Method for manufacturing non-photosensitive polyimide passivation layer

一种聚酰亚胺、非感光性的技术,应用在非感光性聚酰亚胺钝化层的制作领域,能够解决非感光性聚酰亚胺形貌差、光刻胶残留、金属铝显影腐蚀等问题,达到解决非感光性聚酰亚胺形貌问题、防止光刻胶残留的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

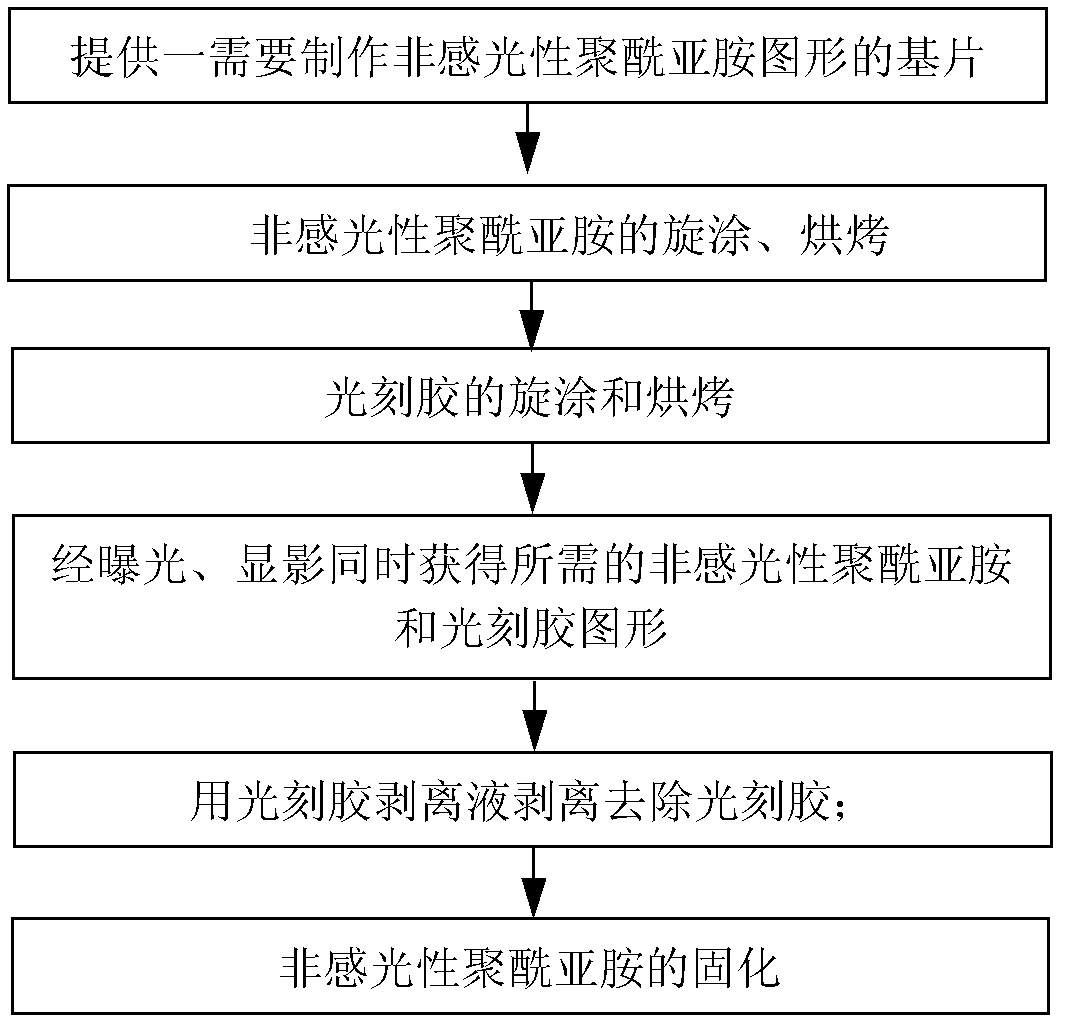

[0033] The invention discloses a method for making a non-photosensitive polyimide passivation layer, the process flow of which is as follows Figure 5 As shown in Figure 6, it specifically includes the following steps:

[0034] (1) As shown in Figure 6 (A), provide a substrate 1 that needs to make a non-photosensitive polyimide passivation layer, and the top layer metal wiring 2 and the dielectric layer passivation film 3 on this substrate 1 The pattern has been formed; the formation process generally adopts the conventional method in the field to form the top layer metal connection 2 on the substrate 1, then deposit the dielectric layer passivation film 3, and etch the dielectric layer passivation film at the position of the top layer metal connection 2 3. Form a contact hole; the dielectric layer passivation film 3 can be silicon nitride, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com