Multi-layer stacking and transferring method for graphene

A transfer method, a multi-layer stacking technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of low transfer efficiency, complicated operation process, deterioration of uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

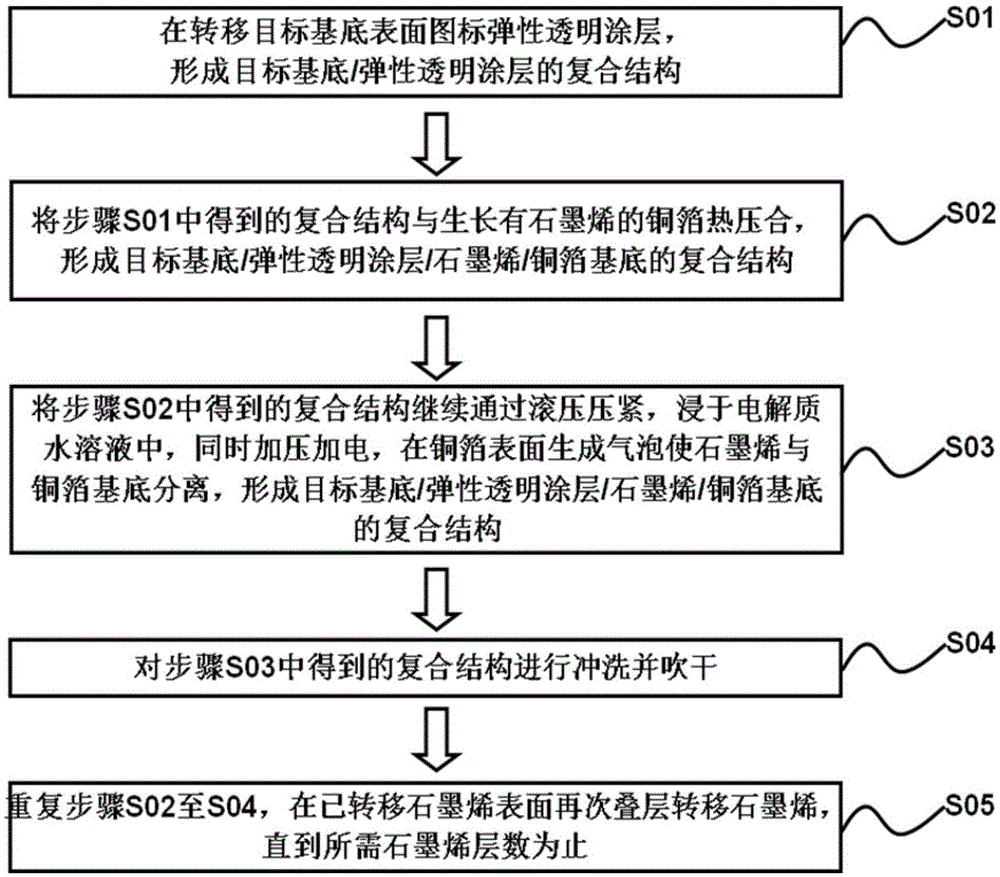

[0021] This embodiment is a graphene multilayer stack transfer method involved in the present invention, and the specific steps are as follows:

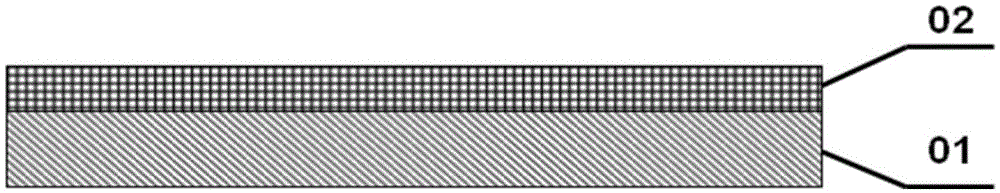

[0022] Step S01, coating polydimethylsiloxane (PDMS) on the surface of the target substrate polyethylene terephthalate (PET) 01, heating, curing and drying to form an elastic transparent coating 02 with a thickness of about 15 microns, Form the composite structure of PET / PDMS 1 such as figure 2 ;

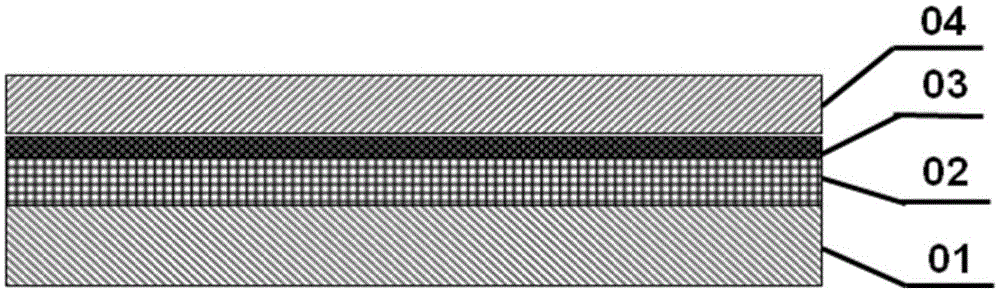

[0023] In step S02, the composite structure 1 obtained in step S01 is rolled and laminated with the grown graphene 03, the pressure is 0.2Mpa, and the heating temperature is 50°C to form a composite structure 2 of PET / PDMS / graphene / copper foil substrate. image 3 ;

[0024] Step S03, pressurize and bond the composite structure 2 obtained in step S02 again, the pressure is 0.5MPa, and at the same time, apply a current of 4A, immerse in the aqueous electrolyte solution, and bubbling with electricity to separate the graphene 03 from the gr...

Embodiment 2

[0029] This embodiment is a graphene multilayer stack transfer method involved in the present invention, and the specific steps are as follows:

[0030] Step S01, coating dimethylsiloxane and diphenylsiloxane copolymer on the surface of the target substrate polyethylene terephthalate (PET) 01, heating, curing and drying to form an elastic layer with a thickness of about 15 microns Clearcoat 02, forming a composite structure of PET target substrate / copolysiloxane elastic clearcoat 1 as figure 2 ;

[0031] Step S02, rolling and bonding the composite structure 1 obtained in step S01 with the grown graphene 03, the pressure is 0.3Mpa, and the heating temperature is 80°C to form a PET target substrate / copolysiloxane elastic transparent coating / graphene / copper Foil-based composite structures 2 such as image 3 ;

[0032] Step S03, pressurize and bond the composite structure 2 obtained in step S02 again, the pressure is 0.1MPa, and at the same time, apply a current of 3A, immerse...

Embodiment 3

[0037] This embodiment is a graphene multilayer stack transfer method involved in the present invention, and the specific steps are as follows:

[0038] Step S01, coating the copolymer solution of methyl methacrylate, butyl acrylate, isooctyl methacrylate and tetrahydrofuryl acrylate on the surface of the target substrate (PET) 01, heating, curing and drying to form an elastic transparent film with a thickness of about 30 microns Coat 02, resulting in a composite structure of PET target substrate / copolyacrylate elastic clear coat 1 as figure 2 ;

[0039] Step S02, roll and pre-laminate the composite structure 1 obtained in step S01 with the grown graphene 03, the pressure is 0.5Mpa, and the heating temperature is 90°C to form a PET target substrate / copolyacrylate elastic transparent coating / graphene / copper Foil-based composite structures 2 such as image 3 ;

[0040] In step S03, press and bond the composite structure 2 described in step S02 again, the pressure is 0.8MPa, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com