Preparation method of graphene steel-based alloy

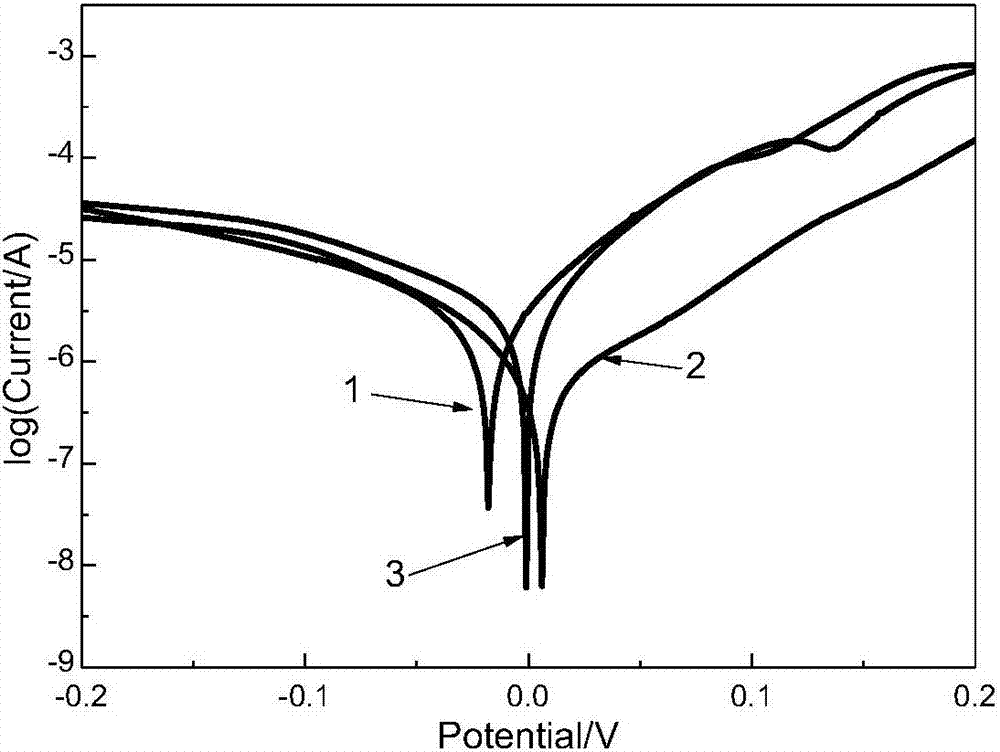

A graphene and alloy technology, applied in the field of preparation of graphene steel-based alloys, can solve the problems of increased grain boundary ratio, cumbersome process, and no data on the corrosion resistance of the alloy, so as to achieve enhanced corrosion resistance and overall The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Carry out simple mechanical treatment on the surface of carbon steel to remove most of the stains on the surface, then mechanically polish the sample to the mirror surface, and then place the sample in an ethanol solution for ultrasonic treatment; Ultrasonic cleaning in deionized water for 5 minutes, twice.

[0036] (2) Put the sample treated in step (1) into the chemical degreasing solution that has been prepared, and perform chemical degreasing treatment on the sample after ultrasonication. The degreasing formula: NaOH: 60g / L, NaOH: 60g / L, Na 2 CO 3: 20g / L, Na 3 PO 4 : 50g / L, NaSiO 3 : 10g / L, the degreasing temperature is 70°C, and the ultrasonic degreasing time is 0.5min.

[0037] (3) Soak the sample treated in step (2) directly in the acid solution, 30wt% HCl hydrochloric acid: 300g / L; the activation temperature is 25°C, and the activation time is 10s.

