A method for preparing black phosphorus two-dimensional materials based on plasma immersion implantation technology

A technology of plasma and two-dimensional materials, which is applied in the field of preparation of black phosphorus two-dimensional materials by ion plasma immersion implantation technology, can solve the problems of unfavorable industrial application, difficulty in increasing the protective layer, cost, instability, etc., and achieve simplification and improvement of the preparation method. High stability and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

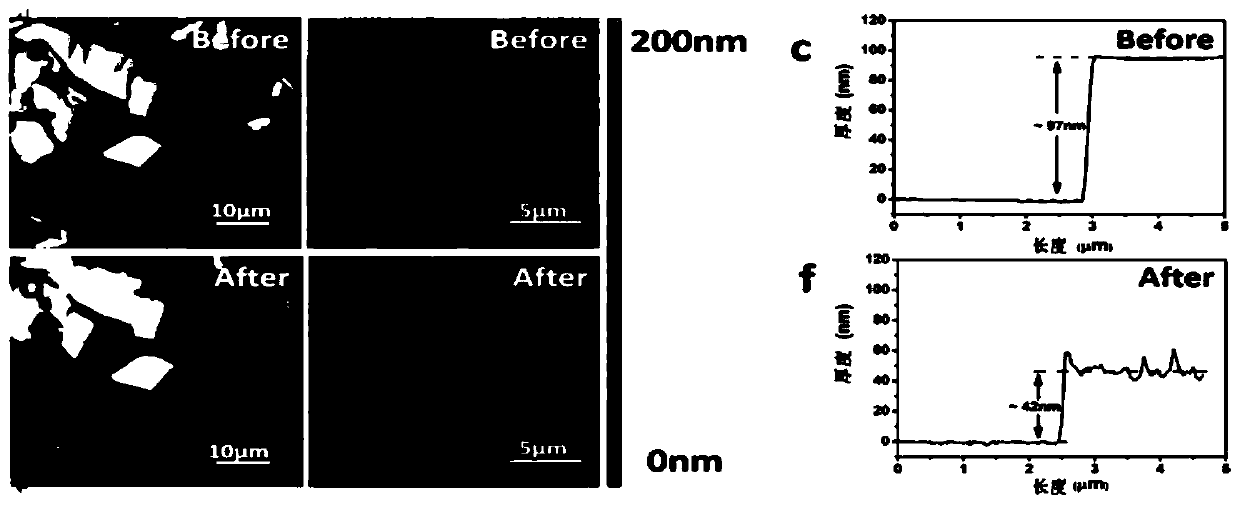

[0049] A method for preparing black phosphorus two-dimensional material using plasma immersion implantation technology, comprising the following steps:

[0050] (1) Transfer black phosphorus crystals with a thickness of 97nm to the surface of silicon dioxide / silicon wafer, soak in acetone, heat to 50°C, soak for 30min, remove impurities on the surface, and obtain a sample;

