Production technology for high-precision fully resistance carbon film overlapping board

A production process and high-precision technology, applied in the direction containing printed electrical components, can solve the problems of increased manufacturing costs, low work efficiency, and product quality that cannot be further improved, so as to reduce manufacturing costs, meet production needs, and break through applications field effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: The user requires the resistance value of the bridge resistor to be 500±20%Ω.

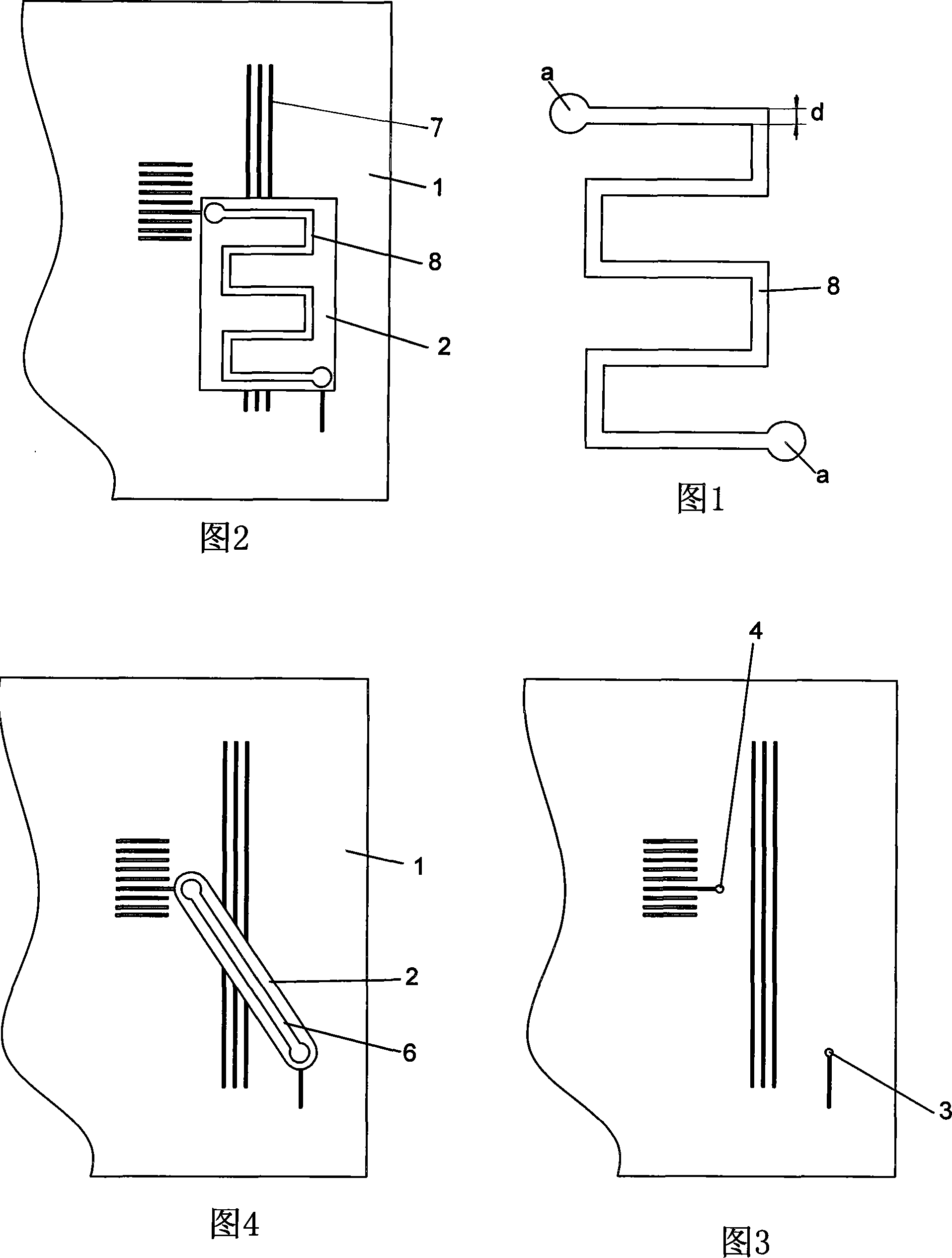

[0033] According to the user's original design (see Figure 4), the carbon film resistor 6 has a length of 1.5cm, a width of 0.2cm, and is printed with fixed carbon oil of 25Ω / □ ("□" means square centimeter, and the thickness of the film is 25чm). According to the calculation formula provided by the present invention, in order to ensure that the resistance value of the resistor is within the range of 500 ± 20% Ω, the length of the carbon film resistor is changed in design, namely:

[0034] Length of carbon film resistor = resistance value of carbon film resistor × width of carbon film resistor ÷ resistance value of fixed carbon oil used = 500Ω×0.2cm÷25Ω=4cm.

[0035] After the length of the carbon film resistor is changed according to this length (the shape of the changed carbon film resistor 8 is shown in Figure 1), the actual resistance value is between 480 and 520Ω after batc...

Embodiment 2

[0036] Embodiment 2: The user requires the resistance value of the bridge resistor to be 300±20%Ω.

[0037] According to the user's original design, the carbon film resistor has a length of 2cm and a width of 0.3cm. It is printed with fixed carbon oil of 25Ω / □ ("□" means square centimeter, and the thickness of the film is 25чm). According to the calculation formula provided by the present invention, in order to ensure that the resistance value of the resistor is within the range of 300 ± 20% Ω, the length of the carbon film resistor is changed in design, namely:

[0038] Length of carbon film resistor = resistance value of carbon film resistor × width of carbon film resistor ÷ resistance value of fixed carbon oil used = 300Ω×0.3cm÷25Ω=3.6cm.

[0039] After the length of the carbon film resistor is changed according to this length (the shape of the changed carbon film resistor is shown in Figure 1), the actual resistance value is between 280 and 330Ω after batch tracking and me...

Embodiment 3

[0040] Embodiment 3: The user requires the resistance value of the bridge resistor to be 1000±20%Ω.

[0041] According to the user's original design, the carbon film resistor has a length of 2cm and a width of 0.15cm. It is printed with fixed carbon oil of 25Ω / □ ("□" means square centimeter, and the thickness of the film is 25чm). According to the calculation formula provided by the present invention, in order to ensure that the resistance value of the resistor is within the range of 1000 ± 20% Ω, the length of the carbon film resistor is changed in design, namely:

[0042] Length of carbon film resistor = resistance value of carbon film resistor × width of carbon film resistor ÷ resistance value of fixed carbon oil used = 1000Ω×0.15cm÷25Ω=6cm.

[0043] After the length of the carbon film resistor is changed according to this length (the shape of the changed carbon film resistor is shown in Figure 1), the actual resistance value is between 960 and 1050Ω after batch tracking an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com