Asphalt modifier granule composition and preparation method thereof

A kind of technology of asphalt modifier and composition, which is applied in the direction of building structure, building components, building insulation materials, etc., can solve the problems of no thermal storage stability data, no further explanation of the degree of improvement, etc., to prevent long-term Floats on the asphalt surface for a long time, prevents rubber powder dust from flying, improves low temperature performance and elastic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

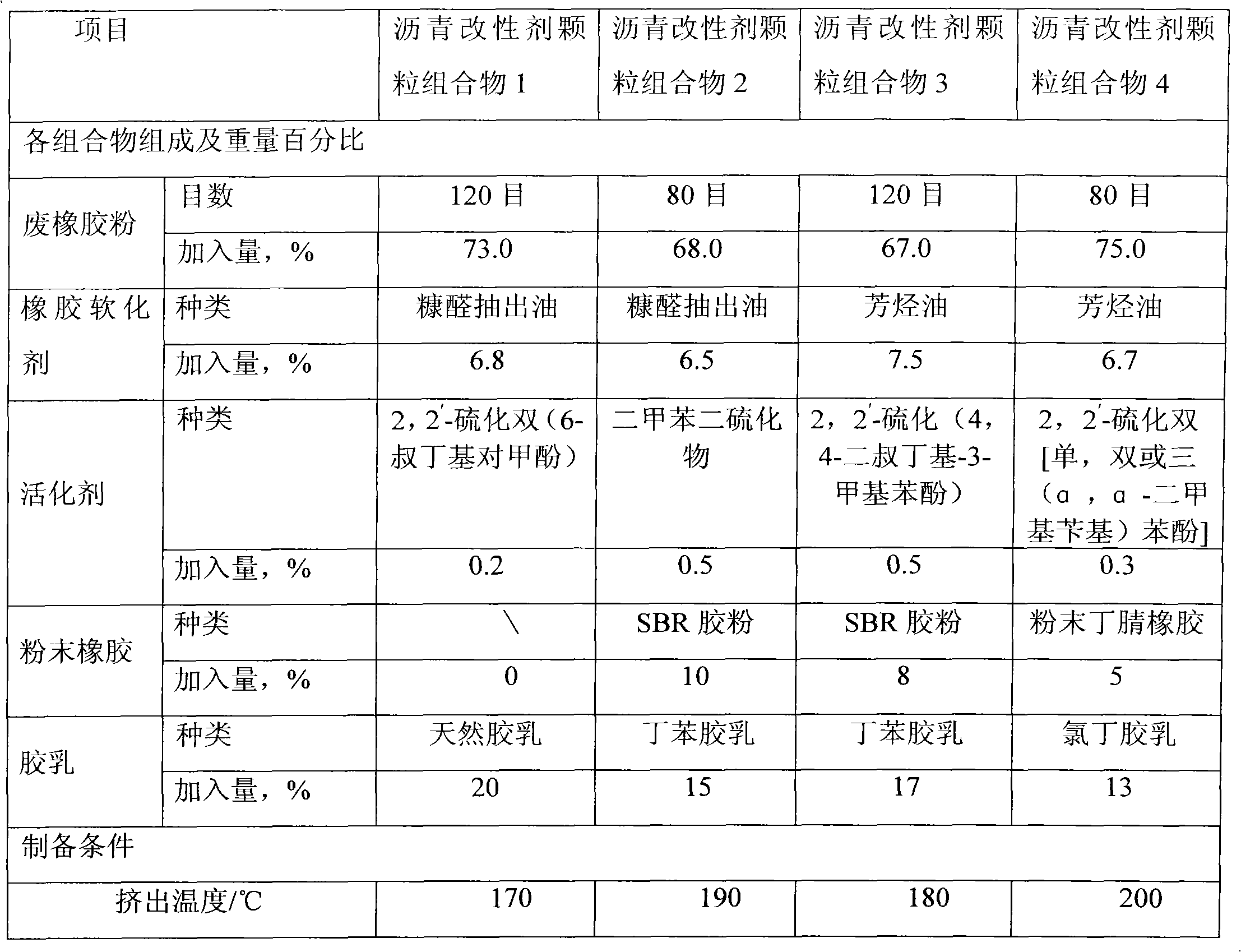

[0032] Examples 1 to 4 prepared bitumen modified particle composition 1, bitumen modified particle composition 2, bitumen modified particle composition 3 and bitumen modified particle composition 4 respectively.

[0033] The laboratory uses the SHJ-30 twin-screw compounding extruder manufactured by Lanzhou Lantai Plastic Machinery Engineering Co., Ltd. to prepare the asphalt modifier granule composition. The specific proportion and preparation conditions are shown in Table 1. The percentage of the added amount is the mass percentage.

