Lithium titanate composite material and preparing method thereof, and lithium ion battery

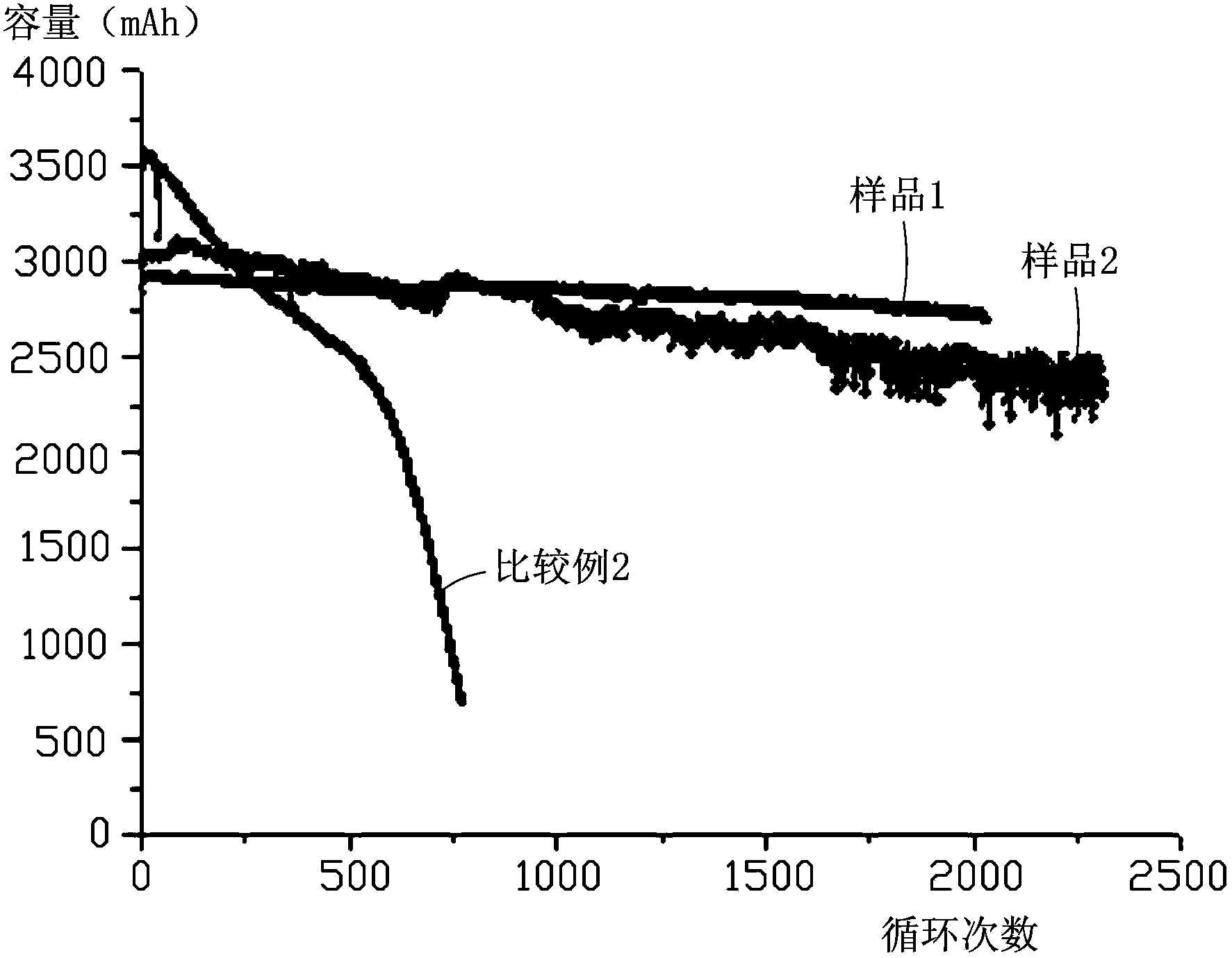

A technology for lithium ion batteries and composite materials, which is applied in the field of lithium titanate composite materials and their preparation, can solve problems such as battery capacity decline, poor electronic conductivity, and lithium ion battery gassing, and achieves good cycle stability and improves cycle stability. The effect of sex and longevity, the production method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

