Heat-exchanging non-corrosive steel alloy foil coil and its manufacture method

A manufacturing method and stainless steel technology, applied in the direction of tubular elements, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of expensive material supply, lack of copper resources, high price, etc., and achieve excellent performance, scientific design and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

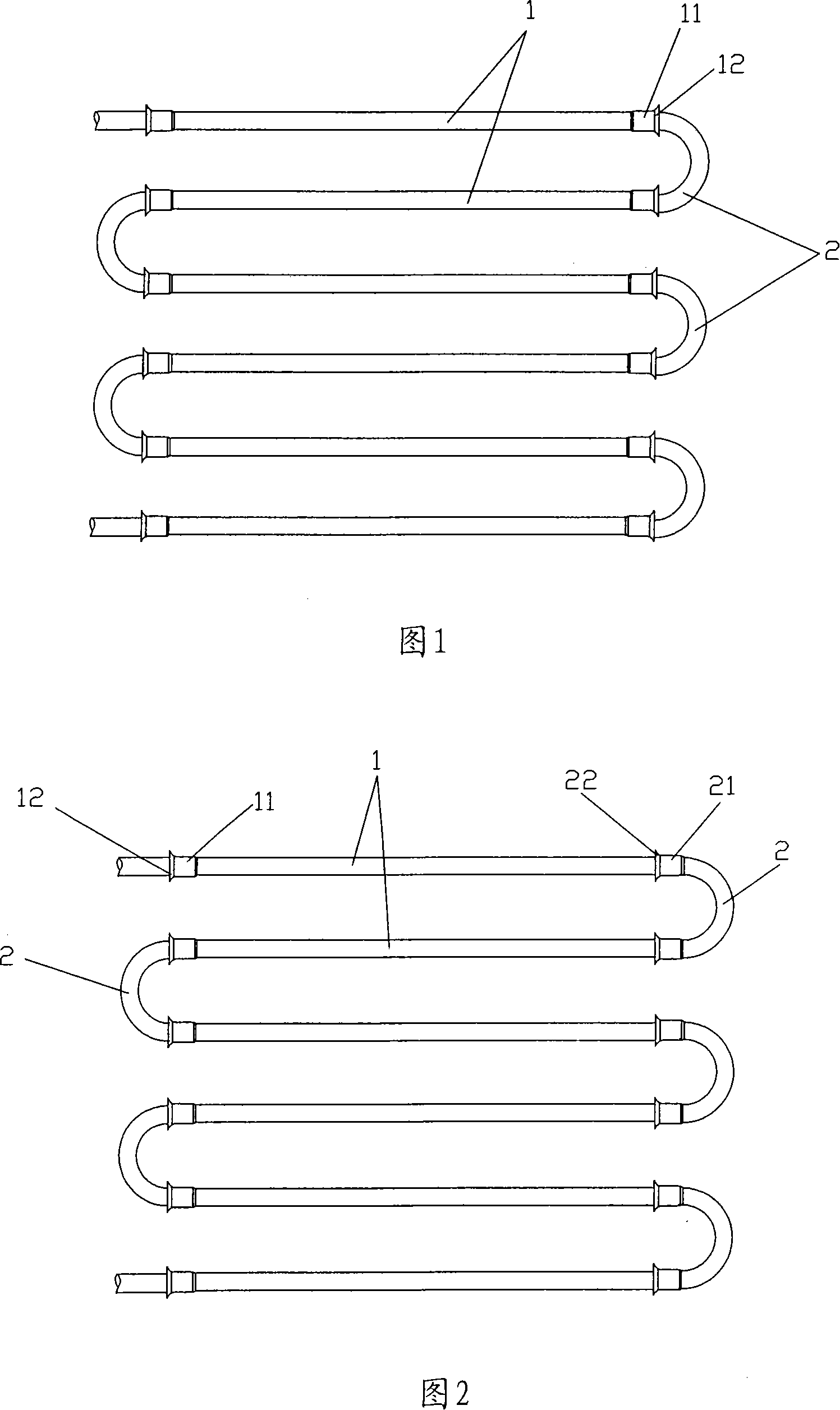

[0026] Embodiment 1: It can be clearly seen from Fig. 1 that the heat exchange stainless steel alloy foil coil tube is composed of six stainless steel alloy foil straight tubes 1 with a tube wall thickness of 0.15 mm and five stainless steel alloy foil U-shaped tubes 2 with a tube wall thickness of 0.3 mm. Both pipe ends of the stainless steel alloy foil straight pipe 1 are provided with cup mouths 11 for connecting pipes to be inserted into, and the mouth ends of the cup mouths 11 are provided with bell mouths 12 . The stainless steel alloy foil U-shaped tubes 2 are respectively inserted into the cup openings 11 and bell mouths 12 at both ends of the arranged stainless steel alloy foil straight tubes 1, and the six arranged stainless steel alloy foil straight tubes 1 are connected to form a coiled tube.

