Hydraulic pressure milling deep-mixing underground-wall machine

A hydraulic milling and deep stirring technology, applied to sheet pile walls, earth movers/excavators, construction, etc., can solve problems such as mechanical failures, poor sealing of sprockets and chains, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

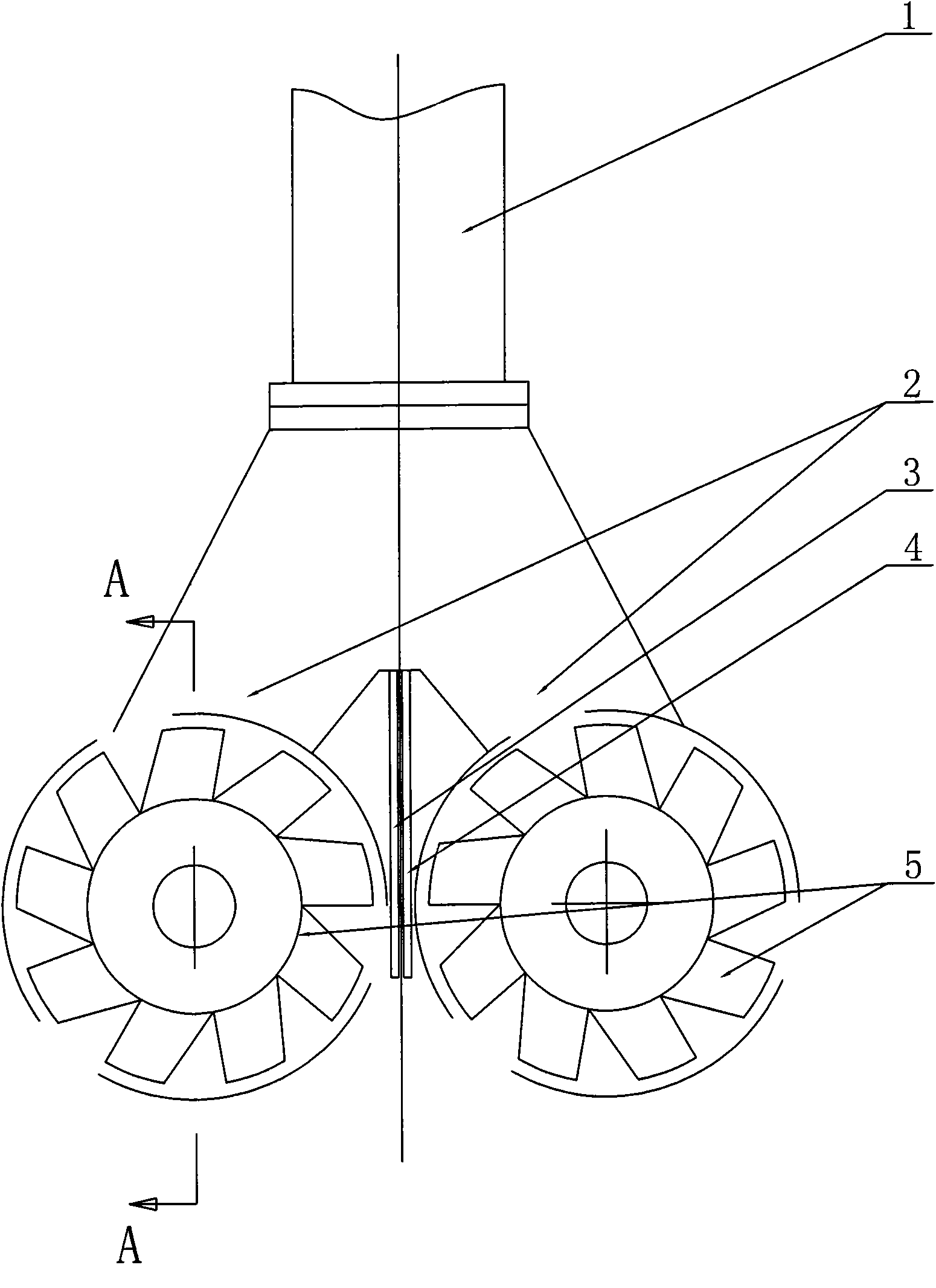

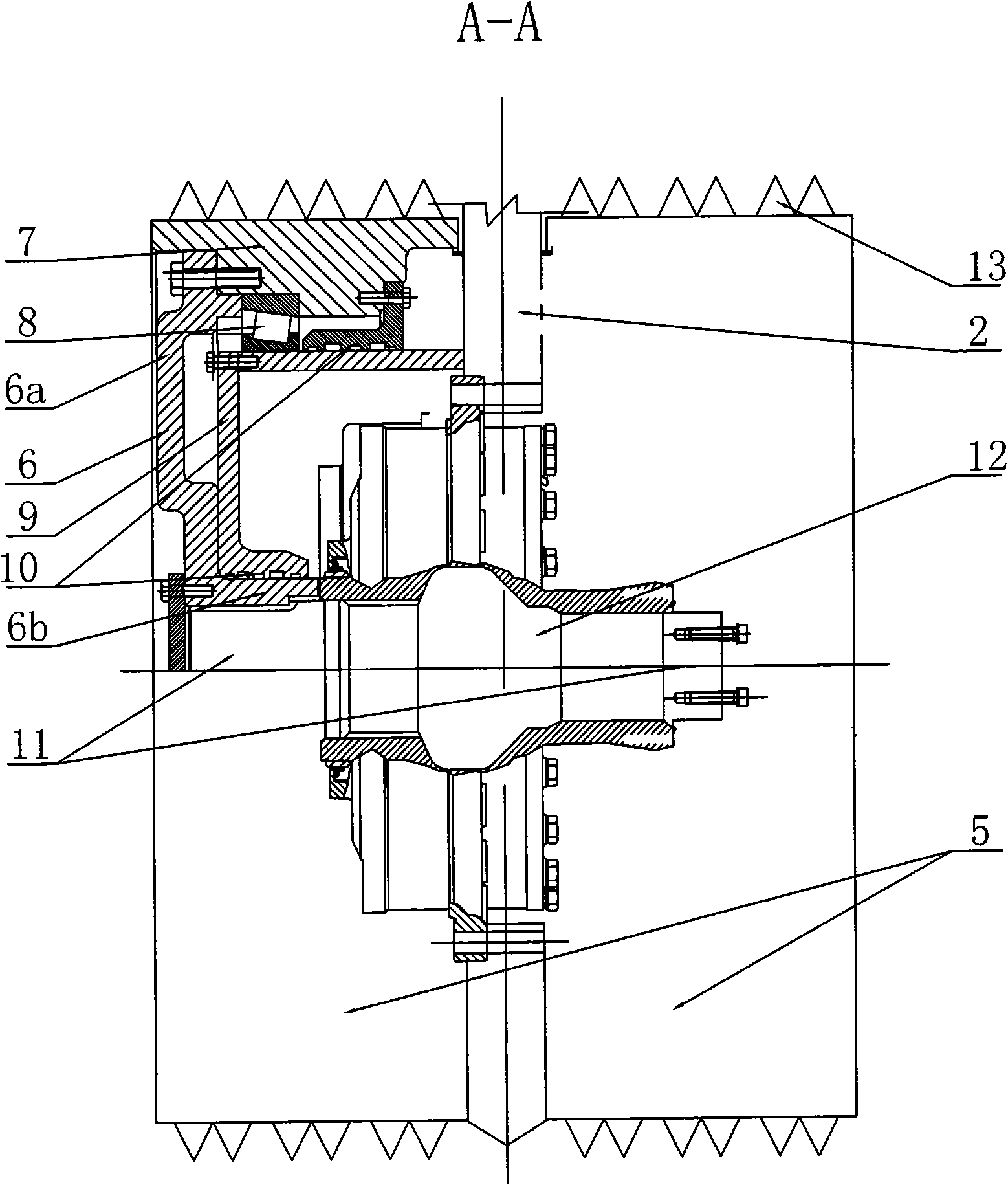

[0018] Such as figure 1 with 2 As shown, it is a hydraulic milling deep mixer, including an upright and hollow guide rod 1, the guide rod 1 can be a Kai-type square rod or a round rod, and the guide rod 1 is provided with a gas pipeline that runs through the guide rod 1 up and down 3 and the slurry pipeline 4, two fixed plates 2 are symmetrically arranged at the lower end of the guide rod 1, and each fixed plate 2 is equipped with a group of sealed milling and digging mechanisms 5, and the sealed milling and digging mechanisms 5 include fixed plates 2 On the hydraulic motor 12, the inlet and outlet oil pipes of the hydraulic motor 12 are set in the guide rod 1; the output shaft 11 of the hydraulic motor 12 protrudes from both ends, and the two protruding ends are respectively equipped with a sealing cover 6, and the sealing cover 6 is set on the The axial section 6b on the output shaft 11 of the hydraulic motor 12 is integrally formed with the radial disk 6a extending radiall...

