Socket pile molding device

A technology for forming equipment and socket piles, which can be used in drilling equipment, sheet pile walls, and driving devices for drilling in boreholes, etc., and can solve the problems of inability to make cement-soil socket piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

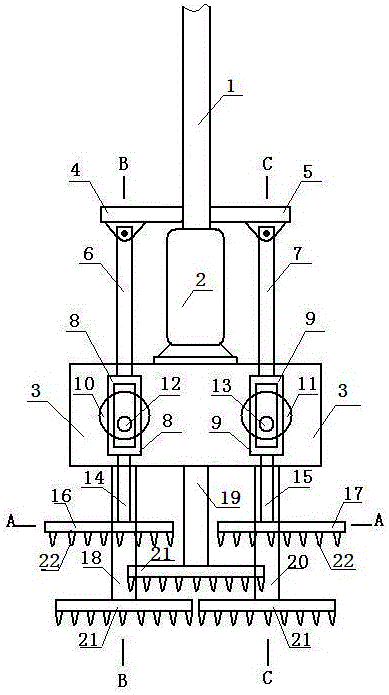

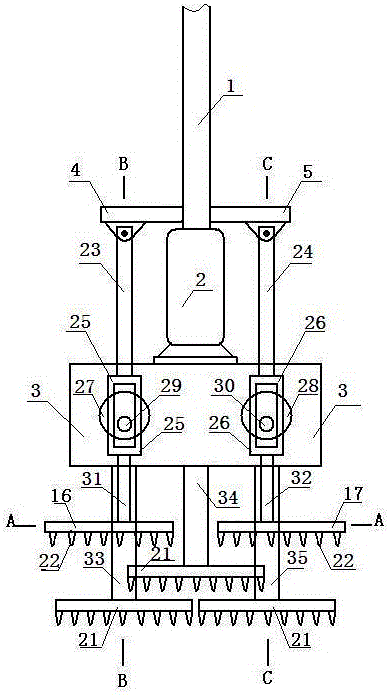

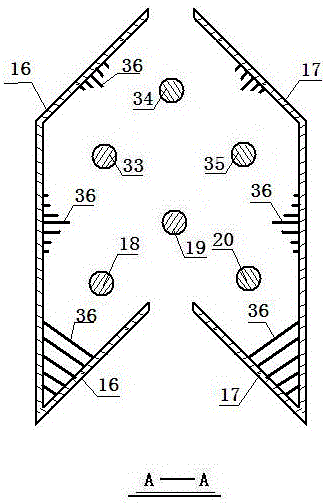

[0016] Accompanying drawing is a kind of specific embodiment of the present invention, and the lower end of drilling rod 1 of this embodiment fixes the upper end of motor 2, and the lower end of motor is equipped with driver 3, and the lower end of driver is provided with stirring rod one 18, stirring rod two 19, stirring rod three 20 , stirring rod four 33, stirring rod five 34, stirring rod six 35, the six stirring rods are divided into three rows of left, middle and right, the upper part of the middle row is stirring rod five, the lower part is stirring rod two, and the upper part of the left row is stirring rod four 1. The lower part is stirring rod one, the upper part of the right row is stirring rod six, and the lower part is stirring rod three. The left part of the front is provided with a dial 10, dial 1 eccentrically fixes the dial arm 12, dial arm 1 is inserted in the square frame 8, and the upper end of the square frame 1 is fixed with the upper swing arm 6, the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com