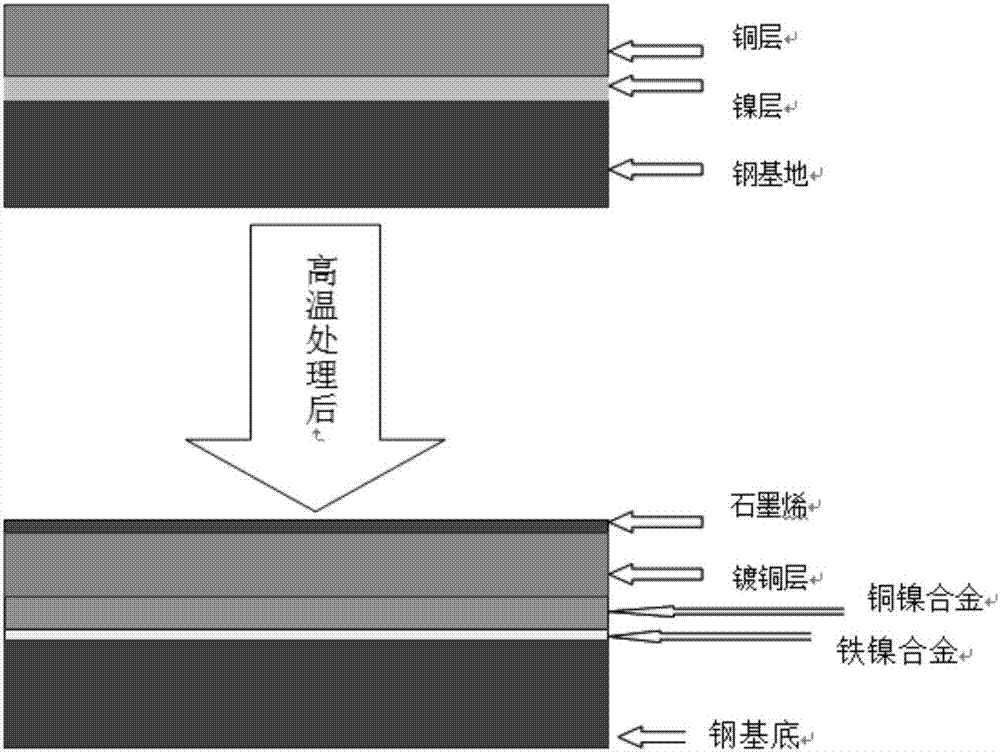

[0038] (4) In the step (3), the sample after the above treatment is placed in the pre-nickel plating sol...

Embodiment 2

[0043] (1) Steps 1, 2, 3, 4 are the same as in Example 1

[0044] (2) Step 5 nickel plating current density is 0.6A / dm 2 , the temperature is 35°C, the electroplating time is 50 minutes, and the electroplating thickness is 2 μm.

[0045] (3) Copper plating: current density 6A / dm 2 , the electroplating time is about 90 minutes, and the sample with a plating thickness of 200 μm is ultrasonically cleaned twice with deionized water, and dried under nitrogen.

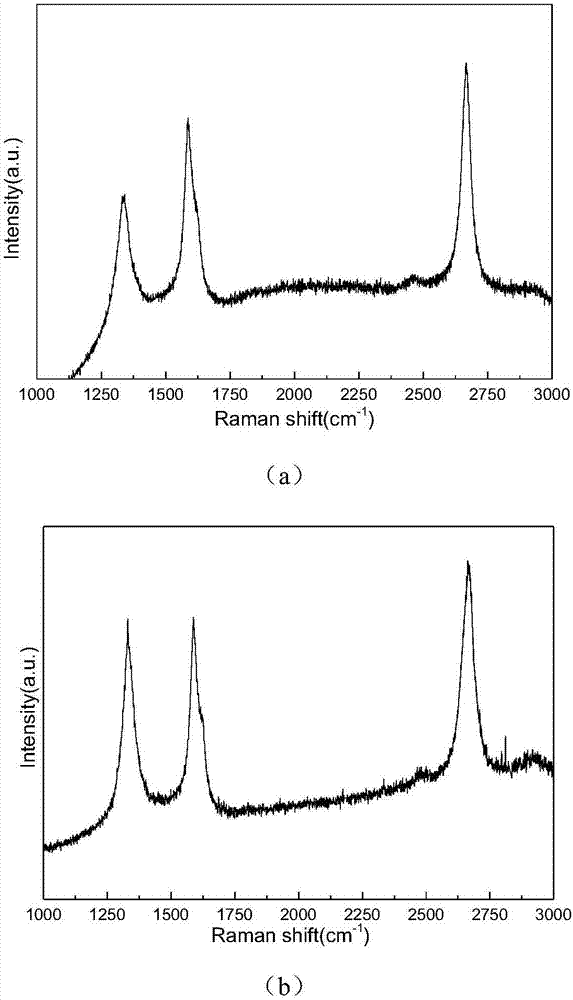

[0046] (4) The dried sample in the step (6) is placed on the quartz boat, then put into the tube furnace, sealed, vacuumized, fed with argon, and repeatedly washed three times, with hydrogen 100sccm as the protective gas, The heating rate is 30°C / min, to 900°C, after reaching the set temperature, change the gas CH 4 and H 2 30sccm and 80sccm gas respectively, the reaction time is 15 minutes, after the reaction is completed, the sample is placed at room temperature and rapidly cooled to obtain the prepared sample.

Embodiment 3

[0048] (1) Steps 1, 2, 3, 4 are the same as in Example 1

[0049] (2) Step 5 nickel plating current density is 1A / dm 2 , the temperature is 25° C., the electroplating time is 60 minutes, and the electroplating thickness is 4.5 μm.

[0050] (3) Copper plating: current density 10A / dm 2 , the electroplating time was about 110 minutes, and the samples with a plating thickness of 450 μm were ultrasonically cleaned twice with deionized water, and dried under nitrogen.

[0051] (4) The dried sample in the step (6) is placed on the quartz boat, then put into the tube furnace, sealed, vacuumized, fed with argon, and repeatedly washed three times, with hydrogen 100sccm as the protective gas, The heating rate is 25°C / min, to 1000°C, after reaching the set temperature, change the gas CH 4 and H 2 30sccm and 100sccm gas respectively, the reaction time is 20 minutes, after the reaction is completed, the sample is placed at room temperature and rapidly cooled to obtain the prepared sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com