Embodiment 2

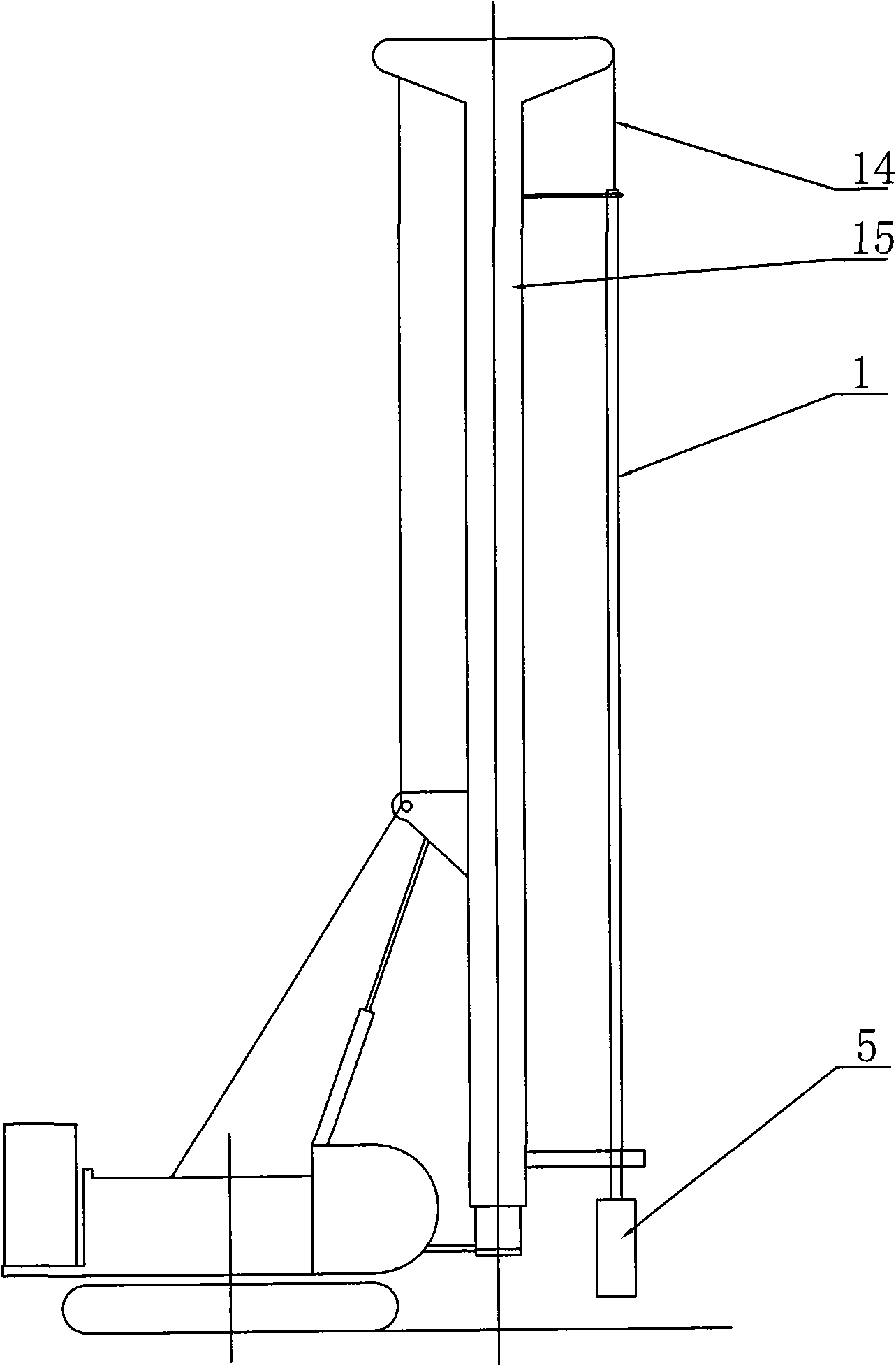

[0021] Such as Figure 4 As shown, the difference from Embodiment 1 is that two groups of sealed milling and digging mechanisms 5 are provided at different positions up and down on the fixed plate 2 on the left and right sides. The mixing effect can be strengthened, so that the constructed underground continuous wall is more uniform, and the strength and material tend to be consistent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com