A kind of sodium polyacrylate/nanocellulose crystal composite superabsorbent resin and its preparation method

A superabsorbent resin and nanocellulose technology, which is applied in the field of superabsorbent resin, can solve the problems that nanocellulose crystals cannot be uniformly and stably dispersed, bacterial cellulose whiskers are prone to agglomeration, and dispersion stability is not very good. , to achieve the effect of increasing the rate of water absorption or saline, easy implementation, and improved salt tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

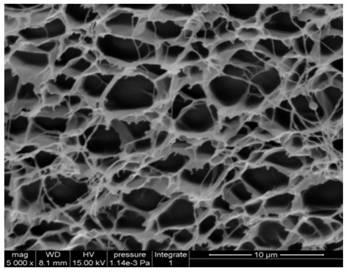

Image

Examples

Embodiment 1

[0026] 1. Preparation of nanocellulose crystals

[0027] Evenly disperse 7g of microcrystalline cellulose in 100mL of sulfuric acid with a mass concentration of 64%, then stir and react at 45°C for 1.5 hours; After repeated washing with water for 4 times, a paste is obtained, wherein the content of nanocellulose crystals is about 10 wt%.

[0028] 2. Preparation of nanocellulose crystal-g-polyacrylamide

[0029]Disperse an appropriate amount of the above-mentioned nanocellulose crystal paste in deionized water to obtain 100 mL of a solution with a concentration of 1% g / mL, and adjust the pH value of the solution to 2 with nitric acid; then pass nitrogen gas for 30 minutes to discharge the air, and add 0.33g of ammonium cerium nitrate, stirred for 10 minutes, then added 3g of acrylamide, and continued to react for 4 hours under nitrogen atmosphere. After the reaction is complete, put the product into a dialysis bag and dialyze to remove unreacted acrylamide and other substance...

Embodiment 2

[0034] 1. Preparation of nanocellulose crystals

[0035] The preparation of nanocellulose crystals in this example is the same as in Example 1.

[0036] 2. Preparation of nanocellulose crystal-g-polyacrylamide

[0037] The preparation of nanocellulose crystal-g-polyacrylamide in this example is the same as that in Example 1.

[0038] 3. Preparation of sodium polyacrylate / nanocellulose crystal composite superabsorbent resin

[0039] In an ice-water bath, 10 g of acrylic acid was neutralized to a neutralization degree of 60% with an aqueous solution of sodium hydroxide with a concentration of 20% g / mL, and after cooling, an appropriate amount of water was added, and the nanocellulose crystal-g-polymer Acrylamide solution, crosslinking agent N,N'-methylenebisacrylamide, photoinitiator 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone, and stir to form a homogeneous solution , so that the concentration of acrylic acid is 20% g / mL, the mass ratio of acrylic acid, nanocellulos...

Embodiment 3

[0042] 1. Preparation of nanocellulose crystals

[0043] The preparation of nanocellulose crystals in this example is the same as in Example 1.

[0044] 2. Preparation of nanocellulose crystal-g-polyacrylamide

[0045] The preparation of nanocellulose crystal-g-polyacrylamide in this example is the same as that in Example 1.

[0046] 3. Preparation of sodium polyacrylate / nanocellulose crystal composite superabsorbent resin

[0047] In an ice-water bath, 10 g of acrylic acid was neutralized to a neutralization degree of 60% with an aqueous solution of sodium hydroxide with a concentration of 20% g / mL, and after cooling, an appropriate amount of water was added, and the nanocellulose crystal-g-polymer Acrylamide solution, crosslinking agent N,N'-methylenebisacrylamide, photoinitiator 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone, and stir to form a homogeneous solution , so that the concentration of acrylic acid is 20% g / mL, the mass ratio of acrylic acid, nanocellulos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com