Combined cable

A technology of combining cables and power lines, applied in power cables, submarine cables, insulated cables, etc., can solve the problem of short life of insulation electrical performance, improve toughness and elasticity, enhance tensile performance and lateral pressure resistance, improve Effect of Tensile Strength and Bending Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

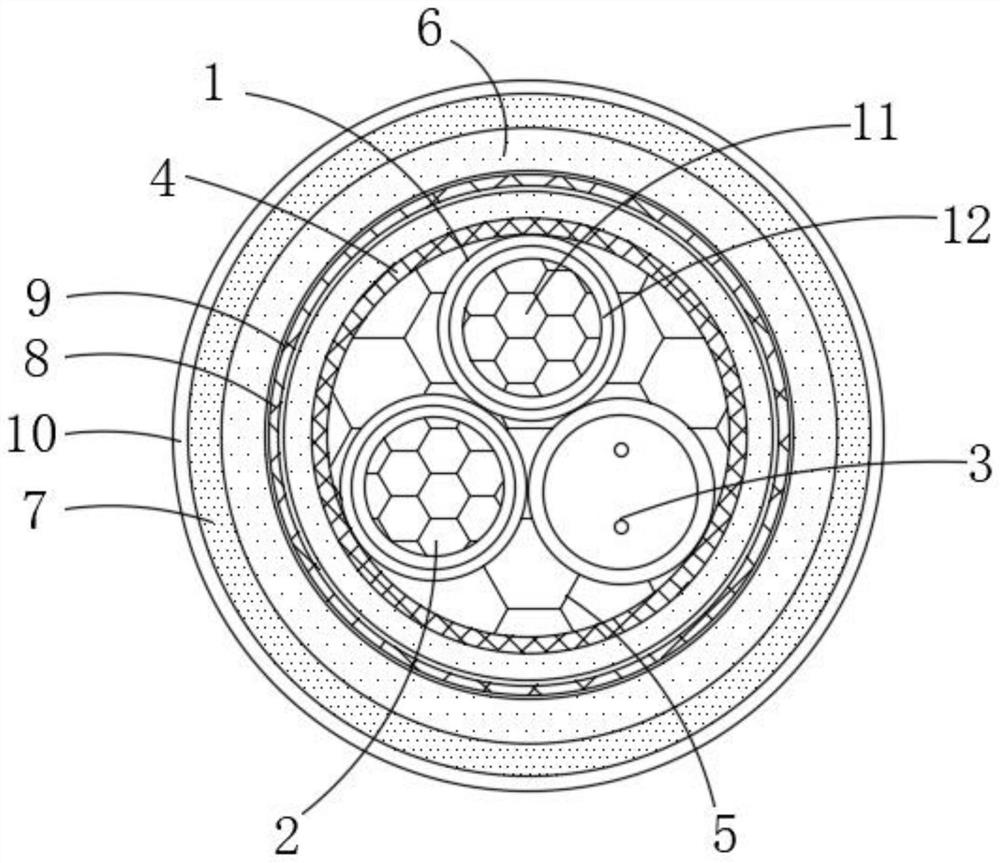

[0024] Please refer to figure 1 A combined cable shown includes a positive power cord 1, a negative power cord 2, an armored optical fiber 3, a Kevlar sheath 4, a water-blocking yarn 5, a polyurethane foam layer 6 and a polyurethane protective layer 7;

[0025] The polyurethane material with high strength and special hardness is integrated with the strands after being cabled, endowing the whole cable with high strength. The new laminated structure provides a sheath system combining flexibility and strength, so that the cable can be rolled by underwater robots. The barrel can be retracted freely to enhance the longitudinal and transverse tensile and lateral pressure resistance, and ensure the low attenuation performance of the cable under dynamic conditions;

[0026] The diameters of the positive power line 1, the negative power line 2, and the armored optical fiber 3 are the same, and a triangular structure is formed between the positive power line 1, the negative power line 2...

Embodiment 2

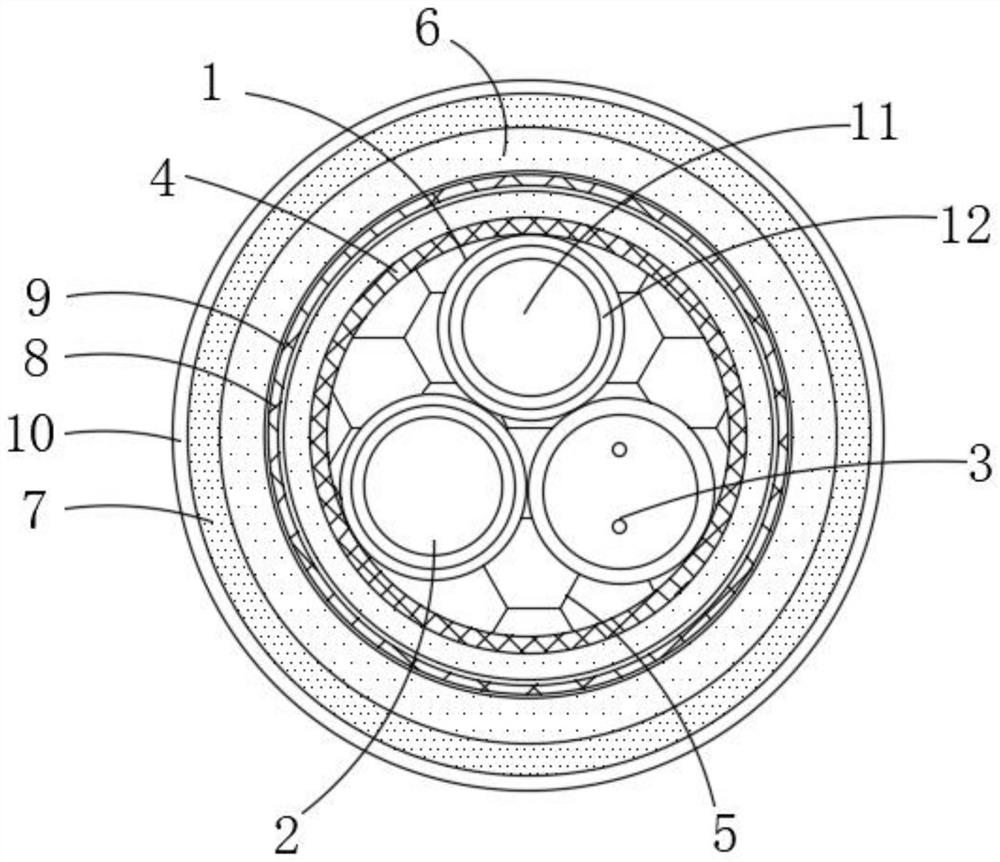

[0031] Please refer to figure 2 A combined cable shown includes a positive power cord 1, a negative power cord 2, an armored optical fiber 3, a Kevlar braided sheath 4, a water-blocking yarn 5, a polyurethane foam layer 6 and a polyurethane protective layer 7, and the embodiment 1 The difference is that the positive power line 1 and the negative power line 2 both include oxygen-free bare copper wires, and the diameter interface of the oxygen-free bare copper wires is 14mm 2 , Using a single-strand wire, reducing consumables and reducing processing difficulty.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com