Gelatine powder modified asphalt and processing method thereof

A technology of modified asphalt and processing method, which is applied in building components, building insulation materials, construction, etc. It can solve the problems of high raw material cost and limited crosslinking effect of additives, and achieve low production cost, ductility index and storage stability The effect of improving indicators and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] With 400 grams of base asphalt (penetration (25°C, 0.1mm) is 88, softening point is 47), first heated to 210°C (modification temperature); slowly add the screened 40 mesh waste rubber powder (100g), Shear and stir for 30 minutes (shear speed 2500rpm); Cool down to 180°C, then add the first crosslinking agent (2.5g, wherein the weight ratio of sulfur and natural asphalt is 1:1), the second crosslinking agent (5g) , keep the temperature constant, stir at high speed for 2 hours, and obtain modified asphalt after cooling.

[0043] Using ordinary rubber powder modified asphalt as a control, compared with this modified asphalt, the softening point increased from 57°C to 58°C, and the ductility at 5°C increased from 14.5cm to 31.0cm; after RTFOT (rotary film oven aging test) Finally, compared with the ordinary rubber powder modified asphalt, the softening point of the modified asphalt decreased from 4°C to 3°C, indicating that the stability of the rubber powder modified asphal...

Embodiment 2

[0044] Example 2. Comparison of the dispersion state of rubber powder in asphalt under different modification temperatures

[0045] Different modification temperatures have a relatively large impact on the performance of modified asphalt. Using the ratio of Example 1, two different modification temperatures were selected for comparison: A) First heat the base asphalt to 180°C, and then proceed to the next step Modification processing; B) First heat the base asphalt to 230°C, and then carry out the subsequent modification processing.

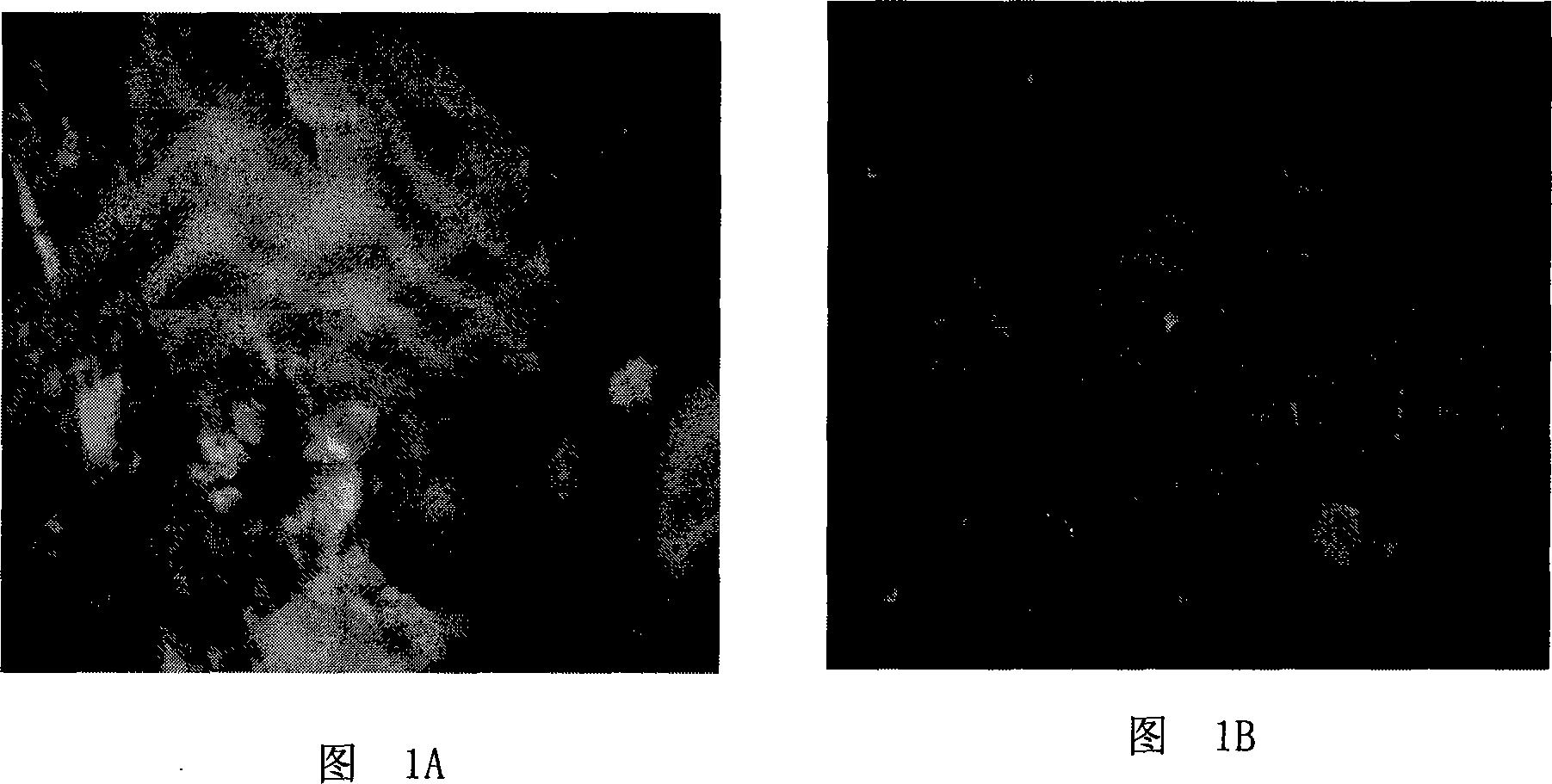

[0046]The microstructure of the modified asphalt was observed with a fluorescence microscope (Figure 1A shows the modified asphalt obtained at a modification temperature of 180 °C, and Figure 1B shows the modified asphalt obtained at a modification temperature of 230 °C). It can be seen from Figure 1 that at the modification temperature of 180°C, the rubber exists in larger blocks, and the asphalt has poor swelling ability on it; while at the mod...

Embodiment 3

[0048] 400 grams of base asphalt (penetration (25°C, 0.1mm) is 68, softening point is 49), first heated to 220°C; then slowly added 60 mesh waste rubber powder (95g) screened, sheared and stirred for 30 minute (shear speed 2500rpm); be cooled to 185 ℃, then add the first crosslinking agent (2.6g, wherein the weight ratio of sulfur and natural asphalt is 1: 0.5), 2% second crosslinking agent (10g), control Keep the temperature constant, high-speed shearing and stirring for 2 hours, and obtain modified asphalt after cooling.

[0049] According to the experimental results, the penetration of the modified asphalt (25°C, 0.1mm) is 70, the softening point is 58°C, and the ductility at 5°C is 34cm. , 0.1mm) is 75, the softening point is 55°C, the ductility is 50cm at 5°C, and the product shows good storage stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Extensibility | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com