Preparation method of flexible transparent conducting polymer thin film with antibacterial properties

A polymer film, transparent and conductive technology, which is applied in the field of graphene nanocomposite materials to achieve the effects of small size, enhanced long-range stability and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

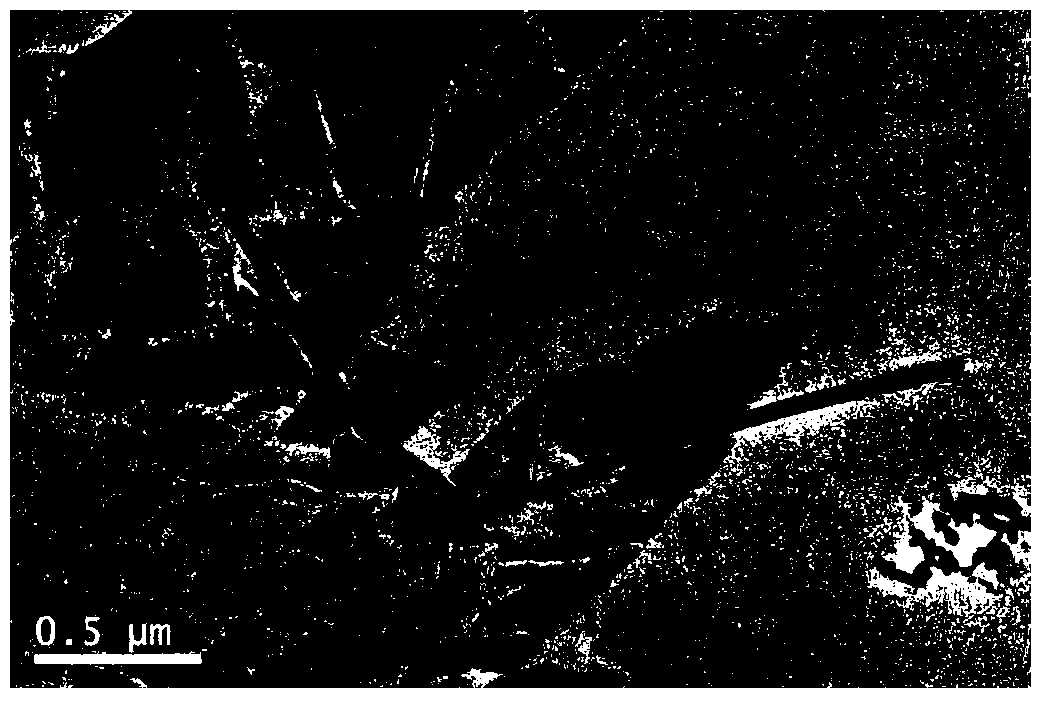

[0029] (1) Prepare 1ml of 0.08M silver nitrate aqueous solution and 1ml of 0.08M sodium citrate aqueous solution respectively, then mix and shake well. After adding 10ml deionized water, sonicate for 30min. Name it A solution. 1.45ml of polydiallyldimethylammonium chloride (PDDA, concentration 40vol%) was dropped into 300ml of graphene oxide aqueous solution with a concentration of 0.12mg / ml, ultrasonicated for 30min, and named solution B. Mix A solution and B solution together, shake well, then sonicate for 1h, pour into a 1000ml one-necked flask, and then use an aluminum film to avoid light and stir magnetically at room temperature for 12h.

[0030] (2) Then heat to 130°C in an oil bath for 3 hours. Then add 0.36g of sodium citrate and keep at 90°C for 10h. Move the product to the platform to cool to normal temperature, wash and centrifuge thoroughly with deionized water and ethanol solution. Prepared as 1.22mg / ml aqueous solution.

[0031] (3) The preparation steps of ...