[0034] Table 1 Composition and preparation conditions of two kinds of asphalt modifier granule compositions

[0035]

[0036] The asphalt modifier granule composition prepared in the example of the present invention is used in the preparation of modified asphalt, illustrating the advantages of the asphalt modifier granule of the present invention.

Embodiment 5~8

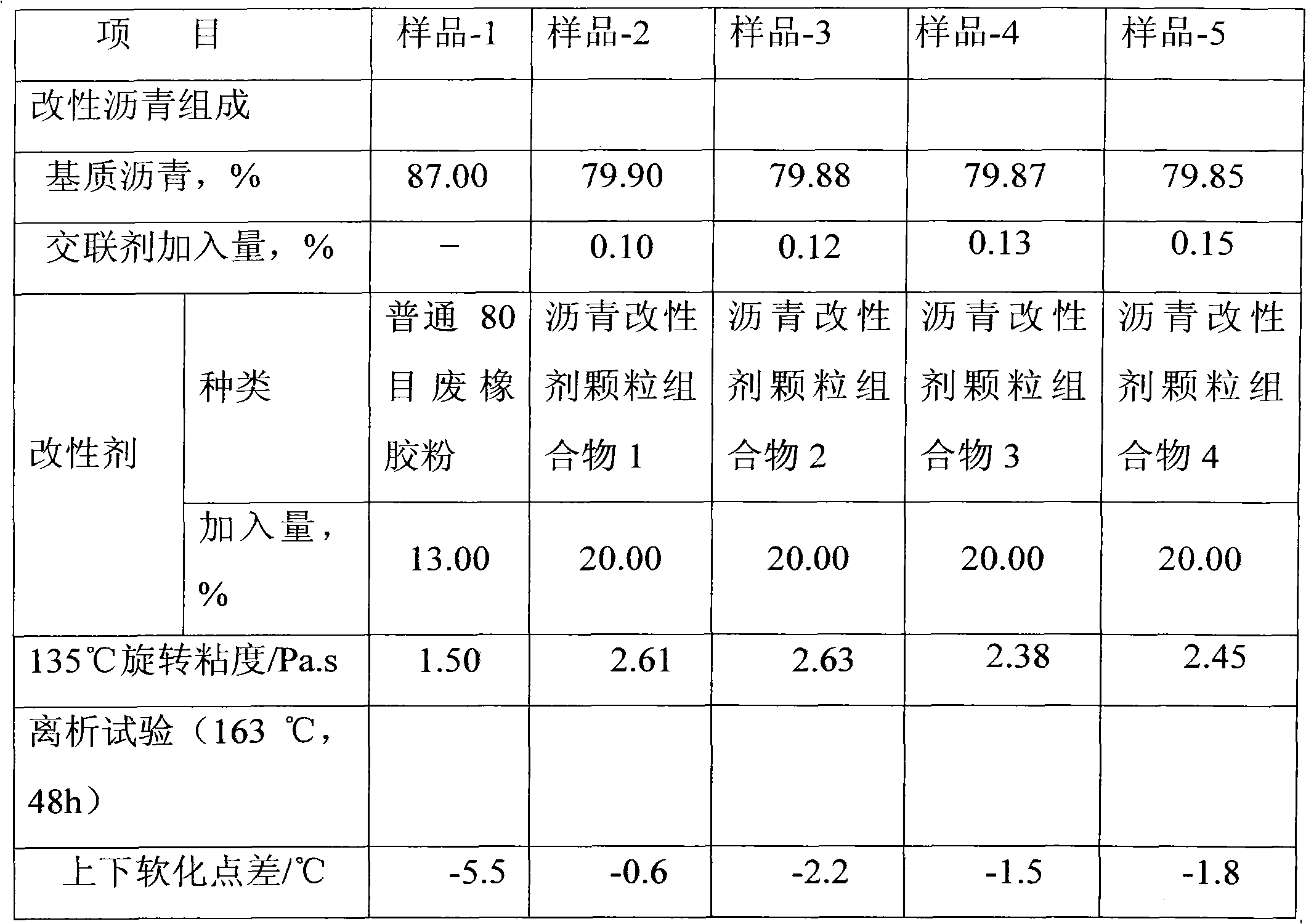

[0040] Heat Huanxiling No. 90 base asphalt to 170°C, slowly add bitumen modifier granule compositions 1 to 4 obtained in the examples of the present invention, and shear at 180°C for 30 minutes at high speed (4000 rpm), Add sulfur cross-linking agent and stir for 1.5 hours to obtain waste rubber powder modified asphalt sample-2, sample-3, sample-4 and sample-5 respectively.

[0041] The specific proportions and test results of Comparative Example 1 and Examples 5-8 are shown in Table 2, wherein the percentages of the compositions are percentages by mass.

[0042] Table 2 Segregation test results of waste rubber powder modified asphalt

[0043]

[0044] Note: (1) The thermal storage stability test of waste rubber powder modified asphalt refers to the thermal storage stability method of JTG F40-2004SBS polymer modified asphalt.

