Method for manufacturing large ceramic co-fired articles

a co-fired ceramic and co-fired technology, which is applied in the manufacture of semiconductor/solid-state devices, basic electric elements, electric apparatus, etc., can solve the problems of warping or unevenness of the clamping surface, eventual cracking of the esc body, damage to the semiconductor wafer, etc., to reduce the number of manufacturing steps in the fabrication process, prevent overheating of the substrate, and high degree of dimensional tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0066]A multilayer heater is produced using the improved HTCC method as a demonstration of feasibility on a small scale.

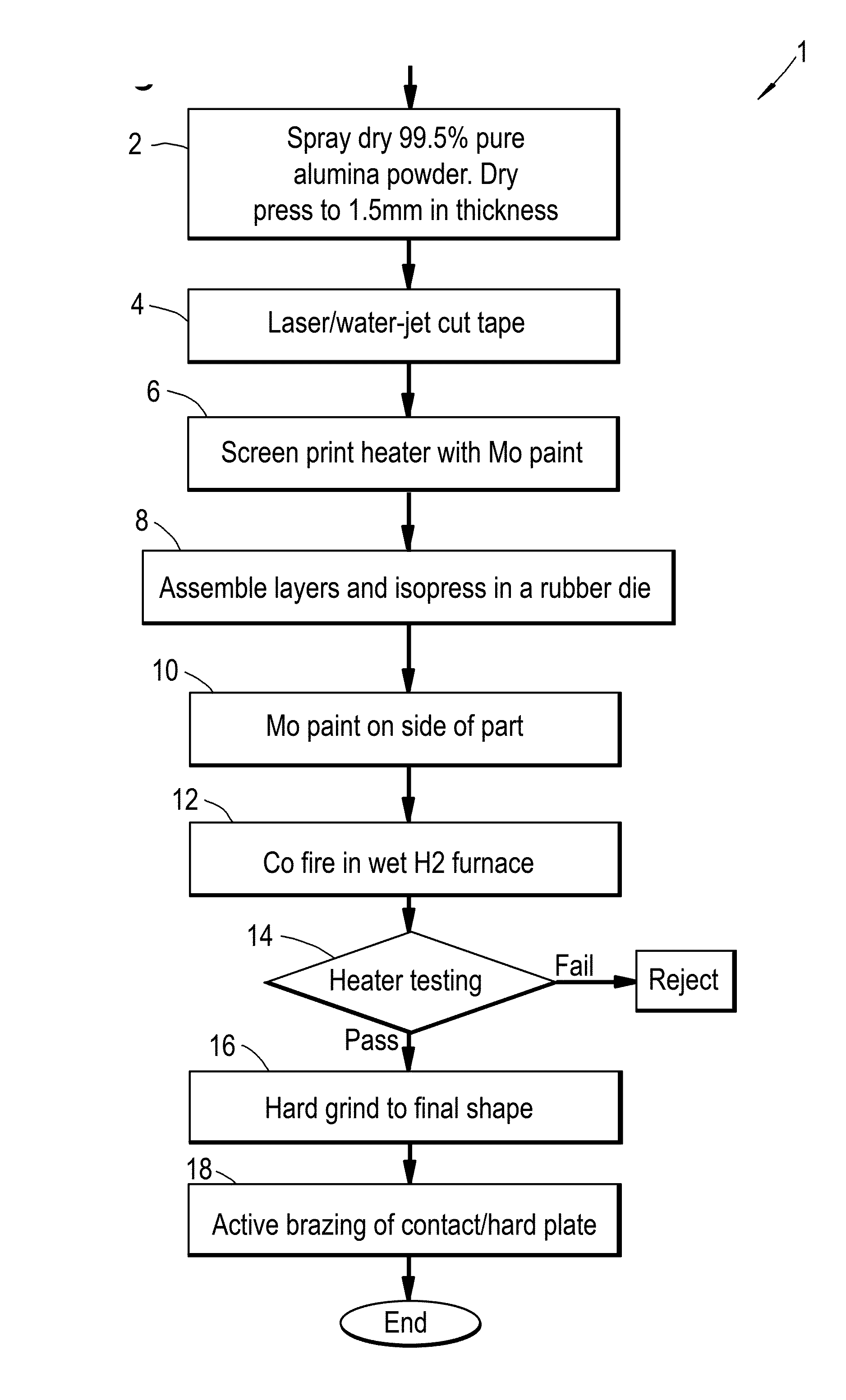

