Method for automatically and continuously making multilayer crusty pancake blanks

A technology of pancakes and cake blanks, applied in the field of food processing technology, can solve the problems of different product specifications, difficulty in supplying a large number of diners, poor production continuity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

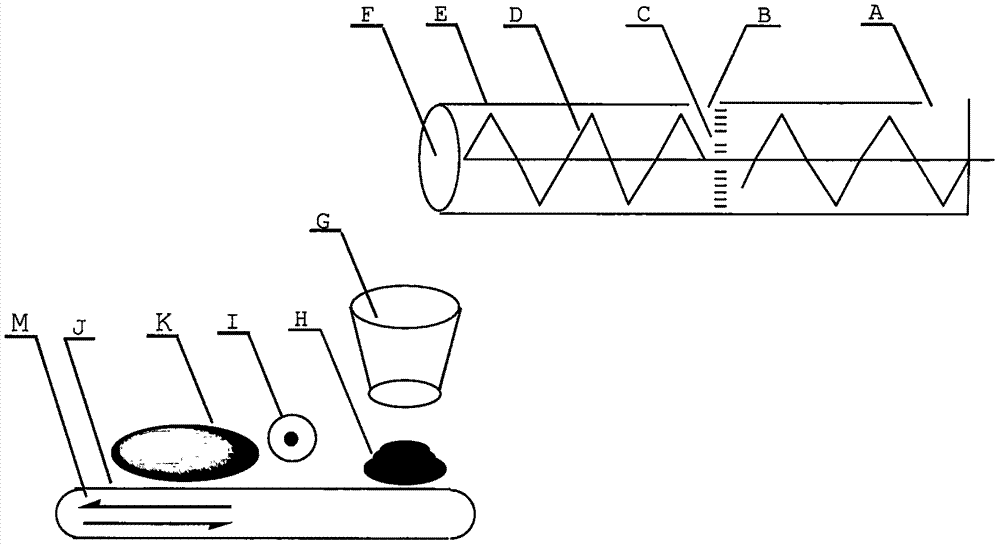

[0018] 1. Dough production: Knead and proof the dough according to the method of making multi-layer pancakes, and make a small dough with a diameter of 30mm.

[0019] 2. Oiling of noodles: Select a 5-hole grate, drive the auger, adjust the oil drip hole while adding the dough, and evenly coat a layer of oil on the surface of the noodles formed by the grate.

[0020] 3. Cake base size adjustment: adjust the inner diameter of the auger outlet to 50mm, the length of the multi-layer structure thick noodles cut by the auger outlet to 50mm, and the height of the cake pressing roller to 10mm.

[0021] 4. Biscuit production: Small sections of thick noodles with multi-layer structure fall on the conveyor belt through the molding cylinder, and are rolled by the cake roller to form a multi-layer pancake with a thickness of 10mm and a diameter of 100mm.

Embodiment 2

[0023] 1. Dough production: Knead and proof the dough according to the method of making multi-layer pancakes, and make a small dough with a diameter of 30mm.

[0024] 2. Oiling of noodles: Select a 7-hole grate, drive the auger, adjust the oil drip hole while adding the dough, and evenly coat a layer of oil on the surface of the noodles formed by the grate.

[0025] 3. Cake base size adjustment: adjust the inner diameter of the auger outlet to 70mm, the length of the multi-layer structure thick noodles cut by the auger outlet to 70mm, and the height of the cake pressing roller to 10mm.

[0026] 4. Biscuit production: small sections of thick noodles with multi-layer structure fall on the conveyor belt through the molding cylinder, and are rolled by the cake roller to form a multi-layer pancake with a thickness of 10mm and a diameter of 140mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com