Well casing installation and removal apparatus and method

a well casing and adapter technology, applied in the direction of manufacturing tools, sealing/packing, borehole/well accessories, etc., can solve the problem that the aforedescribed hammer drill cannot be used to apply upwardly directed hammering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The present invention is concerned with improvements in a well drilling machine of the type having an above-ground mast or tower with a topdrive rotary head or rotary-table drive capable of sinking a well casing and feeding and retracting a downhole drill and a method for utilizing such apparatus to install or remove well casing or the like.

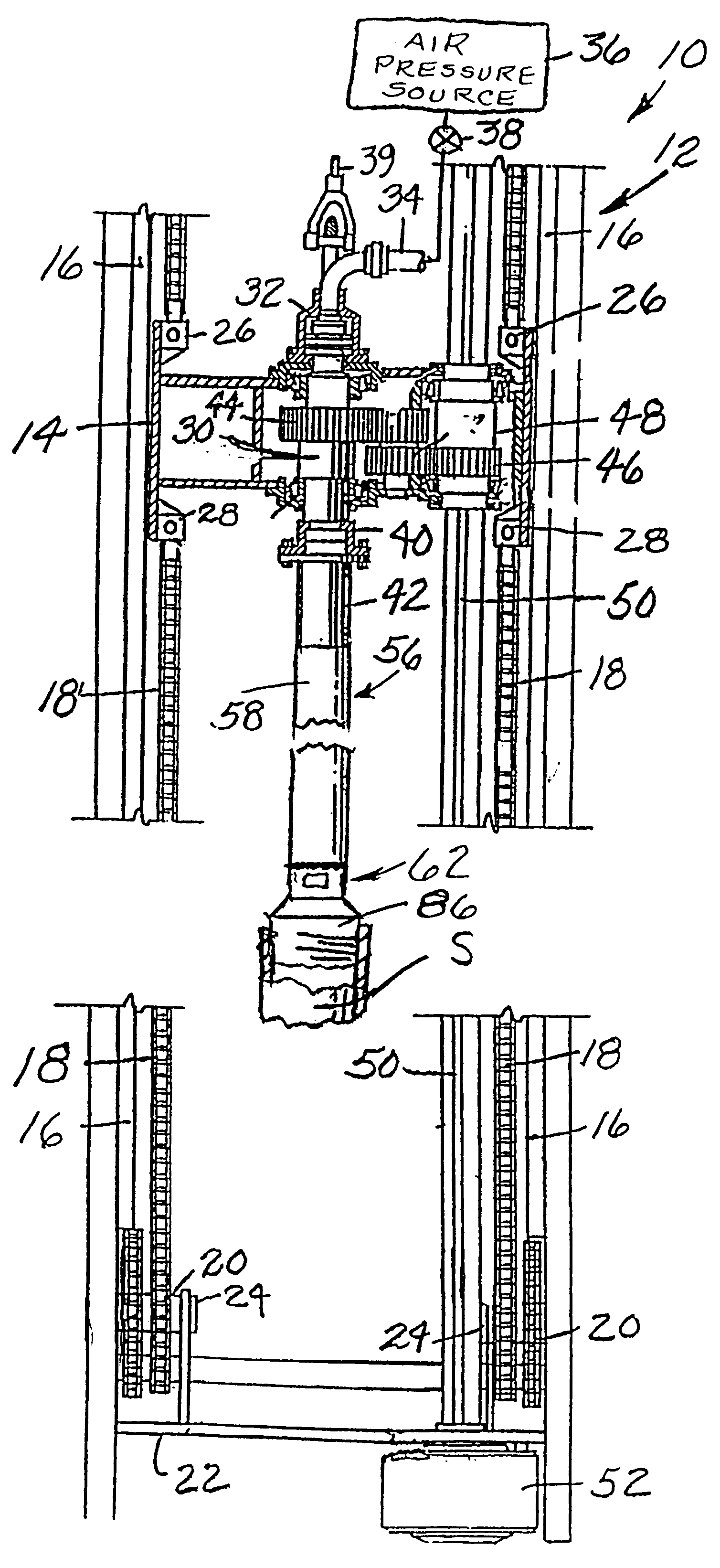

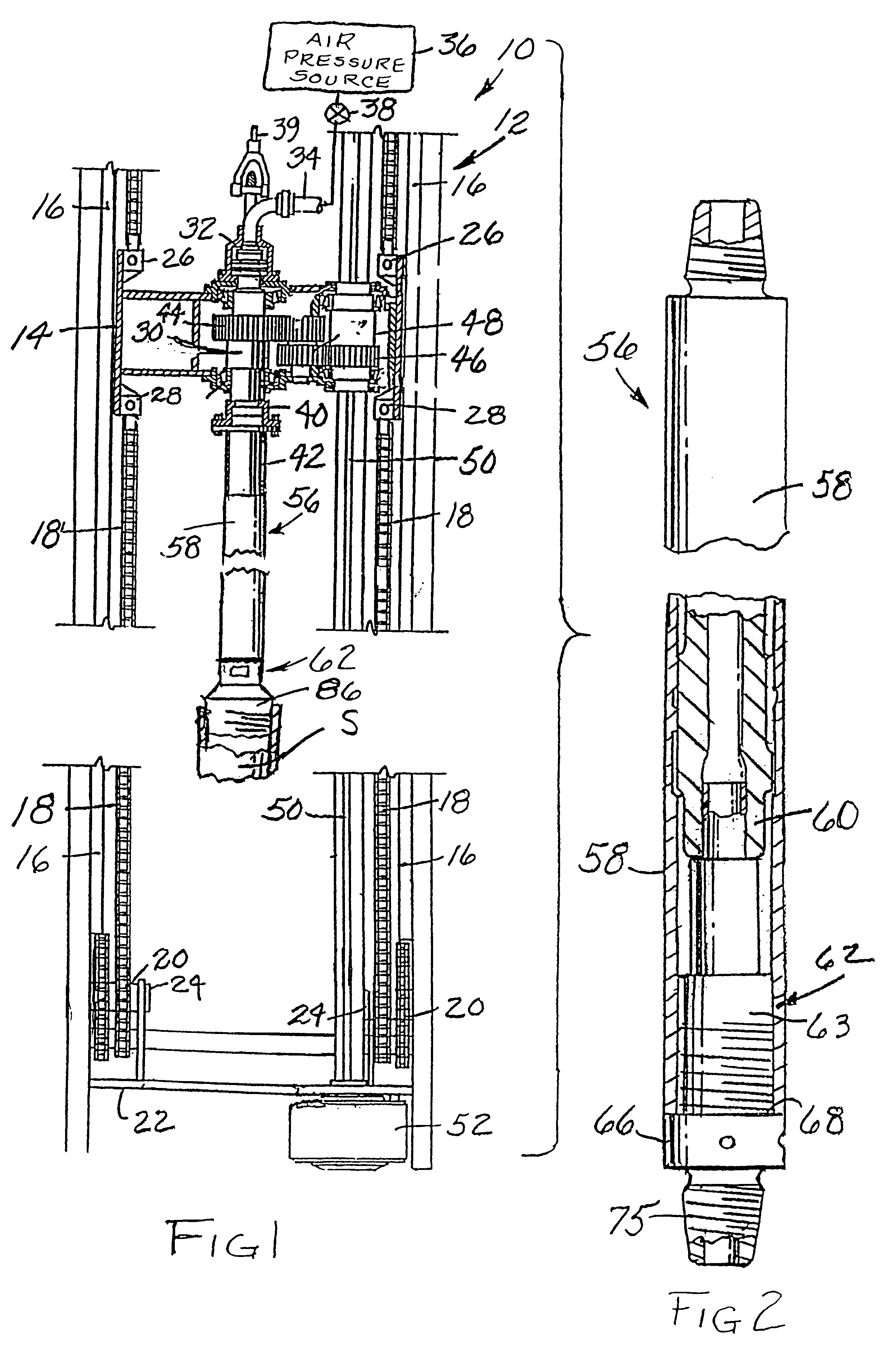

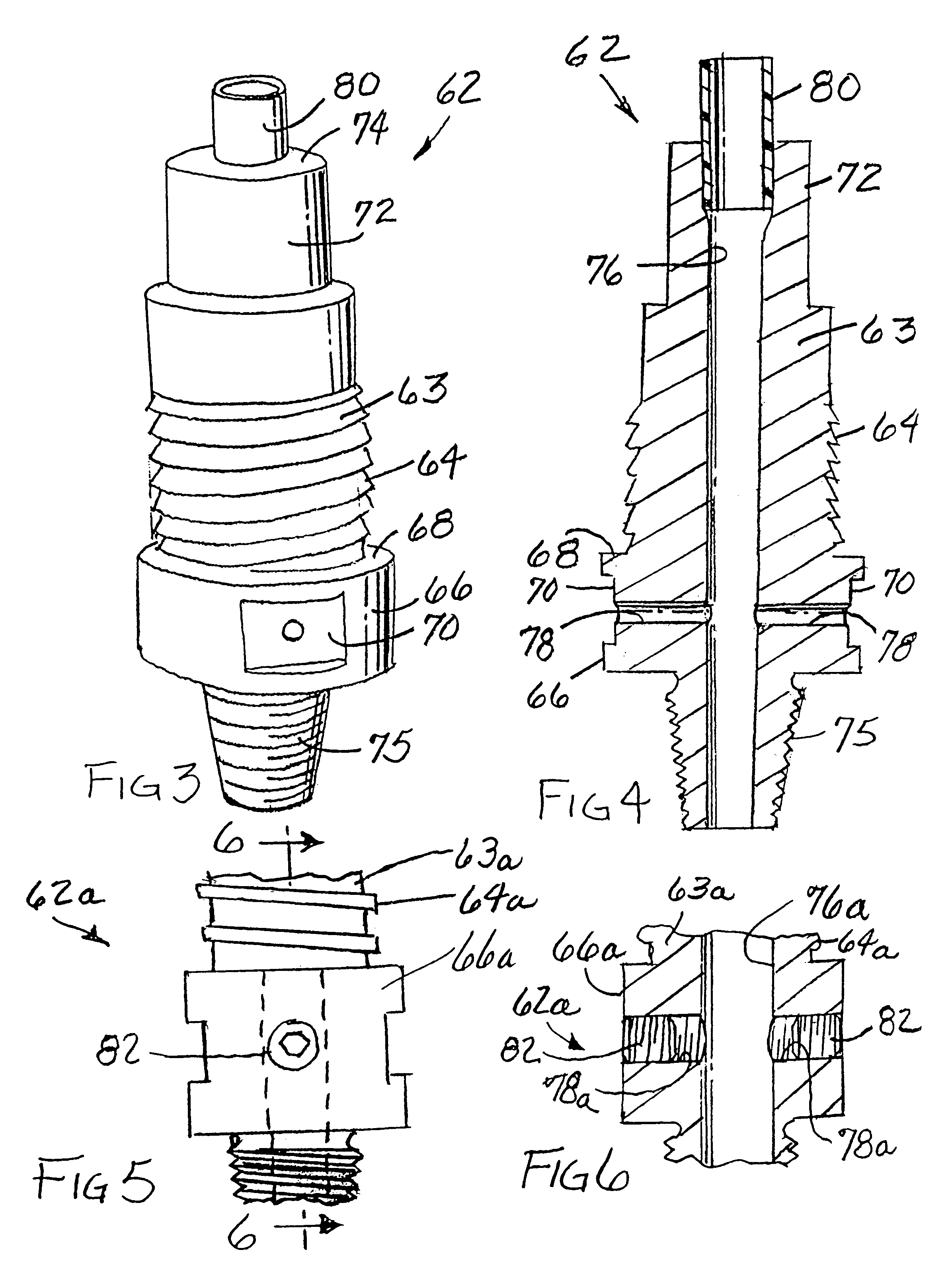

In the drawings and in the description which follows the invention is illustrated and described with reference to an above-ground portion of a drilling machine of the aforedescribed type indicated generally by the numeral 10. The illustrated apparatus 10, shown in FIG. 1, includes a mast or tower indicated generally at 12 and having a traveling head or transmission 14 slideably guided for up and down travel along horizontally opposed and vertically extending guide ways 16, 16 mounted at opposite sides of the mast 12. The traveling head 14 is raised and lowered on the guides by chains 18, 18 which comprise part of a hoisting mechanism and operate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com