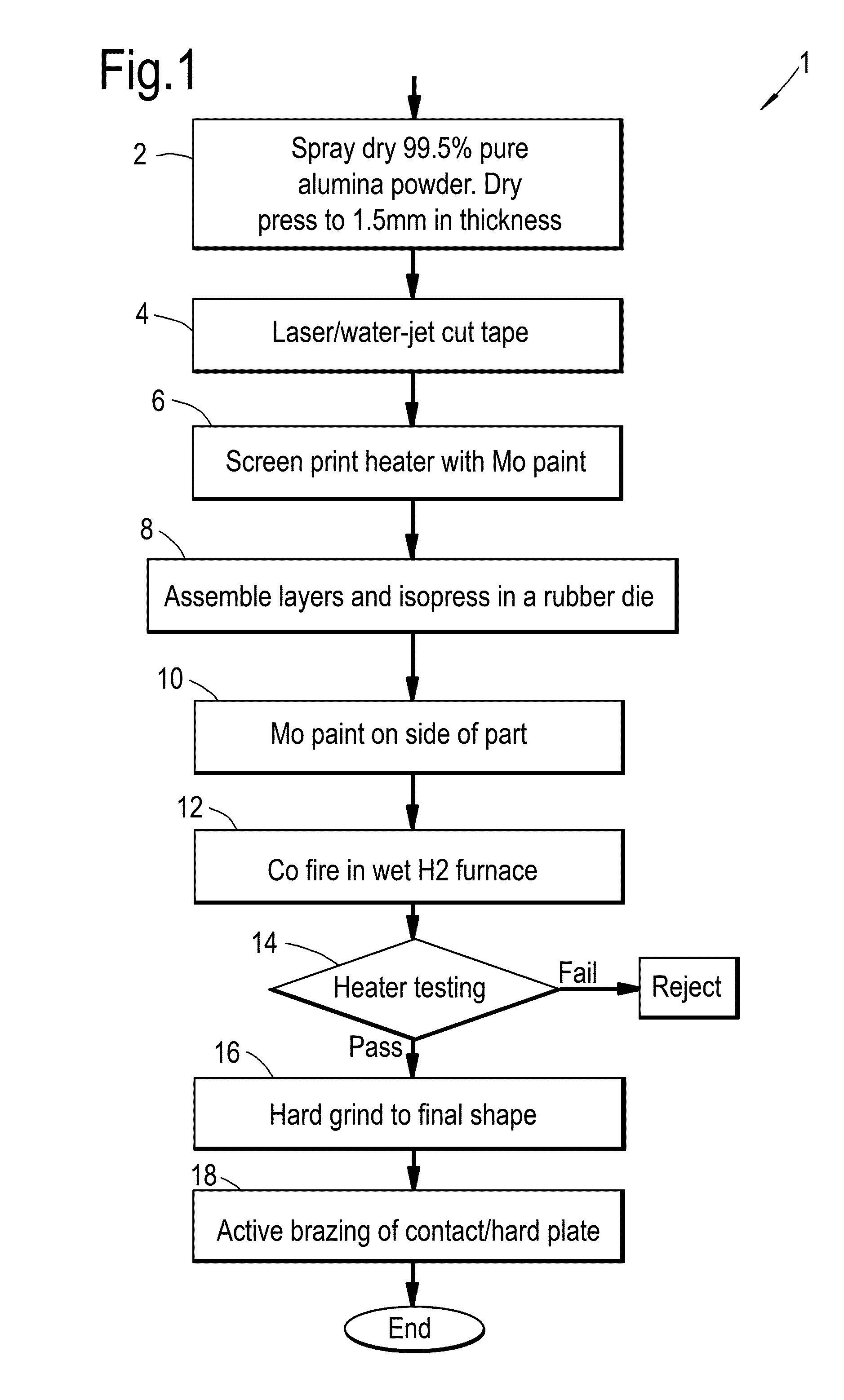

[0067]FIG. 1 illustrates the processing flow chart 1 for manufacturing of a four layer heater.

[0068]The process shown uses the spray dried 99.5% pure alumina powder mentioned previously. It should be noted that the present invention is not restricted to 99.5% alumina and can be used for other ceramics, [e.g. alumina of different purity (for example 90-99.9%), ZrO2, Y2O3, AlN, Si3N4, SiC, or indeed any ceramic].

[0069]At step 2, the spray dry powder is pressed (or uniaxially pressed) in a 2″ die to produce thin sheets of about 1.5 mm thickness from the spray dried powder. The dry pressed green sheets is then cut in the green state to the desired shape (Step 4), e.g. by laser or water jet cutting.

