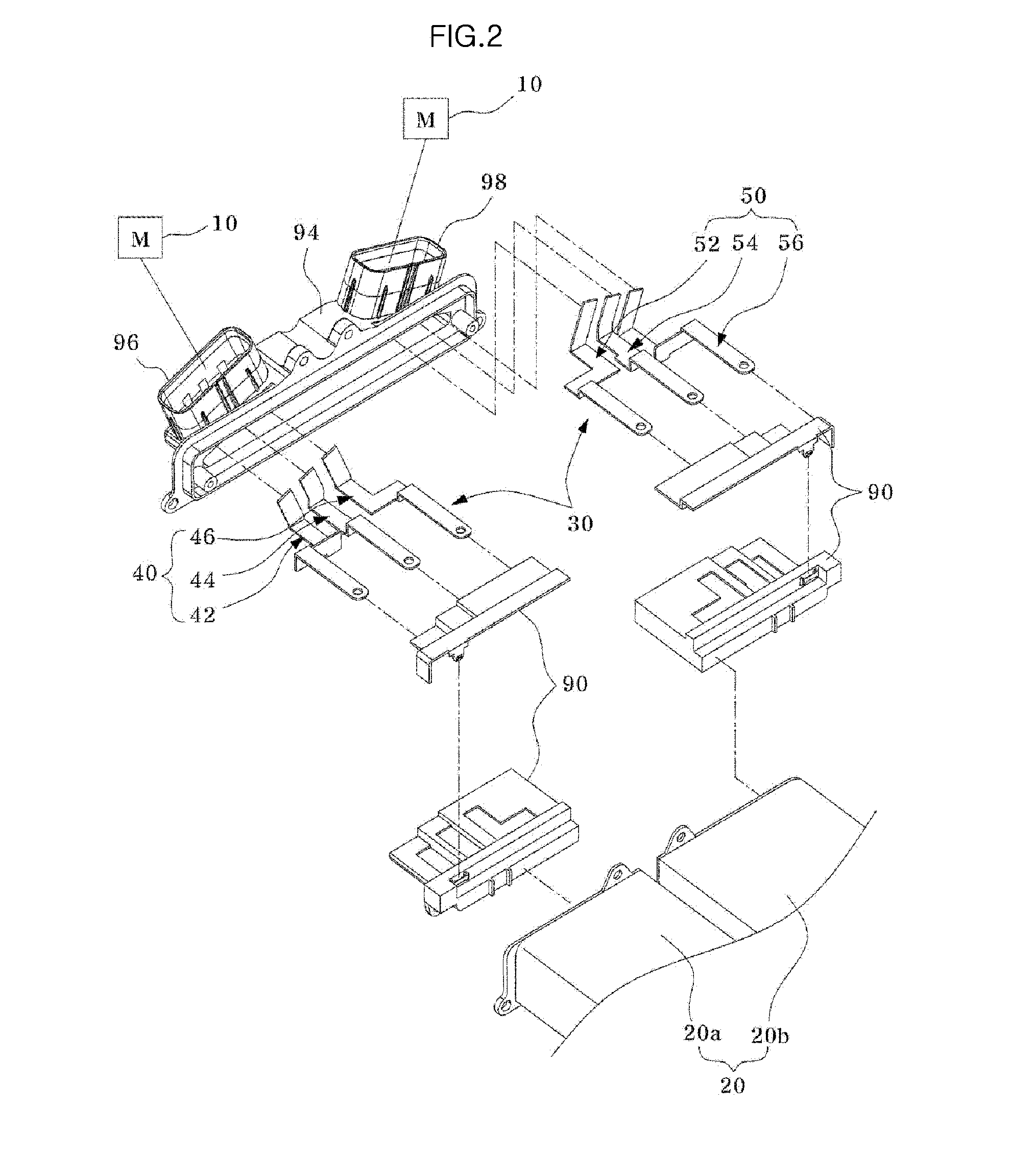

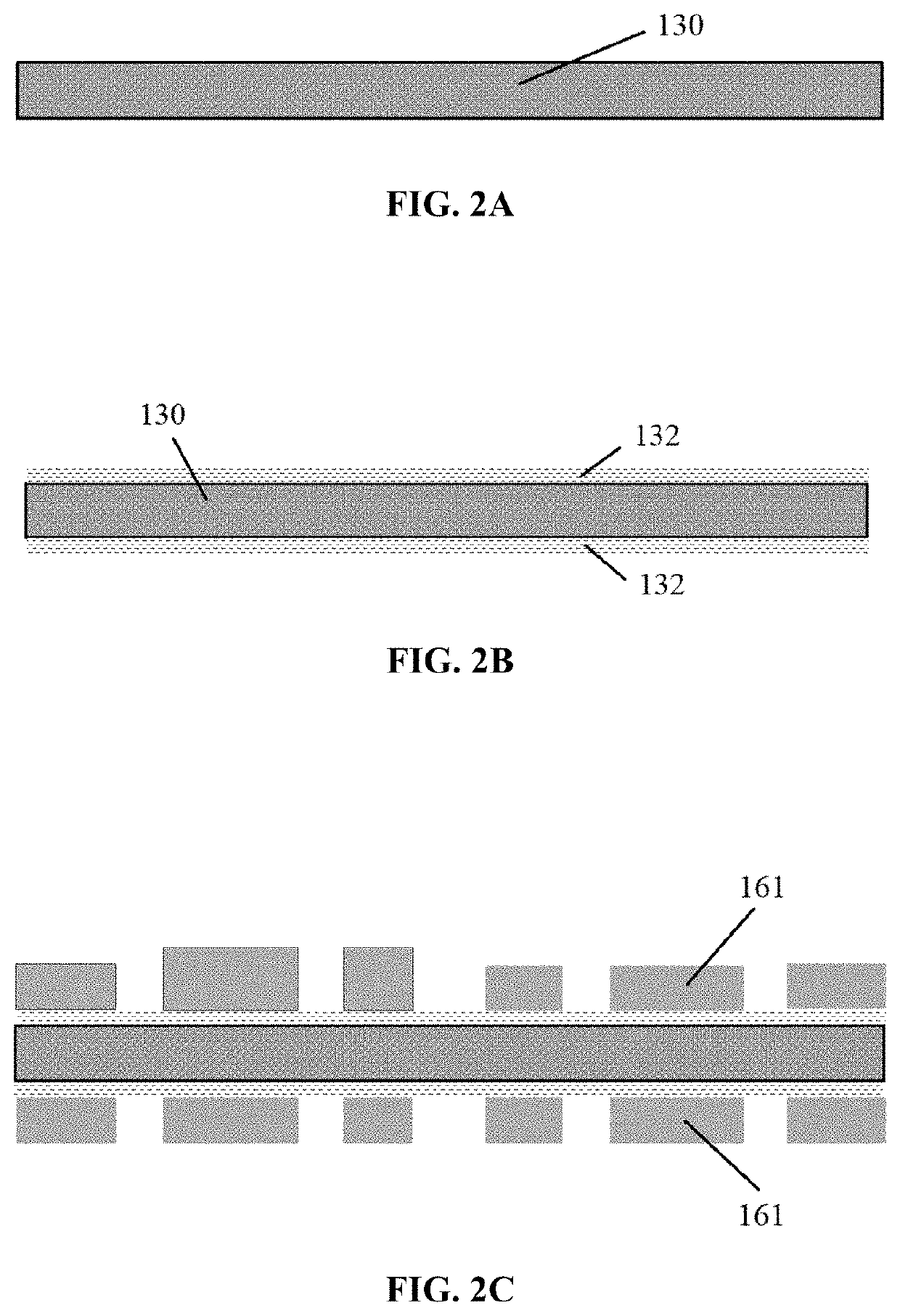

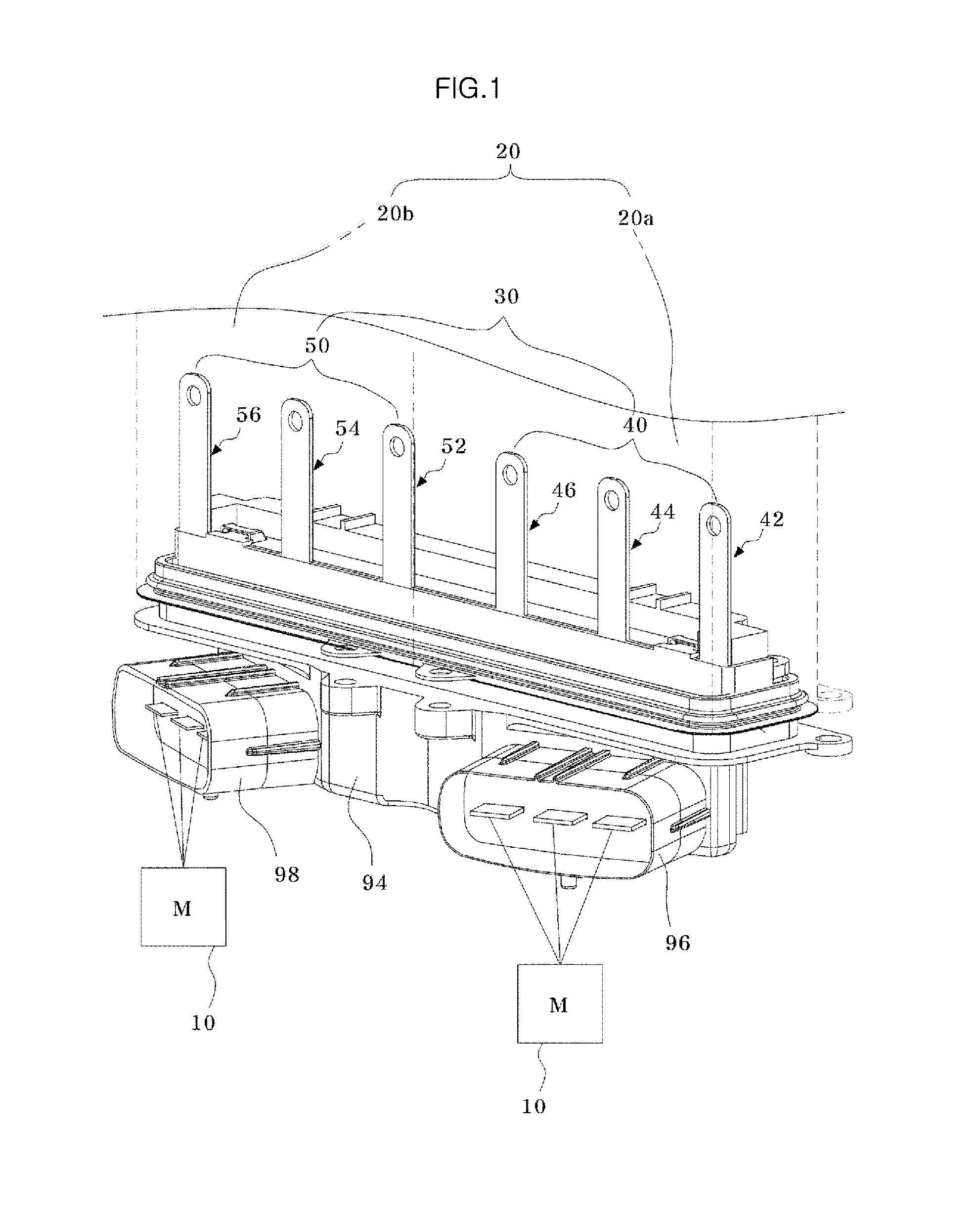

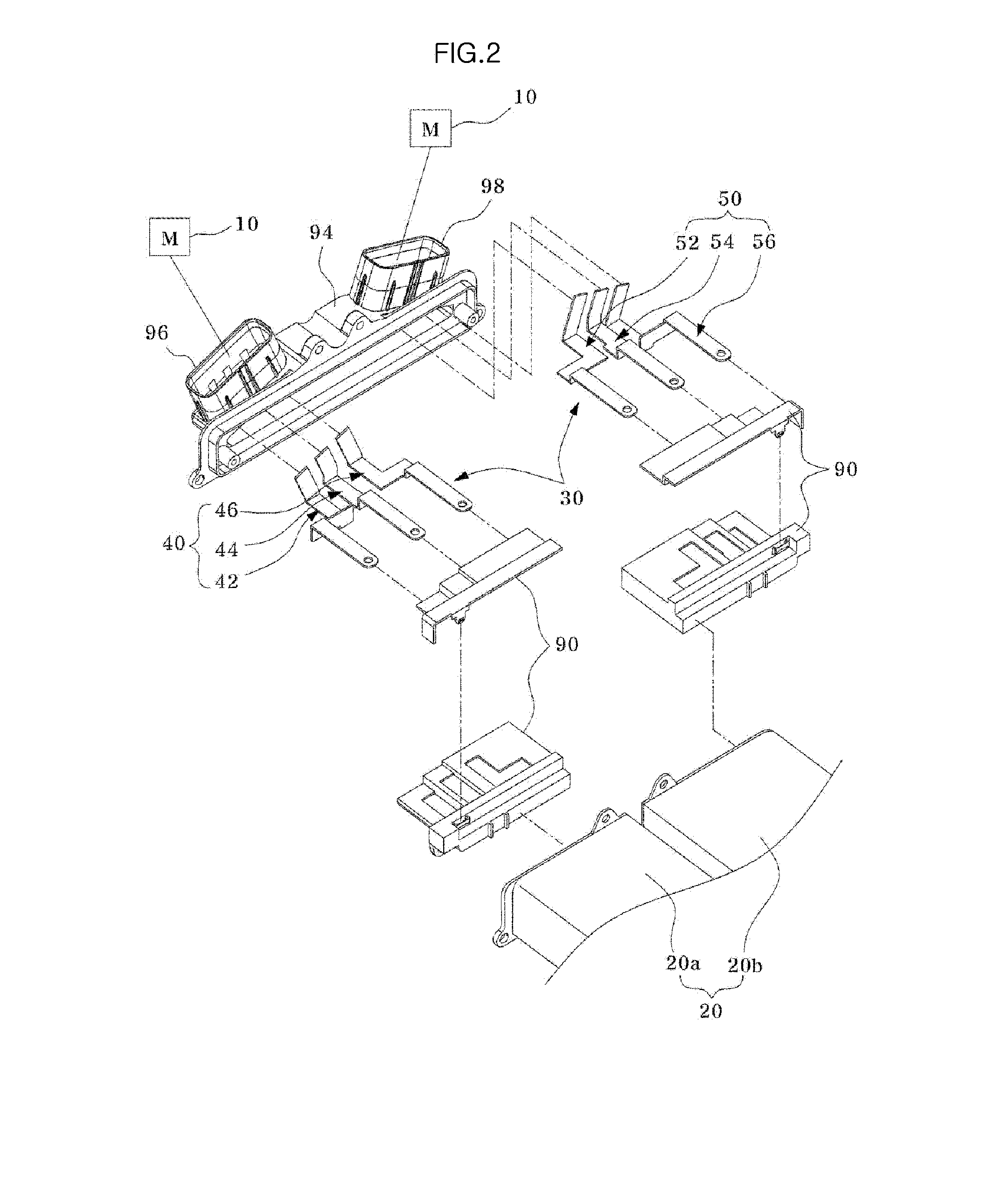

Wire connecting device for hybrid vehicle

ActiveUS8784131B2Avoid interferencePrevent short-circuitingBus-bar installationCoupling contact membersEngineeringTerminal unit

Disclosed is a wire connecting device for a vehicle, preferably a hybrid vehicle, including six individual bus bars for connecting two 3-phase AC sub-devices to a main device, in which the bus bars are divided in to a first unit terminal unit and a second unit terminal unit each composed of a U-pole bus bar, a V-pole bus bar, and a W-pole bus bar, predetermined ends of the U-pole bus bar, the V-pole bus bar, and the W-pole bus bar of the first unit terminal unit bend to a side, and predetermined ends of the U-pole bus bar, the V-pole bus bar, and the W-pole bus bar of the second unit terminal unit bend to the other side.

