Stop device of engine rotor and stator tightened part and use method of stop device of engine rotor and stator tightened part

A technology of a stopper and an engine, applied in metal processing, metal processing equipment, hand-held tools, etc., can solve the problem that the rotating body cannot be tightened with limited force, achieve major social and economic benefits, reduce labor intensity, and reduce assembly. effect of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

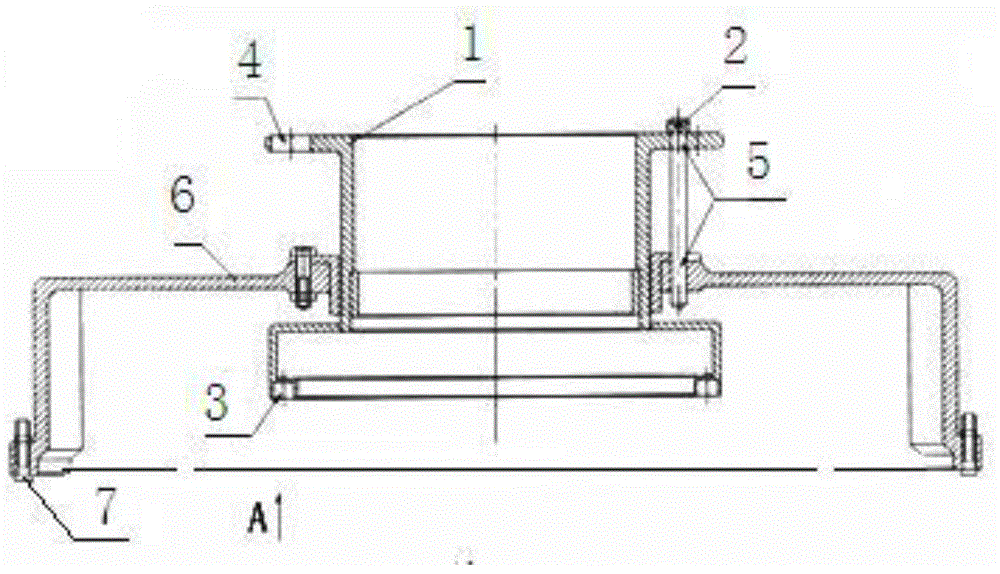

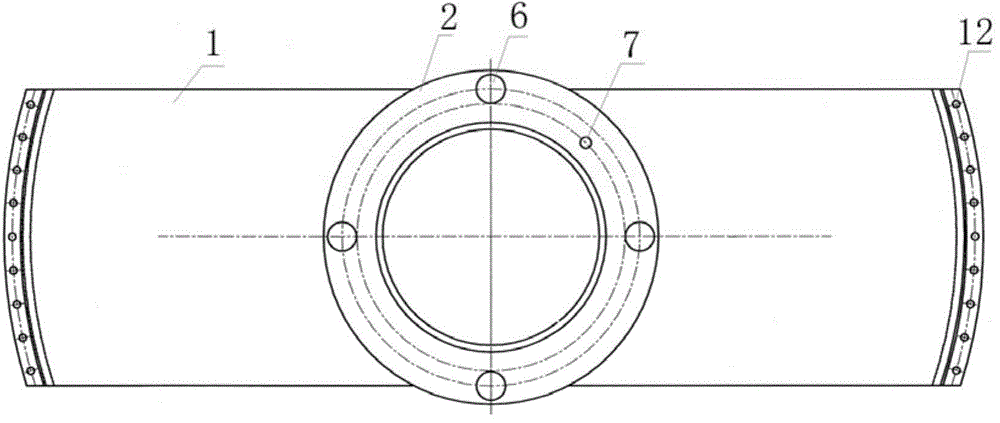

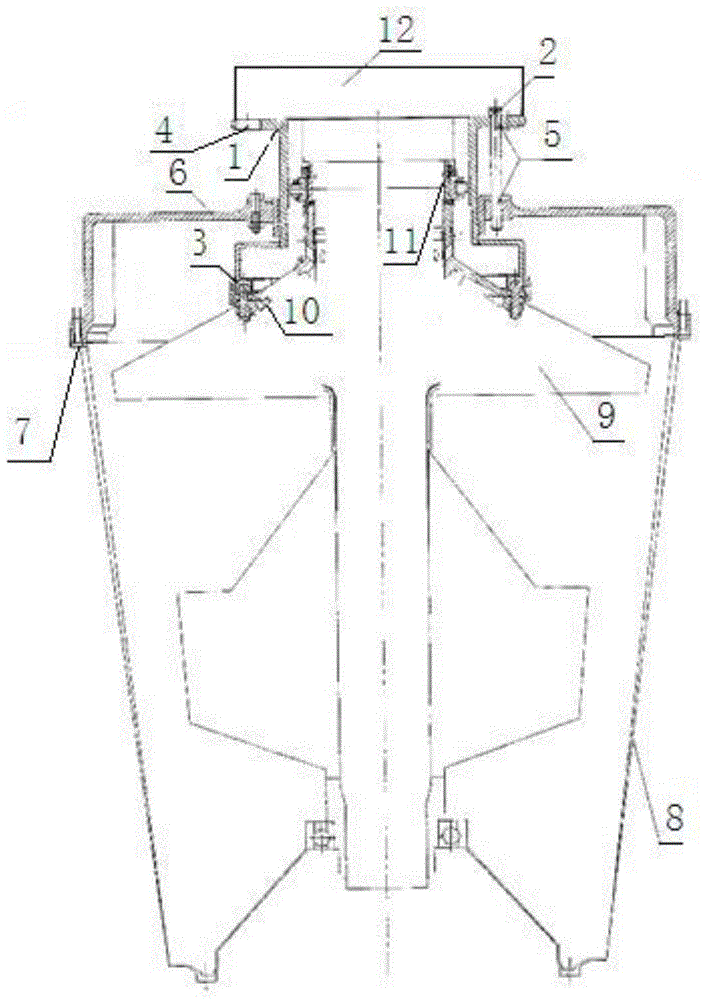

[0019] like Figure 1-4 As shown, a stop device for engine rotor and stator tightening parts, the device includes a process stator casing 1, a rotor stop sleeve 2 and a stop pin 3, and the rotor stop sleeve 2 is installed on the process stator machine In the middle of the box 1, the rotor stopper 2 and the process stator casing 1 can rotate with each other; the process stator case 1 is used to connect the engine stator case 4; the rotor stopper 2 is provided with an upper Mounting edge and lower mounting edge, described upper mounting edge is provided with hole one 5, and described lower mounting edge is provided with hole two 6, and pin hole one 7 is also set on the described upper mounting edge, and described hole two 6 is used for connecting with the engine rotor The bolts 9 on the 8 are installed in cooperation to realize the connection between the rotor stop sleeve 2 and the engine rotor 8; the pin hole 10 is set on the process stator casing 1, and the stop pin 3 can be i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com