Grey water heat recovery system

a heat recovery system and grey water technology, applied in the field of grey water heat recovery system, can solve the problems of energy loss, energy waste on a regular basis, and energy loss in other waste water systems used in residential and commercial environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

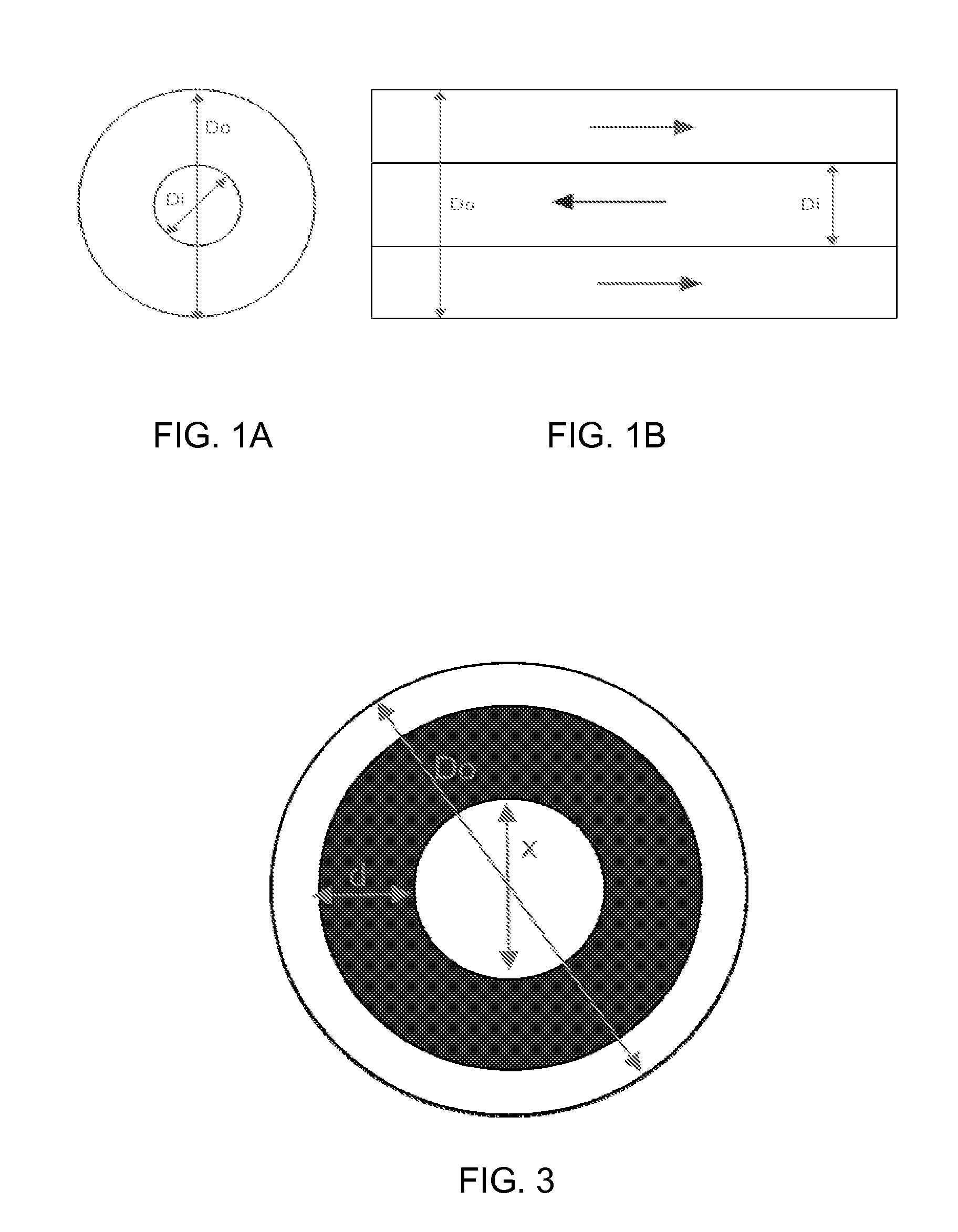

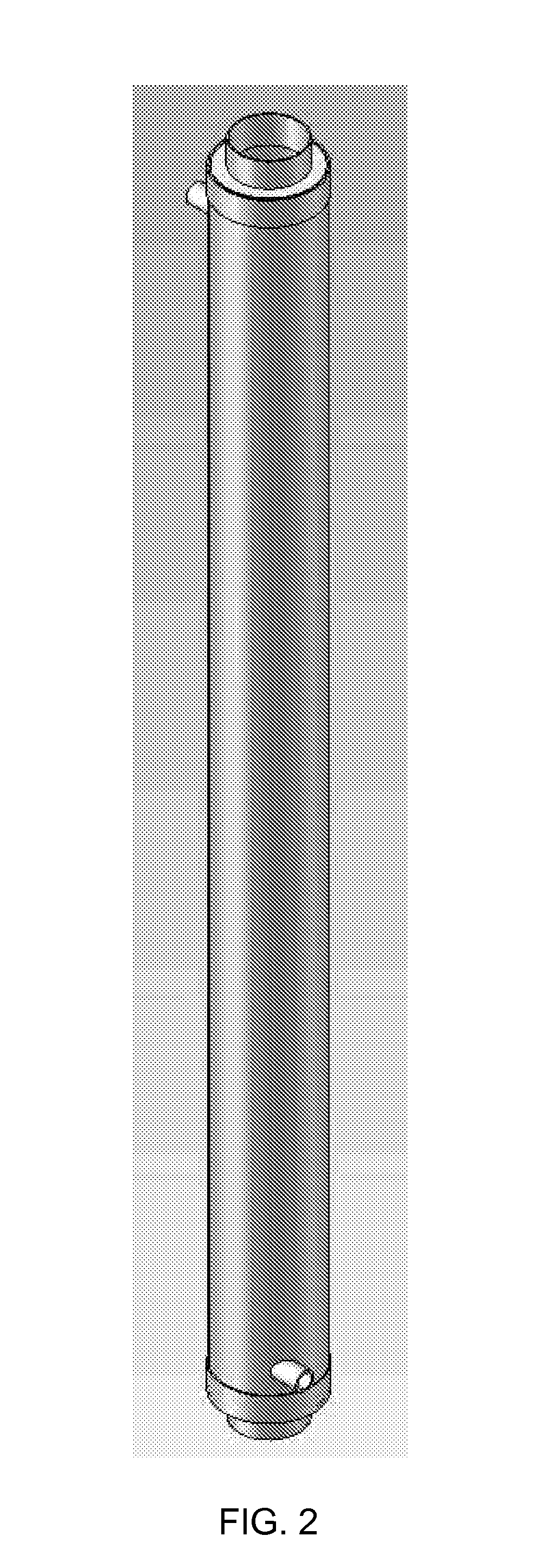

Image

Examples

Embodiment Construction

[0068]We describe an effective wastewater heat recovery system through the use of a simple heat exchanger that can accommodate multiple grey water producing devices. An efficient heat exchanger using a copper helical pipe design has been shown to provide heat recovery of approximately 40.5° F. and a cost savings of approximately $1500 per year. Through the use of this design businesses could significantly reduce overhead operating costs.

[0069]A design that would meet the needs of commercial businesses could be installed in a building's mechanical room or basement. The device would fit within an 8 inch by 8 inch by 8 foot box, these dimensions allow the device to be retrofitted easily into a typical building mechanical room or basement and allow for the existing drains lines to enter and exit the device. The device would use gravity and water main pressure whenever possible to conserve energy. The device should be easily installed in current plumbing and require minimal maintenance. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com