Owner:HYUNDAI MOTOR CO LTD +2

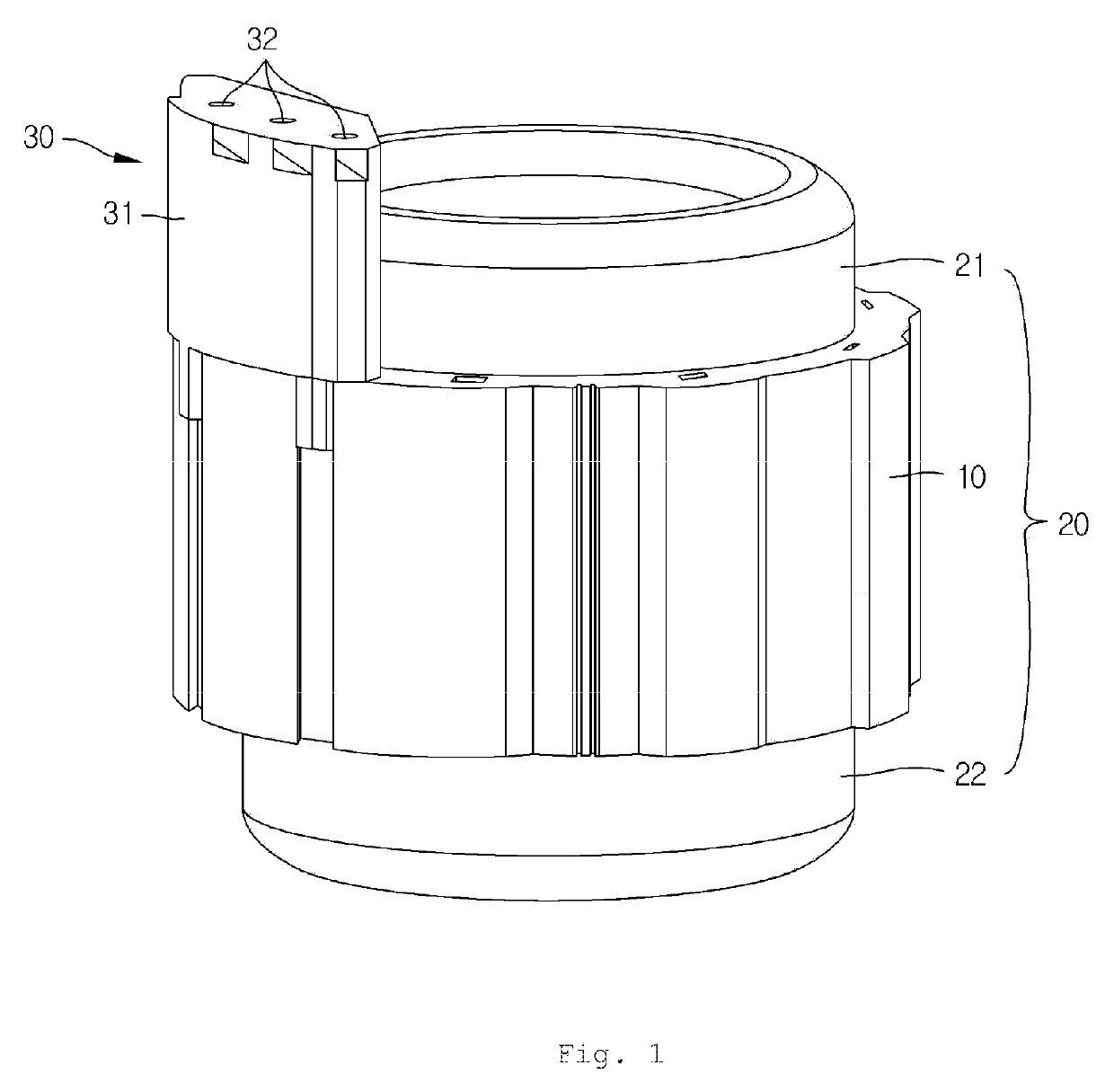

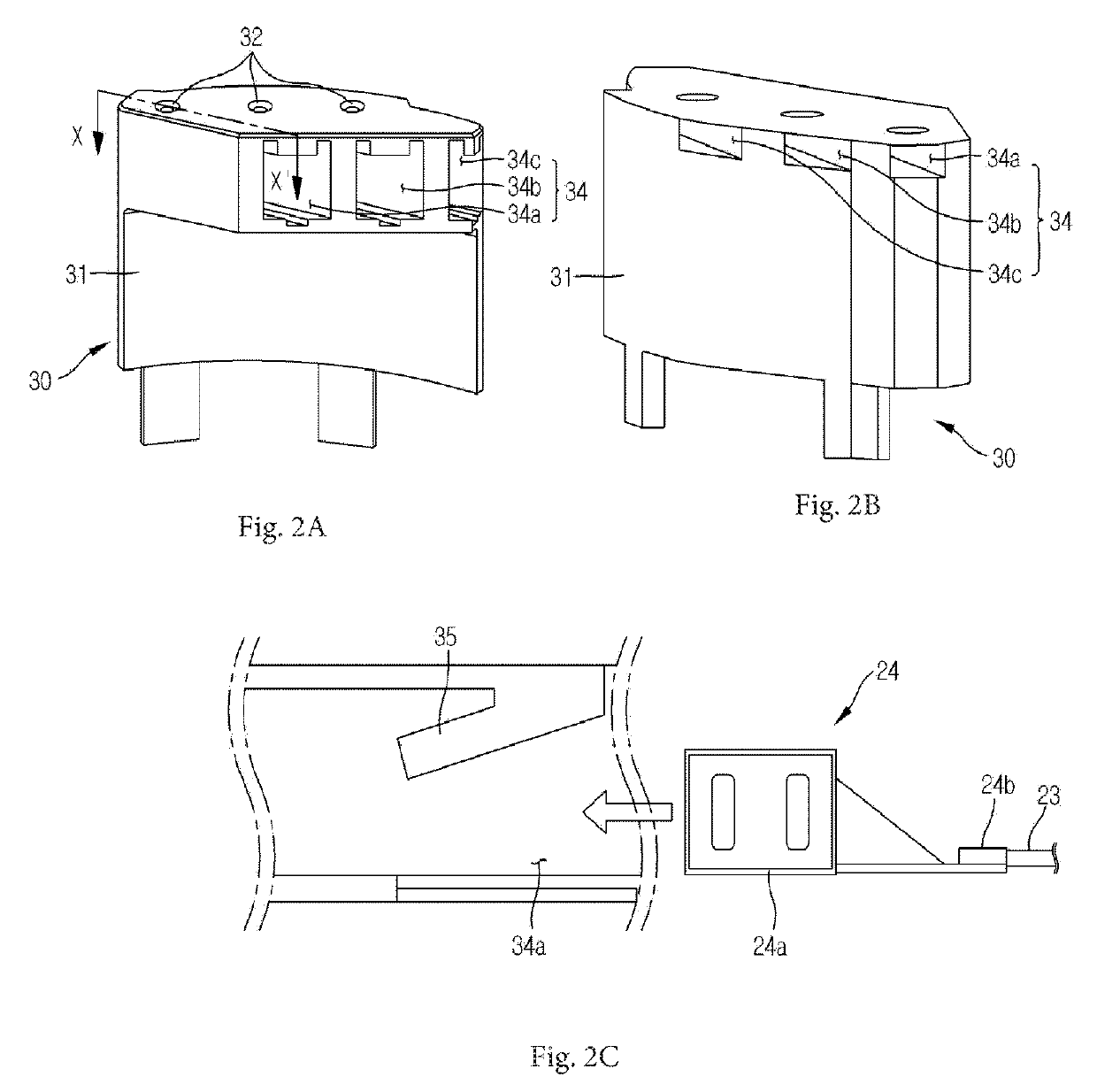

Cluster assembly and electric compressor comprising same

ActiveUS20190203715A1Reinforced Insulation ConstructionEasily equipped in electric motorRotary/oscillating piston combinations for elastic fluidsWindings insulation shape/form/constructionEngineeringCoil insertion

The present invention relates to a cluster assembly and an electric compressor comprising the same and, more particularly, to a cluster assembly which has an improved insulation structure and is convenient to install, and an electric compressor comprising the same. More specifically, the cluster assembly comprises: three terminals; a detachable cluster including first to third coil fixing portions each having a coil insertion hole into which a coil end is insertedly formed therein, and first to third terminal receiving portions having a space formed therein so as to be spaced apart from the first to third coil fixing portions by a predetermined distance in the longitudinal direction of the coil and receive the terminals; and a cluster body which is coupled to one side surface of an electric motor in an axial direction and is formed hollow in the center thereof along the outer circumferential surface of a stator and which includes a cluster insertion portion formed corresponding to the shape of the detachable cluster so that the detachable cluster can be inserted in a horizontal direction.

