Detection device for rotation torque of hot assembly gear

An inspection device and thermal assembly technology, which can be used to measure the direction of torque/torsional force during tightening, can solve the problems of engine failure, failure to detect gear rotation torque, and inspection device literature reports on thermal assembly gear rotation torque, etc., to achieve structural Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

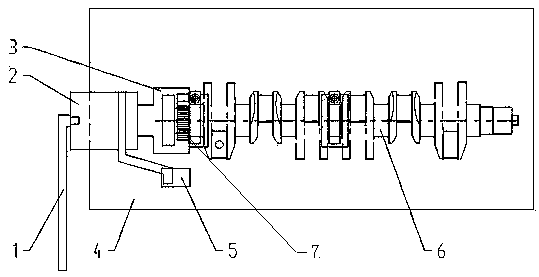

[0009] Such as figure 1 As shown, a thermally assembled gear rotation torque testing device includes a torque wrench 1, a torque multiplier 2, a torsion sleeve 3, and a workpiece to be tested. The workpiece to be inspected is composed of a crankshaft 6 and a gear 7, which are installed on the crankshaft assembly platform 4, and the torsion sleeve 3 is fixed on the gear 7 at the rear end of the crankshaft 6 through an internal gear; the torque multiplier 2 is installed on the torsion sleeve 3; the torque Wrench 1 is installed on the torque multiplier 2.

[0010] The crankshaft assembly platform 4 is also provided with a torque multiplier support seat 5 . Torque multiplier support seat 5 plays the role of auxiliary supporting torque multiplier.

[0011] When the present invention is used, after the torque wrench 1 is set to a certain torque, force is applied to the torque wrench 1 . If the torsion sleeve 3 drives the gear 7 to rotate, the torque value set by the torque wrench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com