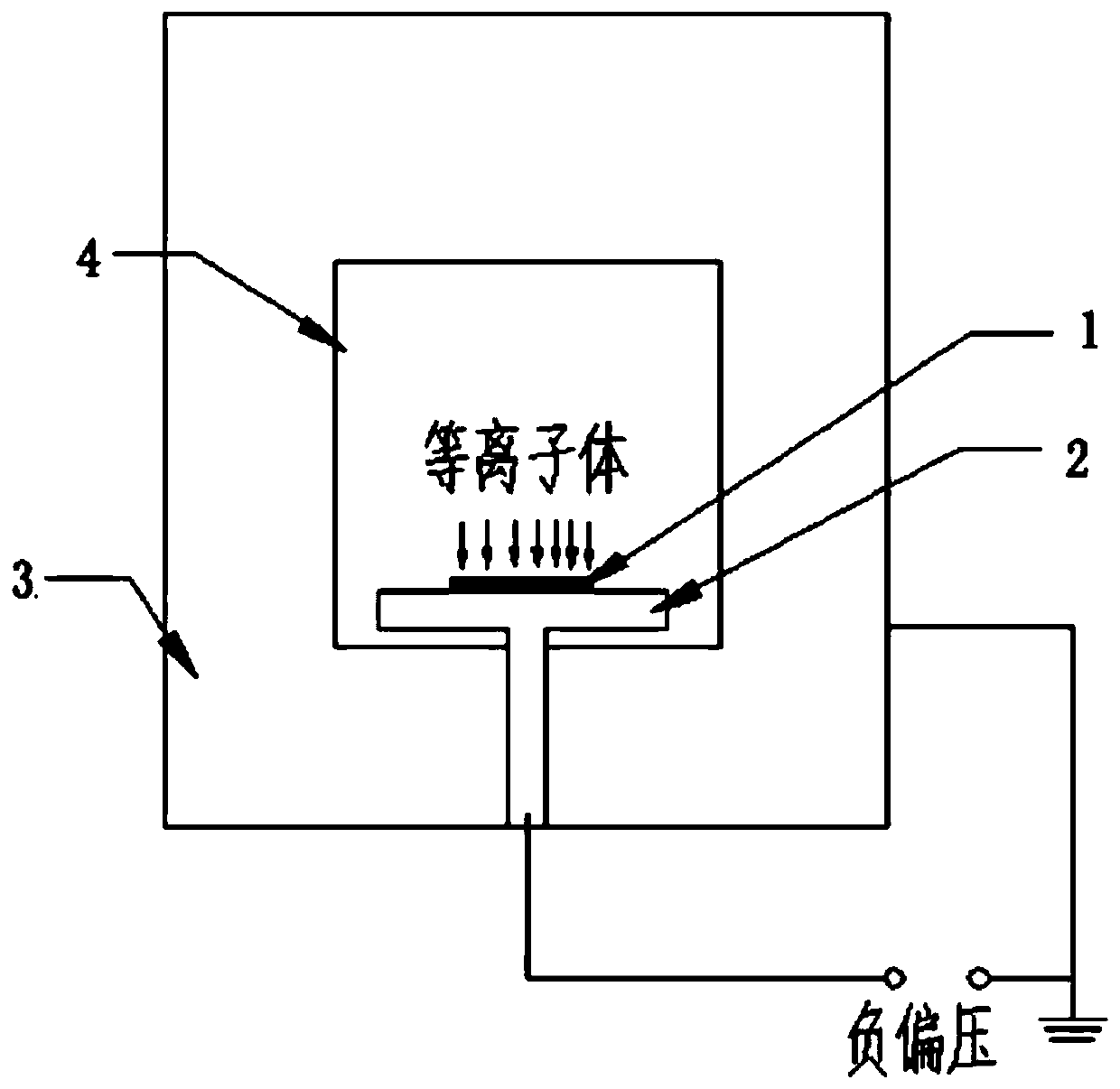

[0051] (2) Put the sample on the target stage of the plasma immersion implantation equipment;

[0052] (3) Vacuum until the vacuum degree in the vacuum chamber is 5×10 -3 Pa;

[0053] (4) Pass into hydrogen, open plasma generator, the flow rate of hydrogen is 150sccm, and air pressure is 0.15Pa, adopts radio frequency to ionize hydrogen, radio frequency power is 200W, and pulse bias is-100V, and the hydrogen plasma that produces begins to black phosphorus The crystal was etched for 15 minutes to obtain a black phosphorus two-dimensional material with a thickness of 42 nm.