Owner:HANON SYST

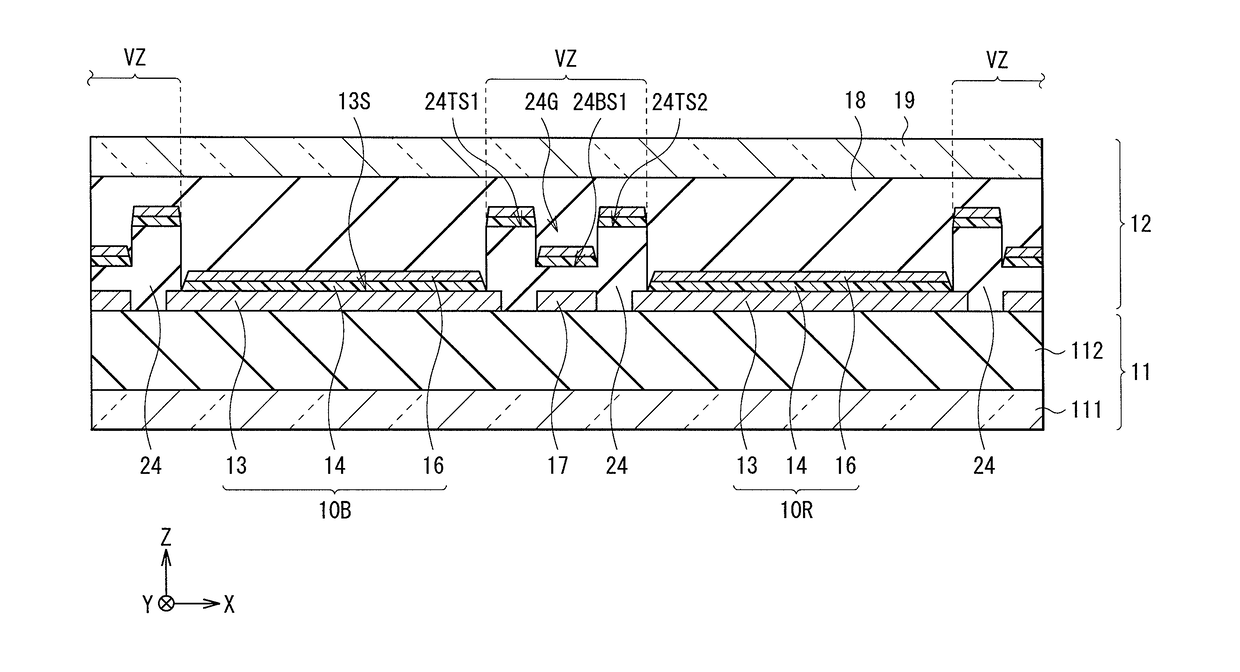

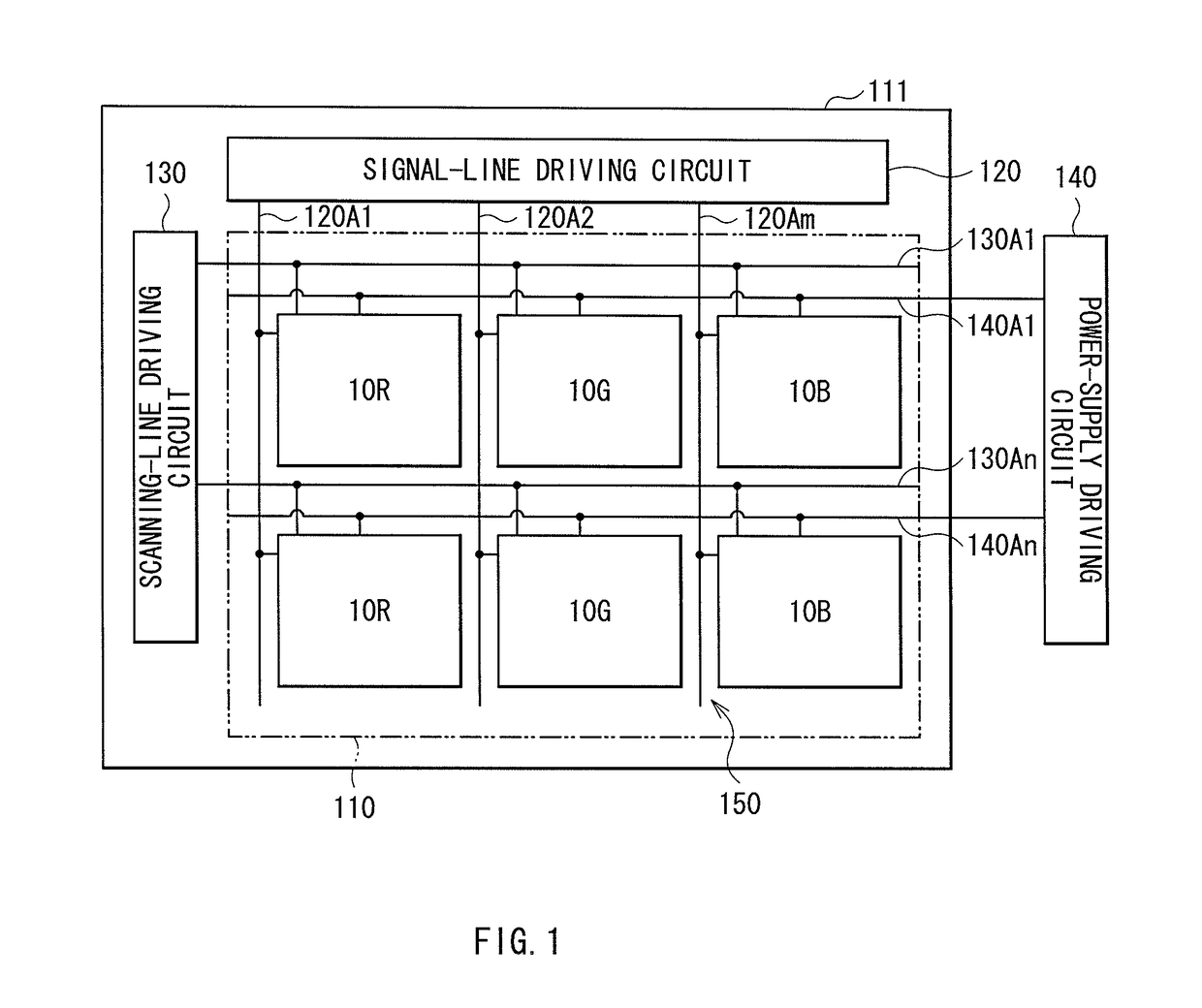

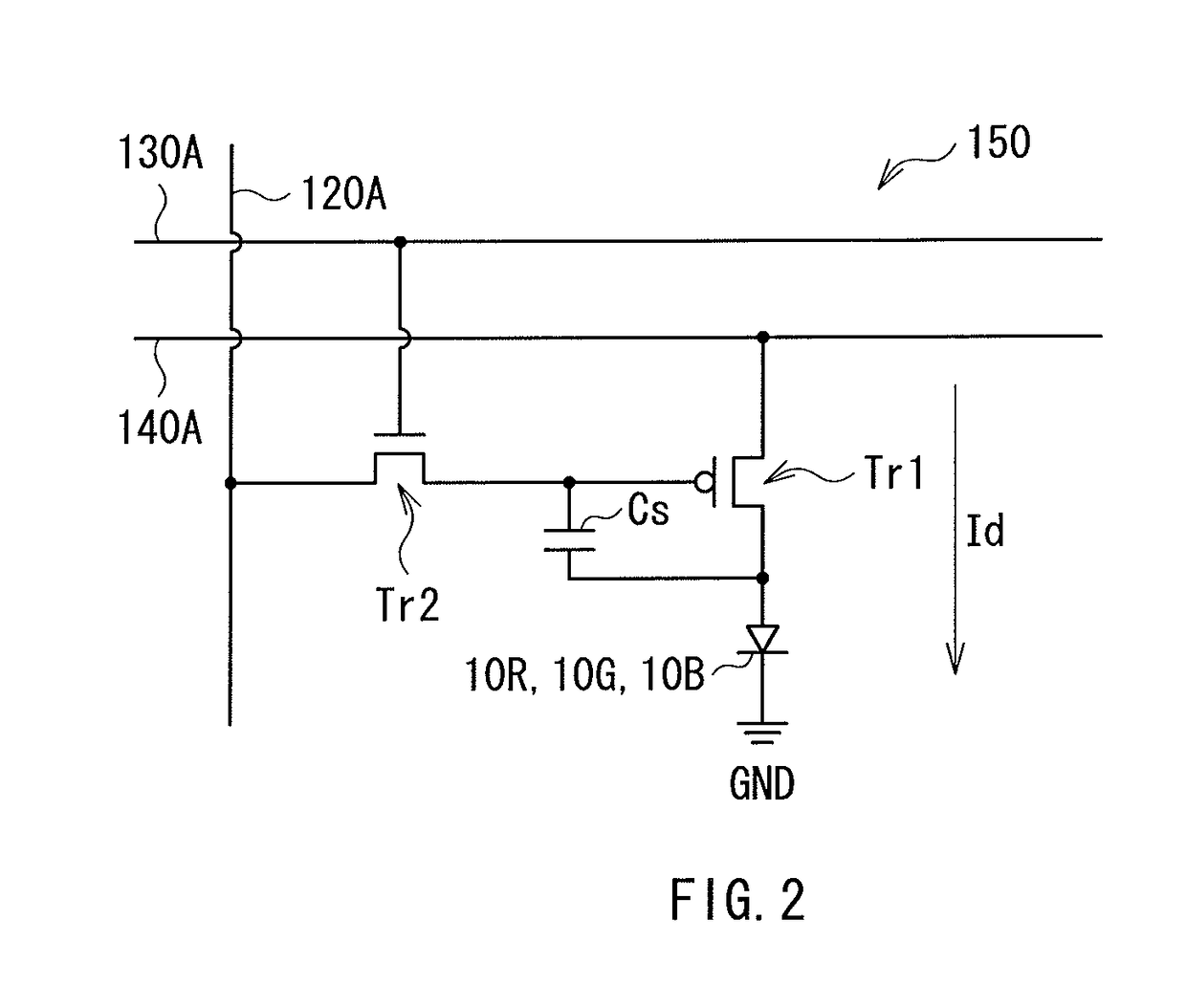

Display device with separation member including steps

ActiveUS20170110524A1Increase the number ofAvoid leakage currentSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOrganic layer

A display device includes: a substrate; a plurality of light-emission elements arranged, on the substrate, in a first direction and a second direction intersecting each other, each of the light-emission elements having a first electrode layer, an organic layer including a luminous layer, and a second electrode layer which are laminated in that order; and a separation section disposed, on the substrate, between the light-emission elements adjacent to each other in the first direction, the separation section having two or more pairs of steps. The first electrode layers in the light-emission elements are separated from each other, and the organic layers as well as the second electrode layers in the light-emission elements adjacent to each other in the first direction are separated from each other by the steps included in the separation section.

