Verification instrument of torque multiplier

A torque multiplier and calibrator technology, which is applied in the direction of instruments, force/torque/power measuring instrument calibration/testing, measuring devices, etc., can solve the problems of low accuracy of detection results, large influence of human factors, and inaccurate measurement indications and other problems to achieve the effect of simple structure, good versatility and accurate measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

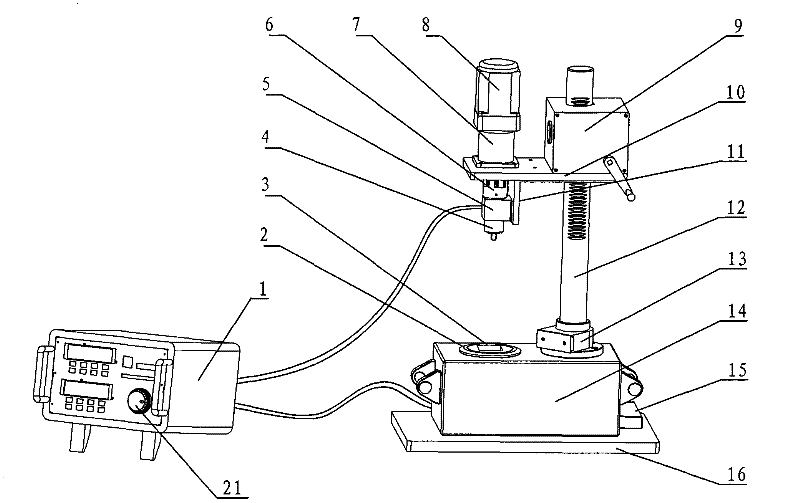

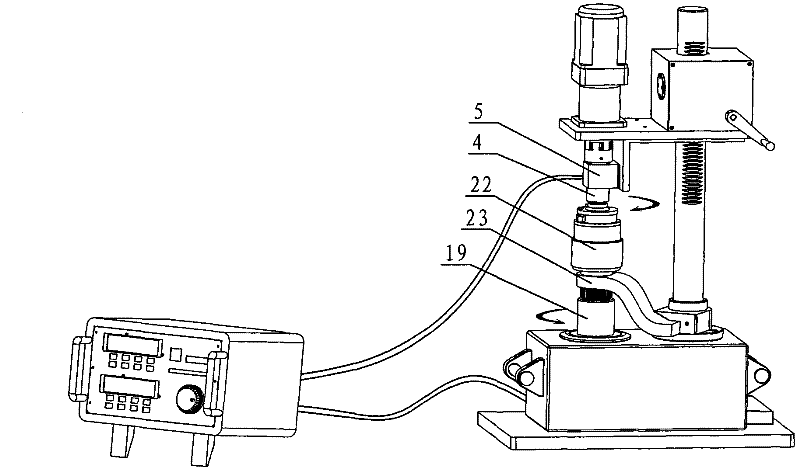

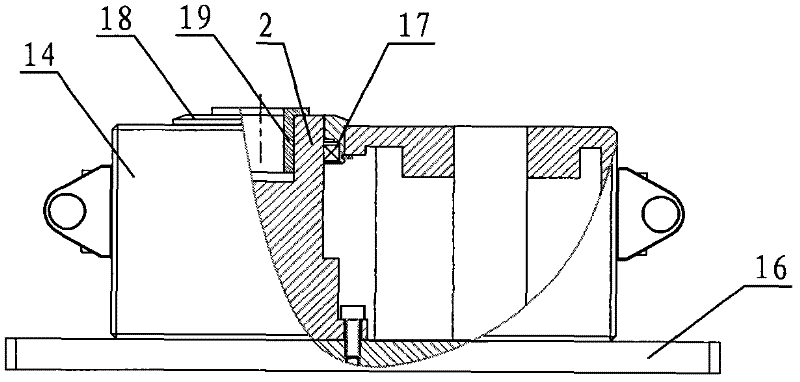

[0014] Such as figure 1 , image 3 and Figure 4 As shown, the torque multiplier calibration instrument of the present invention is mainly composed of a base 16, a torque output sensor 2 installed on the base 16, a guide post 12 fixed on the base 16, a lifting mechanism installed on the guide post 12, and a horizontal The support plate 10 is composed of a torque input assembly fixedly installed on the lifting mechanism and an additional numerical control digital display 1 . A support block 13 for limiting the torque multiplier reaction arm 23 is installed at the position below the guide post 12; the lifting mechanism is a worm gear assembly box 9, and a rocker arm for manipulating its height displacement is installed outside the box body, and the support plate 10 is fixed Installed on the bottom surface of the worm gear assembly box 9; the torque input assembly is compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com