Embodiment 2

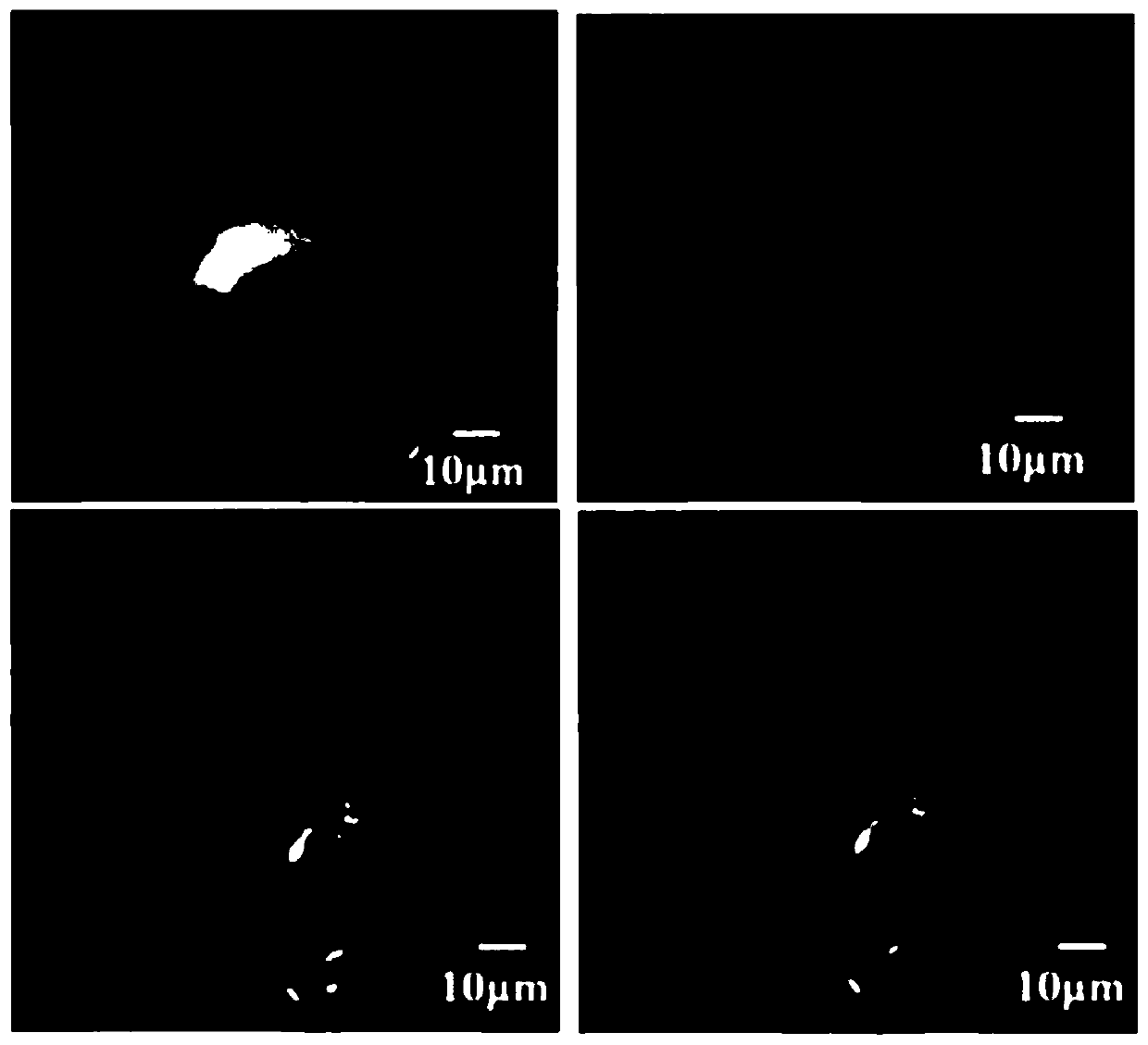

[0055] A method for preparing black phosphorus two-dimensional material using plasma immersion implantation technology, comprising the following steps:

[0056] (1) Transfer black phosphorus crystals with a thickness of 69nm to the surface of silicon dioxide / silicon wafer, soak in acetone, heat to 50°C, soak for 30min, remove the impurities on the surface, and obtain the sample;

[0057] (2) Put the sample on the target stage of the plasma immersion implantation equipment;

[0058] (3) Vacuum until the vacuum degree in the vacuum chamber is 5×10 -3 Pa;

[0059] (4) feed hydrogen, open the plasma generating device, the flow rate of hydrogen is 150sccm, the air pressure is 0.15Pa, adopt radio frequency to ionize hydrogen, radio frequency power is 200W, pulse bias is-120V, the hydrogen plasma that produces begins to black phosphorus The crystal was etched for 15 minutes to obtain a black phosphorus two-dimensional material with a thickness of 16 nm.

[0060] It can be seen fro...

Embodiment 3

[0062] A method for preparing black phosphorus two-dimensional material using plasma immersion implantation technology, comprising the following steps:

[0063] (1) Transfer black phosphorus crystals with a thickness of 80nm to the surface of silicon dioxide / silicon wafer, and soak with acetone to remove impurities on the surface to obtain a sample;

[0064] (2) Put the sample on the target platform in the plasma immersion implantation equipment;

[0065] (3) Vacuum until the vacuum degree in the vacuum chamber is 5×10 -3 Pa;

[0066] (4) Pass into hydrogen, open plasma generator, the flow rate of hydrogen is 150sccm, and air pressure is 0.15Pa, adopts radio frequency to ionize hydrogen, radio frequency power is 200W, and pulse bias is-100V, and the hydrogen plasma that produces begins to black phosphorus The crystal is etched, the etching time is 20min, and the black phosphorus two-dimensional material with a thickness of 15nm is obtained;

[0067] (5) Turn off the plasma ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com