Preparation method of stable graphene aqueous dispersion liquid

A dispersion liquid and olefinic water-based technology, applied in the direction of graphene, chemical instruments and methods, nano-carbon, etc., can solve the problems of low utilization rate of graphene, poor dispersion of graphene, high cost, etc., and achieve excellent electrical and thermal conductivity, etc. Improves dispersion and stability, uniform sheet size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A kind of preparation method of stable graphene aqueous dispersion liquid of the present invention comprises the following concrete steps:

[0027] Step 1: Disperse the graphene powder into the organic co-solvent, and fully disperse the graphene powder in the organic co-solvent under ice bath conditions. The method of sufficient dispersion can be magnetic stirring, ultrasonic shearing or homogeneous dispersion One or more of them, for example, first use a magnetic stirrer to stir, the speed can be set at 500-2000rpm, and then use an ultrasonic device to ultrasonically shear, the optional ultrasonic power is 200-600W, and the ultrasonic duration can be 1-48h, or Use an ultrasonic homogenizer to disperse; obtain a primary graphene dispersion after fully dispersing, preferably, the concentration of the primary graphene dispersion is controlled at 1-10000 μg / mL;

[0028] In the above step 1, the graphene powder can be one or more of mechanically exfoliated graphene, chemica...

Embodiment 1

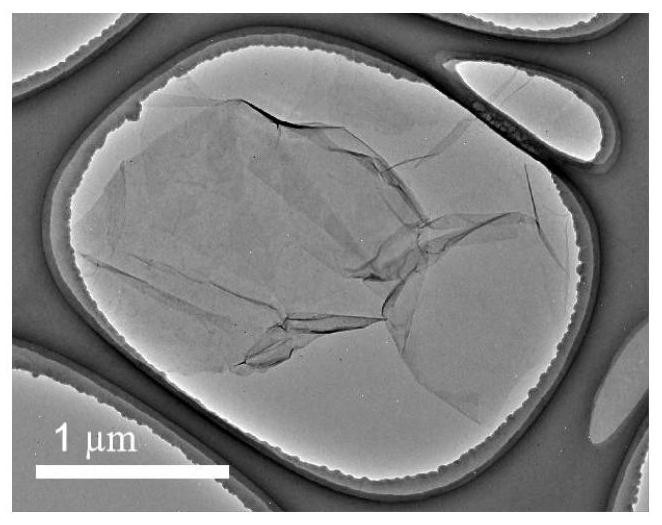

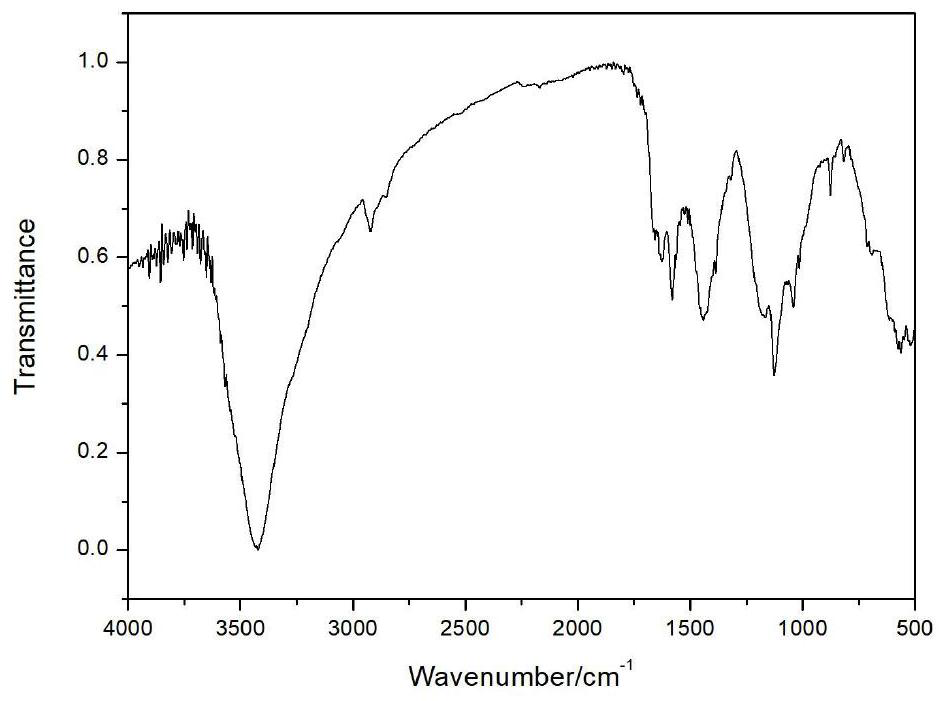

[0036] Weigh 10 g of expanded graphite and disperse it in N-methylpyrrolidone at 0.1 mg / ml, and at low temperature, sonicate for 4 h, centrifuge and vacuum-dry to obtain graphene powder (liquid-phase exfoliated graphene powder).

[0037] At room temperature, according to the ratio of adding 1ml of organic co-solvent per 7mg of graphene powder, add N-methylpyrrolidone, and disperse for 1h under ultrasonic conditions with a power of 200W. , rotating speed 7000rpm, disperse treatment for 2h; obtain a graphene dispersion liquid.

[0038] The primary graphene dispersion is separated from solid and liquid by means of suction filtration to obtain block graphene filter cake. Add deionized water according to the dispersion concentration of the graphene filter cake in water as 3mg / ml, and slowly add an appropriate amount of propanol under 600W ultrasonic conditions. When the viscosity of the dispersion is stable at 18-25mPa·s, continue ultrasonication for 2h to obtain Stable dispersed ...

Embodiment 2

[0040] Through the electrochemical exfoliation method, graphite paper is used as raw material, 0.1M ammonium sulfate solution is used as electrolyte, and the voltage is 10V. Electrochemical exfoliated graphene powder is obtained by electrolysis, washed with deionized water, and freeze-dried to obtain electrochemical exfoliated graphene powder. .

[0041] At room temperature, add N,N-dimethylformamide according to the ratio of 1ml of organic co-solvent per 8mg of graphene powder, stir magnetically for 2 hours, transfer to 200W ultrasonic power, and disperse for 3 hours to complete the preliminary dispersion. Under the condition of ice bath, set the ultrasonic power of the ultrasonic homogenizer to 600W, the rotational speed to 3000rpm, and disperse for 2h; obtain a graphene dispersion.

[0042] The primary graphene dispersion was centrifuged at 12000rpm for 30min to collect the bottom precipitate. The sample was transferred to an oven at 70 °C for 1 h to obtain a graphene filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com