Printed circuit board shielding method and printed circuit board

A technology for printed circuit boards and shielding layers, which is applied to printed circuits, printed circuits, printed circuit components, etc., can solve the problems of high shielding cost and long production cycle, and achieve the effects of simplifying production, reducing costs, and ensuring shielding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

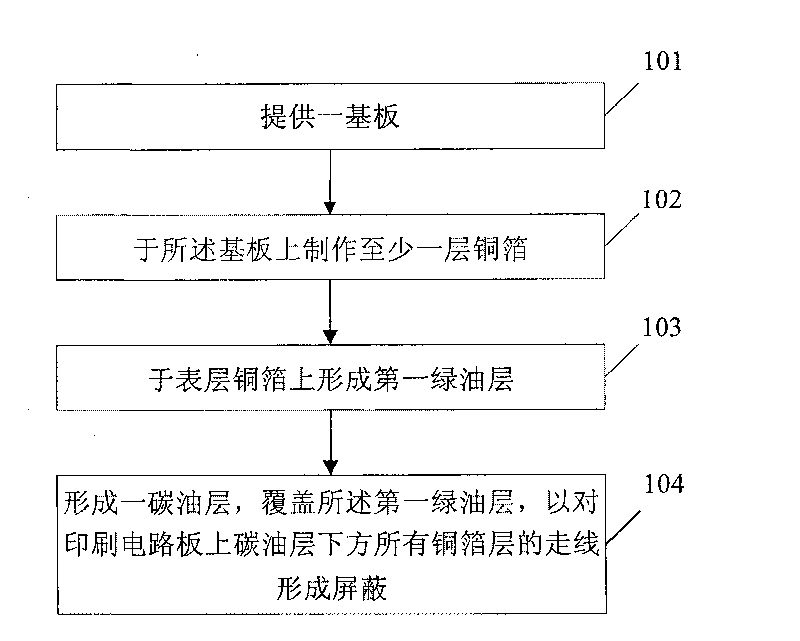

[0015] This embodiment provides a method for shielding a printed circuit board. like figure 1 As shown, the method includes:

[0016] Step 101: providing a substrate;

[0017] Step 102: making at least one layer of copper foil on the substrate;

[0018] In this step, copper foil is fabricated on the surface of the substrate, and the number of layers of copper foil can be 2, 4, 6, etc. multi-layer.

[0019] Step 103: forming a first green oil layer on the surface copper foil;

[0020] In the case of making multi-layer copper foil, the first green oil layer is formed only on the outermost copper foil, that is, the surface copper foil.

[0021] The above three steps can be done using the current commonly used process. The green oil layer covers the surface copper foil, and the position that needs to be connected to the electronic components is exposed. In addition, according to actual process requirements, the positions where the surface copper foil needs to be grounded can ...

Embodiment 2

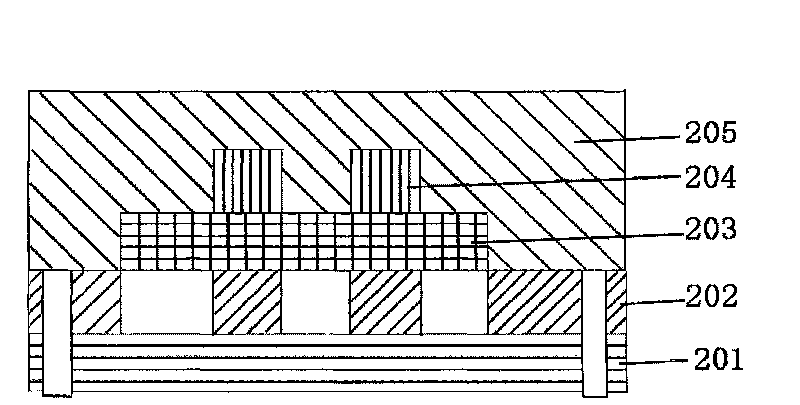

[0034] This embodiment provides a printed circuit board, which is made by the method described in Embodiment 1, such as figure 2 As shown, the printed circuit board includes:

[0035] A substrate 201;

[0036] At least one layer of copper foil 202 is fabricated on the substrate;

[0037] The first green oil layer 203 is formed on the surface copper foil 202;

[0038] In this embodiment, only one layer of copper foil is taken as an example, but it is not limited thereto. In practical applications, circuit boards with different layers of copper foil such as 2, 4, 6, and 8 can be made according to needs, but the first green oil layer And the subsequent insulating layer and carbon oil layer are only formed on the outermost surface copper foil.

[0039] The three-layer structure of the above printed circuit board is the same as that of the prior art printed circuit board.

[0040] A carbon oil layer 205 covers the first green oil layer 203 to form a shield for all copper foil ...

Embodiment 3

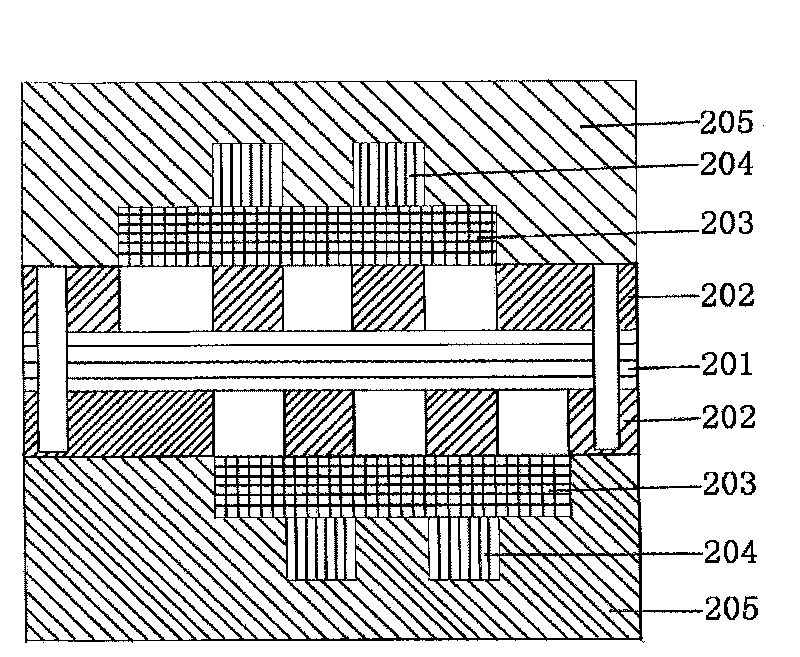

[0048] This embodiment provides a printed circuit board, which is made by the method described in Embodiment 1, such as image 3 As shown, compared with the second embodiment, the printed circuit board provided by this embodiment is double-sided. Double-sided wiring shielding is an expansion on the basis of Embodiment 2. It is outside the double-sided strong radiation wiring of the PCB, each covered with a layer of carbon film and grounded for shielding. The structure of each layer is the same as that of Embodiment 2. No longer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com