Shape modeling method of elliptical vibration assisted cutting microgroove

A technique for elliptical vibration, modeling methods, used in instrumentation, digital control, control/regulation systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0073] 1. a method for modeling the shape of elliptical vibration-assisted cutting micro-grooves, is characterized in that comprising the steps:

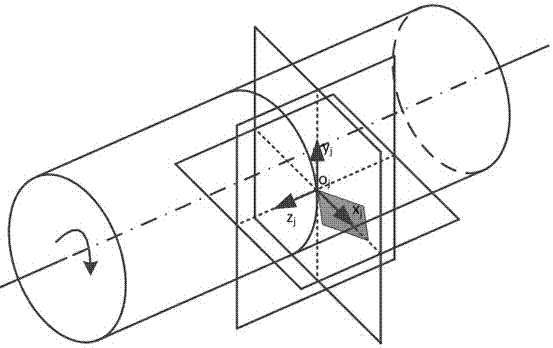

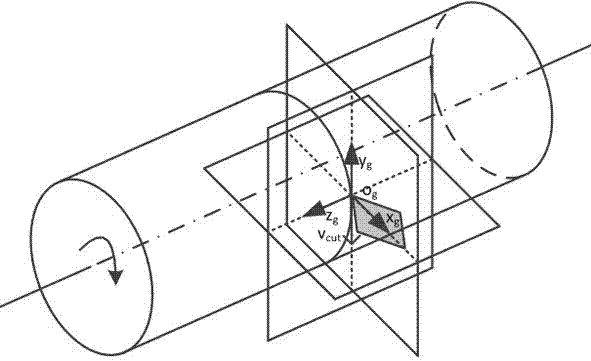

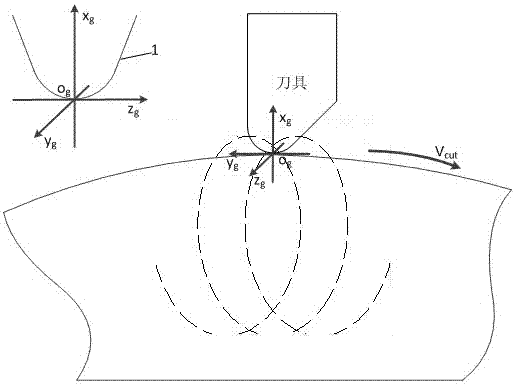

[0074] (1) Establish machine tool processing coordinate system o j -x j the y j z j , workpiece coordinate system o g -x g the y g z g , tool coordinate system o d -x d the y d z d and elliptical vibration assisted cutting local coordinate system o z -x z the y z z z , the above coordinate systems are all right-handed Cartesian standard Cartesian coordinate systems.

[0075] Establish the machining coordinate system of the machine tool: take the initial contact point of the turning tool nose arc curve and the workpiece as the coordinate origin o j point o j The plane where the point and workpiece axis are located is x j o j z j plane, where o j z j The axis is parallel to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com