Manufacturing method for rigid-flexible circuit board

A production method, a combination of soft and hard technology, which is applied in the direction of printed circuit manufacturing, printed circuit, printed circuit, etc., can solve the problems of uneven lamination, easy to break soft boards, and burst boards, so as to achieve a flat lamination structure and prevent contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The fabrication method of the rigid-flex circuit board provided by the technical solution will be further described below in conjunction with the accompanying drawings and embodiments.

[0045] The manufacturing method of the soft-rigid circuit board provided by the technical solution includes the following steps:

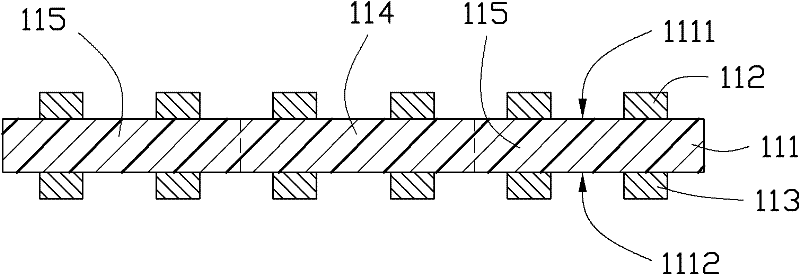

[0046] For a first step, see figure 1 , providing a flexible circuit board 110 .

[0047] The flexible circuit board 110 is a circuit board fabricated with conductive circuits. The flexible circuit board 110 can be a single-sided circuit board or a double-sided circuit board. In this embodiment, the flexible printed circuit board 110 is taken as an example for illustration. The flexible circuit board 110 includes a first insulating layer 111 , a first conductive circuit 112 and a second conductive circuit 113 . The first insulating layer 111 includes an opposite first surface 1111 and a second surface 1112, the first conductive circuit 112 is formed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com