Flexible perovskite solar cell with metal grid graphene composite electrode and preparation method thereof

A graphene composite, solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problem of high square resistance of graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

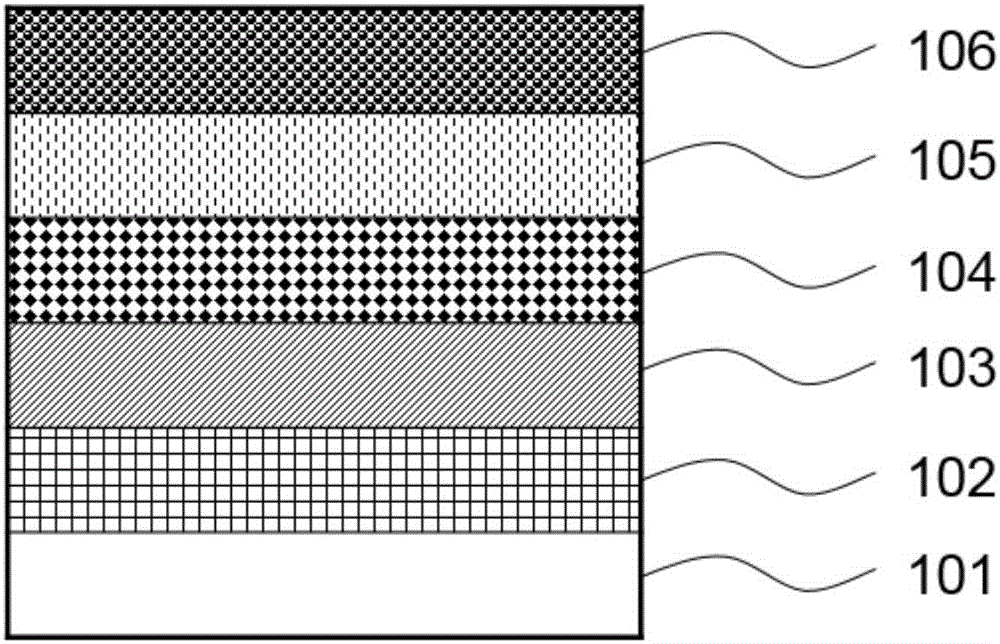

[0024] The structure of the flexible perovskite solar cell based on the metal grid graphene composite electrode of the present embodiment is as follows: figure 1 Shown, the preparation method steps of the flexible perovskite solar cell based on the metal grid graphene composite electrode of the present embodiment are as follows:

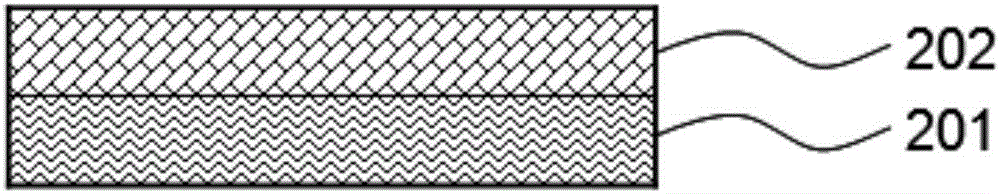

[0025] 1. Prepare the metal grid 201: Coat the UV-curable resin 7um on the flexible substrate 101PET, use the nanoimprint process to pattern it, and make a regular quadrilateral nickel mold by electroforming, with a side length of 80um and a width of 2um, the height is 1um. Under ultraviolet light, a nickel mold (0.25g pressure) was used to imprint a resin with a regular quadrilateral groove structure. The grooves were filled with Ag ink, and finally the excess ink was scraped off. Repeat three times to completely fill the grooves. An embedded Ag grid structure is formed.

[0026] 2. Using chemical vapor deposition (CVD) to prepare a single-layer g...

Embodiment 2

[0030] The structure of the flexible perovskite solar cell based on the metal grid graphene composite electrode of the present embodiment is as follows: figure 1 Shown, the preparation method steps of the flexible perovskite solar cell based on the metal grid graphene composite electrode of the present embodiment are as follows:

[0031] 1. Prepare the metal grid 201: Coat the UV-curable resin 7um on the flexible substrate 101PET, use the nanoimprint process to pattern it, and make a regular hexagonal nickel mold by electroforming, the diagonal of which is 90um, The width is 4um and the height is 2um. Under ultraviolet light, a nickel mold (0.25g pressure) was used to imprint a resin with a regular hexagonal groove structure, the groove was filled with Ag ink, and finally the excess ink was scraped off, and the groove was completely filled by repeating three times. An embedded Ag grid structure is formed.

[0032] 2. Prepare redox graphene (RGO) 202 by spin coating to form c...

Embodiment 3

[0036] The structure of the flexible perovskite solar cell based on the metal grid graphene composite electrode of the present embodiment is as follows: figure 1 Shown, the preparation method steps of the flexible perovskite solar cell based on the metal grid graphene composite electrode of the present embodiment are as follows:

[0037] 1. Prepare the metal grid 201: Coat the flexible substrate 101PEN with a 7um UV-curable resin, pattern it using a photolithography process, and obtain a resin with a regular triangular groove structure under UV light, the side length of which is 100um, width 2um, height 1um. The groove is filled with Ag ink, and finally the excess ink is scraped off, repeating three times so that the groove is completely filled. An embedded Ag grid structure is formed.

[0038] 2. Using chemical vapor deposition (CVD) to prepare a single-layer graphene film 202 on the copper foil, and transfer it to the metal grid to form the composite metal grid graphene co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com