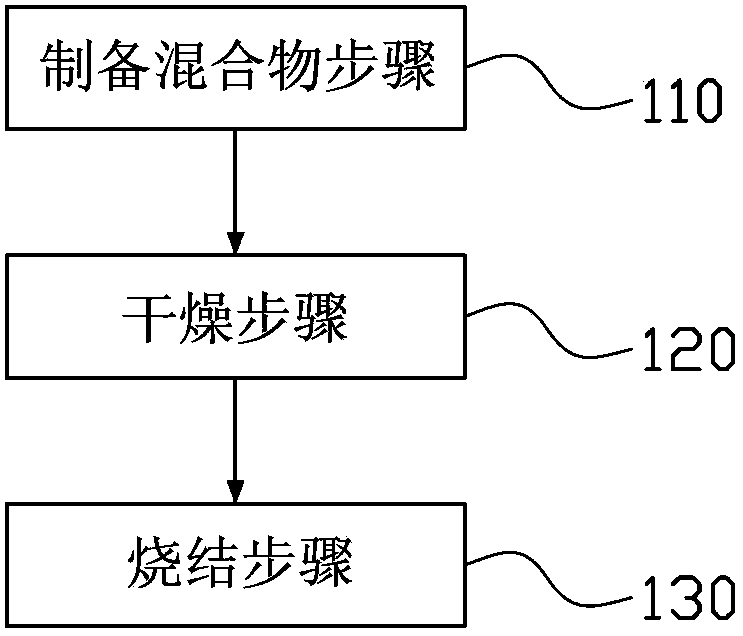

Method used

Image

Examples

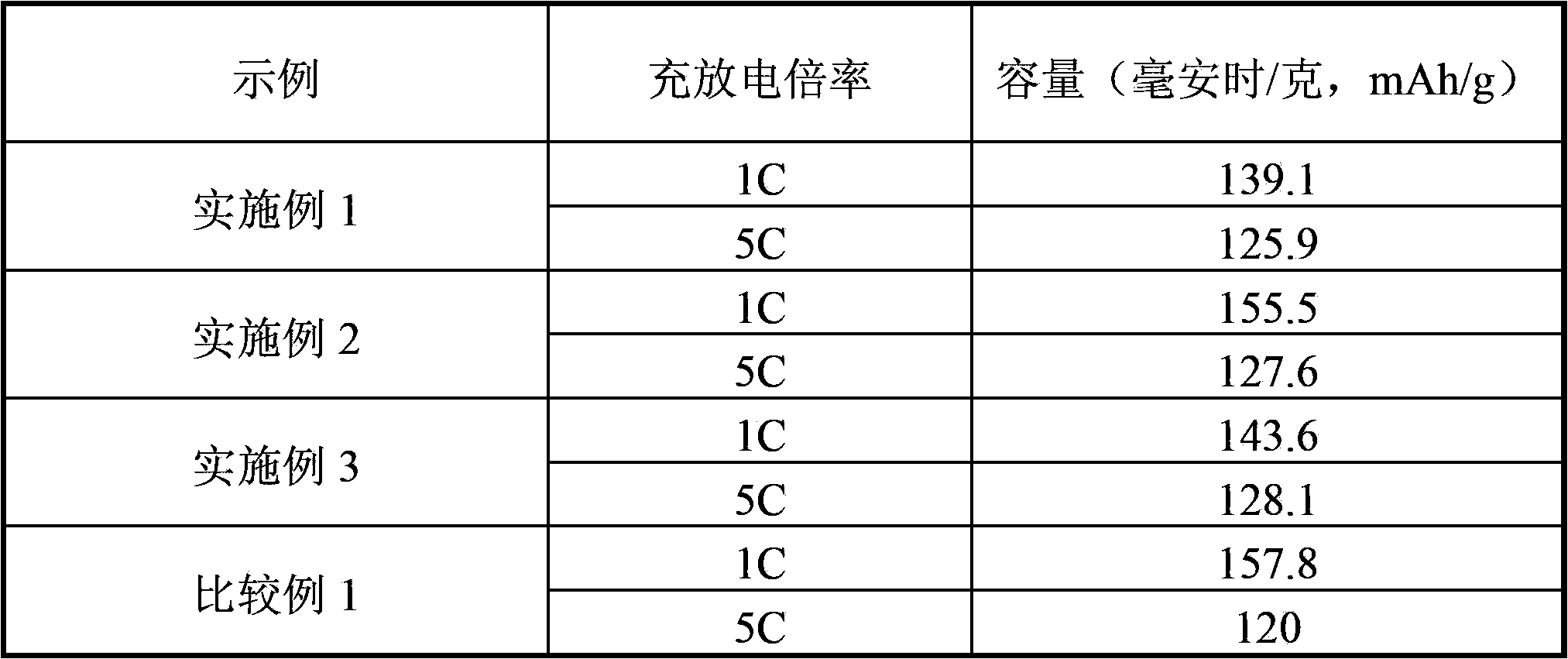

Embodiment 1

[0032] Weigh 1280.4g of LiOH·H with a purity of 98% 2 O and 3000g of TiO with a purity of 99.5% 2 Mix, and add 3.0L deionized water and stir evenly, then add 214.8g of Ba(OH) with a purity of 98% 2 ·8H 2 O, after continuing to stir for 5h, a mixed slurry was obtained. Then the prepared mixed slurry was spray-dried and sintered at 750° C. for 5 hours to obtain a lithium titanate composite material, which can be directly used as a negative electrode material of a lithium-ion battery. In this example, the lithium titanate composite material Ba x Li 4 Ti 5 o 12+x x=0.09. If Ba is calculated as BaO, the content of BaO is 3.0% based on the mass percentage of BaO in LTO.

[0033] Weigh 1.200g of the above-mentioned lithium titanate composite material, add a certain proportion of conductive agent, binder and N-methyl-2-pyrrolidone (N-methyl-2-pyrrolidone, NMP), use a planetary ball mill for 4 hours, and obtain the result after ball milling The lithium titanate composite mater...

Embodiment 2

[0035] Weigh 1280.4g of LiOH·H with a purity of 98% 2 O and 3000g of TiO with a purity of 99.5% 2 Mix, and add 3.0L deionized water and stir evenly, then add 143.2g of Ba(OH) with a purity of 98% 2 ·8H 2 O, after continuing to stir for 5h, a mixed slurry was obtained. Then the prepared mixed slurry was spray-dried and sintered at 750° C. for 5 hours to obtain a lithium titanate composite material, which can be directly used as a negative electrode material of a lithium-ion battery. In this embodiment, the lithium titanate composite material Ba x Li 4 Ti 5 o 12+x x=0.06 in . If Ba is calculated as BaO, the mass percentage of BaO is 2.0%.