[0045]It can be seen from Table 2 that after using the asphalt modifier particles of the present invention, after heat storage at 163°C for 48 hour...

Embodiment 9

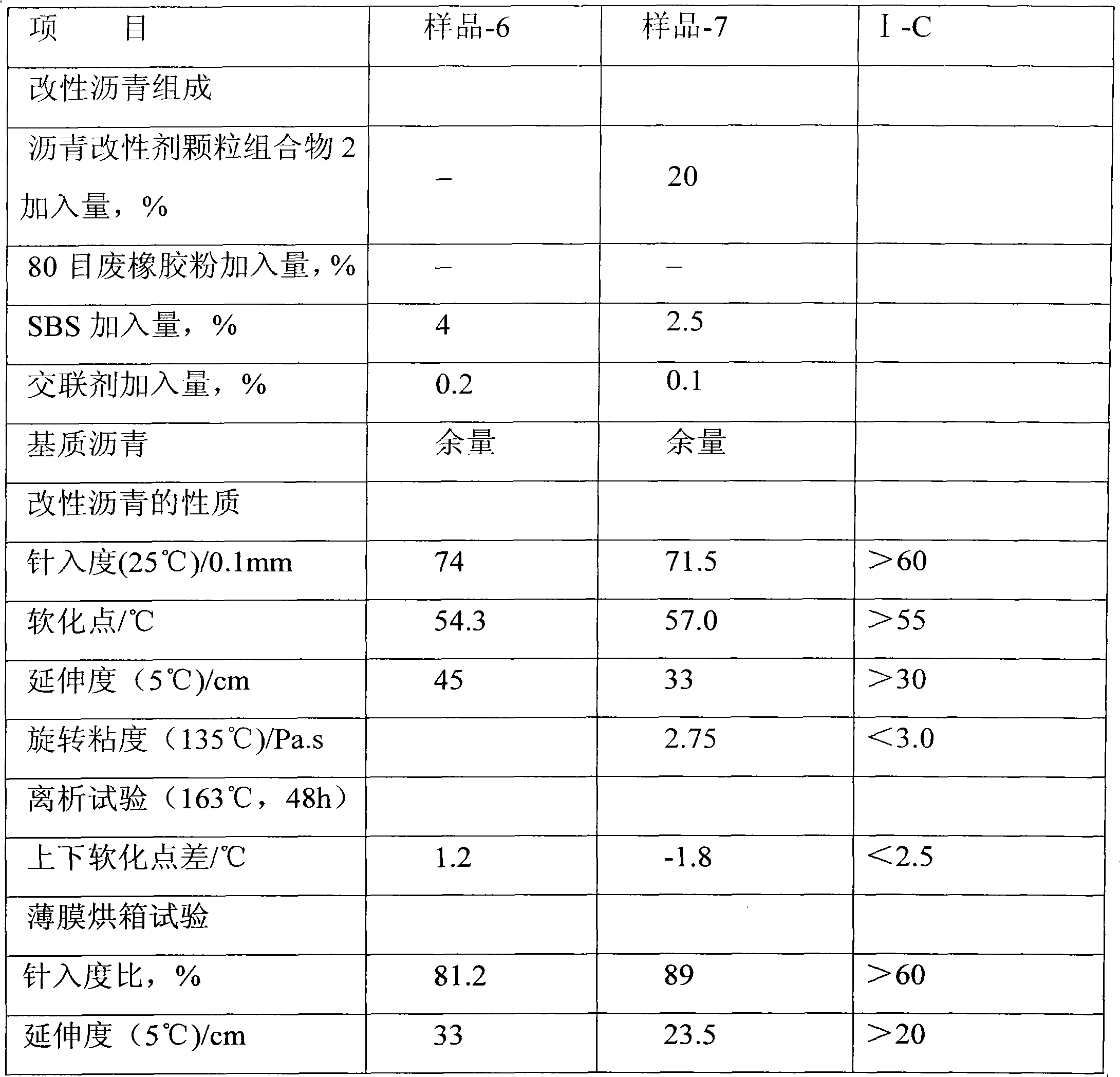

[0049] In this example, the asphalt modifier particles 2 of the present invention are compounded with an appropriate amount of SBS to modify the asphalt. The method is as follows: first, heat Huanxiling No. 90 base asphalt to 170°C, and slowly add the asphalt modifier particles 2 of the present invention. , at 180°C, high-speed shear (rotating speed 4000 rpm) for 30 minutes, then add 2.5% (weight) of SBS (YH-791, produced by Yueyang Petrochemical, linear structure, block ratio (styrene S: butadiene Alkene B)=30:70) and sulfur crosslinking agent for 30 minutes and stirred for 2.5 hours to obtain composite modified asphalt sample-7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com