Macro-preparation for big size graphene

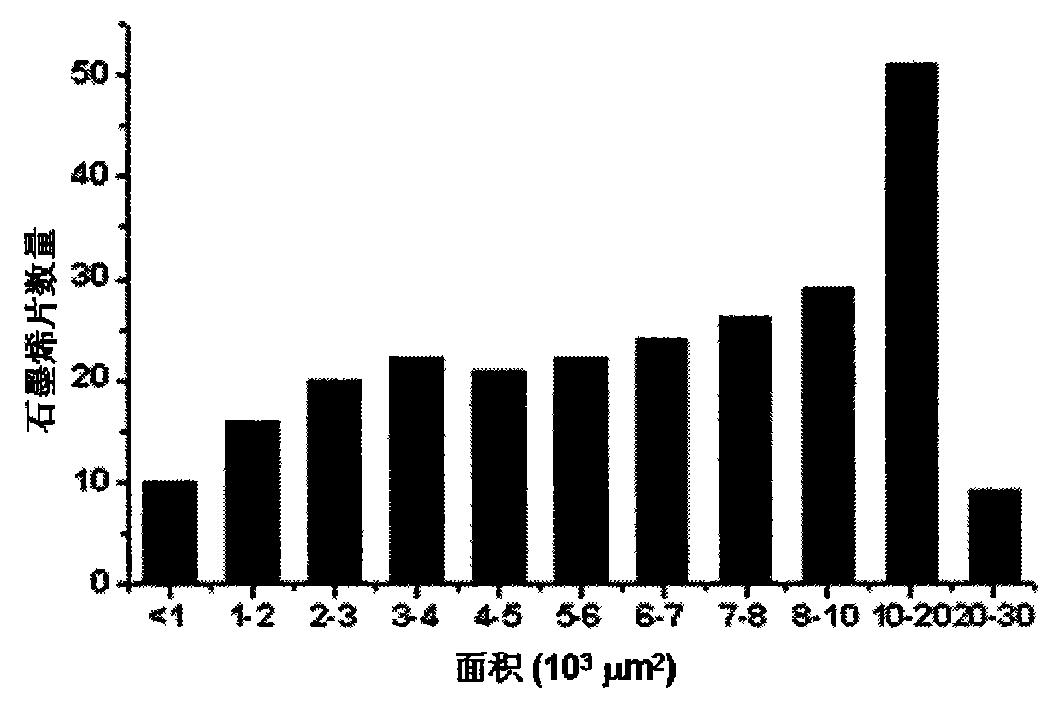

A graphene, large-scale technology, applied in the field of graphene preparation, can solve the problems of uneven size of graphene, small size of graphene, many graphene defects, etc., and achieve uniform product size, large product size, and technological process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