Embodiment 2

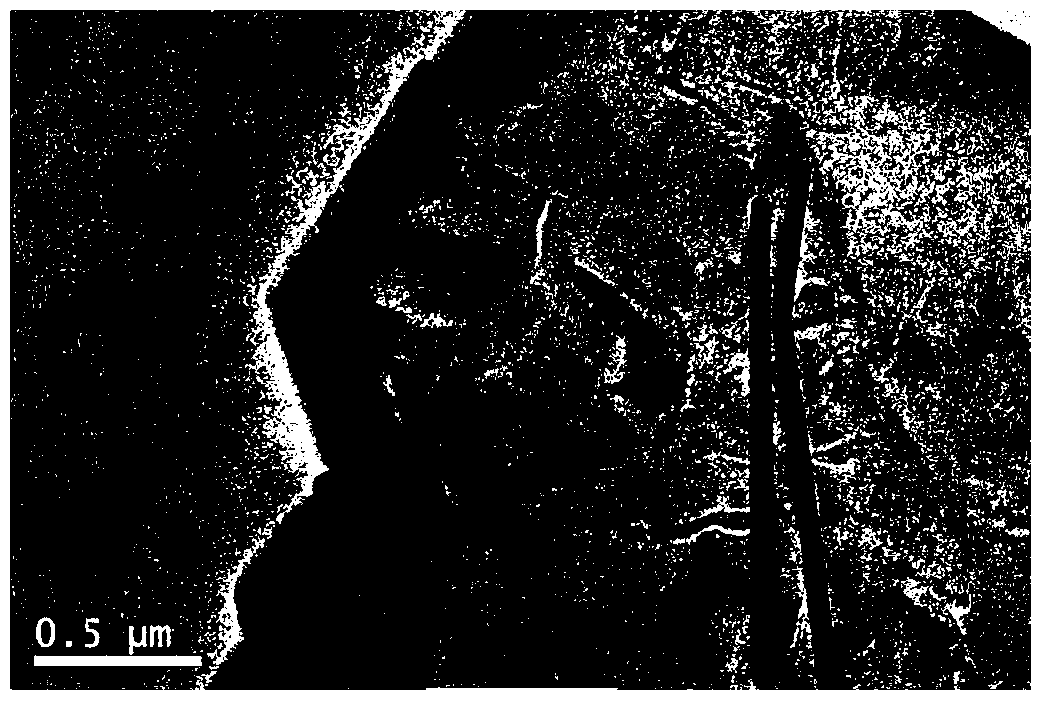

[0033] (1) Prepare 1ml of 0.1M silver nitrate aqueous solution and 1ml of 0.1M sodium citrate aqueous solution respectively, then mix and shake well. After adding 10ml deionized water, sonicate for 30min. Name it A solution. 1.8ml of polydiallyldimethylammonium chloride (PDDA, concentration 40vol%) was dropped into 300ml of graphene oxide aqueous solution with a concentration of 0.12mg / ml, ultrasonicated for 30min, and named solution B. Mix A solution and B solution together, shake well, then sonicate for 1h, pour into a 1000ml one-necked flask, and then use an aluminum film to avoid light and stir magnetically at room temperature for 12h.

[0034] (2) Then heat to 130°C in an oil bath for 3 hours. Then add 0.36g of sodium citrate and keep at 90°C for 10h. Move the product to the platform to cool to normal temperature, wash and centrifuge thoroughly with deionized water and ethanol solution. Prepared as 1.46mg / ml aqueous solution.

[0035] (3) The preparation steps of pol...

Embodiment 3

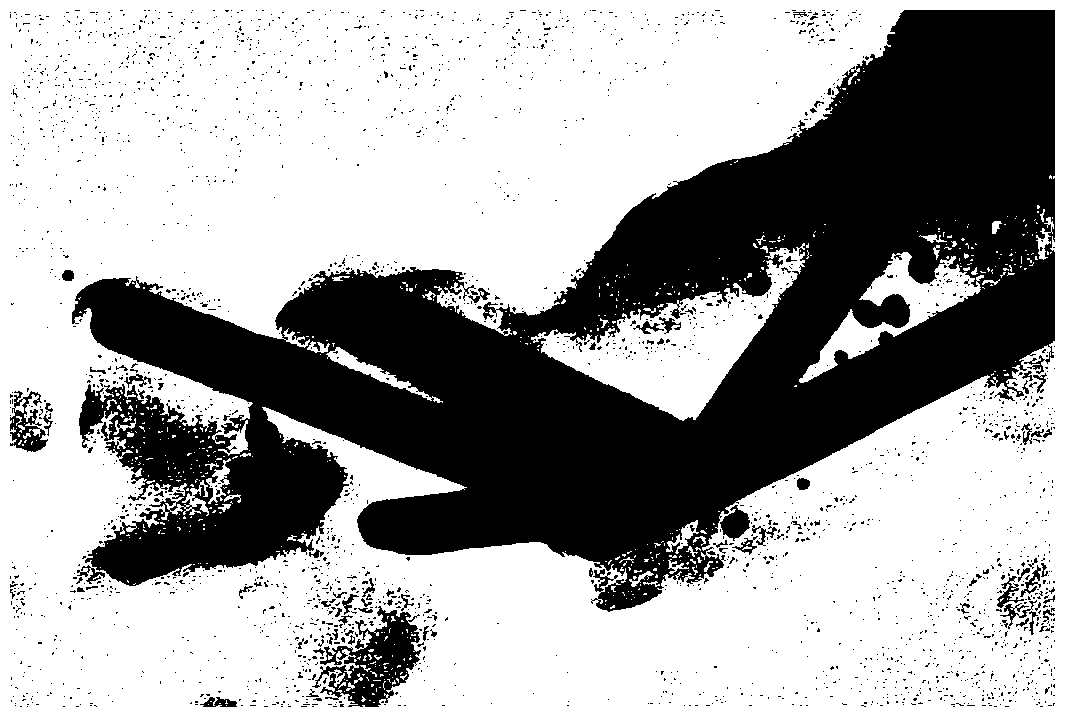

[0037] (1) Prepare 1ml of 0.11M silver nitrate aqueous solution and 1ml of 0.11M sodium citrate aqueous solution respectively, then mix and shake well. After adding 10ml deionized water, sonicate for 30min. Name it A solution. 2.12ml of polydiallyldimethylammonium chloride (PDDA, concentration 40vol%) was dropped into 360ml of graphene oxide aqueous solution with a concentration of 0.12mg / ml, ultrasonicated for 30min, and named solution B. Mix A solution and B solution together, shake well, then sonicate for 1h, pour into a 1000ml one-necked flask, and then use an aluminum film to avoid light and stir magnetically at room temperature for 12h.

[0038] (2) Then heat to 130°C in an oil bath for 3 hours. Then add 0.432g of sodium citrate and keep at 90°C for 10h. Move the product to the platform to cool to normal temperature, wash and centrifuge thoroughly with deionized water and ethanol solution. Prepared as 1.41mg / ml aqueous solution.

[0039] (3) The preparation steps of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com