Multifunctional calibrating and loading device for torque multiplier

A technology of torque multiplier and loading device, which is applied in measuring devices, calibration/testing of force/torque/power measuring instruments, instruments, etc., and can solve problems such as inability to realize torque measuring instrument verification, small measurement range, and low measurement accuracy , to achieve the effect of large bending and torsional rigidity, large load range and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

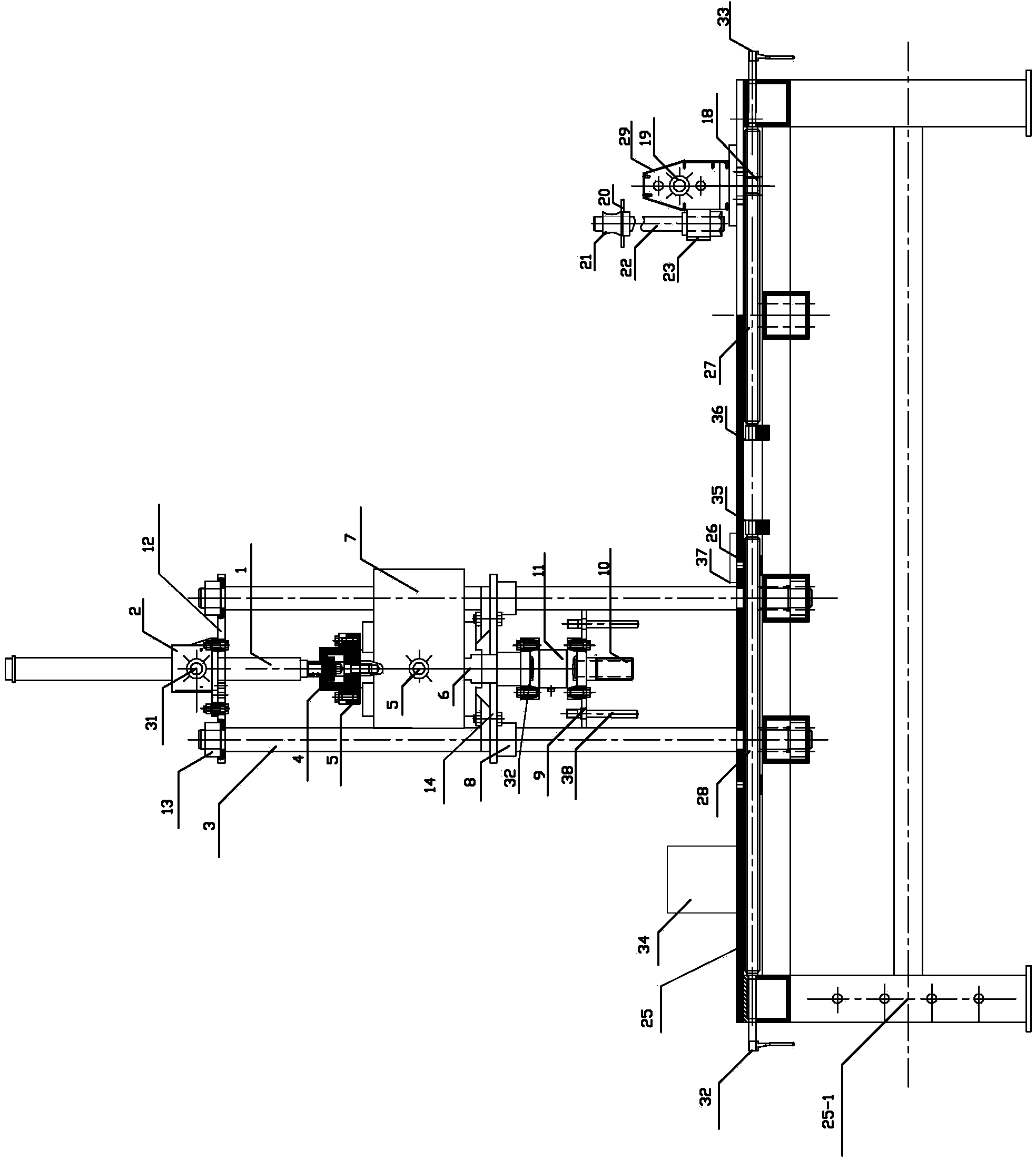

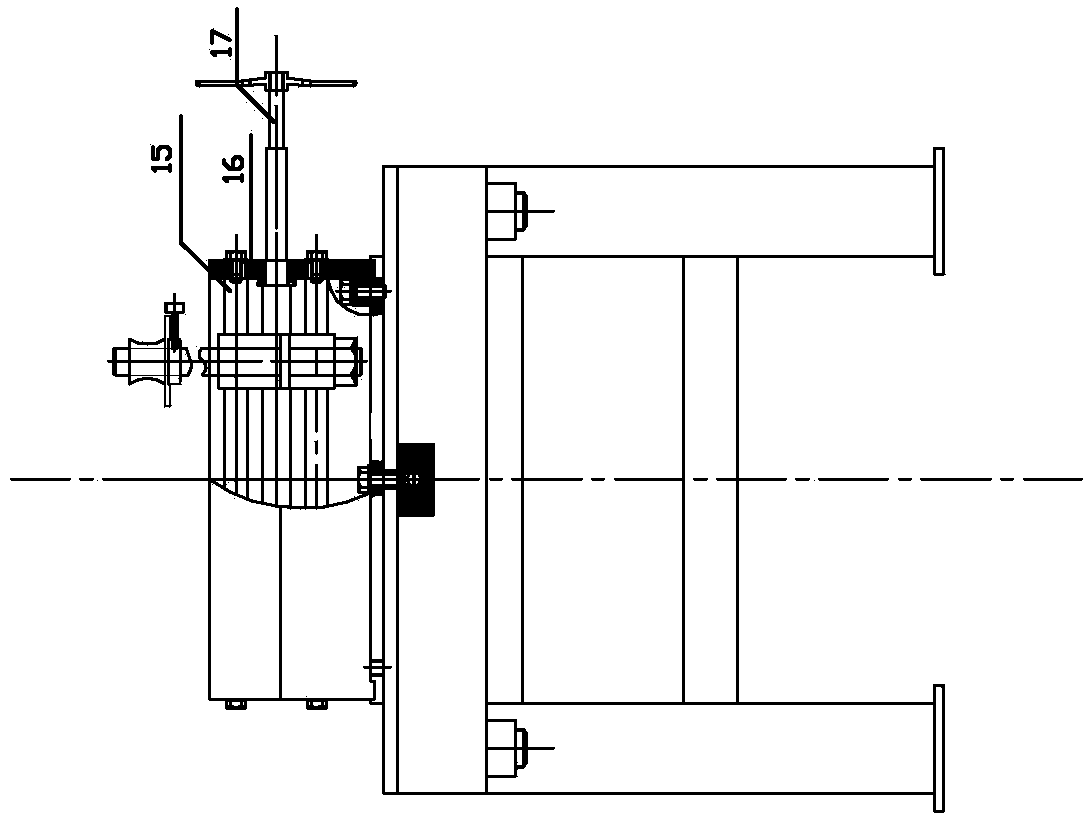

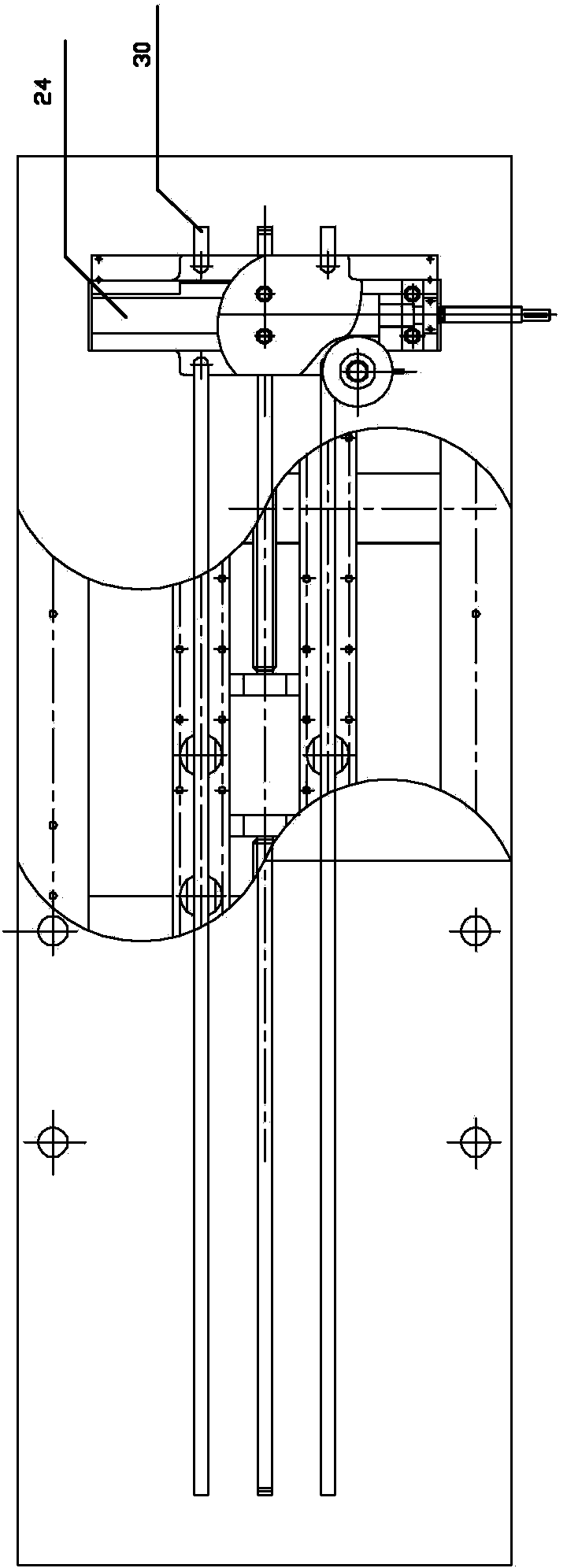

[0012] Specific implementation mode one: combine Figures 1 to 6 , a multifunctional torque multiplier calibration loading device described in this embodiment includes a pure torque loading subsystem, a lifting mechanism subsystem, a lead screw loading subsystem, a non-coaxial multiplier loading installation adjustment subsystem, and a loading platform system;

[0013] The pure torque loading subsystem includes a torque loading handle 5, a speed reducer 7, a speed reducer torque output shaft 6, a standard torque sensor and a flange connection 11, a coaxial loading spline 10 and a double arm loading assembly 9, all of which are Installed on the moving beam 14, the moving beam 14 moves up and down along the four columns 3 on the loading platform 25 through four copper guide sleeves 8; the handle 5 is used to apply a torque load (the loading method is to apply a small torque load through the handle 5 ), the torque load is amplified by 20 times through the reducer 7, the output to...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination Figures 1 to 5 The calibration loading device in this embodiment also includes a laser centering device subsystem 32. The laser centering device subsystem 32 is installed on the drive shaft 6 of the reducer, and its purpose is to accurately install the loading shaft system of the non-coaxial torque multiplier Location. The red laser is emitted by the laser to indicate the position of the torque load axis when installing a non-coaxial torque multiplier, improving the centering accuracy and ensuring the calibration accuracy of the torque. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0019] Embodiment 3: The coaxial loading spline 10 in this embodiment is a hollow shaft with external splines. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com