Metallurgical intelligent factory building air purification system

An air purification system and plant technology, applied in the field of air purification, can solve problems such as high energy consumption, large equipment footprint, and complex construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

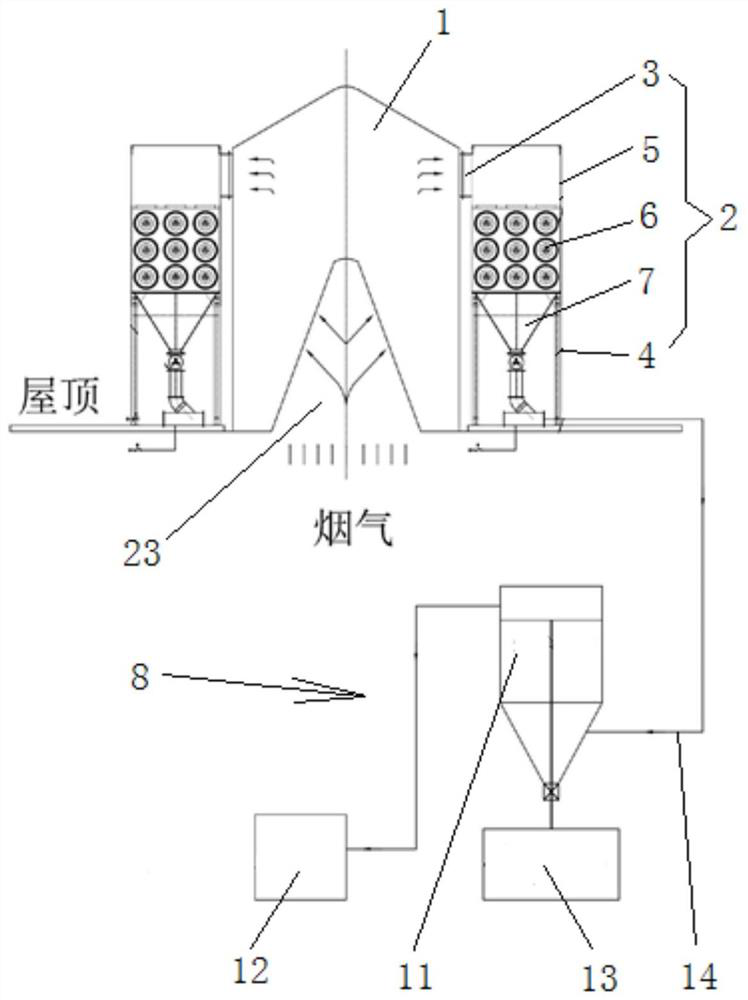

[0033] Such as Figures 1 to 4 Shown is an embodiment of an air purification system for a metallurgical intelligent workshop of the present invention, including a roof air collector 1 arranged on the roof of the production workshop, a number of filters arranged adjacent to the sides of the roof air collector 1 Cartridge dust collector 2, the lower end of the roof air collector 1 is directly connected to the inner space of the production workshop, and the air inlet 3 of the filter cartridge dust collector 2 is directly connected to and communicated with the side of the roof air collector 1 to the inside of the roof air collector 1 .