[0036] Weigh 1.200g of the above-mentioned lithium titanate composite material, add a certain proportion of conductive agent, binder and N-methyl-2-pyrrolidone (N-methyl-2-pyrrolidone, NMP), use a planetary ball mill to perform ball milling for 4 hours, after ball milling The obtained lithium titanate composite material powder is coa...

Embodiment 3

[0038] Weigh 1280.4g of LiOH·H with a purity of 98% 2 O and 3000g of TiO with a purity of 99.5% 2 Mix, and add 3.0L deionized water and stir evenly, then add 71.6g of Ba(OH) with a purity of 98% 2 ·8H 2 O, after continuing to stir for 5h, a mixed slurry was obtained. Then the prepared mixed slurry was spray-dried and sintered at 750° C. for 5 hours to obtain a lithium titanate composite material, which can be directly used as a negative electrode material of a lithium-ion battery. In this embodiment, the lithium titanate composite material Ba x Li 4 Ti 5 o 12+x x=0.03. If Ba is calculated as BaO, the mass percentage of BaO is 1.0%.

[0039] Weigh 1.200g of the above-mentioned lithium titanate composite material, add a certain proportion of conductive agent, binder and N-methylpyrrolidone, use a planetary ball mill to perform ball milling for 4 hours, and coat the lithium titanate composite material powder obtained after ball milling on aluminum A film with a thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com