Air delivery unit

a technology of air delivery device and air delivery device, which is applied in the direction of lighting and heating apparatus, heating types, and mechanical/solid-state device details, etc., can solve the problems of high rigidity of the fan guard and is not easily deformed, so as to reduce the amount and speed of air, suppress the rise of the static pressure of the air delivery device, and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

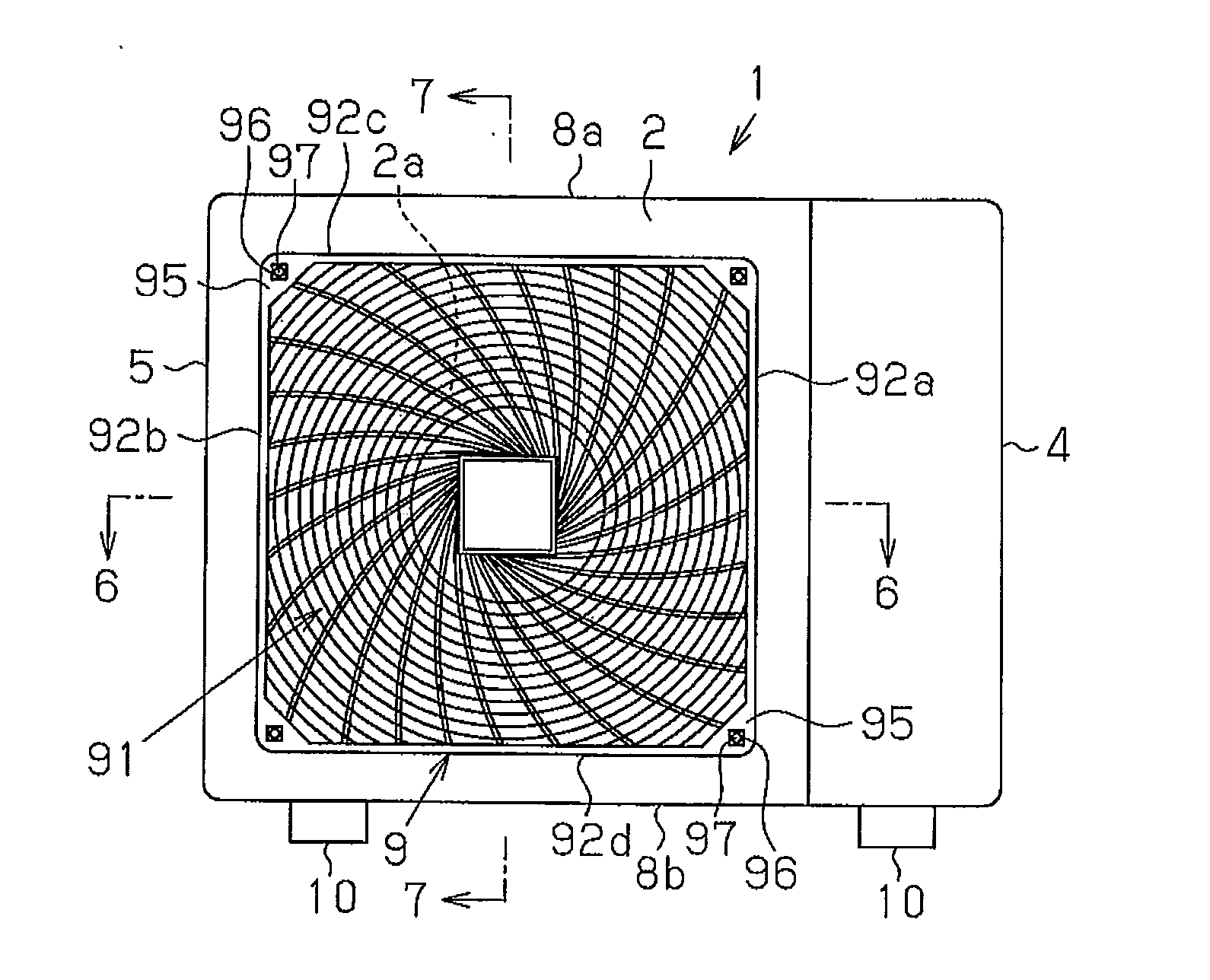

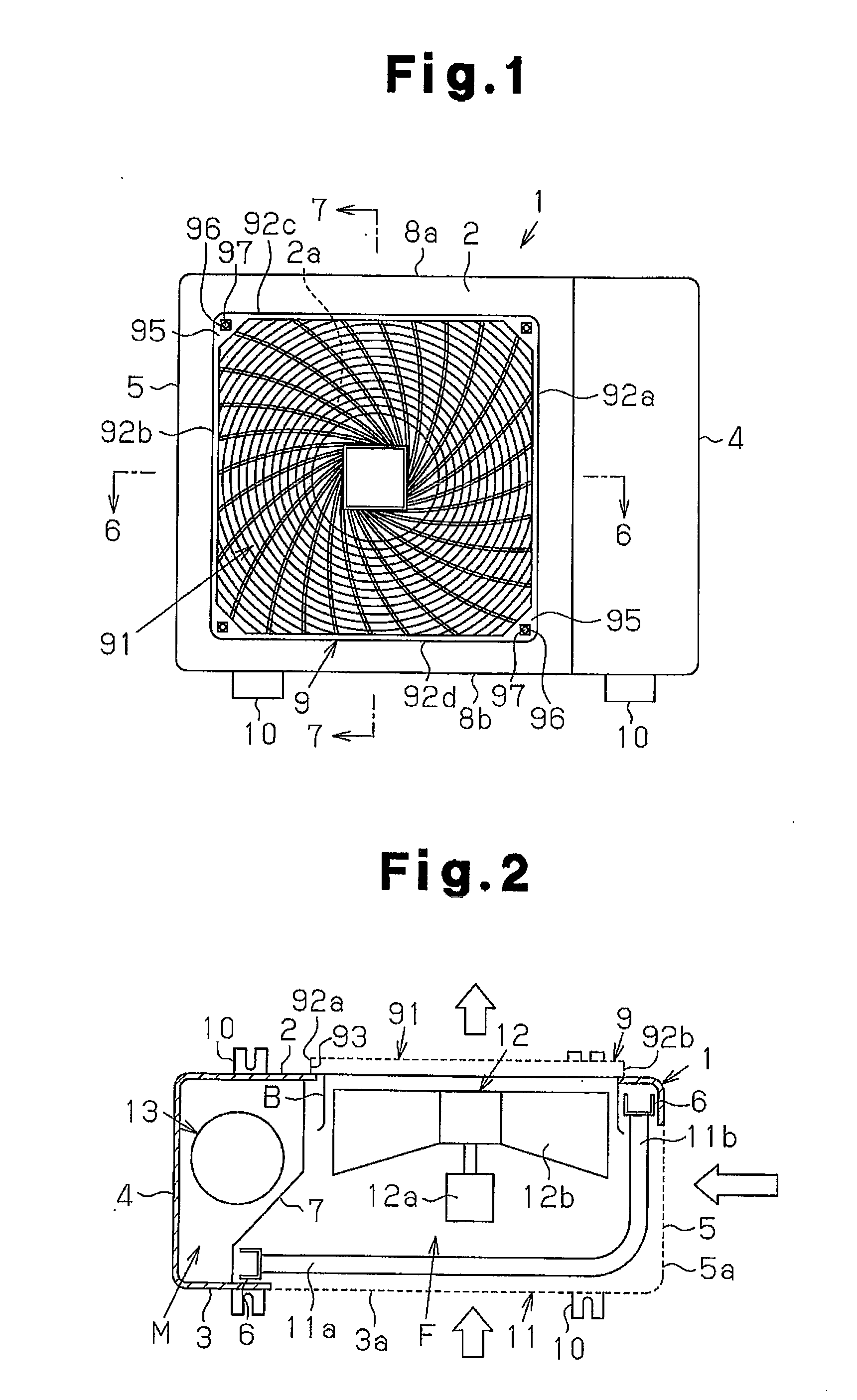

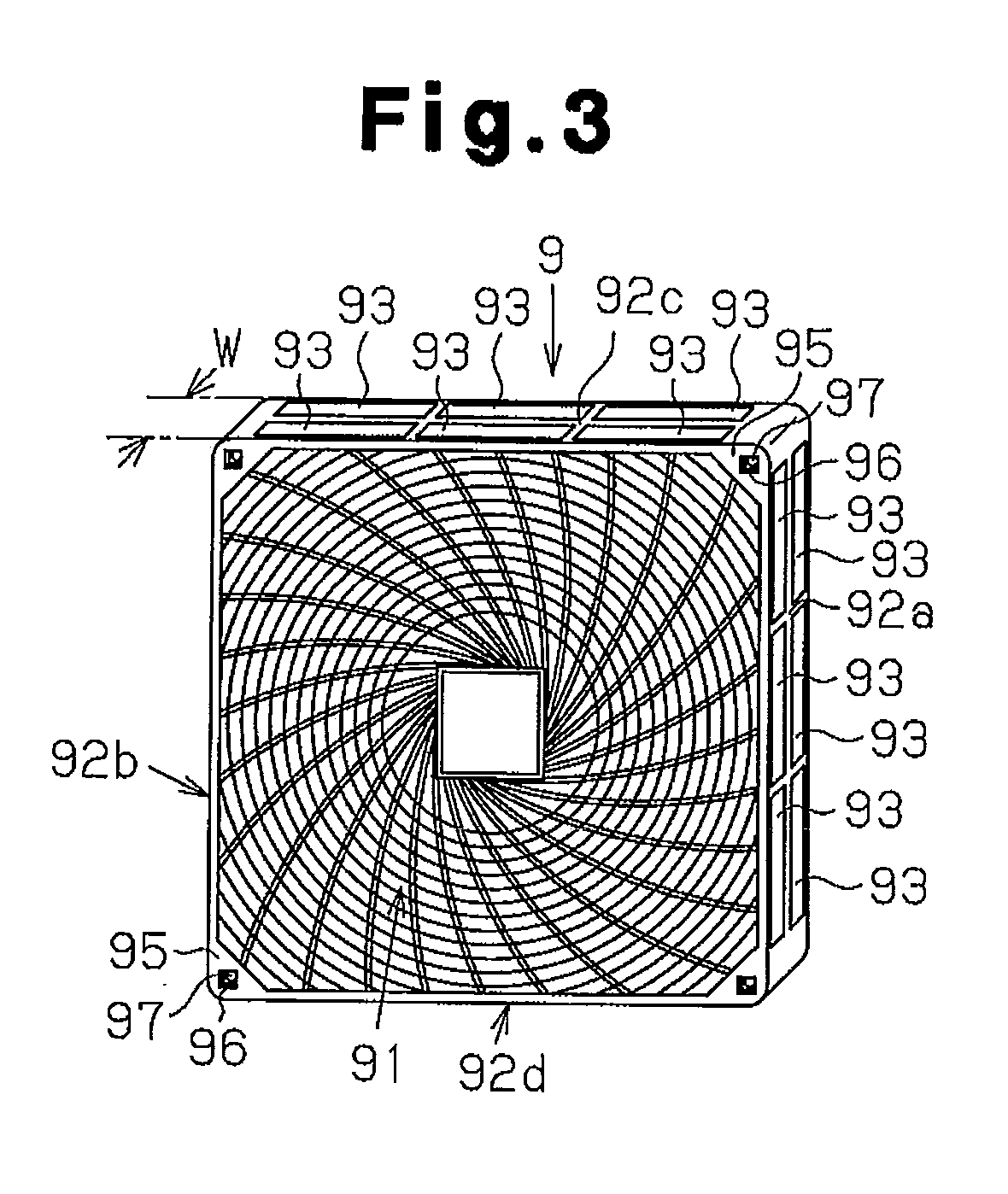

[0041]FIGS. 1 to 7 show the structure of an air delivery unit according to a first embodiment of the present invention as a whole and a main portion of the air delivery unit. In the present embodiment, the air delivery unit is embodied as an outdoor unit of an air conditioner.