Owner:SONY CORP

Method of manufacturing clad board for forming circuitry, clad board and core board for clad board

InactiveUS20050249933A1Improve yieldPrevent a short circuitNatural cellulose pulp/paperSynthetic cellulose/non-cellulose material pulp/paperConductive pasteMetal foil

A manufacturing method of a clad board includes: sticking a releasing film to a pre-preg sheet; forming a non-through-hole or through-hole in the pre-preg sheet including the releasing film; filling the hole with conductive paste; peeling off the film; and heating and pressing a metal foil onto the pre-preg sheet. The clad board has a smooth face formed on one face or both the faces of the pre-preg sheet, so that the conductive paste is restrained from spreading in an interface between the pre-preg sheet and the releasing film. This structure can avoid short-circuit between circuits and prevent insulating reliability from lowering. As a result, an yield rate is improved, and a reliable circuit board is obtainable.

Owner:PANASONIC CORP

Method of manufacturing clad board for forming circuitry, clad board and core board for clad board

InactiveUS7754321B2Improve yieldPrevent a short circuitNatural cellulose pulp/paperSynthetic cellulose/non-cellulose material pulp/paperConductive pasteMetal foil

A manufacturing method of a clad board includes: sticking a releasing film to a pre-preg sheet; forming a non-through-hole or through-hole in the pre-preg sheet including the releasing film; filling the hole with conductive paste; peeling off the film; and heating and pressing a metal foil onto the pre-preg sheet. The clad board has a smooth face formed on one face or both the faces of the pre-preg sheet, so that the conductive paste is restrained from spreading in an interface between the pre-preg sheet and the releasing film. This structure can avoid short-circuit between circuits and prevent insulating reliability from lowering. As a result, an yield rate is improved, and a reliable circuit board is obtainable.

Owner:PANASONIC CORP

Battery

ActiveUS8389153B2Improve securityLarge capacitySmall-sized cells cases/jacketsSecondary cellsParticulatesElectrolyte

A battery including: a battery case having a bottom, a side wall, and an upper opening; an electrode assembly; an electrolyte; and a sealing plate covering the upper opening of the battery case accommodating the electrode assembly and the electrolyte, the electrode assembly including a positive electrode, a negative electrode, and a separator interposed between the positive electrode and the negative electrode, a gasket is interposed between an opening-edge portion of the battery case and the sealing plate, a first resistive layer is disposed between the opening-edge portion of the battery case and the gasket, or a second resistive layer is disposed between the sealing plate and the gasket. The first or second resistive layer contains a mixture of a particulate inorganic oxide and a binder. This configuration makes it possible to prevent a short circuit between the battery case and the sealing plate even when the gasket is broken.

Owner:PANASONIC CORP

Electrode for solid state battery and solid state battery

InactiveUS20200212450A1High mechanical strengthAvoid breakingElectrode rolling/calenderingSolid electrolytesSolid-state batteryBattery cell

The disclosure provides an electrode for solid state battery and a solid state battery, wherein the electrode using a foamed metal as a collector has excellent mechanical strength and can maintain the insulation from a counter electrode when constituting the solid state battery. In the electrode for solid state battery, which uses a collector composed of a foamed porous body that has a mesh structure, a layer that achieves reinforcement and insulation is provided in the boundary between a filled part filled with an electrode mixture and an unfilled part.

Owner:HONDA MOTOR CO LTD

Connector for implementing multi-faceted interconnection and manufacturing method thereof

ActiveUS20220068825A1Improve space utilizationElectric transmission is shortenedSemiconductor/solid-state device detailsSolid-state devicesMechanical engineeringDielectric layer

A connector for implementing multi-faceted interconnection according to an embodiment of the present disclosure includes a first dielectric layer between a first circuit layer and a second circuit layer, a first copper pillar layer connecting the first circuit layer and the second circuit layer in the first dielectric layer, a second dielectric layer on the first circuit layer, a third circuit layer on the second dielectric layer, and a vertical second copper pillar layer connected to the third circuit layer, wherein an opening is formed in the second dielectric layer to expose the first circuit layer, and the second copper pillar layer exposes side faces facing side end faces of the first dielectric layer and the second dielectric layer.

Owner:ZHUHAI ADVANCED CHIP CARRIERS & ELECTRONICS SUBSTRATE SOLUTIONS TECH

Wire connecting device for hybrid vehicle

ActiveUS20120329344A1Avoid interferencePrevent short-circuitingElectrically conductive connectionsBus-bar installationComputer terminalHybrid electrical vehicle

Disclosed is a wire connecting device for a vehicle, preferably a hybrid vehicle, including six individual bus bars for connecting two 3-phase AC sub-devices to a main device, in which the bus bars are divided in to a first unit terminal unit and a second unit terminal unit each composed of a U-pole bus bar, a V-pole bus bar, and a W-pole bus bar, predetermined ends of the U-pole bus bar, the V-pole bus bar, and the W-pole bus bar of the first unit terminal unit bend to a side, and predetermined ends of the U-pole bus bar, the V-pole bus bar, and the W-pole bus bar of the second unit terminal unit bend to the other side.

Owner:HYUNDAI MOTOR CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com