Waste and old rubber modified asphalt

A technology for modifying asphalt and waste rubber, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of high preparation cost and improved dispersion stability of rubber powder, and achieve the effect of solving the problem of dispersion stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

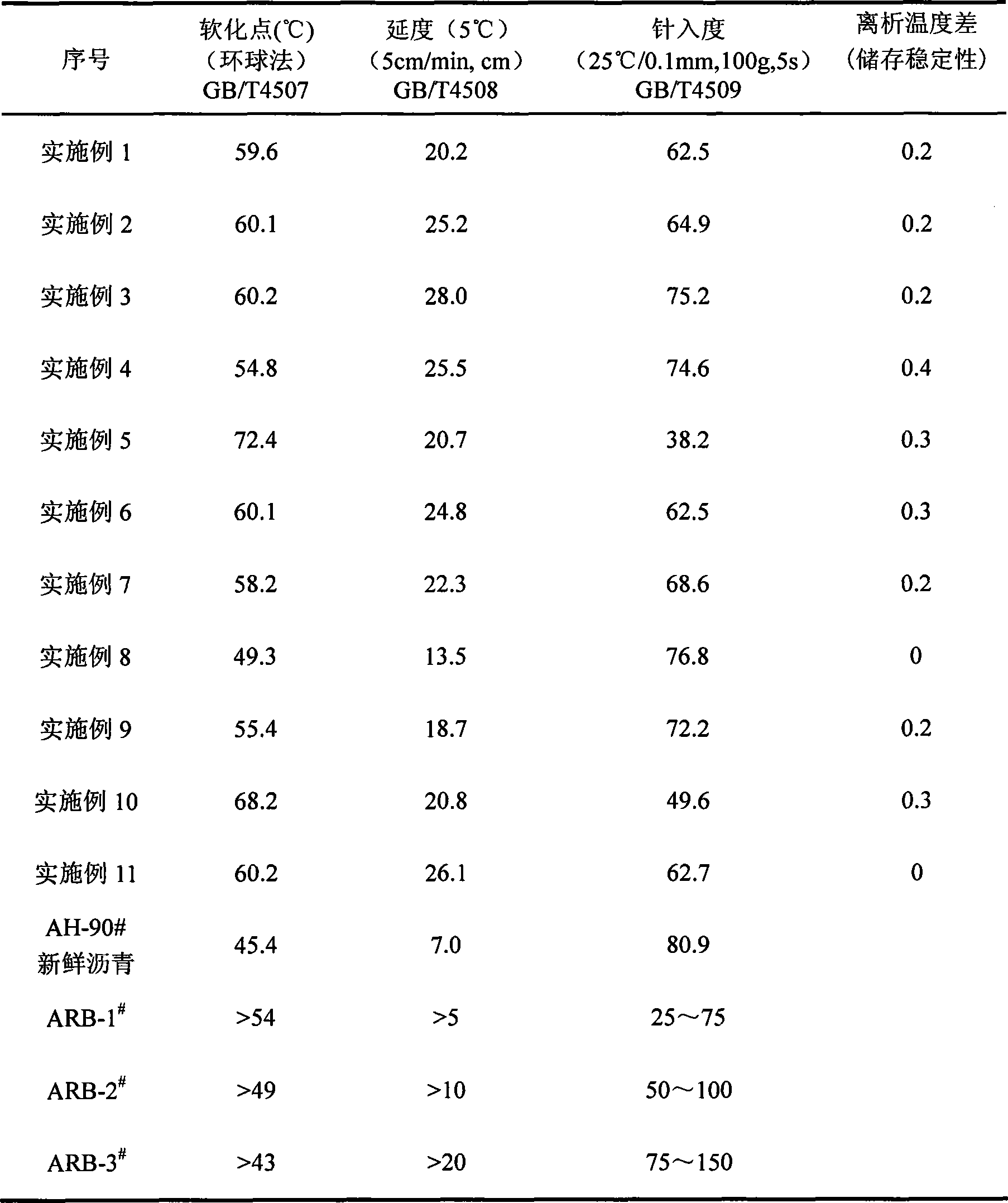

[0018] Mix 30wt% 20-mesh microwave desulfurized waste rubber powder (hereinafter referred to as desulfurized rubber powder), 69.99wt% AH-90# Zhenhai heavy traffic road asphalt, and 0.01wt% sulfur at 250°C for 0.5 hours Modified asphalt is obtained. Its performance is shown in Table 1.

Embodiment 2

[0020] Mix 20wt% 60-mesh microwave desulfurized rubber powder, 79.6wt% AH-90# Zhenhai heavy traffic road asphalt, and 0.4wt% sulfur at 175°C for 0.5 hours to prepare waste rubber powder modified asphalt. Its performance is shown in Table 1.

Embodiment 3

[0022] 20wt% 80 mesh microwave desulfurized rubber powder, 79.2wt% AH-90# Zhenhai heavy traffic road asphalt, 0.8wt% sulfur were stirred and mixed at 200°C for 1.0 hour to prepare waste rubber powder modified asphalt. Its performance is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com