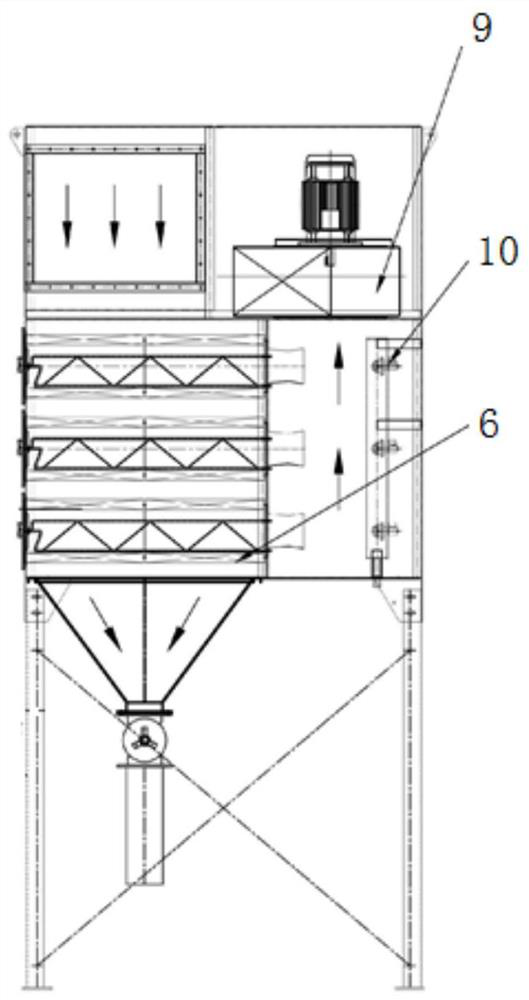

[0034] In this embodiment, the filter cartridge dust collector 2 includes a frame 4, a dust removal box 5 arranged on the frame 4, and a filter cartridge 6 arranged in the dust removal box 5, and the dust removal box The lower end of 5 is provided with ash hopper 7, and said ash hopper 7 is connected with negative pressure pneumatic ash conveying...

Embodiment 2

[0044] The overall working principle of the air purification system is described as follows:

[0045] The dust-laden smoke rises to the ventilation floor at the top of the production workshop. Due to the buoyancy of the gas, the gas enters around the roof air collector 1. The roof air collector 1 is a sealed structure of steel plates on the outer side of the steel support. The inside of the roof air collector 1 is set The equalizing plate can evenly inhale the rising air into the interior of the roof air collector 1 to prevent the occurrence of inconsistency and deviation of the incoming air flow. Set up a row of RH / XE filter cartridge dust collector 2, the air inlet of RH / XE filter cartridge dust collector 2 is directly facing the side of roof air collector 1, without connecting pipes, greatly reducing system resistance, saving equipment investment, and because there is no need to consider dust The sedimentation effect can greatly reduce the air inlet speed of the RH / XE filte...

Embodiment 3

[0059] The technical description of RH / XE filter cartridge dust collector is as follows:

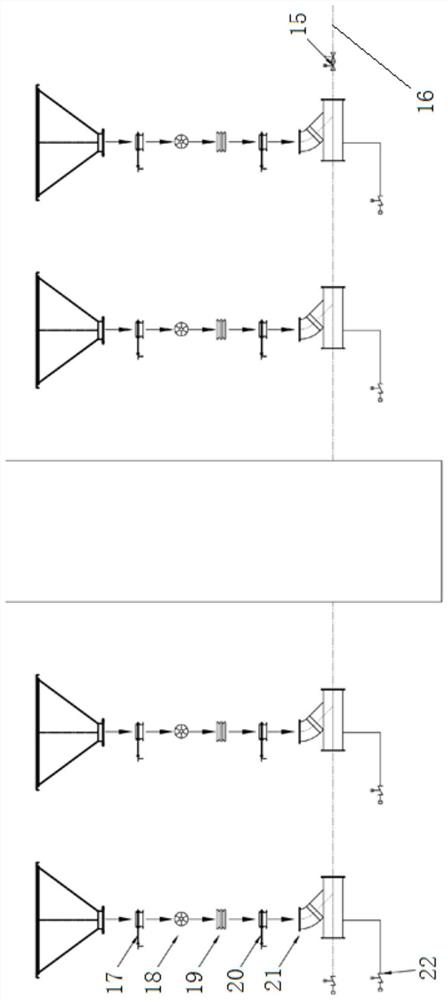

[0060] The RH / XE type filter cartridge dust collector 2 is a specially improved and designed high-efficiency and low-resistance filter cartridge dust collector 2. The round filter cartridge 6 is used as the filter element. The equipment is small in size and comes with a centrifugal fan 9, which does not require In addition, it is equipped with a fan and an air outlet pipe, which further reduces the resistance of the entire purification system. The air inlet of the cartridge dust collector 2 is directly connected to the flue gas inlet, which is larger than the conventional dust collector. The air inlet speed is greatly reduced, and the air inlet resistance is also greatly increased. Reduced, the air flow reduces the washing of the filter cartridge 6, and the service life of the filter cartridge is prolonged. The ash hopper 7 of the filter cartridge dust collector 2 is connected to the neg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com