[0070]Following cutting of the green sheets, the shaped dry pressed green sheets are metallized to deposit a metallization layer or metallic precursor on its surface (Step 6)...

example 2

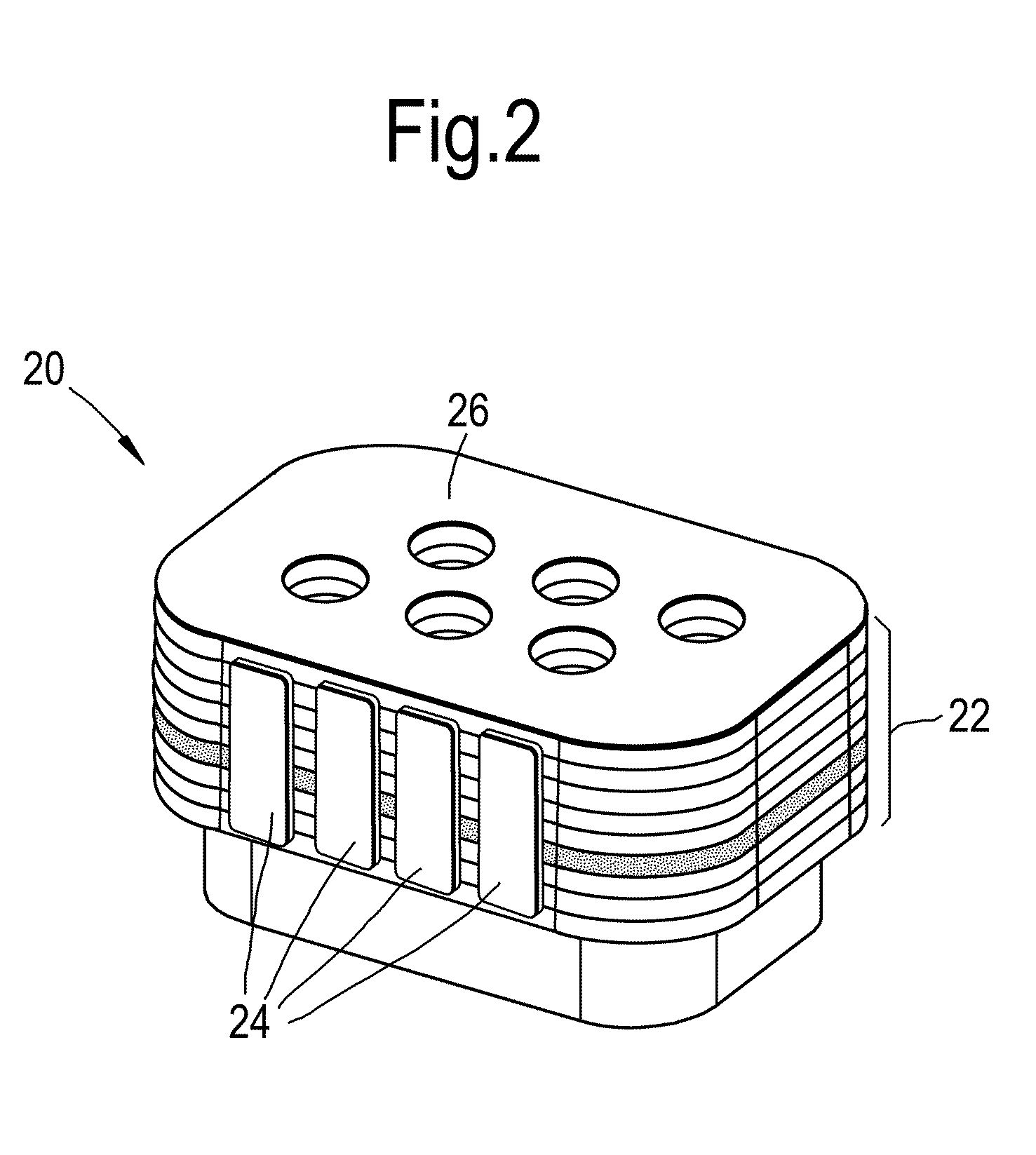

[0075]The objective of the example is to demonstrate the new HTCC processing method can be used to produce large sized wafer processing apparatus such as heater and electrostatic chuck (ESC) combination or electrostatic chuck (ESC). The goal is to ensure the 300 mm heater is capable of thermal cycling between room temperature and 600° C. with good temperature uniformity.

[0076]FIG. 3 illustrates the flowchart of the manufacturing process 30. Similar to example 1, the manufacturing process for a 300 mm wafer heating device starts with spray drying of 99.5% pure alumina powder using the alumina powder (Step 32) as mentioned previously.

[0077]The spray dried powder is dry pressed using a 2500 ton dry press (uniaxial press) with an 81 cm diameter die to generate green sheets of 81 cm diameter with thickness in the range of about 2.5 mm to 6 mm (Step 34). In the particular embodiment where the ESC is used in combination with a heater, the combination may be based on assembling three dry pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com