Method for functionalizing polymer on surface of nano graphene oxide

A technology of nano-graphene oxide and polymer, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of graphene research and application difficulties, insoluble in water, etc., and achieve accelerated development and application, the experimental process is simple, and the effect of a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Mix 1.5 g of graphite powder and 40 mL of concentrated sulfuric acid and stir at room temperature (25°C) for 12 h, then add 9.0 g of potassium permanganate to the reactant, heat to 40°C and stir for 30 min, then put The temperature was slowly raised to 90 °C and heated for 90 min, then 69 mL of deionized water was added, heated to 105 °C and maintained for 25 min, after the heating was stopped, 210 mL of deionized water and 15 mL of 30% hydrogen peroxide were added, Let stand for a while, cool to normal temperature, filter with suction, and wash with 5% hydrochloric acid solution and distilled water successively until the pH of the filtrate is about 7, and finally obtain graphene oxide after vacuum drying.

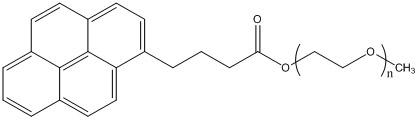

[0024] (2) Weigh 5.0 g of polyethylene glycol monomethyl ether, dissolve and disperse it in dichloromethane, add 0.58 g of 1-pyrenebutyric acid, after dissolving, add 0.41 g of DCC, 0.012 g of DMAP, and react at 25°C After 24 h, after suction filtration, precipi...

Embodiment 2

[0029] (1) Graphene oxide is prepared with the same process steps as in Example 1;

[0030] (2) Weigh 5 g of polyethylene glycol monomethyl ether, dissolve and disperse it with N,N-dimethylformamide, add 0.58 g of pyrenebutyric acid, and after dissolving, add 0.41 g of DCC and 0.012 g of DMAP. Reaction at 30°C for 24 h, suction filtration, precipitation with ether, and vacuum drying to obtain polyethylene glycol Py-PEG with pyrenyl as the end group;

[0031] (3) Weigh 0.06 g graphene oxide, disperse it in 60 mL N,N-dimethylformamide and ultrasonically to form a uniformly dispersed graphene oxide solution with a mass concentration of 1 mg / mL, and then add 0.10 g Py -PEG, continue to ultrasonically disperse, remove the solvent by rotary evaporation, precipitate with methanol, and dry in vacuum to obtain graphene oxide grafted with Py-PEG through non-covalent bonds.

Embodiment 3

[0033] (1) Graphene oxide is prepared with the same process steps as in Example 1;

[0034] (2) Weigh 5 g of polyethylene glycol monomethyl ether, dissolve and disperse it in tetrahydrofuran, add 0.27 g of pyrenebutyric acid, and after dissolving, add 0.41 g of DCC and 0.012 g of DMAP, and react at 10°C for 48 h. After suction filtration, precipitation with ether, and vacuum drying, the polyethylene glycol Py-PEG with pyrenyl as the end group was obtained;

[0035] (3) Weigh 0.30 g graphene oxide, disperse it in 60 mL N,N-dimethylformamide and ultrasonically to form a uniformly dispersed graphene oxide solution with a mass concentration of 5 mg / mL, and then add 1.0 g Py -PEG, continue to ultrasonically disperse, remove the solvent by rotary evaporation, precipitate with methanol, and dry in vacuum to obtain graphene oxide grafted with Py-PEG through non-covalent bonds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com