Manufacturing method of thick hole copper PCB

A manufacturing method and thick-hole copper technology, applied in multilayer circuit manufacturing, printed circuit manufacturing, circuit metal processing, etc., can solve problems affecting PCB quality, stretching, etc., to improve production efficiency, reduce thickness, and benefit The effect of etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

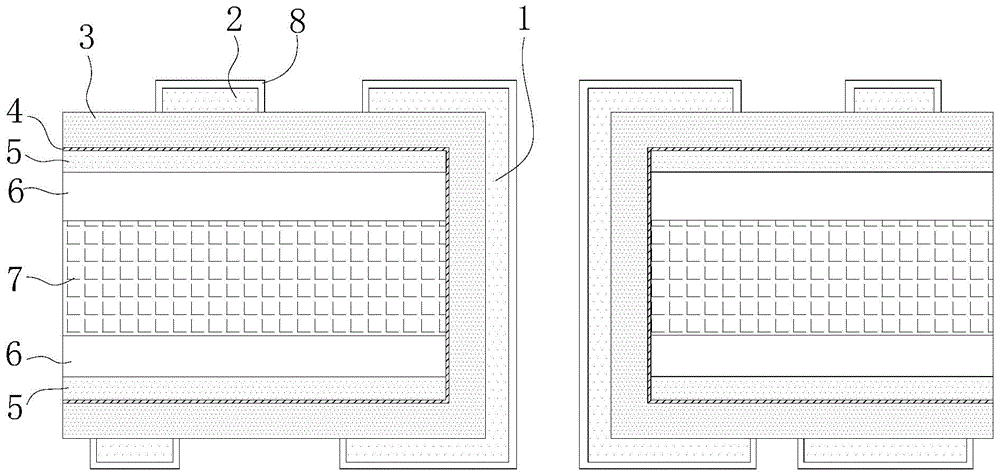

[0016] This embodiment provides a method for making a thick hole copper PCB. After using this method to carry out pattern electroplating on the multilayer board, the structure of the multilayer board is as follows: figure 1 shown.

[0017] Wherein, the parameters of the manufactured PCB are as follows.

[0018] Finished plate thickness: 2.0mm; completed minimum hole diameter: 0.25mm; thickness-to-diameter ratio: 8:1; thickness of the copper layer on the hole wall ≥ 60μm; minimum line width / line spacing: 0.2 / 0.2mm.

[0019] The specific production steps are as follows:

[0020] (1) Pressing to form a multi-layer board

[0021] First, as in the PCB production process of the prior art, the PCB raw material is cut to obtain the core board 7, and then the inner layer pattern is transferred on the core board 7 to form the inner layer circuit circuit, and then the core board 7 and the outer layer are connected through the prepreg 6 The copper foils are pressed together to form a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com