Copper foil for printed circuit boards and method for manufacturing the same

A technology of printed circuit boards and manufacturing methods, applied in the direction of printed circuits, printed circuits, printed circuit components, etc., can solve the problems of polluted printed circuit boards, poor disconnection, poor wiring pattern formation, etc., and achieve high visibility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Using a rolled copper foil with a thickness of 16.3 μm as the original foil 1, in an aqueous solution of 40g / L sodium hydroxide and 20g / L sodium carbonate, set the temperature at 40°C and the current density at 5A / dm 2 1. Under the process condition of 10 seconds of processing time, electrolytic degreasing treatment is carried out through cathodic electrolysis process.

[0081] Next, at a temperature of 25° C., it was immersed in a 50 g / L sulfuric acid aqueous solution for 10 seconds to perform pickling treatment.

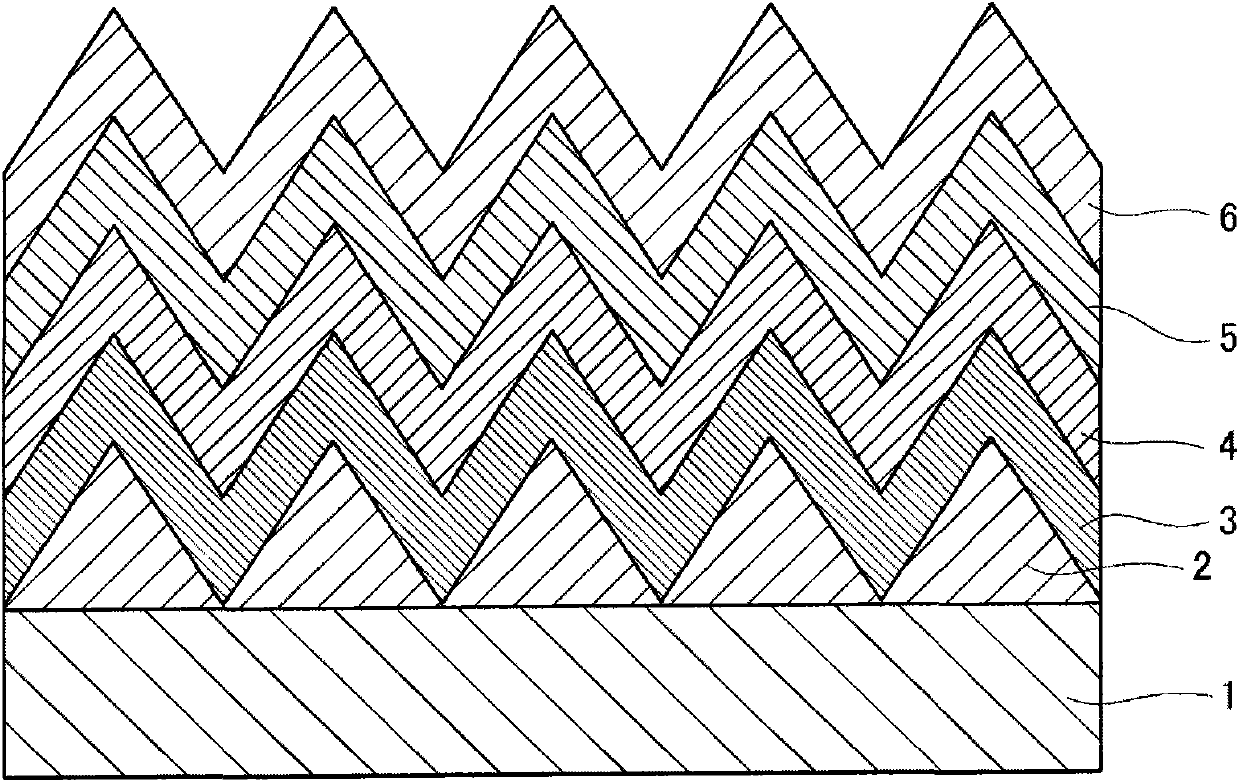

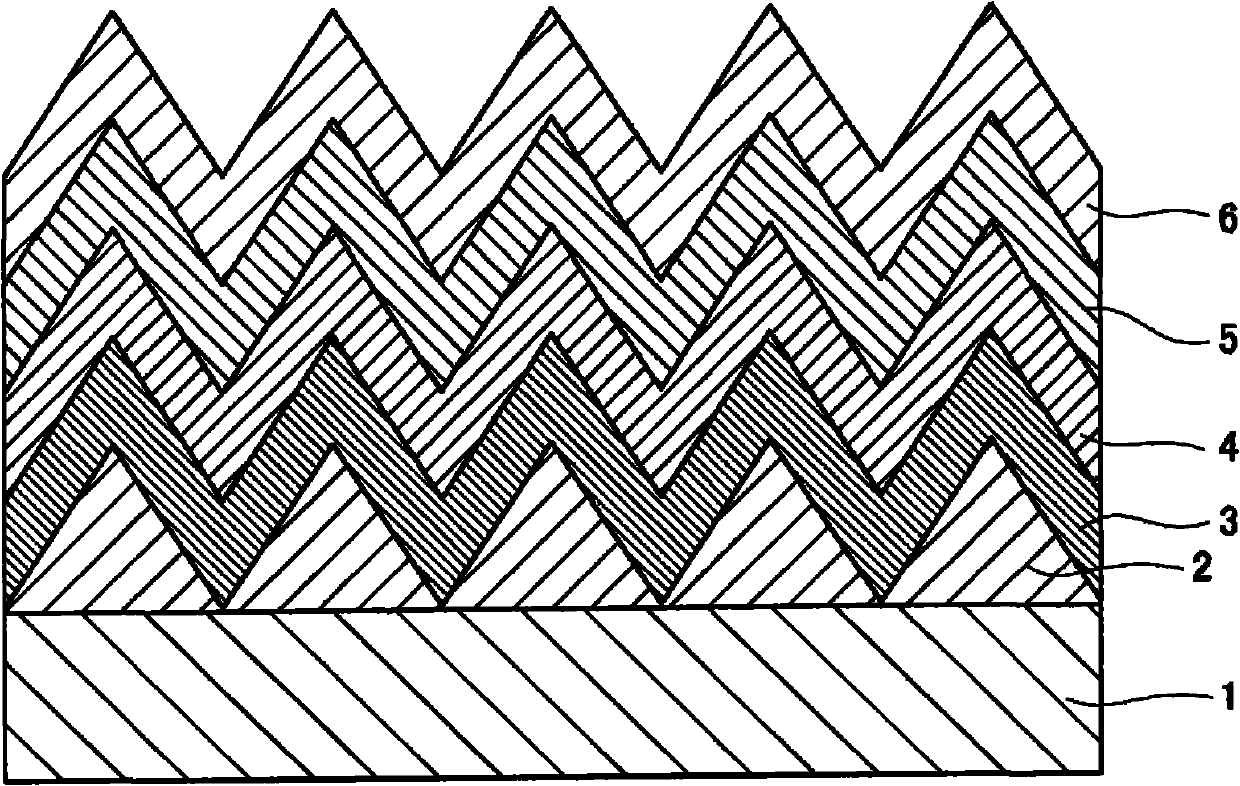

[0082] After roughening the original foil 1 to form the roughening plating layer 2, a nickel-cobalt alloy plating layer 3, a zinc plating layer 4, a chromium plating layer, and Salt treatment layer 5, silane coupling treatment layer 6.

[0083] More specifically, the nickel-cobalt alloy plating layer 3 is formed by a sulfuric acid bath, the zinc plating layer 4 is formed by a sulfuric acid bath after being prepared from a chemical, and the chromate treatmen...