[0042]As shown in FIGS. 1 and 2, the outdoor unit includes a heat exchanger 11, an air delivery device 12, and a casing 1. The casing 1 has a front plate 2, a rear plate 3, a pair of side plates 4, 5, a top plate 8a, and a bottom plate 8b. The heat exchanger 11 has an L shape as viewed from above. The heat exchanger 11 has an elongated portion 11a corresponding to the backside of the casing 1 and a short portion 11b corresponding to a side surface of the casing 1. The air delivery device 12 includes a fan motor 12a and a fan (a impeller) 12b. The casing 1 has a laterally elongated trunk-like shape. A compressor 13, which compresses refrigerant, is received in the casing 1. The fan motor 12a of the air delivery ...

second embodiment

[0057]FIGS. 11 and 12 show the structure of an air delivery unit according to a second embodiment of the present invention as a whole and a main portion of the air delivery unit. In the present embodiment, the air delivery unit is embodied as an outdoor unit of an air conditioner of a type that draws air from sides through three surfaces and blows the air upward.

[0058]The outdoor unit has a frame-like casing 1 with a rectangular cross section extending in the vertical direction. An air inlet 23a having a grill structure is formed in the entire portion of a front surface 23 of the casing 1. Air inlets 24a, 25a are each formed in the front surface of the corresponding one of two side surfaces 24, 25. A backside 22 of the casing 1 as a whole and rear portions of the side surfaces 24, 25 are formed by blind patches. A heat exchanger, which has a U shape as viewed from above, is received in the casing 1 in correspondence with the air inlet 23a of the front surface 23 and the air inlets 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com