H-shaped mixing pile equipment

A technology of mixing piles and equipment, which is applied in the direction of sheet pile walls, buildings, foundation structure engineering, etc., and can solve problems such as the inability to form H-shaped mixing piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

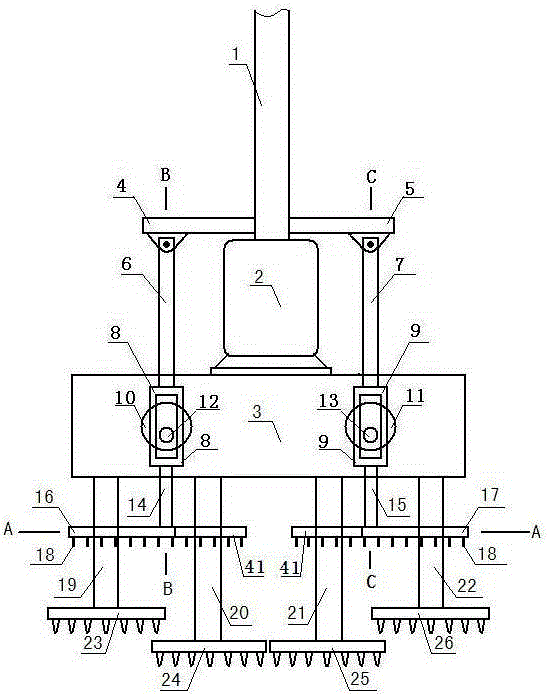

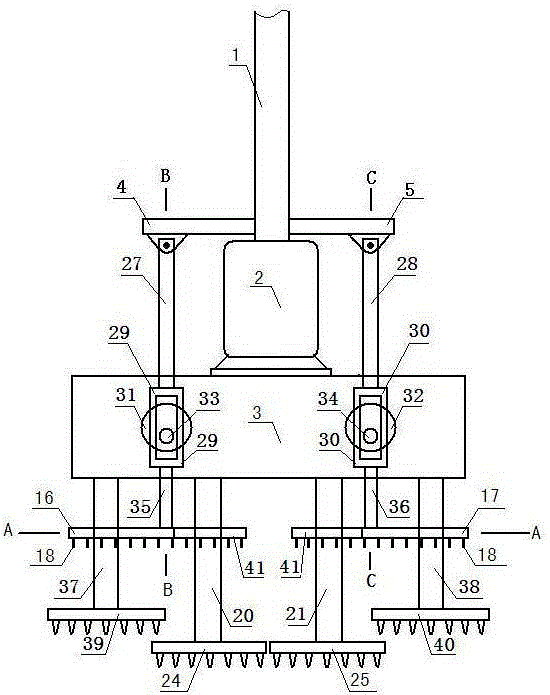

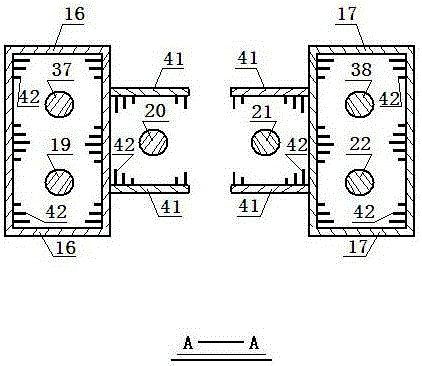

[0015] Accompanying drawing is a kind of specific embodiment of the present invention, and the lower end of main pole 1 of this embodiment is fixed motor 2 upper end, and motor lower end is provided with driving box 3, and the lower end of driving box outputs agitating shaft one 19, agitating shaft two 20, agitating shaft three 21 , stirring shaft four 22, stirring shaft five 37, stirring shaft six 38, the stirring shaft lower end is provided with stirring drill bit 1 23, the stirring shaft 2 lower end is provided with stirring drill bit 2 24, the stirring shaft 3 lower end is provided with stirring drill bit 3 25, stirring Axle four lower ends are provided with stirring drill bit four 26, stirring shaft five lower ends are provided with stirring drill bit five 39, and stirring shaft six lower ends are provided with stirring drill bit six 40; the right end of cross bar one and the left end of cross bar two are respectively fixed on main rod; The front left part of the case is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com