Oil-resistant air tank capsule and preparation method thereof

An air bag and capsule technology, which is applied in the field of oil-resistant air bag capsules and its preparation, can solve the problems of weak corrosion resistance, reduced air bag service life, low tear resistance, bending fatigue resistance and aging resistance, and the like. Increase plasticity, improve physical and mechanical properties and aging resistance, and improve the effect of tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The preparation method of the oil-resistant air-encapsulated capsule comprises the following steps:

[0017] (1) Cut the nitrile rubber into blocks with a rubber cutter, put it in an open mill for 5 times of thin pass plasticizing, and then discharge the material, and place it for 8~12h;

[0018] (2) Put the plastic compounded by Botong into the internal mixer, and add zinc oxide, stearic acid, accelerator DM, accelerator CZ, dioctyl phthalate, and coumarone resin , anti-aging agent DMBPPD, anti-aging agent MB, anti-aging agent HB-5, spray carbon black and white carbon black were mixed evenly, and mixed for 10 minutes;

[0019] (3) Send the mixed rubber after mixing into the open mill to produce a piece with a thickness of 10~13mm and a size of 45cm×65cm, and then place it for more than 10h;

[0020] (4), re-send the film from the open mill in step (3) into the open mill, add sulfur and dicumyl peroxide for refining, and then release the film;

[0021] (5) Preliminary...

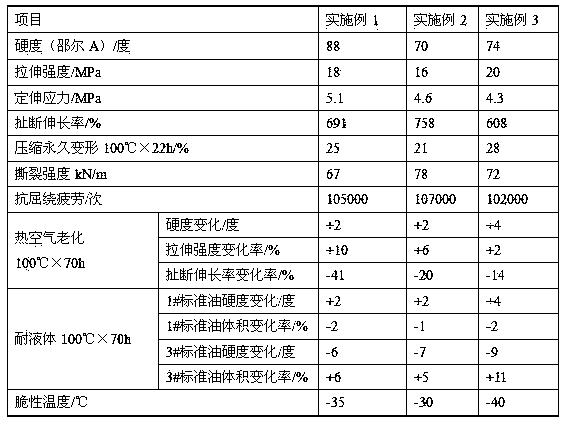

Embodiment 1

[0024] Oil-resistant air-encapsulated capsules, in parts by weight, are composed of: 15 parts of nitrile rubber, 0.5 parts of zinc oxide, 0.1 part of stearic acid, 0.1 part of accelerator DM, 0.1 part of accelerator CZ, and 1 part of phthalic acid Dioctyl ester, 0.5 part of coumarone resin, 0.1 part of anti-aging agent DMBPPD, 0.1 part of anti-aging agent MB, 0.1 part of anti-aging agent HB-5, 3 parts of spray carbon black, 1 part of white carbon black, 0.2 part of sulfur and 0.1 part of super Dicumyl oxide.

Embodiment 2

[0026] Oil-resistant air-encapsulated capsules, in parts by weight, are composed of: 20 parts of nitrile rubber, 1 part of zinc oxide, 0.3 parts of stearic acid, 0.3 parts of accelerator DM, 0.2 parts of accelerator CZ, and 2 parts of phthalic acid Dioctyl ester, 1 part of coumarone resin, 0.15 part of antioxidant DMBPPD, 0.15 part of antioxidant MB, 0.2 part of antioxidant HB-5, 5 parts of spray carbon black, 2 parts of white carbon black, 0.3 part of sulfur and 0.12 part of super Dicumyl oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com