Dual-ingredient degreasing agent for battery aluminum shell and preparation and use methods of dual-ingredient degreasing agent

A battery aluminum shell, two-component technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using liquids, etc., can solve the problems of slow degreasing speed, small degreasing area, and large corrosion. Achieve the effect of strengthening cleaning, increasing productivity, and improving wetting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

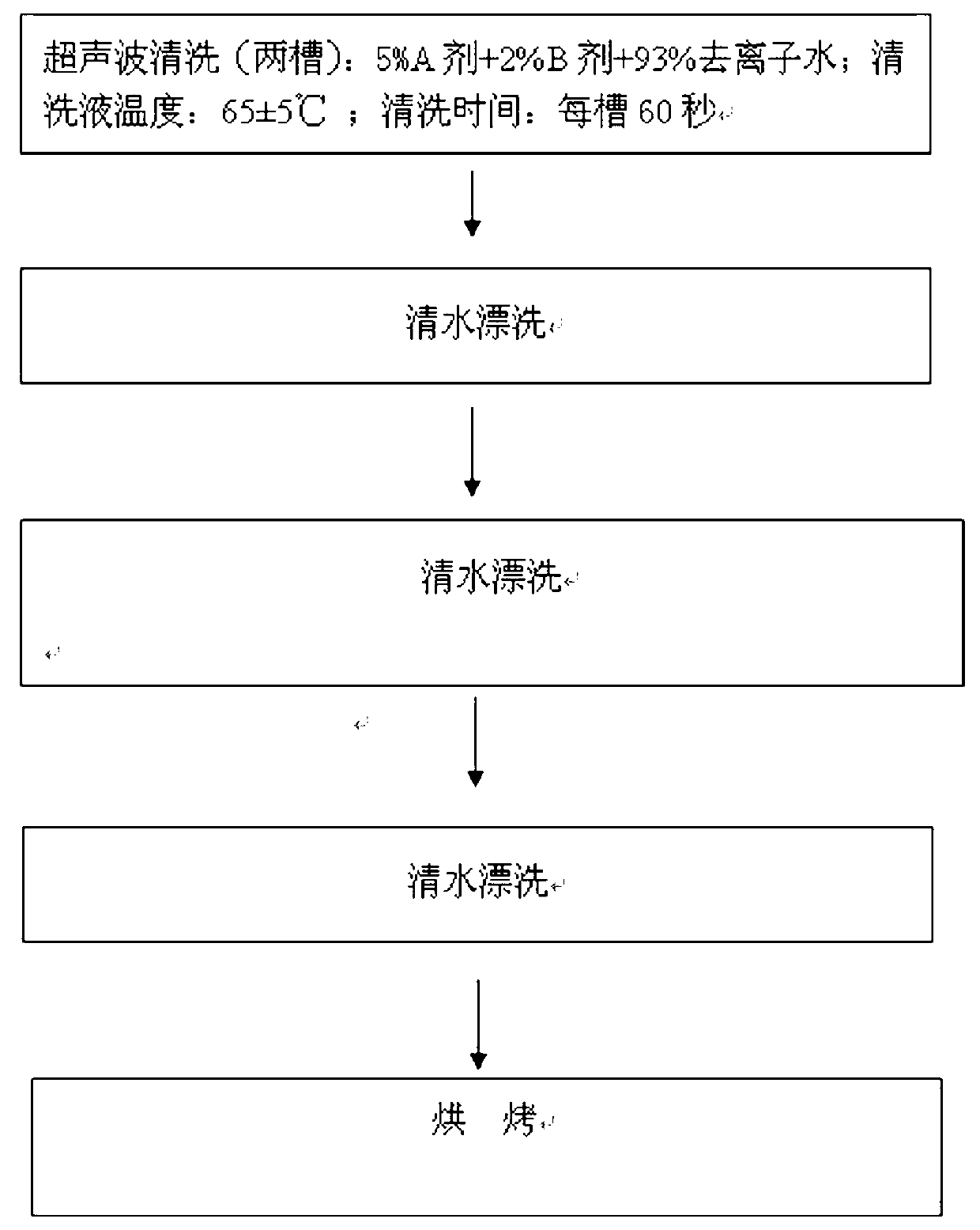

Method used

Image

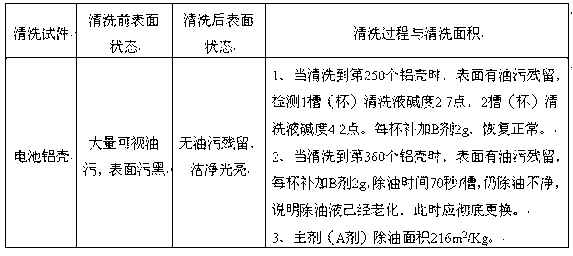

Examples

Embodiment 1

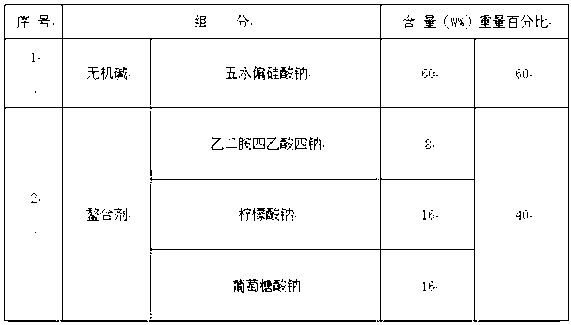

[0066] The composition and content of the two-component battery aluminum case degreaser are shown in the following table:

[0067] A agent components and content:

[0068]

[0069] B component and content:

[0070]

[0071] The manufacture method of making 100Kg above-mentioned A agent is as follows:

[0072] Weigh 5Kg of sodium secondary alkylsulfonate (SAS-60) and 10kg of sodium dodecylbenzenesulfonate, put them into a mixing bucket, first heat 20Kg of water, and then stir;

[0073] Weigh isomer fatty alcohol polyoxyethylene ether AEO 7 (C 13 ) 20Kg, fatty alcohol polyoxyethylene ether AEO9 25Kg, put into a mixing tank, and fully stir to form a clear liquid;

[0074] Weigh 10kg of 2-methyl-2,4-pentanediol, put it into a mixing bucket, add the remaining 10kg of water (plus the previous hot water, the total weight of the water is 30Kg), and stir well to obtain the above-mentioned two-group One part battery aluminum shell degreaser A agent.

[0075] The manufacture ...

Embodiment 2

[0081] The composition and content of the two-component battery aluminum case degreaser are shown in the following table:

[0082] A agent components and content:

[0083]