[0027] The manufacturing method of the heat exchange stainless steel alloy foil coil of the present invention comprises the following steps:

[0028] 1. Material preparation...

Embodiment 2

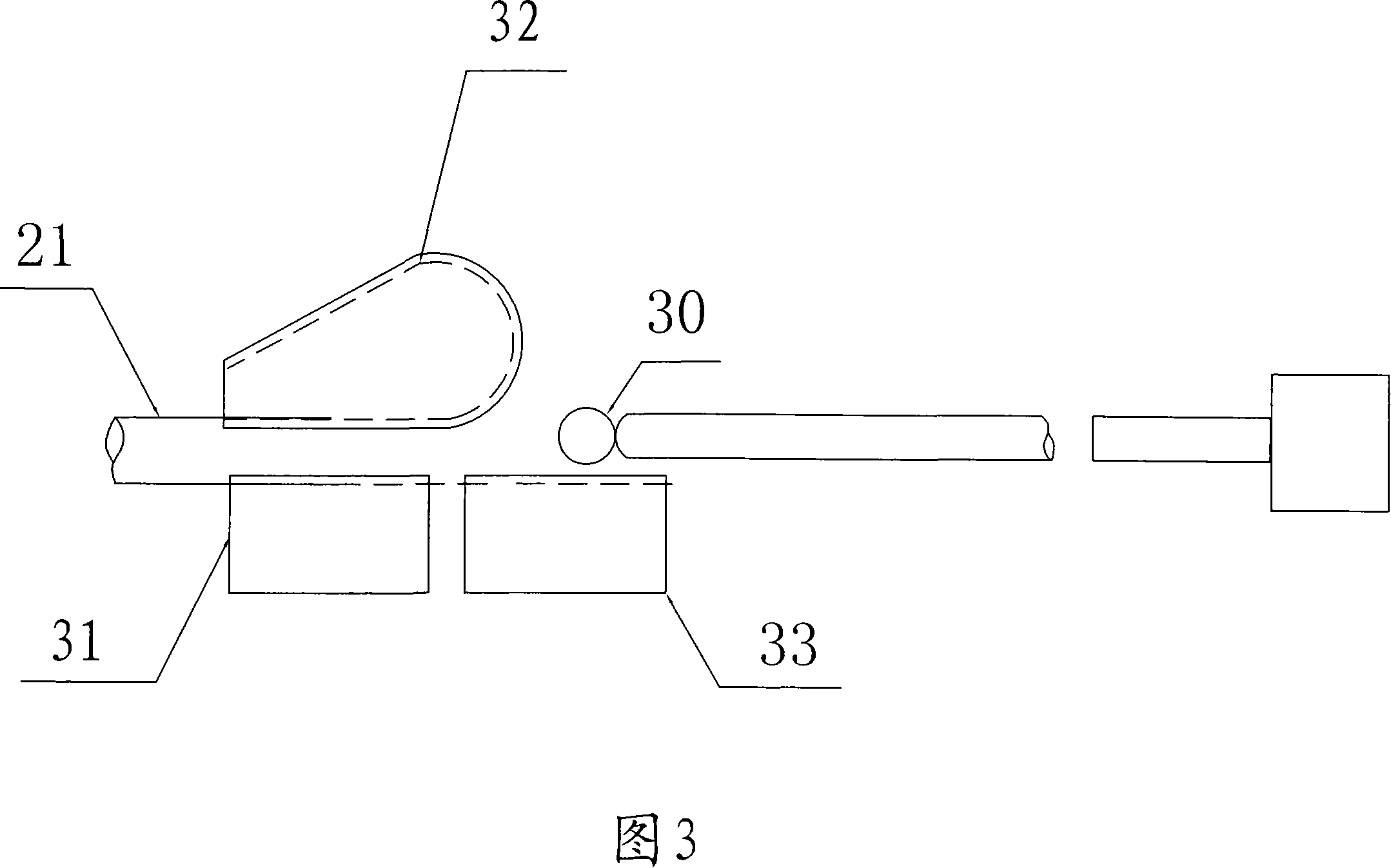

[0040] Embodiment 2: It can be clearly seen from Fig. 2 that this is another structure of stainless steel alloy foil coil for heat exchange. A cup mouth 21 for inserting the straight pipe 1 is provided, and a bell mouth 22 is provided at the mouth end of the cup mouth 21 . The two ends of the arranged stainless steel alloy foil straight pipes 1 are respectively inserted into the cup mouth 21 and bell mouth 22 of the stainless steel alloy foil U-shaped pipe 2, and the six arranged stainless steel alloy foil straight pipes 1 are connected to form a coil pipe.

[0041] The manufacturing method of the heat exchange stainless steel alloy foil coil in this embodiment is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com