Embodiment 2

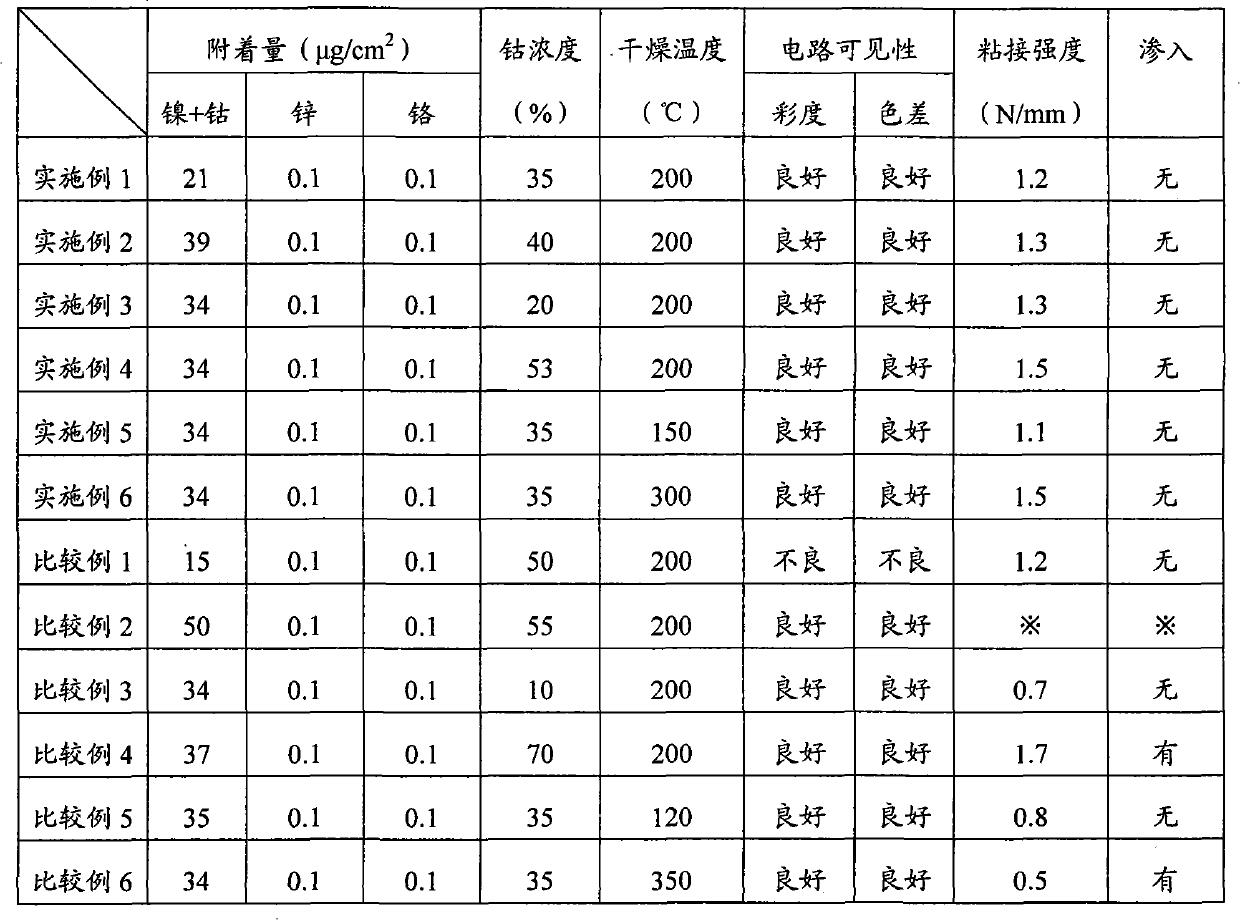

[0093] In the sample related to this Example 2, the deposition amount of the nickel-cobalt alloy plating layer 3 was set to 39 μg / cm 2 , and the concentration of cobalt (Co) in the nickel-cobalt alloy plating layer 3 was set to 40% by mass. Then, other settings were the same as those of the sample according to Example 1.

[0094] It was confirmed that the sample according to this Example 2 was also good in all characteristics such as circuit visibility, adhesive strength, and penetration. In particular, the adhesive strength was 1.3 N / mm, which was somewhat improved compared to 1.2 N / mm in the case of Example 1.

Embodiment 3

[0096] In the sample related to this Example 3, the deposition amount of the nickel-cobalt alloy plating layer 3 was set to 34 μg / cm 2 , and the concentration of cobalt (Co) in the nickel-cobalt alloy plating layer 3 was set to 20% by mass. Then, other settings were the same as those of the sample according to Example 1.

[0097] It was confirmed that the sample according to this Example 3 was also good in all characteristics such as circuit visibility, adhesive strength, and penetration as in the case of Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com