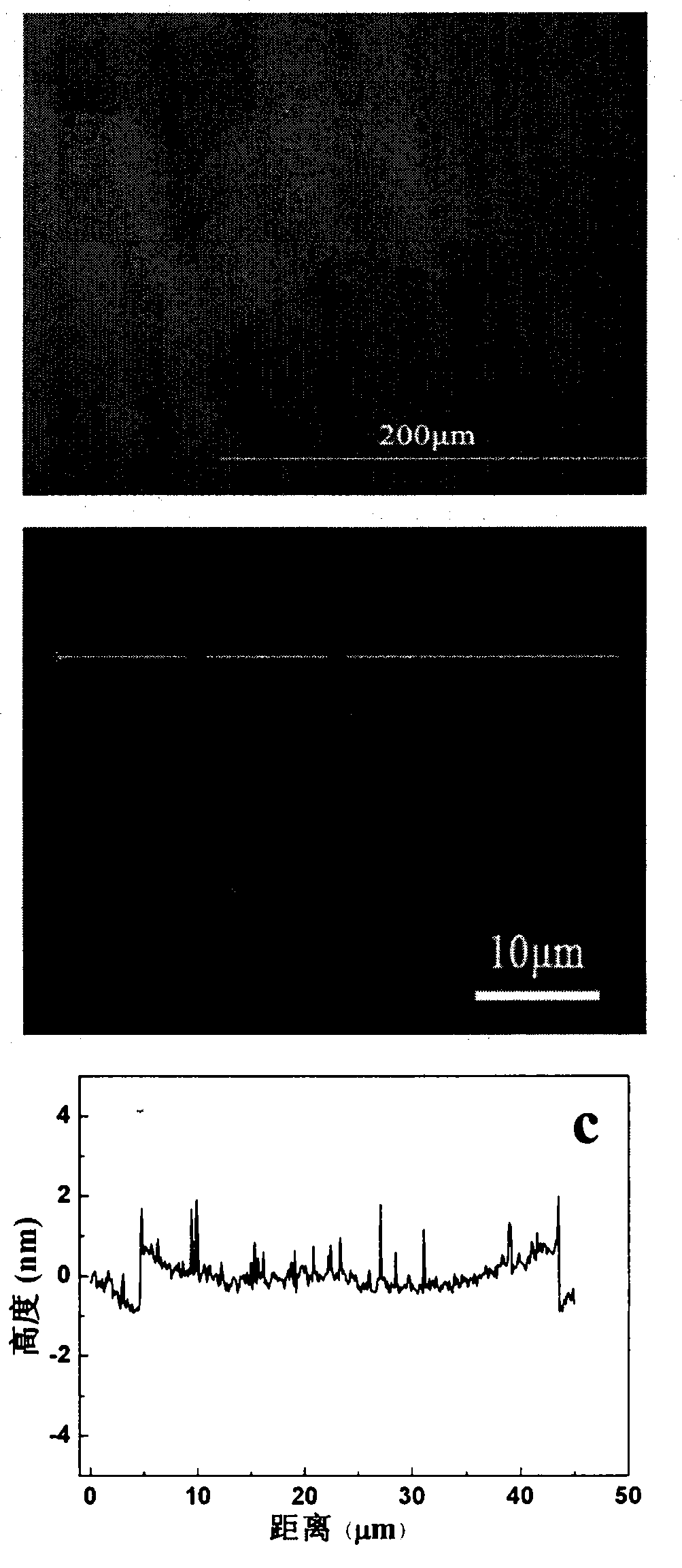

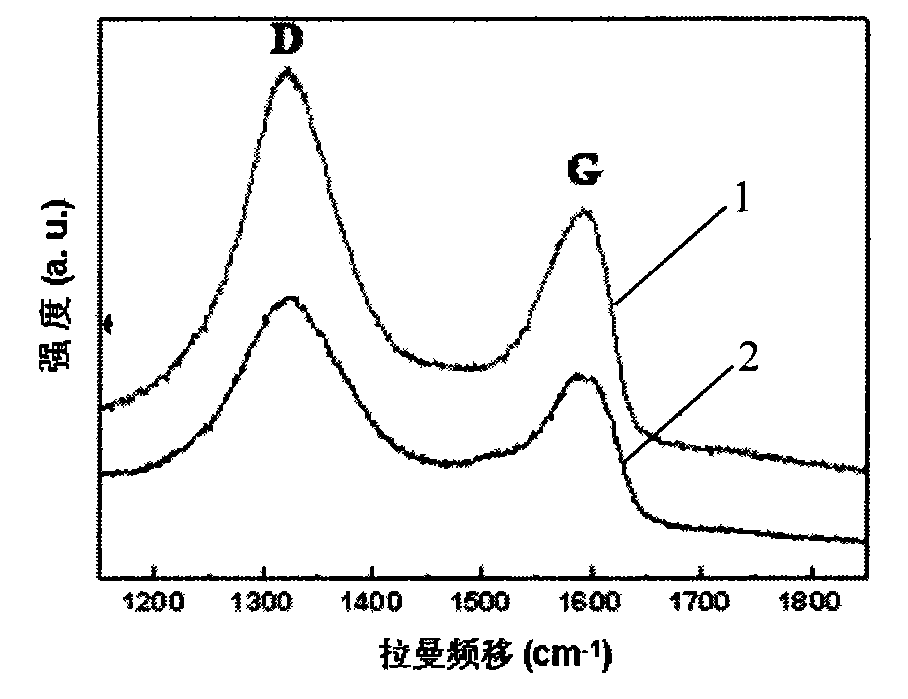

[0026] The modified Hummers method ["Hummers method", please refer to the literature: Hummers W, Offman R Journal of The American Chemical Society 1958, 80:1339.] is used to weakly oxidize graphite: In this example, the lateral grain size of 2g is first Natural flake graphite with a thickness of about 500μm and a thickness of about 1μm~500μm is added to 2g NaNO 3 , 12g KMnO 4 With 96ml H 2 SO 4 In the mixed solution, stir for 2h at 0℃, then adjust the temperature to 35℃ and stir for 1h, and finally add 200ml distilled water and 10ml H 2 O 2 , The mixture is washed with water to neutral, thereby preparing graphite oxide.

[0027] The graphite oxide is dispersed in water, and the graphite oxide is gently exfoliated by weak ultrasound to obtain graphene oxide. Among them, the ultrasonic power is 350W, and the ultrasonic time is 10min.

[0028] Centrifuge the ultrasonically dispersed graphene oxide. First, remove the graphite oxide that has not been completely peeled off. The centrifug...

Embodiment 2

[0032] The modified Hummers method is used to weakly oxidize graphite: In this embodiment, first, 2g of natural flake graphite with a lateral grain size of about 500μm and a thickness of about 1μm~500μm is added to 2g NaNO 3 , 12g KMnO 4 With 96ml H 2 SO 4 In the mixed solution, stir at 0°C for 2h, and then adjust the temperature to 90°C (during this process, slowly add 80ml of distilled water to prevent uneven interlayer expansion of graphite caused by partial heating of the mixture, which will affect the final result Graphene oxide size), stir for 1h, and finally add 200ml distilled water and 10ml H 2 O 2 , The mixture is washed with water to neutral, thereby preparing graphite oxide.

[0033] The graphite oxide is dispersed in water, and the graphite oxide is gently exfoliated by weak ultrasound to obtain graphene oxide. Among them, the ultrasonic power is 350W, and the ultrasonic time is 10min.

[0034] Centrifuge the ultrasonically dispersed graphene oxide. First, remove the g...

Embodiment 3

[0037] The modified Hummers method is used to weakly oxidize graphite: In this embodiment, first, 2g of natural flake graphite with a lateral grain size of about 500μm and a thickness of about 1μm~500μm is added to 2g NaNO 3 , 24g KMnO 4 With 96ml H 2 SO 4 In the mixed solution, stir for 2h at 0℃, then adjust the temperature to 35℃, stir for 2h, and then adjust the temperature to 90℃ (during this process, slowly add 80ml of distilled water dropwise to prevent local heating of the mixture causing graphite Uniform interlayer expansion, thus affecting the size of the final graphene oxide), stir for 1h, and finally add 200ml distilled water and 10ml H 2 O 2 , The mixture is washed with water to neutral, thereby preparing graphite oxide.

[0038] The graphite oxide is dispersed in water, and the graphite oxide is gently exfoliated by weak ultrasound to obtain graphene oxide. Among them, the ultrasonic power is 600W, and the ultrasonic time is 1h.

[0039] Centrifuge the ultrasonically d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com