Preparation method and application of double-layer oxide solid electrolyte

A solid electrolyte and solid electrolyte technology, applied in the field of batteries, can solve the problems of high interface impedance, large battery polarization, poor cycle performance, etc., and achieve the effect of excellent working cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

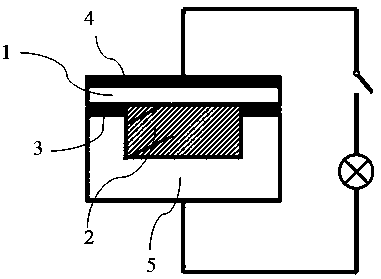

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing a double-layer oxide solid electrolyte, the method comprising:

[0027] (1) Prepare a dense garnet-type (Garnet) LLZO ceramic electrolyte layer by vacuum hot pressing: put the lithium lanthanum zirconium oxide solid electrolyte powder into a mold, and compact it on a tablet machine at 1-5 Mpa; Pressurize 5-10 Mpa in a vacuum atmosphere in a vacuum hot-pressing furnace, hold at 1140°C for 0.5-6 hours, and heat up at a rate of 1-10°C / min; after the sintering is completed, cut and grind it into a disc to obtain a dense LLZO Ceramic electrolyte layer; the ionic conductivity of the LLZO ceramic electrolyte layer is 1.6×10-3S / cm, the thickness is 0.3-1 mm, and the relative density is greater than 99.6%.

[0028](2) Prepare porous LATP solid electrolytes by sol-gel method, such as solid electrolytes with NASICON structure or perovskite structure: mix the reactant precursors according to the stoichiometric ratio of each solid electr...

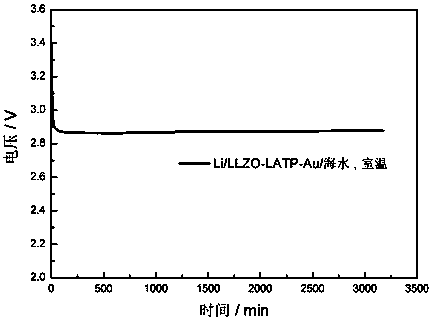

Embodiment 1

[0033] The preparation method of the double-layer oxide solid electrolyte of this embodiment includes:

[0034] (1) Preparation of Garnet-type lithium lanthanum zirconium oxide (LLZO) ceramic electrolyte layer:

[0035] The chemical formula is Li prepared by solid state reaction method 6.4 La 3 Zr 1.4 Ta 0.6 o 12 Lithium lanthanum zirconium oxide solid electrolyte powder, its preparation steps include: according to the molar ratio of Li, La, Zr, Ta is 6.4:3:1.4:0.6, select LiOH, La 2 o 3 , ZrO 2 and Ta 2 o 5 LiOH is used as a raw material with an excess of 5% LiOH, ball milled in alcohol for 24 hours and then dried; then calcined at 900°C for 10 hours with a heating rate of 4°C / min, after the sintering is completed, the powder is crushed and sieved to obtain Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 Powder (LLZO), which is sieved to obtain LLZO powder with a particle size of 5 μm;

[0036] The LLZO ceramic electrolyte layer was prepared by vacuum hot pressing method. The LL...

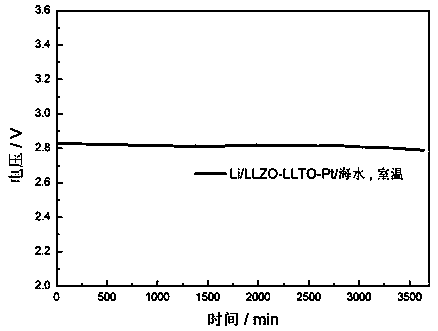

Embodiment 2

[0042] The preparation method of the double-layer oxide solid electrolyte of this embodiment includes:

[0043] (1) Preparation of Garnet-type lithium lanthanum zirconium oxide (LLZO) ceramic electrolyte layer:

[0044] The chemical formula is Li prepared by solid state reaction method 6.4 La 3 Zr 1.4 Ta 0.6 o 12 Lithium lanthanum zirconium oxide solid electrolyte powder, its preparation steps include: according to the molar ratio of Li, La, Zr, Ta is 6.4:3:1.4:0.6, select LiOH, La 2 o 3 , ZrO 2 and Ta 2 o 5 LiOH is used as a raw material with an excess of 5% LiOH, ball milled in alcohol for 24 hours and then dried; then calcined at 900°C for 10 hours with a heating rate of 4°C / min, after the sintering is completed, the powder is crushed and sieved to obtain Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 Powder (LLZO), which is sieved to obtain LLZO powder with a particle size of 5 μm;

[0045] The LLZO ceramic electrolyte layer was prepared by vacuum hot pressing method, the LL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com