[0084] B component and content:

[0085]

[0086] The manufacture method of making 100Kg above-mentioned A agent is as follows:

[0087] Weigh 5Kg of sodium secondary alkylsulfonate (SAS-60) and 15kg of sodium dodecylbenzenesulfonate, put them into a mixing bucket, first heat 25Kg of water, and then stir;

[0088] Weigh the material isomerized fatty alcohol polyoxyethylene ether AEO 7 (C 13 ) 15Kg, fatty alcohol polyoxyethylene ether AEO9 15Kg, put into a mixing tank, and fully stir to form a clear liquid;

[0089] Weigh 10kg of 2-methyl-2,4-pentanediol, put it into a mixing bucket, add the remaining water 10kg (plus the previous hot water, the total weight of water is 35Kg), and stir well to obtain the above-mentioned two-group One part battery aluminum shell degreaser A agent.

[0090] The m...

Embodiment 3

[0097] The composition and content of the two-component battery aluminum case degreaser are shown in the following table:

[0098] A agent components and content:

[0099]

[0100] B component and content:

[0101]

[0102] The manufacture method of making 100Kg above-mentioned A agent is as follows:

[0103] Weigh 6Kg of sodium secondary alkylsulfonate (SAS-60) and 12kg of sodium dodecylbenzenesulfonate, put them into a mixing bucket, heat 20Kg of water first, and then stir;

[0104] Weigh the material isomerized fatty alcohol polyoxyethylene ether AEO 7 (C 13 ) 20Kg, fatty alcohol polyoxyethylene ether AEO9 20Kg, put into a mixing tank, and fully stir to form a clear liquid;

[0105] Weigh 12kg of 2-methyl-2,4-pentanediol, put it into a mixing bucket, add the remaining 10kg of water (plus the previous hot water, the total weight of the water is 30Kg), and stir well to obtain the above-mentioned two-group One part battery aluminum shell degreaser A agent. The man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com