Waste rubber powder modified asphalt composition and preparation method thereof

A technology of asphalt composition and modified asphalt, which is applied in building structures, building components, building thermal insulation materials, etc., can solve the problems of small processing capacity, environmental pollution, complicated spraying process of waste rubber powder, etc., so as to reduce side reactions. The incidence of , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The activation and grafting process of waste rubber powder in this embodiment.

[0035] The preparation process of activated waste rubber powder: dissolve 2 parts of potassium oleate and 1 part of sodium dodecylbenzenesulfonate in 100 parts of aqueous sodium hydroxide solution at 50±5°C and pH value of 10, stir well; then add Cut 40 parts of waste rubber powder at a speed of 2500-3000r / min for 60 minutes; dry the sheared emulsion in an oven at 60°C to obtain activated waste rubber powder, which is designated as rubber powder A.

[0036] The grafting process of activated waste rubber powder: Mix 90 parts of rubber powder A and 10 parts of polyethylene evenly and then add them to the twin-screw extruder. ℃, the intermediate temperature control point is between 90 and 110 ℃, the residence time is 2 minutes, and the extruded material is granulated. Then mix evenly with 2 parts of dithiotetramethylthiuram and 1 part of maleic anhydride and then add it to the twin-screw extr...

Embodiment 2

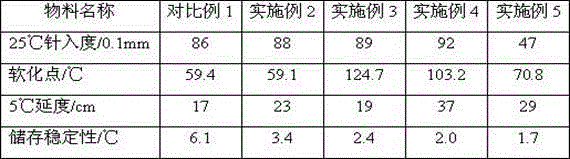

[0038] 564 grams (94%) of base asphalt with a penetration of 93 was heated and melted, and 36 grams (6%) of rubber powder A was added, and sheared at 170°C~175°C for 30 minutes to obtain waste rubber powder modified asphalt. The product properties are shown in Table 1.

Embodiment 3

[0040] 510 grams (59%) of base asphalt with a penetration of 197, after heating and melting, add 30 grams (15%) of aromatic oil, add 120 grams (20%) of rubber powder B, add 12 grams (5%) of polyethylene, add 6 grams (1%) of sulfur powder was sheared at 185°C to 190°C for 60 minutes to obtain waste rubber powder modified asphalt. The properties of the product are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com